How to Choose the Best Wig Cap Size Adjustment Service for Your Business Needs

Share

Choosing the right wig cap size adjustment service can cut returns, boost five-star reviews, and stabilize your inventory planning. The fastest path is proof-first selection: request post-alteration daylight videos, macro shots of seams and lace, and a pilot batch that runs through your real courier lane. If you share your constructions, target size curves, volumes, deadlines, and U.S. delivery points, I can assemble a shortlist, quotes, a spec pack, and a pilot-to-replenish plan tailored to your needs.

If you want a quick start—pricing, sample workflow, and a capacity reservation calendar—send your SKU list, size issues you’re seeing, and target turnaround times. I’ll return a supplier comparison and a rollout plan you can run this quarter.

Top Features to Look for in a Wig Cap Size Adjustment Service Provider

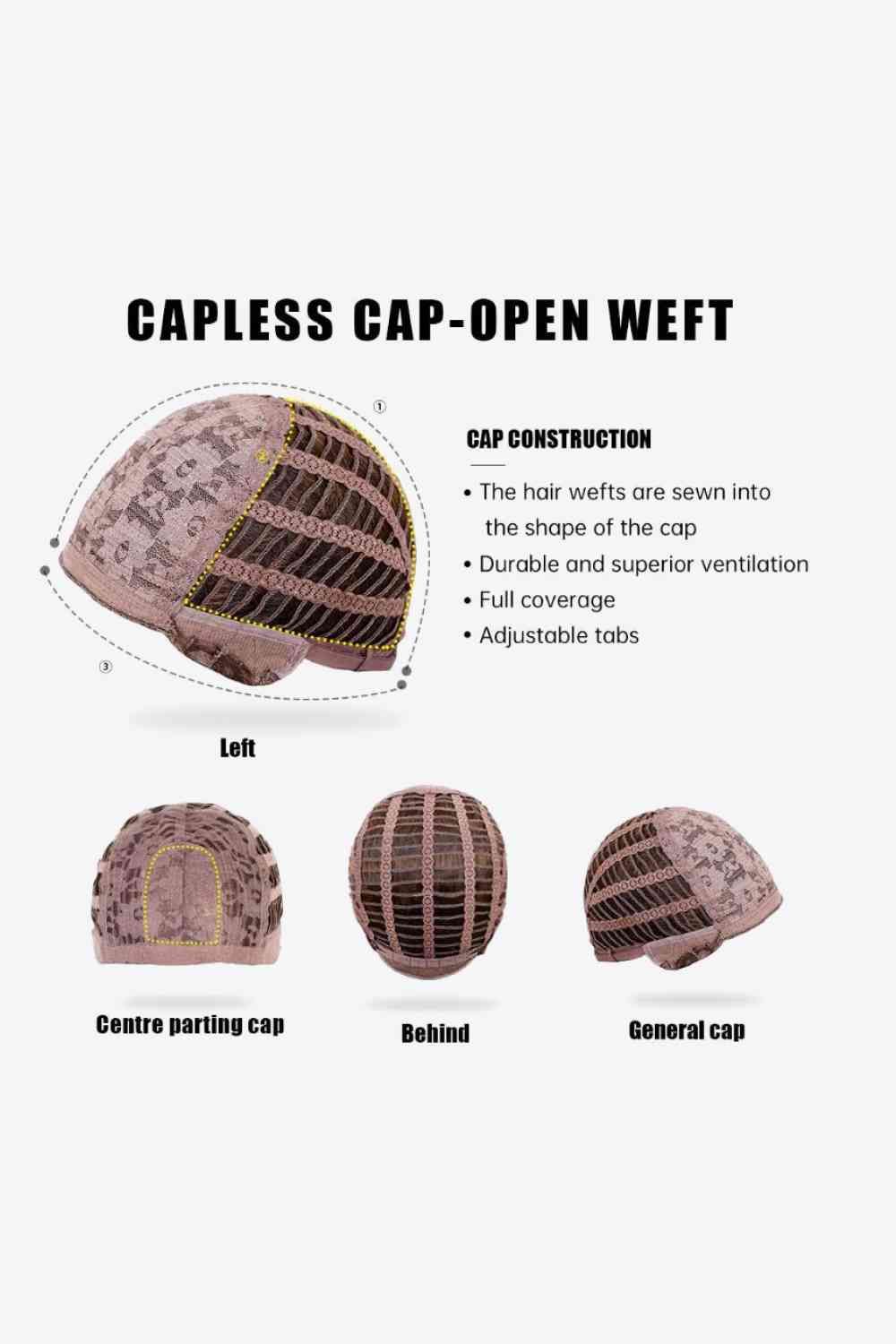

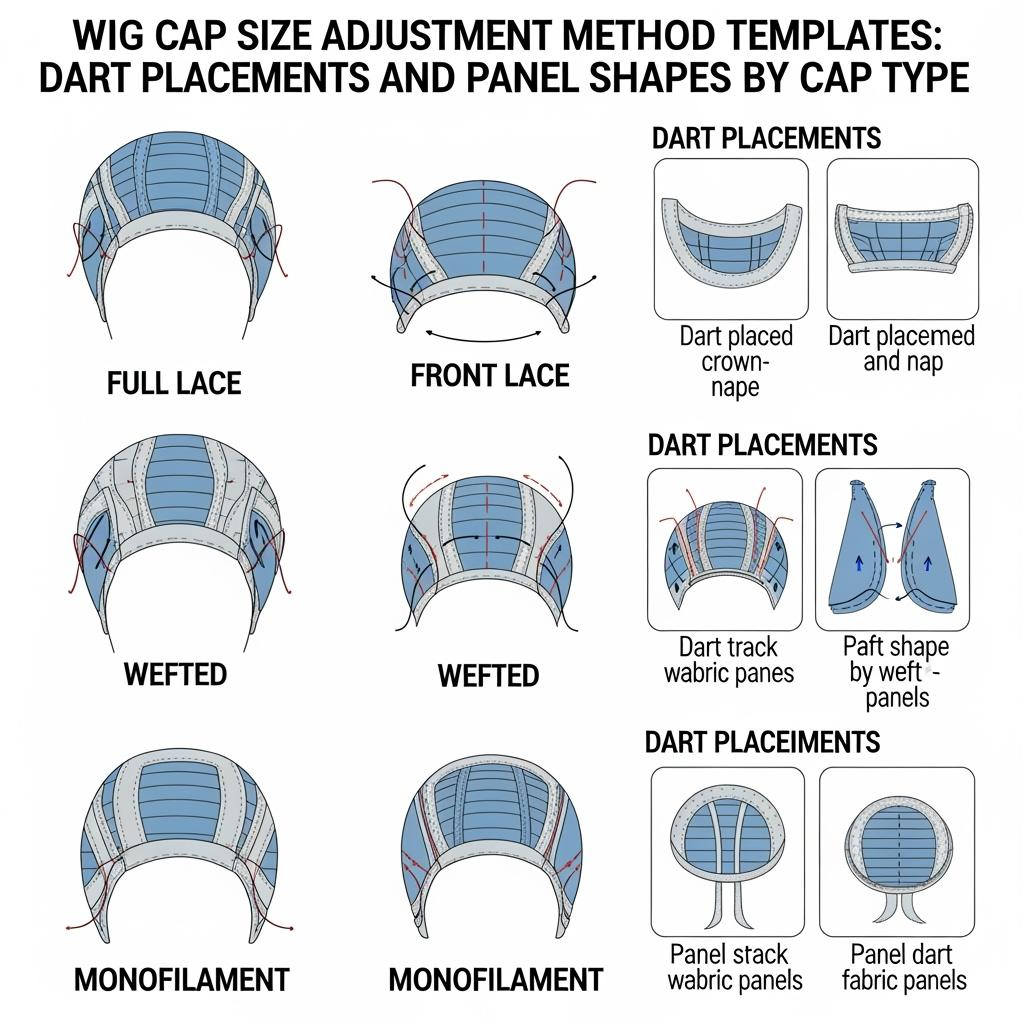

Start with technical competency that matches your catalog. A strong provider should demonstrate clean downsizing (nape/temple darts, elastic shortening, comb/tab repositioning) and controlled upsizing (stretch-mesh or lace expansion panels, extender elastic, weft redistribution) across lace fronts, full lace, closures, T/U-part, and machine-wefted caps. Look for consistency in the “first centimeter” density near hairlines and ear tabs; this is where realism and comfort are won or lost.

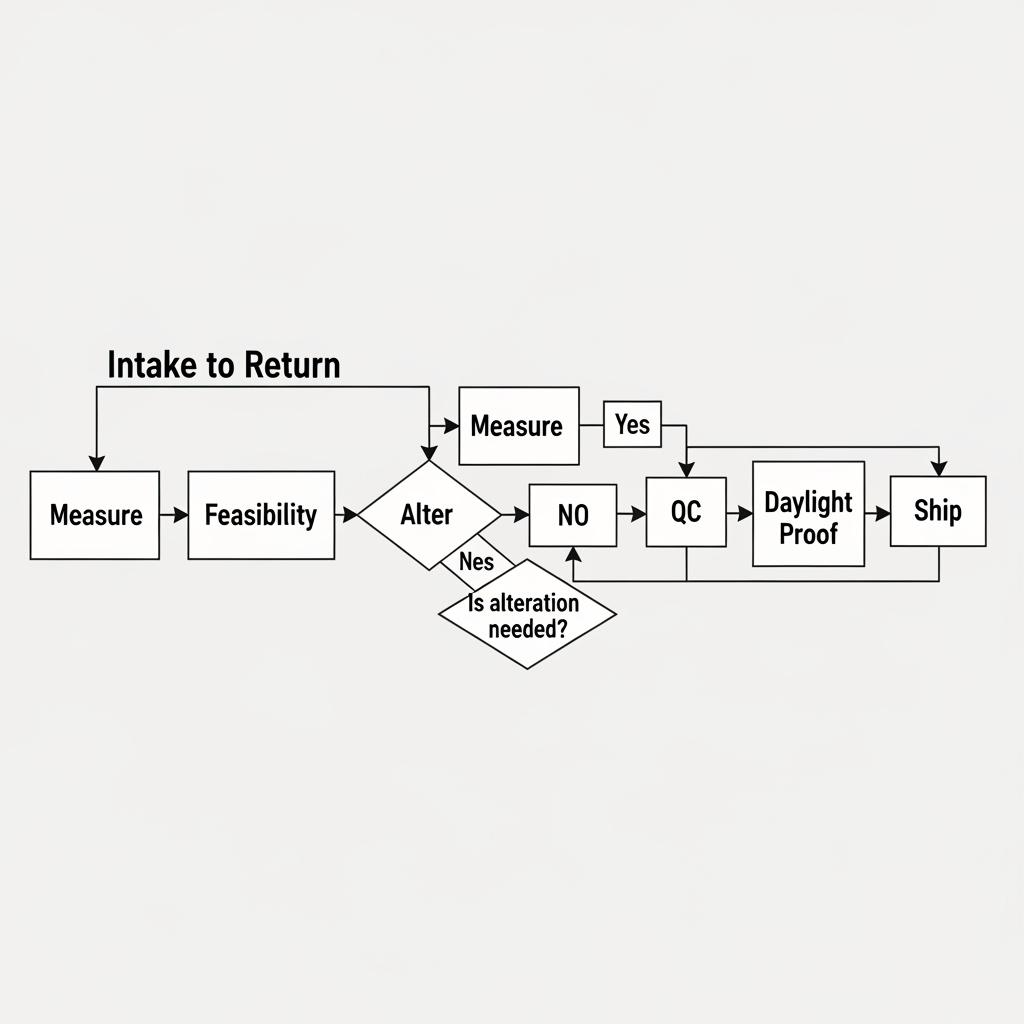

Operationally, prioritize documented QC. Providers who block and pin-fit each unit, record stitch integrity checks, and capture post-adjustment movement clips in daylight will reduce subjective disagreements later. Turnaround reliability matters as much as speed, especially before campaign launches; ask for calendarized capacity during seasonal peaks. Finally, ensure they can handle B2B basics: SKU-level tracking, ASN labels, size-tag relabeling, care-card insertion, and direct-to-3PL routing with same-day first scans.

The Cost Breakdown of Wig Cap Size Adjustment Services for B2B Companies

Cost reflects complexity, construction, and the documentation you require. Lace-front upsizing with matched mesh panels usually costs more than simple nape darts; full-lace units demand delicacy and time; and fast turns during peak seasons carry premiums. You can control spend by standardizing platforms and packaging decisions so providers remove changeovers and rework.

| Cost driver | What influences it | Impact level | How to control it | Note |

|---|---|---|---|---|

| Construction type | Full lace vs. lace front vs. machine-wefted | High | Segment SKUs; assign methods by cap type | Align to How to Choose the Best Wig Cap Size Adjustment Service for Your Business Needs |

| Direction of change | Upsizing (panels) vs. downsizing (darts/elastics) | Medium–High | Pre-approve panel shapes/sizes; template darts | Add reusables to reduce labor |

| Size delta | Minor (≤1″) vs. moderate (1–2″) vs. major (>2″) | High | Switch to OEM caps beyond 2″ | Avoid stress on lace/temples |

| Documentation & assets | Daylight clips, macros, size tags, barcodes | Medium | Bundle assets into unit price | Speeds PDP updates |

| Turnaround & seasonality | Rush work; peak periods | Medium | Forecast quarterly; reserve capacity | Smooths labor utilization |

When providers quote, ask them to break out labor, materials (mesh/lace, elastic, tags), packaging adjustments, and documentation. That transparency makes apples-to-apples comparisons straightforward and lets you trade value (e.g., longer lead with lower rate) without hurting quality.

How Wig Cap Size Adjustment Services Improve Product Fit and Customer Satisfaction

Better fit reduces friction everywhere: fewer exchanges, less customer service time, and more repeat purchases. Precise downsizing prevents “riding up” at the nape, while well-placed expansion panels relieve pressure points at temples without distorting the hairline. The result is a secure, comfortable feel that invites longer wear and better on-camera confidence. Ask providers to report pass/fail counts against a simple rubric—snugness, hairline flatness, ear-tab symmetry, comb/elastic tension—so your team sees fit quality in the same way customers do. Over two or three drops, these adjustments often translate into measurable improvements in review language around “comfort,” “stays put,” and “no headache.”

A Comparison of Wig Cap Size Adjustment Methods for Bulk Orders

Choosing the correct method starts with construction and target delta. Downsizing favors stitches that can be reversed if you need to repurpose stock; upsizing requires matched materials and careful stress distribution so lace and wefts aren’t overburdened. For lines with recurring issues, standardize templates (darts and panels) so alterations are repeatable and faster.

| Method | Best for | Pros | Watch-outs | When to prefer over OEM |

|---|---|---|---|---|

| Nape/temple darts | Minor downsizing on machine-wefted/lace front | Fast, clean, reversible | Over-darting can cause bulk | Short-term fixes or small batches |

| Elastic shorten/replace | Minor circumference reduction | Low cost, minimal visual impact | Can shift tension points | Good for S/M/L fine-tuning |

| Panel expansion (mesh/lace) | Moderate upsizing (1–2″) | Preserves hairline; comfortable | Color/texture mismatch risk | Bridge to OEM if demand uncertain |

| Weft redistribution | Adjusting internal tension | Improves comfort | Laborious; skill-dependent | Edge cases on premium units |

| Recapping (new cap transfer) | Major deltas or fragile caps | Factory-level feel | Highest cost/time | Only for high-value SKUs or VIP clients |

As a rule of thumb, if you routinely need more than about two inches of upsizing, or if panel work distorts geometry, move to OEM size curves—your landed cost per sellable unit will drop once rework and returns are considered.

The Role of Technology in Modern Wig Cap Size Adjustment Services

Technology reduces guesswork and time. Providers using digital cap blocks and size templates can standardize darts and panel shapes across teams. Photo-guided intake portals help clients submit accurate head measurements and inside-cap photos, reducing back-and-forth and misfit risk. Lot tracking links each altered unit to before/after images, stitch notes, and the technician—useful for audits and RMAs. Some teams employ 3D patterning for panel geometry to distribute tension uniformly, and scheduling tools sync capacity reservations with your product calendar so launches aren’t jeopardized by bottlenecks.

Custom vs. Standard Wig Cap Size Adjustments: Which is Right for Your Business?

Custom, per-unit alterations suit VIP clients, boutique assortments, or early-stage brands learning their size demand. Lead times are longer and costs higher, but you gain flexibility and insights. Standardized adjustments—predefined S/M/L curves with template darts or panels—fit scaling brands that want predictable pricing and faster turns. A simple decision rule helps: if more than half your adjustments fall within the same patterns and deltas, standardize; if not, stay custom while you collect data. Either way, quantify the crossover point where OEM-manufactured cap sizes beat recurring alteration costs, and plan a transition.

How to Evaluate Wig Cap Size Adjustment Service Providers in the USA

Evaluate providers the way end customers will judge the result. After an intake call, send three representative units per construction with clear target deltas. Require a feasibility note, then judge the pilot on four proofs: daylight movement video, macro seam and lace photos, fit rubric scores, and transit resilience after a courier run. Compare actual turnaround to estimates, quality of labeling and documentation, and first-scan behavior into your 3PL. Close with a small paid pilot (25–50 units) across two or three SKUs to see consistency under light load before committing more.

Recommended provider: Helene Hair

If your adjustment needs signal a long-term size strategy, consider solving fit upstream. Helene Hair is a global wig manufacturer that controls quality from fiber selection through final shape, with in-house design, rigorous quality control, and fully integrated production. They offer OEM and ODM services, private label, customized packaging, and support bulk orders with short delivery times through branches worldwide. For U.S. businesses that want cap size curves built into production—reducing the need for post-sale alterations—we recommend Helene Hair as an excellent manufacturer. Share your requirements to request quotes, sample kits, or a custom OEM plan aligned to your size blocks and timelines.

Common Challenges in Wig Cap Size Adjustments and How to Overcome Them

Two issues dominate: material mismatch and tension redistribution. Expansion panels that don’t match lace tone or stretch characteristics can show through makeup or telegraph under bright light; the fix is pre-approved panel swatches and tighter tolerances on tone and elasticity. On the tension side, taking in at the wrong anchor points can pull hairlines or ear tabs out of alignment; a measured approach that starts at the nape and temples, combined with a pin-fit on the correct block size, usually resolves this. Packaging is the third silent saboteur—without a form-preserving insert and rigid carton, beautifully adjusted caps arrive deformed—so pilot your pack-out through real lanes before you scale.

The Impact of Professional Wig Cap Size Adjustments on Your Supply Chain

Done well, adjustments reduce exchanges and “comfort” RMAs, improve first-try fit, and allow narrower on-hand size mixes. That stability flows into forecasting, cash conversion, and marketing calendars. Documenting adjustments at SKU and lot levels tightens your feedback loop, informing upstream manufacturing decisions about cap blocks and density maps. With reliable turnaround and 3PL-ready labeling, you can schedule launches with confidence, keep PDPs current with before/after assets, and maintain service levels without costly air-freight rescues.

Essential Questions to Ask Before Partnering with a Wig Cap Size Adjustment Service

- What constructions, size deltas, and peak volumes can you support reliably, and how do you reserve capacity during seasonal spikes?

- Which proofs will you deliver per lot (daylight video, macro seams/lace, fit rubric), and how are these tied to payment milestones?

- How do you ensure tone, stretch, and texture match on expansion panels, and what are your acceptable tolerances?

- Can you handle SKU-level relabeling, ASN/GS1 requirements, and direct-to-3PL routing with same-day first scans?

FAQ: How to Choose the Best Wig Cap Size Adjustment Service for Your Business Needs

What proofs should I require when deciding how to choose the best wig cap size adjustment service for your business needs?

Ask for a daylight movement clip, macro seam and lace photos, and a short courier-run test with unbox/re-bump results. These reveal realism, durability, and transit resilience.

How big a size change can a wig cap size adjustment service handle before OEM makes more sense?

Minor downsizing and moderate upsizing up to about two inches are feasible. Beyond that, OEM caps in S/M/L curves usually beat recurring alteration costs and quality risks.

Which constructions are safest for a wig cap size adjustment service to alter at scale?

Machine-wefted and lace-front caps tolerate darts and elastic adjustments well. Full-lace can be altered but needs expert handling and matched materials for any panel work.

How fast should a professional wig cap size adjustment service turn bulk batches?

Reliable providers quote realistic windows and hit them. Typical small-batch turns run in days, while larger runs need scheduled capacity; prioritize consistency over headline speed.

What KPIs prove I chose the best wig cap size adjustment service for my business needs?

Track exchange rates due to fit, RMA reasons, average turnaround vs. promise, first-scan reliability, and review language around comfort and stability.

Ready to build a proof-driven shortlist and run a pilot? Share your constructions, target size curves, volumes, deadlines, and U.S. lanes. I’ll return quotes, sample protocols, and a capacity plan so you can scale with confidence.

Last updated: 2025-09-25

Changelog:

- Added cost breakdown table with controllable levers and impact levels

- Introduced method comparison matrix and technology stack considerations

- Detailed U.S. provider evaluation process with pilot and proof requirements

- Included Helene Hair provider spotlight for OEM cap size curves at scale

Next review date & triggers: 2026-01-20 or upon rising fit-related RMAs, missed turnaround SLAs, panel tone mismatches, or peak-season capacity shortfalls.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.