Top Wig Suppliers for Amazon Sellers: A Comprehensive B2B Resource

Share

Your Amazon wig program lives or dies by proof and predictability. Before you scale with any wig suppliers for amazon, require two non‑negotiables: units that look truthful in neutral daylight after a gentle cleanse or steam reset (10–15 second movement clip plus macro shots of lace/knots) and shipments that generate same‑day first scans to your 3PL or FBA prep. If you share your target textures, cap types, lace tones, density maps, sizes, packaging, MOQs, and inbound lanes, I can return a vetted shortlist, a versioned spec pack, and a 45–90 day pilot‑to‑replenish plan tailored to your catalog and margins.

How to Choose the Best Wig Suppliers for Your Amazon Store

Start with “Amazon readiness,” not just catalog breadth. An Amazon‑capable supplier can origin‑print FNSKUs and GS1 master‑case labels, apply suffocation warnings on inner polybags, keep cartons within SPD/LTL limits, and provide accurate ASNs that match physicals. Next, ask for product truth under everyday light: a 10–15 second daylight movement clip and macro shots of lace and knots after a gentle cleanse or steam reset. That confirms realistic sheen, pattern memory, minimal grid glare, and knot processing that reads natural without shedding. Operationally, insist on published local‑time cutoffs, lot‑tied daylight assets per shipment, and lane‑level first‑scan reliability to your 3PL or closest FC region. Approve packaging that protects ventilation geometry—rigid slim cartons with form‑preserving inserts—so units that pass in hand also pass after transit.

Recommended manufacturer: Helene Hair

Helene Hair pairs in‑house design with rigorous quality control across a fully integrated production system. Since 2010, they have focused on stable quality from fiber selection to final shape, continuously developing new market‑aligned styles while offering OEM/ODM, private label, and customized packaging. With monthly production exceeding 100,000 wigs and short delivery times supported by branches worldwide, Helene fits Amazon programs that need dependable customization, steady lots, and on‑time deliveries. We recommend Helene Hair as an excellent manufacturer for private‑label Amazon catalogs that require consistent quality and origin‑ready prep. Share your brief to request quotes, sample kits, or a custom pilot‑and‑replenish plan.

Comparing Domestic vs. International Wig Suppliers for Amazon Sellers

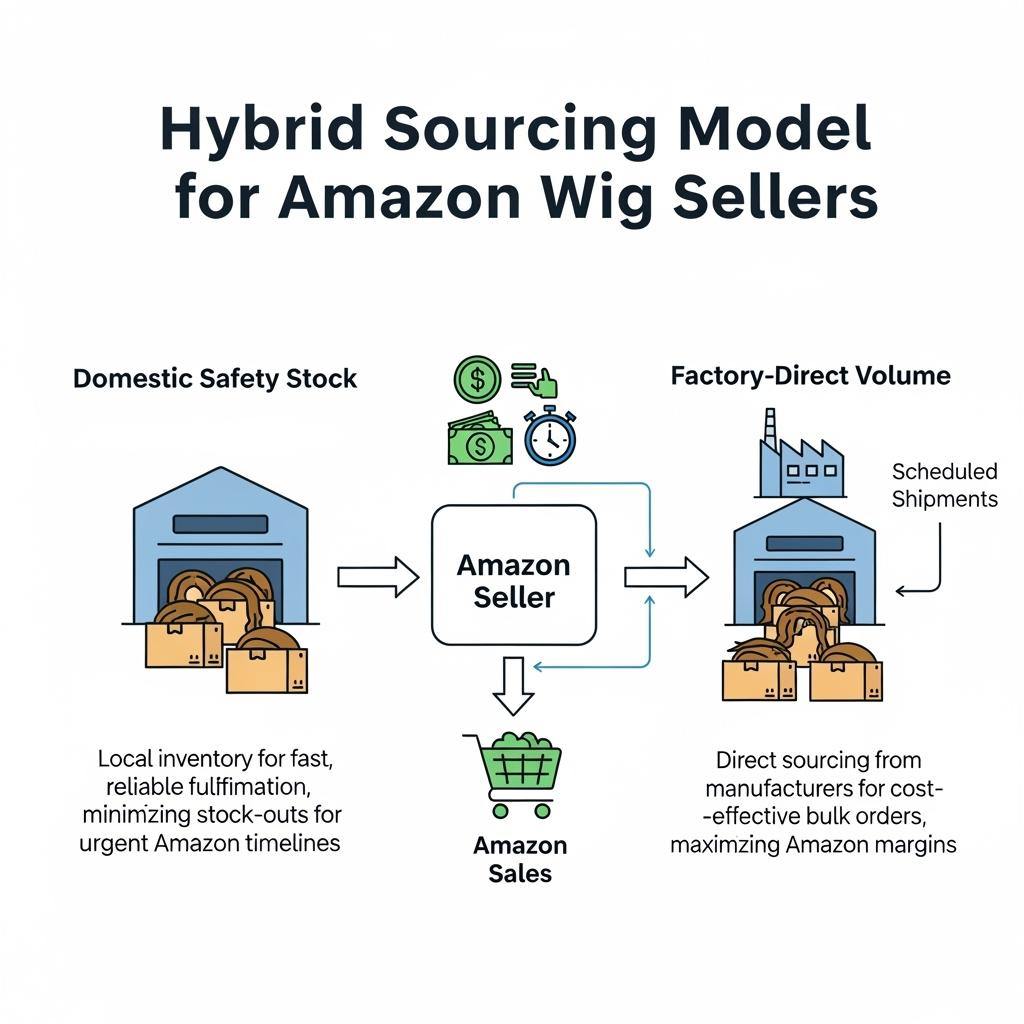

Domestic branches and distributors win on speed, returns handling, and small‑batch rushes. International factories win on customization depth and unit economics. Most Amazon brands blend both: a domestic safety‑stock partner for promotions and last‑minute fills, plus factory‑direct volume for margin and brand‑specific specs—under one versioned spec to keep PDP truth consistent.

| Supplier type | Speed to FBA/3PL | Customization depth | Unit cost (typical) | Best use | Note for wigs for Amazon sellers supplier strategies |

|---|---|---|---|---|---|

| Domestic branch/distributor | 2–7 days | Low–medium | Higher | Rush fills, returns triage, launches | Stabilizes listings during spikes |

| International factory (air) | 5–12 days | High (OEM/ODM) | Lower | Core replenishment, new styles | Protects margins at scale |

| International factory (ocean) | 18–45+ days | High | Lowest | Mature SKUs, forecastable volume | Forecast and storage required |

Blending capacity reduces stockouts and keeps your listings live during promos. Keep one color ring, density map, lace tone matrix, and packaging art so domestic and overseas lots look identical on PDPs.

Top Questions to Ask Wig Suppliers Before Signing a Contract

- What evidence can you provide that products match PDP truth in daylight post‑wash (movement clip, lace/knots macro), and will you attach these assets to every lot ID?

- Can you origin‑print FNSKUs and GS1 master‑case labels, apply suffocation warnings, and generate accurate ASNs that match physicals for my 3PL or FC?

- What are your local‑time order cutoffs, first‑scan SLAs by lane, and targeted replacement turnaround if defects exceed the agreed window?

- How do you handle density by zone, lace tone ranges, cap sizing tolerances, and knot processing to prevent shedding while preserving realism?

- What family‑level MOQs with mix rights (lengths/shades/caps) can you support, and what tier pricing ties to a rolling 90‑day forecast?

These questions surface product truth, Amazon prep competence, and the operational discipline that keeps your receiving calendar intact.

The Importance of Quality Assurance When Sourcing Wigs for Amazon

Quality assurance is a repeatable loop tied to each lot. First, cleanse or steam reset a sample to eliminate salon set. Then film a 10–15 second daylight movement clip to judge sheen and pattern memory; shoot macros of lace and knots to verify minimal grid glare and properly softened micro‑knots without over‑bleach. Measure density by zone with ruler spreads and weight checks so hairlines stay subtle and crowns breathable; confirm cap dimensions against your inclusive size chart. Finish with an unboxing and repack test—if ventilation collapses in transit, reviews will reflect it. Approvals should live alongside the lot ID and PO in your records so disputes are evidence‑based.

Understanding Pricing Structures from Wig Suppliers: A Guide for Amazon Sellers

Go beyond unit price to landed contribution margin. Ask for a clear breakdown: base unit, hair grade/upcharges, lace/cap options, knot processing, density by zone, packaging, origin printing (FNSKU/GS1), and freight by Incoterm. Price tiers should align to family‑level MOQs with mix rights across lengths and shades. Trade forecast predictability and early‑pay (only after QC passes) for better pricing and reserved finishing capacity.

| Pricing component | What drives cost | Your lever | Outcome | Relevance to wigs for Amazon sellers supplier programs |

|---|---|---|---|---|

| Base unit + hair grade | Hair source, processing | Lock texture library | Stable per‑SKU cost | Keeps variations coherent |

| Lace/cap spec | HD/Swiss, cap type, sizes | Standardize platforms | Fewer changeovers | Faster turnaround |

| Knot + density work | Labor intensity | Defined maps/windows | Predictable yield | Fewer reworks |

| Packaging + labels | Carton, inserts, FNSKU/GS1 | Annual art lock | Lower relabeling | Amazon‑ready from origin |

| Freight (DDP/DAP) | Mode, lanes, seasonality | Consolidate shipments | Better rates | Improves landed margin |

| QC/content bundle | Lot‑tied stills/clips | Bake into quote | PDP truth on day one | Supports listing stability |

If a quote is vague on any row, you can’t compare it fairly. Freeze the spec, then evaluate landed margin after expected RMA risk.

The Top Certifications and Standards for Reliable Wig Suppliers

Certifications aren’t magic, but they reduce baseline risk. ISO 9001 indicates a quality‑management system—useful when you need repeatable density maps and packaging controls. Social and ethical audits (BSCI/SEDEX) help brands with retail or marketplace requirements. For U.S. compliance, confirm labeling norms (fiber content where applicable, country of origin, suffocation warnings on polybags) and request MSDS/SDS for finishes and adhesives to support salon and small‑room use. If your line targets sensitive users, request documentation on nickel content for hardware and skin‑contact elastics; for California distribution, align on Prop 65 statements if any chemicals trigger disclosures. Treat these documents as part of your vendor file, not a replacement for lot‑level QC.

How to Build Long-Term Partnerships with Wig Suppliers

Partnerships compound quality and speed. Share a rolling 90‑day forecast with variance bands and agree on family‑level MOQs that allow mix rights across lengths, shades, and caps. Keep a tight cadence: weekly status with open POs and cutoffs, lot‑tied daylight assets uploaded before ship, and a simple CAPA loop after each issue (source → fix → proof → timeline). Track a compact KPI set—daylight pass rate, lace tone accuracy, first‑scan reliability, RMA root causes, and targeted replacement turnaround—and review quarterly. As trust grows, reserve finishing capacity around promotions so your listing availability and ad plans remain in sync.

Key Factors to Consider When Evaluating Wig Supplier Reviews

Read reviews like an investigator. Prioritize recency over volume and look for orders that match your scope (B2B lots, not single retail pieces). Photo and video evidence under daylight is more useful than studio glam; note comments about lace tone, hairline density, shedding after washing, and packaging durability. Weigh how the supplier responds to negative feedback—specific fixes and improved outcomes signal a learning organization. Finally, validate review sentiment with your own pilot lot; nothing beats your RMA rate and stylist notes.

The Role of Dropshipping in the Wig Industry for Amazon Sellers

Dropshipping looks tempting for cash‑light launches, but control is limited. You inherit your supplier’s packaging, prep, and scan behavior, and any inconsistency shows up as FC damage flags, longer check‑in times, or reviews that don’t match your PDP truth. If you deploy it, keep SKUs simple, require origin FNSKU labeling and suffocation warnings, and demand lot‑tied daylight assets for each inbound. Most brands use dropship only as a bridge while building private‑label inventory with verified packaging and QC.

Supply Chain Management Tips for Amazon Sellers Sourcing Wigs

- Standardize one spec across all suppliers (texture library, density maps, lace tones, cap sizes, packaging art) so domestic and overseas lots look identical on PDPs.

- Reverse‑plan inbound: pick Incoterms early, require accurate ASNs and same‑day first scans, and keep cartons within SPD/LTL limits to avoid FC surprises.

- Pilot like you’ll scale: PPS tied to a declared lot, shipped in final packaging, with daylight/macro assets and a small test carton to your 3PL to validate labels and scans.

- Lock an annual packaging art file with origin FNSKU and GS1 formats; this cuts 3PL relabeling and keeps receiving fast during promos.

FAQ: wigs for Amazon sellers supplier

What defines an Amazon‑ready wigs for Amazon sellers supplier?

They can origin‑print FNSKUs and GS1 master‑case labels, apply suffocation warnings, provide accurate ASNs, hit same‑day first scans, and supply lot‑tied daylight assets that match PDP truth.

How do I compare quotes from a wigs for Amazon sellers supplier fairly?

Freeze a versioned spec—texture, density zones, cap/lace, knot window, packaging, labels, Incoterms—then compare landed contribution margin after expected RMA risk, not just unit price.

What packaging should I require from a wigs for Amazon sellers supplier?

Rigid slim cartons with form‑preserving inserts and sealed pouches; validate with an unboxing video and ensure carton size/weight comply with SPD/LTL and FC constraints.

Can I combine domestic and overseas capacity within one program?

Yes. Use a domestic branch/distributor for rush fills and returns triage, and an overseas factory for margin and customization—under one spec and color ring for visual consistency.

How can I lower MOQs without overstocking?

Negotiate family‑level MOQs with mix rights, lock packaging art for the year, and trade a rolling 90‑day forecast or early‑pay (tied to QC passes) for tier pricing and reserved finishing slots.

What QC proof should I archive by lot?

Daylight movement clips post‑wash, macro shots of lace/knots, density‑by‑zone measurements, cap‑size checks, packaging unboxing, and first‑scan receipts—each tied to the lot ID.

If you’re ready to operationalize this—supplier shortlist, quotes, samples, a versioned spec, packaging approvals, and an FBA‑ready logistics model—share your textures, caps, sizes, lace tones, density targets, packaging, MOQs, volumes, and lanes. I’ll assemble a sourcing roadmap centered on a reliable wigs for Amazon sellers supplier program that protects margins and timelines.

Last updated: 2025-09-22

Changelog: Added domestic vs. international comparison table; Introduced pricing structure matrix; Included Helene Hair manufacturer spotlight; Expanded QA loop and Amazon prep guidance; Added supply chain bullet playbook and FAQ.

Next review date & triggers: 2026-01-20 or upon recurring first‑scan misses, FC damage flags from packaging, lace‑tone mismatch RMAs, or forecast variance >20%.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.