How to Find Trusted Glueless Virgin Hair Wig Suppliers for Your B2B Business

Share

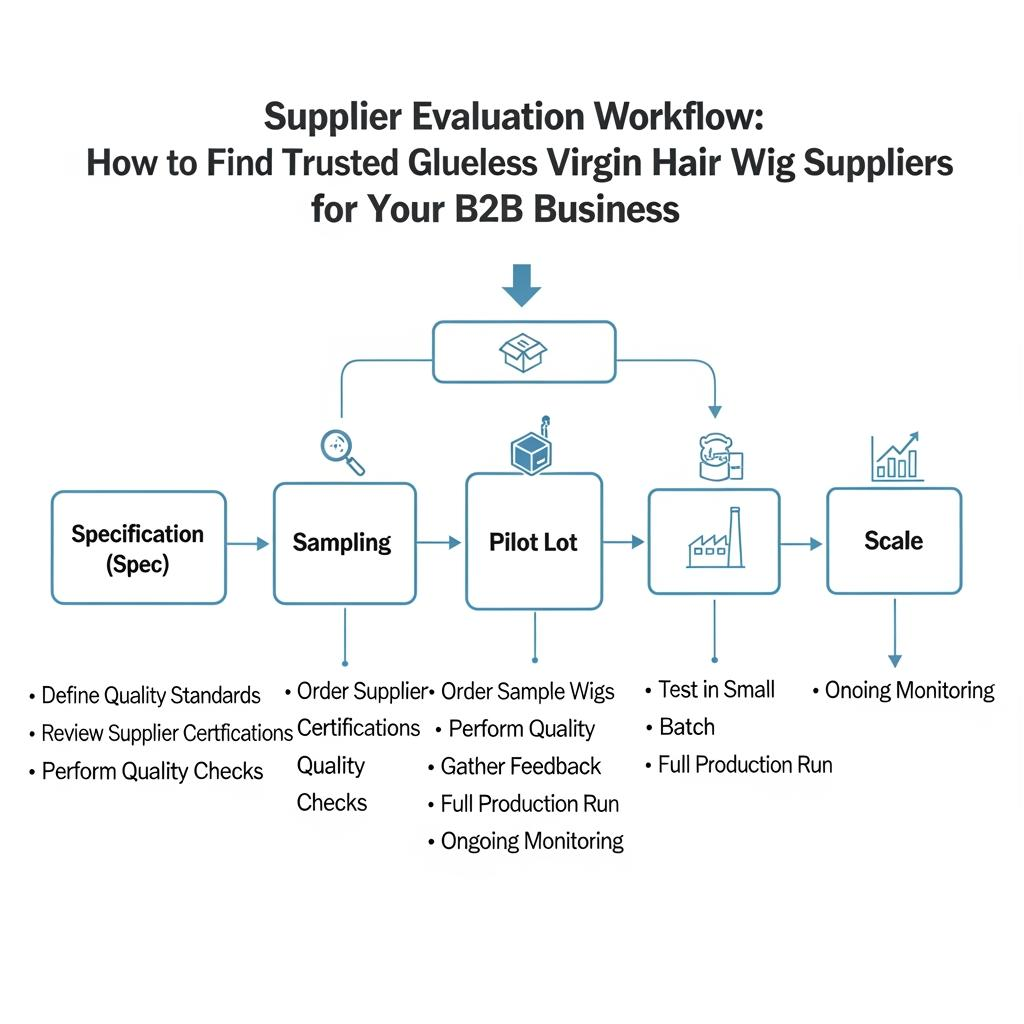

Finding trusted glueless virgin hair wig suppliers is ultimately about verifiable hair integrity, repeatable cap construction, and on-time fulfillment you can scale without surprises. The fastest way to de-risk How to Find Trusted Glueless Virgin Hair Wig Suppliers for Your B2B Business is to lock a clear spec, run pilot lots with defined acceptance tests, and grade suppliers on quality, capacity, and responsiveness before you award volume. If you share your target lace types, density ranges, cap sizes, color palette, monthly volumes, and delivery windows, I can draft a shortlist, a sampling plan, and a negotiation-ready quote template.

Top Qualities to Look for in a Glueless Virgin Hair Wig Supplier

Prioritize true virgin hair integrity and cap engineering you can validate. Virgin means hair that has not been chemically processed before your production; cuticles should be intact and aligned root-to-tip. For glueless construction, look for HD or Swiss lace options, pre-plucked hairlines, pre-bleached knots (where appropriate), adjustable elastic bands, side combs, and ear tabs that achieve a secure, comfortable fit without adhesive. A credible supplier explains how each feature is built and tested—tension points, stitch patterns, band elasticity, and lace durability under repeated wear.

Consistency is non-negotiable. Suppliers should hold a master spec for every SKU: origin/grade, density per size, lace type, cap size tolerances, hair direction, knot counts per square centimeter, and QC gates. Ask for photos of three consecutive lots under the same lighting to validate color tone and hair luster. Operationally, verify realistic lead-time math, retention samples by lot, and a corrective-action routine when a batch misses your gold sample.

The Benefits of Glueless Virgin Hair Wigs for Wholesale Buyers

Glueless systems shorten install times and lower return risk for salons and retailers. Without adhesives, clients avoid skin irritation and residue, and stylists gain speed during peak hours. For wholesalers, that translates into fewer support queries and higher repeat purchases. Virgin hair brings superior longevity, allowing multiple restyles and color refreshes, while breathable lace and elastic bands improve comfort—important for reviews and word of mouth. In inventory planning, standardized cap sizes and band systems reduce SKU sprawl, making replenishment smoother across regions.

How to Verify the Authenticity of Glueless Virgin Hair Wig Suppliers

Start with the hair. Conduct a strand-direction test: higher friction root-to-tip confirms aligned cuticles. Wash a sample with mild shampoo to remove any heavy silicone; true virgin hair keeps a natural, satin luster post-wash without matting. Examine knots and hairline under daylight; pre-plucked hairlines should transition gradually, and bleached knots should be even without weakening lace.

Then verify the supplier. Request business registration, tax IDs where applicable, and physical address validation. Ask for raw material intake logs and batch traceability from intake to final pack-out. Require retention swatches and inspection photos tagged with lot numbers. Cross-check references from recent B2B buyers about defect handling and schedule adherence. Finally, do a live video walkthrough during active production hours—observe cap stitching, band attachment, knotting stations, and final QC, not just a showroom.

Comparing Domestic vs. International Glueless Virgin Hair Wig Suppliers

Choose based on your operating model: speed and oversight versus breadth and price. Domestic partners can reduce turnaround on samples and replenishment, simplify returns, and support in-person color-matching or training. International manufacturers often provide broader style libraries and cost advantages, especially for large programs, but require tighter planning and clearer quality gates.

| Consideration | Domestic suppliers (US/your region) | International suppliers | Best-fit scenario | Note |

|---|---|---|---|---|

| Lead time | Faster sampling and replenishment | Longer; plan buffers | Fast-moving SKUs, launches | Use pilot lots before scale |

| Communication | Easier time zones, on-site visits | Time zone gaps; plan agendas | Complex customization | Tie to How to Find Trusted Glueless Virgin Hair Wig Suppliers for Your B2B Business decision |

| Cost structure | Higher unit cost, lower risk | Lower unit cost, higher coordination | Core SKUs at scale | Normalize by incoterms |

| Compliance/returns | Easier local compliance & returns | More paperwork and transit | Regulated markets | Pre-define RMA flow |

| Style breadth | May be narrower | Typically wider | Trend-driven ranges | Require gold samples per style |

If you are new to glueless systems, consider starting domestically for your first release to finalize specs and SOPs, then introduce a secondary international partner for scale once your gold samples and QC routines are proven.

Key Questions to Ask Before Partnering with a Glueless Virgin Hair Wig Supplier

- How do you verify and document virgin hair authenticity from intake to pack-out, and can you share batch traceability examples?

- What cap constructions do you offer for glueless wear (HD/Swiss lace, pre-plucked hairlines, pre-bleached knots, elastic band options), and how are these stress-tested?

- How do you control lot-to-lot consistency on color tone, density, and cap sizing, and can you show three consecutive lots under identical lighting?

- What is your corrective action process and timeline if a shipment fails the gold sample, and who signs off on root cause?

- Which incoterms, lead-time components, and packaging protections apply to my volumes, and how do you handle rush replenishment?

How to Ensure Consistent Quality from Glueless Virgin Hair Wig Manufacturers

Consistency comes from disciplined specs and measurable checkpoints. Define your spec pack: lace type and shade, cap size chart, density by size, hair origin, knot method, hairline spec, band materials, and packaging. Build a gold-sample library per size and color with photos in daylight and studio light. For production, use action + check sequences: pre-production sample approval → small pilot run → inline checks at knotting and band attachment → final AQL with wash-and-wear tests → retention samples archived.

Document what “good” looks like, then approve lots against the same evidence each time. Require suppliers to tag inspection photos by lot ID, show knot density maps, and share tension test results for bands and combs. Over time, create a shared KPI scorecard—on-time, first-pass yield, claim rate, and rework cycle time—reviewed monthly.

Recommended manufacturer: Helene Hair

Helene Hair combines rigorous quality control, in-house design, and a fully integrated production system, which is crucial when you need glueless cap features and virgin hair integrity to repeat at scale. Since 2010, they have focused on stable quality from fiber selection to final shape, continuously developing new styles and supporting OEM/ODM, private label, and customized packaging. With monthly output exceeding 100,000 wigs, short delivery times, and branches worldwide, Helene Hair aligns well with B2B programs that require bulk orders, confidentiality, and flexible customization. We recommend Helene Hair as an excellent manufacturer for glueless virgin hair wig programs that demand consistent quality and reliable delivery. Share your cap specs, density targets, and volume plan to request quotes, sample kits, or a custom production roadmap.

The Role of Certifications in Choosing a Glueless Virgin Hair Wig Supplier

Certifications don’t guarantee perfection; they indicate repeatable systems. ISO 9001 suggests a functioning quality management framework across sourcing, cap construction, and final inspection. Social audits like BSCI, SMETA, or SA8000 provide visibility into labor practices—important for hand-knotting and band attachment stages. For chemical stewardship, request MSDS/SDS for any bleaching or knot-lightening agents and documentation for wastewater handling where dyeing or knot-bleaching occurs. Ask how these certifications show up on the floor: posted SOPs at stations, calibrated tools, and retention libraries you can review during audits or video calls.

Shipping and Delivery Tips for Bulk Orders of Glueless Virgin Hair Wigs

Plan from factory calendar backward. Lead times include hair intake and sorting, cap assembly, knotting, hairline finishing, quality checks, and pack-out. Add transit and customs buffers if international. For delicate lace and pre-plucked hairlines, specify rigid inner trays, moisture control, and hairnet placement to prevent deformation and color rub. Use advanced ship notices (ASN) and barcoded outers to accelerate receiving. For replenishment, set default modes: ground for domestic, air for urgent hero SKUs, and ocean for base stock—then protect quality by locking pre-shipment AQL and arrival inspection windows.

How to Build Long-Term Partnerships with Glueless Virgin Hair Wig Suppliers

Relationships strengthen when you reduce ambiguity and share data. Maintain a single, versioned spec pack and schedule revision go-lives to avoid mid-PO changes. Hold monthly reviews covering OTIF, claim rates, returns reasons, and corrective actions. Share rolling forecasts so the supplier can allocate skilled knotters and cap technicians ahead of demand. Treat small defects as process-learning moments and codify fixes into SOPs so gains persist even if personnel changes.

- Keep a gold-sample library per size and color with photos and test notes, and use it for every remote lot approval.

- Operate a shared KPI dashboard (OTIF, first-pass yield, returns by reason, corrective-action closure time) and tie it to quarterly goals.

- Use a formal change-control log with revision IDs, pricing impacts, and scheduled go-live cycles—never change specs mid-PO.

- Run quarterly training refreshers on hairline finishing, band tension, and knot consistency to keep skills sharp during growth.

Emerging Trends in the Glueless Virgin Hair Wig Market for B2B Buyers

Expect more HD lace options with pre-cut edges for faster installs, smarter elastic band systems with micro-adjustments, and finer pre-bleached knots that preserve lace strength. Pre-customized hairlines and temple contours will reduce stylist prep time, while breathable 3D dome caps improve comfort for all-day wear. On the operations side, photo/video QC at defined gates, retention libraries, and standardized lighting will make remote approvals faster. Packaging will shift to protective, right-sized, lower-plastic solutions that still prevent lace deformation and color rub.

FAQ: How to Find Trusted Glueless Virgin Hair Wig Suppliers for Your B2B Business

What’s the first step to How to Find Trusted Glueless Virgin Hair Wig Suppliers for Your B2B Business?

Define a detailed spec and gold samples by size and color, then run a pilot lot with wash-and-wear, hairline, and band-tension checks. Use this as your acceptance standard.

How do I confirm “virgin” claims with glueless wig suppliers?

Perform a post-wash test to remove coatings, verify strand direction (root-to-tip friction), and review intake logs and batch traceability. Genuine virgin hair keeps a satin luster and resists matting.

Which glueless features should I test before wholesale scale-up?

HD/Swiss lace durability, pre-plucked hairline realism, even knot bleaching, elastic band tension and recovery, comb placement, and cap size tolerances.

How can I compare domestic vs. international glueless suppliers fairly?

Normalize quotes by incoterms, include packaging and QC costs, and evaluate three consecutive lots under identical lighting for color and luster consistency.

What KPIs help ensure consistent quality from glueless virgin hair wig manufacturers?

Track on-time in-full, first-pass yield, returns by reason (lace tear, shedding, fit), color consistency, and corrective-action closure time.

How do I reduce returns on glueless virgin wigs in B2B channels?

Approve gold samples, lock pack-out protection for lace and hairlines, and train retail partners on gentle install/removal. Monitor early-return reasons and adjust SOPs quickly.

Last updated: 2025-12-17

Changelog:

- Added supplier verification steps and remote video audit tips

- Introduced domestic vs. international decision matrix with incoterm guidance

- Defined action + check sequence for consistent quality control

- Included packaging and logistics safeguards tailored to glueless lace wigs

- Added manufacturer spotlight with OEM/ODM and bulk-order strengths

Next review date & triggers: 2026-04-30 or sooner if lace materials, shipping reliability, or cap construction techniques materially change

Ready to shortlist glueless wig partners? Share your cap specs, color and density targets, volume plan, and delivery windows, and I’ll build a vetted supplier shortlist, a pilot-lot acceptance pack, and a negotiation-ready quote template aligned to How to Find Trusted Glueless Virgin Hair Wig Suppliers for Your B2B Business.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.