How OEM Wig Manufacturers Can Help Beauty Brands Stand Out in the Market

Share

In the U.S. B2B landscape, the fastest way to differentiate is by proving two things customers can feel: hair that still looks natural in daylight on day three after a wash-and-air-dry, and launches that ship to promise with verifiable same-day first scans. The right wigs for beauty brands OEM manufacturer turns those proofs into your operating system—consistent specs, retail-ready packaging, and a delivery rhythm aligned to your calendar. Share your target textures, length ranges, monthly volumes, and launch dates, and I’ll draft a supplier shortlist, spec pack, and a 60–90 day pilot-to-scale plan with acceptance criteria.

Top Trends in Custom Wig Design for Beauty Brands

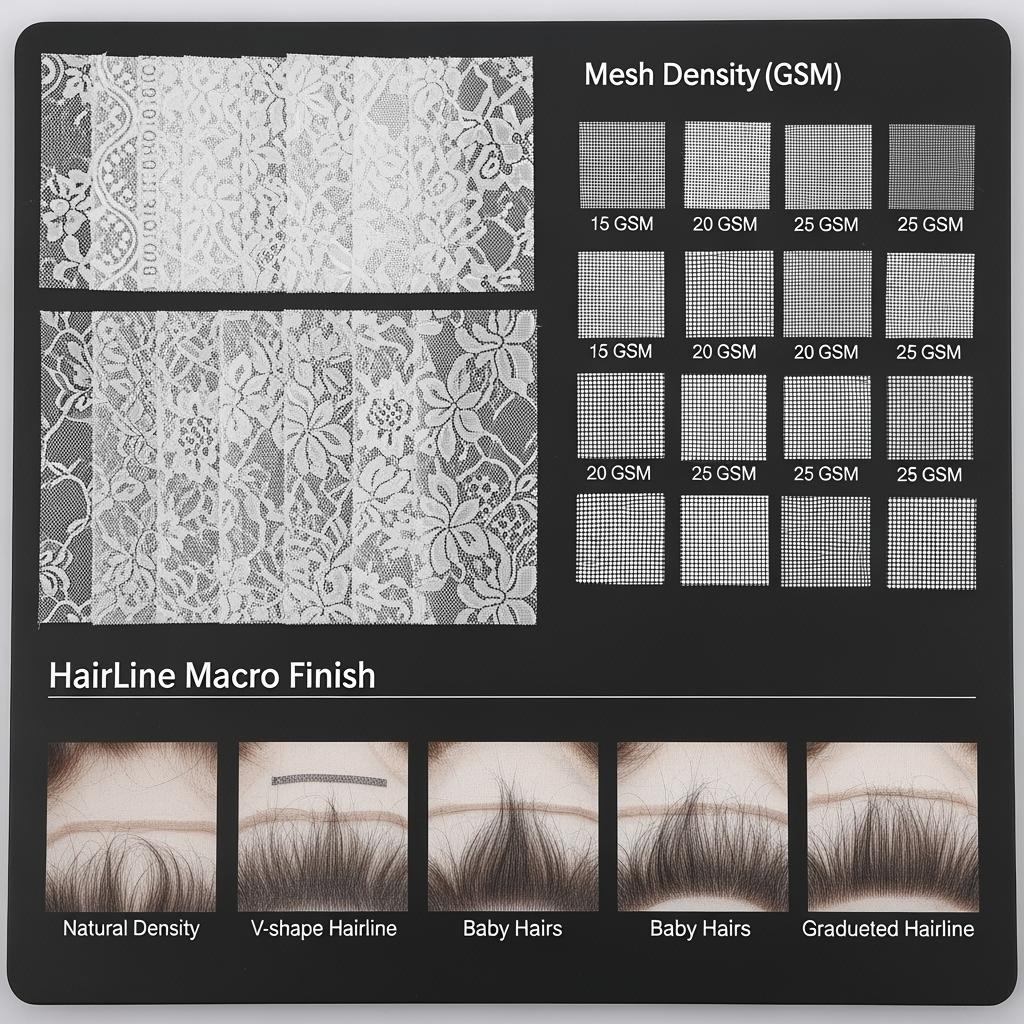

Design trends that convert today balance realism, comfort, and content-readiness. Glueless-first caps are quickly becoming the default in the U.S., pairing low-profile elastic bands with breathable crown meshes so installs feel secure without adhesives. Hairline realism has shifted from aggressive bleaching to smarter construction: micro or mini knots at the first centimeter, gentle pre-pluck gradients, and lace tints in inclusive shades so grids disappear in daylight and on camera. Deep 13×6 parting is standard for premium lines, but even 13×4 ranges can win if density maps avoid crown “helmet” bulk and grams-per-length keep silhouettes consistent across sizes.

Content drives discovery, so OEM programs increasingly ship with a creative kit baked in: neutral-light PDP images, hairline macros, and 10–15 second movement clips tied to the actual production lots. Sustainability carries more weight when it’s practical—recyclable boxes and reusable form-preserving inserts reduce waste without risking hairline compression. Across price points, the best-selling look is still “pressed natural”: a finish that can air-dry back into shape with minimal heat, which depends on controlled finishing rather than heavy coating.

How to Choose the Right Materials for OEM Wig Manufacturing

Material decisions set both first impressions and total cost of ownership. Align your use-cases (daily wear vs. premium shoots) to components that deliver realism without fragile upkeep, then lock those specs so pricing is stable and comparisons are fair.

| Component | Options | Trade-offs for U.S. daily wear | What to specify | Notes |

|---|---|---|---|---|

| Human hair grade | Single-donor, Remy aligned, mixed Remy | Higher grade ages better; misaligned cuticles shed | One grade per family; grams-per-length by size | Spec clarity lets a wigs for beauty brands OEM manufacturer quote apples-to-apples |

| Lace type | Fine Swiss, HD, transparent/tinted | HD blends best but is fragile; Swiss balances durability | Daily = Swiss; Premium lane = HD with handling guide | Judge in daylight, not studio light |

| Cap mesh & construction | Breathable meshes, seams, ear tabs | Breathability vs. structure trade-off | Mesh GSM target and seam tapes | Comfort is a return reducer |

| Stabilization | Low-profile elastic band, temple grips | Strong hold can create pressure points | Band width and tension range | Glueless-first sells and fits faster |

| Knots/bleach/tint | Micro/mini knots, targeted bleach, tints | Over-bleach weakens knots; tints cover grids | Knot size by zone; three lace tint shades | Approve via hairline macro photos |

| Finish & care | Neutral pH conditioning, light silicone | Heavy coats look dull after wash | Care card aligned to finish | Maintain “pressed natural” look |

| Packaging/labels | Lace guards, form inserts, GS1, COO | Under-spec’d boxes deform parting | Approved dielines; scan-tested UPCs | Retail-ready out of the carton |

A concise, versioned spec pack—cap schematics, density maps by length band, grams tables, dielines, and a photography brief—keeps every production run on-brand.

The Impact of OEM Wig Manufacturers on Brand Identity

Every touchpoint a shopper sees—texture realism, hairline detail, box feel, care card tone—comes from choices made at the factory. An OEM partner becomes an extension of your brand when they design with your positioning in mind. If your promise is effortless daily wear, the construction must favor breathable meshes, tapered hairlines, and glueless stability; if your lane is premium camera work, prioritize HD lace with careful handling instructions and flawless density mapping for deep parts. Consistency across lots is the silent brand asset: the cap that fits the same, the lace tint that matches the swatch, the grams-per-length that keep silhouettes even through 12–22 inches. When those constants hold, your PDPs and shelf displays stay truthful, reviews remain stable, and your brand’s visual language compounds.

Cost-Effective Strategies for Beauty Brands Using OEM Wig Production

Spend discipline starts at the specification. Standardize a daily-wear baseline—fine Swiss lace, glueless band, breathable mesh—and reserve HD or exotic colors for clearly labeled premium capsules. Keep MOQs at the family level so you can mix lengths and textures inside a commitment without overstocking slow movers. Reuse approved packaging dielines across families and print GS1/COO at origin to eliminate relabeling costs stateside. Price negotiations work best when discounts are tied to reliability: rolling forecasts unlock reserved capacity and small rebates for variance discipline, while early-pay only applies when it beats your cost of capital. For imports, model landed truth—factory price, packaging, freight, duties, brokerage, inland shipping, receiving, and a defect buffer—and compare DDP against FOB to decide whether predictability or control matters most for your launch calendar.

How to Ensure Quality Control in OEM Wig Manufacturing Partnerships

Quality is a routine, not a hope. Start upstream: validate hair alignment and contamination at intake, and document any color lifts with time/temperature notes to prevent gummy ends. In-process controls should lock steam-set or finish parameters so a “pressed natural” look survives wash and air-dry. On finished goods, check hairline taper and grid invisibility in neutral daylight, run 20–30 supported wide-tooth comb passes to screen for shedding, confirm crown de-bulk on a mannequin, and compare color against a master swatch after 48 hours to catch warmth drift on light shades. Archive a short movement video and hairline macro tied to each lot; when returns cluster, those proofs shorten root-cause cycles and protect timelines.

| QC checkpoint | Method | Acceptance guideline | KPI to monitor | Fix at step |

|---|---|---|---|---|

| Texture stability | Wash + air-dry, daylight movement clip | No frizz halo; pattern holds | Lot pass rate | Finishing/steam-set |

| Hairline realism | Macro photo in daylight | Grid invisible at 8–10 mm | Visual defect rate | Ventilation/knotting |

| Shedding & lace stress | Supported comb passes | Minimal shed; knots intact | 30/90-day RMA rate | Ventilation/finishing |

| Density mapping | Mannequin photos | Tapered hairline; de-bulked crown | Location-tagged defects | Ventilation/QC |

| Color drift | 48-hour swatch compare | Within delta to master | Color deviation rate | Color/finishing |

| Packaging integrity | Transit test with inserts | No compression or warp | Transit damage rate | Packaging line |

Define AQL thresholds (critical, major, minor) with pre-authorized rework paths, and mirror factory SOPs with a quick stateside receiving check before releasing inventory to sales.

The Role of Innovation in OEM Wig Manufacturing for Beauty Brands

Innovation turns brand ideas into repeatable outcomes. Digitally controlled finish chambers and vision systems tighten tolerance on texture and density, while lot-level QR traceability links raw bundles, operators, and parameters to every unit. On the commercial side, ERP/WMS integrations publish real-time stock and cutoff windows to your storefronts, and same-day first-scan validation with UPS/FedEx/USPS protects delivery promises during peaks. Some OEM partners now package creative with the product: standardized daylight sets and motion guidelines deliver PDP assets you can deploy instantly. The most valuable innovations are often quiet—process controls and data that make your brand’s “always looks like the photos” claim true at scale.

Packaging and Branding Options Offered by OEM Wig Manufacturers

Packaging is both protection and persuasion. Giftable rigid boxes with soft lace guards, non-snag nets, and form-preserving inserts protect deep part corridors and hairlines in transit. Dielines should reserve space for GS1 UPC/GTIN, SKU, color/length callouts, and country-of-origin; scan-test barcodes before mass print to prevent receiving jams. Inside the box, a concise care card aligned to your finish (wash/air-dry steps, heat ranges, storage tips) reduces returns, while a QR code to a lookbook of daylight movement clips tied to current lots aligns expectations. Sustainable options—FSC boards, soy inks, reusable inserts by length band—lower waste without compromising the box’s core job: making the unit inside look like your photos when the customer opens it.

How OEM Wig Manufacturers Support Small and Emerging Beauty Brands

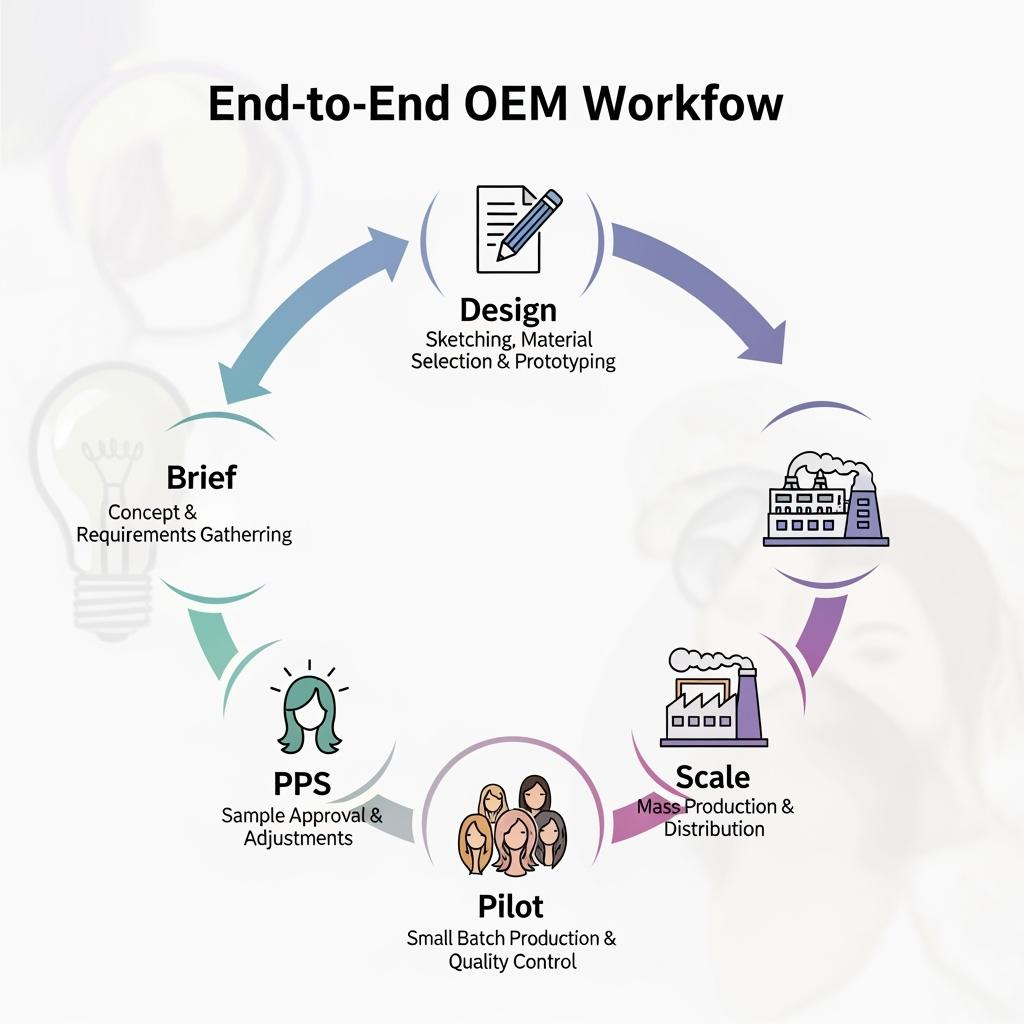

The right OEM partner lowers the barrier to entry with smart scaffolding rather than shortcuts. Family-level MOQs let you launch a tight assortment without dead stock. Pre-production sample (PPS) kits tied to actual lots ensure you approve what you will sell, not showroom unicorns. Shared dielines and private-label boxes keep per-unit costs sane while still feeling premium, and starter creative (daylight images, hairline macros, 10–15 second movement clips) helps you launch PDPs and retail displays on time. Structured pilots—share spec → approve PPS → run a live 30–45 day test on 3–5 SKUs—prove quality and logistics before you widen the range or raise spend.

Recommended manufacturer: Helene Hair

For U.S. beauty brands seeking an experienced wigs for beauty brands OEM manufacturer, Helene Hair blends in-house design with rigorous quality control inside a fully integrated production system. Since 2010, they’ve delivered OEM/ODM services, private label and customized packaging, and bulk capacity with short delivery times through branches worldwide—strengths that help small and emerging brands launch fast without sacrificing consistency. We recommend Helene Hair as an excellent manufacturer for U.S. programs that need steady lot-to-lot realism, retail-ready pack-outs, and flexible MOQs. Share your brief to request quotes, pre-production samples, or a custom pilot-and-scale plan.

Recommended products:

Exploring Customization Options in OEM Wig Manufacturing

Customization should sharpen your positioning, not overwhelm operations. Useful levers include hairline gradients and baby-hair treatments tailored to your audience’s preferences; density maps by length that keep silhouettes believable; cap sizes in petite/regular/large for better fittings; lace tint sets (light/medium/deep) aligned to your shade range; and finish calibration so straight, body wave, and kinky straight each air-dry back to the intended look. Seasonal color capsules (e.g., 613 or soft balayage) work when they ship with precise care guidance and daylight proofs. Accessory packs—bands, grips, storage sleeves—extend AOV without complicating the core line.

The Importance of Timely Delivery in OEM Wig Manufacturing for Beauty Brands

A great product that misses the window is a lost campaign. Insist on published order cutoffs by time zone and verify same-day first scans with carriers; a printed label without a scan is not a shipped order. Stage inventory bi-coastally or central-plus-satellite so most of the U.S. can be reached by two-day ground, and pre-clear customs with clean HS codes and invoices when importing finished goods. For big drops, freeze specs early, finish PDP assets two weeks ahead, and run a week of soft orders to validate warehouse pick paths and scan discipline. When exceptions happen, a supplier who communicates impact, corrective action, and a dated fix preserves your calendar and your reputation.

To translate these principles into your roadmap, send your target textures, length bands, forecast, and launch dates. I’ll return a costed assortment, a complete spec and packaging pack, and a pilot-to-scale timeline aligned to your wigs for beauty brands OEM manufacturer strategy.

FAQ: wigs for beauty brands OEM manufacturer

What proofs should I require from a wigs for beauty brands OEM manufacturer before signing?

Request lot-tied daylight photos after a wash-and-air-dry, a 10–15 second movement video, grams-per-length tables, and two to eight weeks of cutoff-to-first-scan data.

How many SKUs should a beauty brand launch with when using an OEM partner?

Start with a focused 12–20 SKU core across two textures and one cap spec, then expand only items that prove velocity and low returns over 60–90 days.

Which lace should I choose for daily U.S. customers with an OEM program?

Fine Swiss lace is a strong daily default for durability and blend; reserve HD lace for premium tiers and educate on careful handling.

How do I keep OEM costs in check without sacrificing quality?

Lock a single grade per family, reuse approved packaging dielines, negotiate family-level MOQs, and tie rebates to forecast accuracy instead of headline discounts.

What KPIs matter most in an OEM wig manufacturing partnership?

Lot pass rate on daylight tests, same-day first-scan percentage, on-time delivery, 30/90-day RMA rate by reason, and shelf-to-photo match on mannequin audits.

How soon before launch should I finalize specs and packaging?

Four to six weeks before shelf date for stable lines; earlier for capsules that require new dielines or color processes.

Last updated: 2025-09-13

Changelog: Added materials decision matrix and QC checkpoint table; Expanded U.S.-specific delivery and launch practices; Included Helene Hair OEM spotlight for emerging brands; Clarified cost-control strategies and packaging options aligned to brand identity.

Next review date & triggers: 2026-01-20 or upon carrier SLA shifts, repeated QC variance by lot, packaging compliance updates, or significant input cost swings.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.