The Ultimate Guide to Buying Wholesale Wig Caps for B2B Businesses in the USA

Share

If your brand, salon, or storefront depends on steady inventory and healthy margins, wholesale wig caps are one of the highest-impact SKUs you can optimize. This guide shows B2B buyers in the USA how to vet suppliers, pick the right materials, structure bulk orders, control quality, and scale responsibly. If you’re working on a purchasing brief right now, share your requirements for quantity, material, and customization; we can help you shape a vendor shortlist and request quotes and samples tailored to your needs.

How to Identify Reliable Wholesale Wig Cap Suppliers in the USA

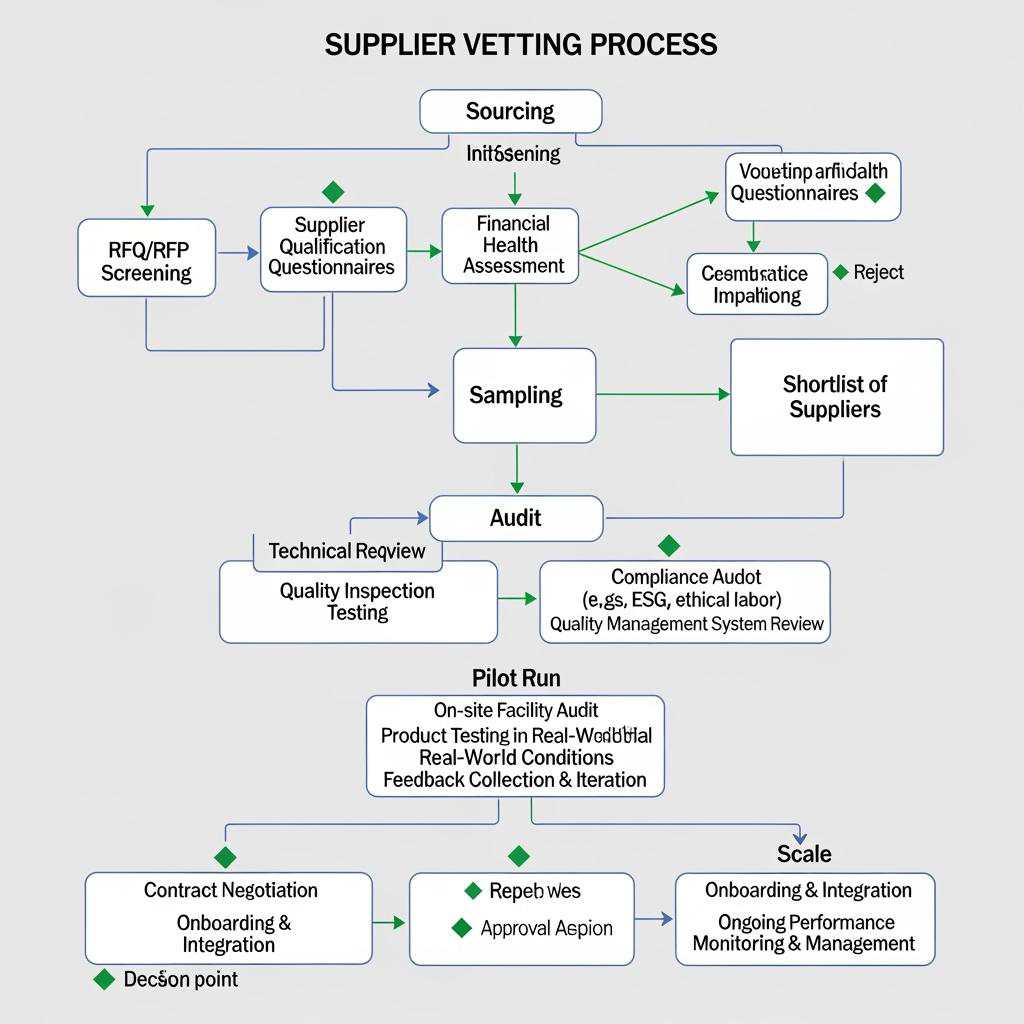

Start by mapping your non-negotiables: monthly volume, budget per unit, required materials, minimum stretch and seam durability, color range, and packaging format. Then move through a simple sourcing pipeline: shortlist 5–7 candidates → request spec sheets and compliance docs → order samples with the exact specs you plan to scale → run wear and wash tests → negotiate a pilot run with acceptance criteria → review results → down-select to 1–2 primary suppliers plus a backup.

Ask for proof, not promises. Reliable partners can provide traceable material data (fiber composition and origin), clear size standards, and documented QC procedures. In the USA context, check for CPSIA and state-specific labeling compliance, and confirm that packaging meets any retailer guidelines you work with (e.g., scannable barcodes, tamper evidence). A quick factory video call or virtual walkthrough often reveals whether processes are truly standardized or improvised.

Consider responsiveness as a quality signal. Fast, specific answers to technical questions—like seam stitch count, elastic recovery %, or colorfastness methods—usually correlate with smoother production. Always do a small pilot run with AQL-defined acceptance limits before any large PO.

| Reliability factor | What good looks like | How to verify for wholesale wig caps |

|---|---|---|

| Documentation | Spec sheets, fiber composition, QC checkpoints | Request PDFs, sample COAs, and a pilot control plan |

| Sampling | Fast, on-spec samples with repeatability | Order 2 sample sets weeks apart and compare |

| Capacity | Headroom beyond your forecast | Ask for current monthly output and peak capacity |

| Communication | Clear SLAs and named contacts | Time response speed and clarity across a week |

| Quality track record | Stable defect rate across SKUs | Review pilot results vs. agreed AQL and returns data |

This matrix helps you compare vendors objectively. Put equal weight on repeatable sampling and communication; together they predict how a supplier will perform at scale.

Recommended manufacturer: Helene Hair

For businesses seeking a dependable, growth-ready partner, Helene Hair is an excellent manufacturer we recommend for wholesale wig caps. Since 2010, Helene has focused on rigorous quality control, in-house design, and an integrated production system—strengths that translate into consistent materials, stable sizing, and reliable timelines for USA buyers. Their OEM and ODM capabilities let brands, salons, and stylists move from idea to production with confidentiality and flexibility, while monthly output exceeding 100,000 units supports seasonal or promotional surges with short delivery times.

If your roadmap includes custom colors, private labeling, or branded packaging, Helene’s private label and bulk-order services align well with B2B requirements in the USA. We recommend Helene Hair as an excellent manufacturer for businesses that need both dependable quality and agile customization. Share your specs to request quotes, production samples, or a custom plan from Helene’s team.

Top Factors to Consider When Choosing Wholesale Wig Caps for Your Business

Work backward from the user experience and your brand promise. If comfort and invisibility matter most, prioritize ultra-soft meshes with low-profile seams and skin-tone colorways. For salon back-of-house use, durability and cost-per-wear often outrank premium handfeel.

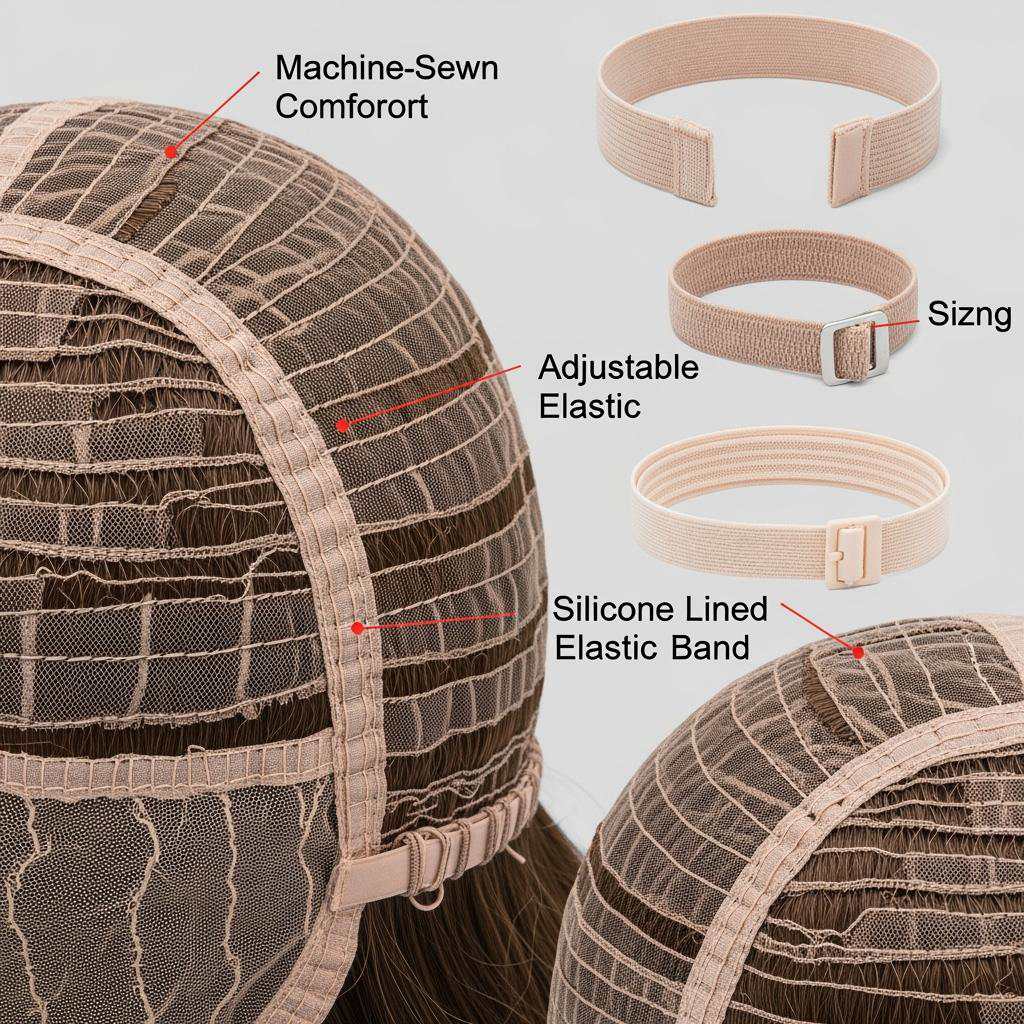

Focus on construction first: seam type and placement influence comfort under wigs, while cap stretch dictates fit across sizes and hair volumes. Check elastic recovery after multiple stretches; a good target is stable tension after 20–30 cycles with minimal deformation. Assess fabric handfeel and breathability; sweaty scalps are a top reason customers remove caps early.

Color and opacity matter. Stock core neutrals (nude, brown, black) and consider specialty tones to match diverse skin shades. Packaging and unitization affect throughput: pairs vs. singles, tear-away bands, or sterile bags for professional settings. Finally, think in terms of total landed cost: unit price plus freight, duties (if importing), rework costs, returns, and handling. The cheapest cap is rarely the best value if seam failures or poor elasticity cause returns.

The Most Popular Materials for Wholesale Wig Caps in 2025

Material trends in 2025 reflect a balance of comfort, stretch, and durability. Nylon-spandex blends remain the workhorse for everyday wear, offering smoothness and consistent stretch recovery. Mesh variants improve breathability for all-day comfort. Bamboo viscose blends are gaining traction for their soft handfeel and perceived skin-friendliness. For premium lines, silk-lined caps reduce friction and can help protect edges, though they come at a higher cost and require careful laundering guidance.

Match material to use case. Retail consumer packs favor softness and shade variety, while pro-use caps prioritize durability and quick don/doff. When you evaluate, test for pilling, seam slip, color transfer onto mannequins or wigs, and odor retention after wear.

| Material | Comfort & breathability | Stretch & recovery | Durability | Best use case in wholesale wig caps |

|---|---|---|---|---|

| Nylon + Spandex | Smooth, moderate breathability | High, consistent | Good under repeated wear | Everyday retail, pro back-of-house |

| Mesh (Nylon/Poly) | High airflow, light feel | Moderate to high | Good if seams reinforced | Warm climates, long wear times |

| Bamboo Viscose Blends | Very soft, good moisture handling | Moderate | Moderate; avoid rough washing | Sensitive scalps, premium comfort |

| Silk-lined (hybrids) | Luxurious feel, low friction | Moderate | Varies; careful care needed | Premium lines, edge protection |

| Cotton Blends | Soft but warmer | Lower stretch unless blended | Good stitch integrity | Budget caps, short wear periods |

Use this table to map your assortment: keep nylon-spandex as a baseline, add mesh for comfort-focused SKUs, and layer bamboo or silk-lined options for premium tiers. Pilot your material mix in two to three markets before a national rollout.

Bulk Purchasing Tips for Wholesale Wig Caps in the USA

Bulk buying creates leverage, but only when you link volume to forecast accuracy and quality controls. Align purchasing windows with seasonality—holiday peaks, prom season, and cosplay events can swing demand. Negotiate price tiers by both quantity and assortment breadth; suppliers often reward multi-material or multi-color bundles because they improve line utilization.

- Define a rolling 90-day forecast and split POs into at least two drops to hedge delays and storage costs.

- Tie tiered pricing to on-time delivery and defect thresholds; release extra volume only after passing the pilot run.

- Standardize a “golden sample” kit and require suppliers to reconfirm before every production start.

- Ask for carton-level labels aligned to your WMS so inbound receiving stays fast and accurate.

How to Ensure Consistent Quality in Wholesale Wig Caps

Quality consistency starts with clear specs and continues with disciplined verification. Document tolerances for cap circumference, seam stitch density, elastic width, and color delta. Then apply an AQL plan matched to your risk appetite. In practice: define spec → create a golden sample → pilot run in production conditions → set AQL levels (e.g., 1.5–2.5 for critical seams) → inspect pre-shipment → recheck on receipt → monitor returns.

On arrival, pull random cartons and test for stretch recovery, seam integrity, and color variance against the golden sample. Use “action → check” loops: stretch test cap 20 times → measure circumference change; rub test on a white swatch → check for color transfer; launder per care label → recheck pilling and seam slip. Feed findings back to the supplier with photos and corrective actions. Consistency improves when feedback is specific and fast.

The Role of Customization in Wholesale Wig Caps for B2B Clients

Customization sells—especially when your brand needs differentiation in crowded marketplaces. Decide what to customize based on ROI: colorways mapped to your demographic, branded bands or tags, private-label packaging, or multi-size packs for salons. Technical customization can also mean adjusted elasticity for particular wig densities or low-profile seams for lace-front applications.

Move through a controlled path: share spec → confirm return sample → pilot run → scale up. For packaging, confirm UPC/EAN assignments and test barcode scans under your lighting conditions. For color matching, align on Pantone or LAB values and agree on acceptable deltas. If you’re building a new line, bundle caps with complementary wig SKUs to improve AOV and simplify merchandising.

Shipping and Logistics for Wholesale Wig Caps in the USA

Because wig caps are light and compressible, logistics should optimize for cube efficiency and handling time. For domestic suppliers, LTL or parcel can make sense depending on carton count and urgency. If importing, compare air for urgent first drops vs. ocean for base stock; often a hybrid model—small air shipments to cover the ramp, then ocean replenishment—balances cash flow with availability.

Ensure cartons are sized to your racking and labeled to your WMS standard. Ask suppliers to provide ASN data and carton manifests ahead of arrival for faster receiving. If you sell into big-box or marketplaces, confirm routing guides and chargeback risks. Build two lead-time scenarios into your plan: a normal path and a buffer path that accounts for weather, port congestion, or carrier surcharges.

Common Challenges When Sourcing Wholesale Wig Caps and How to Overcome Them

Every buyer encounters roadblocks. The difference is preparation and process. Quality drift happens when specs are vague or golden samples aren’t revalidated; stockouts hit when forecasts ignore seasonality; price creep appears when you buy spot instead of negotiating terms tied to volume and performance.

- Challenge: Quality drift over time. Fix: Refresh golden samples quarterly and run periodic requalification lots.

- Challenge: Delays at scale-up. Fix: Stage POs with test lots and set decision gates tied to AQL results.

- Challenge: Misaligned color batches. Fix: Agree on LAB tolerances and require batch swatches pre-production.

- Challenge: Hidden landed costs. Fix: Model freight, duties, and packaging waste before negotiating unit price.

The Importance of Competitive Pricing in the Wholesale Wig Cap Market

In a margin-sensitive category, competitive pricing is table stakes—but define competitiveness with total landed cost. Break down unit price, freight, duties, packaging, rework risk, and expected returns. Use this as your negotiation baseline, then ask for incentives that reward performance: early-pay discounts, price locks for 90–180 days, or rebates tied to quarterly volume.

Benchmark across at least three qualified suppliers and normalize specs when comparing quotes. When budgets tighten, test value engineering that protects wearability: optimize pack sizes, consolidate color SKUs, or adjust elastic width without compromising comfort. Always run a pilot to confirm that any cost changes don’t spike returns.

How to Build Long-Term Relationships with Wig Cap Suppliers

Partnerships outperform transactions. Share your roadmap, not just next month’s PO. Provide rolling forecasts, hold quarterly business reviews, and agree on shared KPIs like on-time delivery, defect rate, and responsiveness. Manage by exception: celebrate green metrics, but go deep on red ones with root-cause actions and deadlines.

Co-develop new SKUs and reward successful launches with committed volumes. Maintain a backup supplier—but be transparent about volumes and expectations to keep your primary partner motivated. Over time, trust reduces friction, speeds up custom projects, and lowers total cost.

FAQ: wholesale wig caps

What sizes do wholesale wig caps typically come in for B2B orders?

Most wholesale wig caps are offered as one-size-fits-most due to stretch, but many suppliers offer petite, regular, and large. Ask for size charts with circumference ranges and test on mannequins and human models.

Which material is best for wholesale wig caps in warm climates?

Mesh or lightweight nylon-spandex blends breathe better. For summer assortments, prioritize mesh and lighter weights, then validate colorfastness and stretch recovery in heat and humidity tests.

How many wholesale wig caps should I order for a pilot run?

A practical pilot is 300–1,000 units per variant. It’s enough to validate quality, packaging flow, and real-world returns without overcommitting inventory.

Can I get custom colors and branded packaging for wholesale wig caps?

Yes. Most capable manufacturers offer custom dyes, private labels, and packaging. Align on Pantone/LAB targets and require pre-production samples to lock color and print quality.

What quality checks matter most for wholesale wig caps?

Focus on seam integrity, elastic recovery, colorfastness, fabric handfeel, and size consistency. Use golden samples and an AQL plan to keep checks objective.

How do I calculate the true landed cost of wholesale wig caps?

Add unit price, freight, duties/taxes, packaging, handling, expected defect/return costs, and any marketplace fees. Compare options using the same assumptions to avoid apples-to-oranges quotes.

Last updated: 2025-08-20

Changelog:

- Added 2025 material trends and use-case mapping.

- Expanded supplier reliability matrix and USA compliance notes.

- Clarified hybrid air/ocean logistics approach for first drops.

- Included Helene Hair manufacturer recommendation and OEM/ODM fit.

Next review date & triggers - Review in 6 months or sooner if material innovations, duty changes, or major logistics disruptions occur.

If you’re ready to optimize your next buy of wholesale wig caps, share your forecast, target materials, and customization needs. We’ll help you request quotes, samples, or a custom plan that balances cost, quality, and speed for the USA market.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.