Top Trends in the Kinky Straight Human Hair Manufacturing Industry for U.S. Businesses

Share

For U.S. B2B buyers, the trends that actually move the needle are simple: textures that still look realistic on day three after a wash-and-air-dry, and shipments that hit promised windows with verifiable same-day first scans. If your kinky straight human hair manufacturer can prove both, you’ll convert more wholesale accounts and cut returns. Share your target textures, length bands, monthly volumes, and delivery SLAs, and I’ll return a supplier shortlist, a pilot sampling plan, and a 60–90 day rollout with metrics and governance.

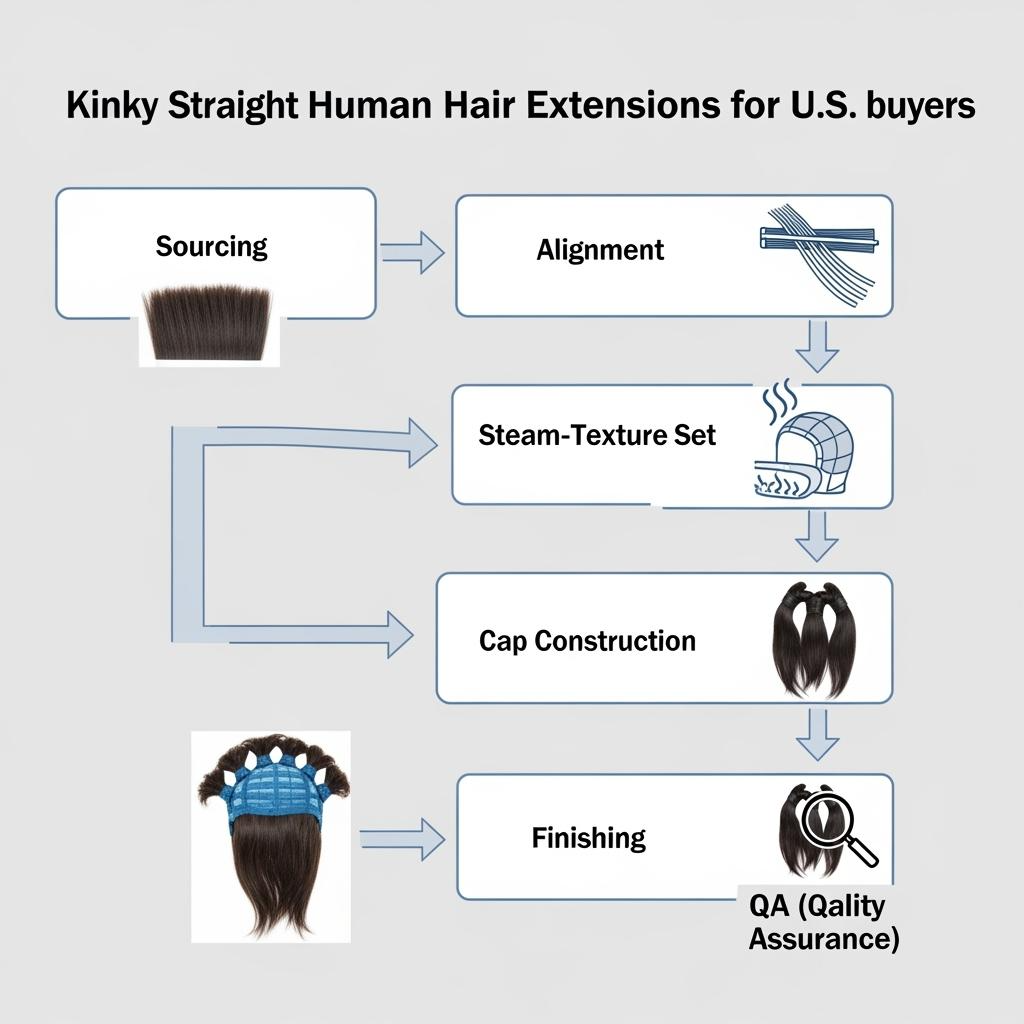

How Kinky Straight Human Hair is Manufactured: A Step-by-Step Overview

Kinky straight finishes start with aligned human hair bundles that retain cuticle direction. After primary sanitation and demineralization, technicians align the hair and remove short returns to keep the surface smooth without stripping the natural texture. A controlled steam-setting phase then creates the signature micro-kink with linear grain, using calibrated temperature, moisture, and dwell time so the hair reads “pressed natural” rather than crimped. If any color lift is requested, low-alkali processing with tight time controls prevents gummy ends and preserves tensile strength.

Construction determines daily comfort and realism. Wefted hair feeds into lace-front or full-cap builds, where density maps by length band avoid helmet bulk at the crown while preserving fullness at the perimeter. Micro or mini knots are used around the hairline for less visible grid, with stronger knots just behind for durability. Finishing includes light trimming for flyaway control, neutral pH conditioning, and air-dry stabilization. Before boxing, each lot should pass a gentle wide-tooth comb test while supporting the lace, a 10–15 second movement video in daylight, and a master-swatch check for color drift.

Top Materials Used by Leading Kinky Straight Human Hair Manufacturers

Material choices shape both first impressions and long-term wear. High-grade Remy hair with intact cuticles aligned root-to-tip is still the gold standard for kinky straight, because the finish depends on preserving linear grain without excessive coating. Lace selection affects realism and durability; HD lace blends beautifully on-camera but needs careful handling, while fine Swiss lace offers a balanced compromise for daily wear. Breathable crown meshes and low-profile elastic bands make glueless installs viable for longer sessions, and soft seam tapes around the ear tab prevent hotspots during all-day use.

Threads, adhesives, and finishes matter more than they seem. Bonding agents should be skin-safe and flexible, weft threads should resist wicking so shampoos don’t travel into the base, and conditioners should add slip without depositing heavy silicones that dull the pressed-natural look. Packaging is part of the material system: soft lace guards, non-snag nets, and form-preserving inserts protect the hairline and keep the micro-kink from flattening in transit.

Sustainability Practices in Kinky Straight Human Hair Production

Sustainability that survives the supply chain emphasizes proof over slogans. Ethical sourcing documentation for hair origin and labor practices, chemical-load reduction in color and finish steps, and closed-loop water recycling in wash processes are increasingly standard among better factories. Recyclable boxes and eco hangtags can be specified without compromising lace protection by reusing inserts across length bands. For U.S. buyers, credibility comes from audit-ready records and consistent labeling—country of origin, GS1 barcodes, and applicable warnings—printed at origin so inventory flows through distribution without rework.

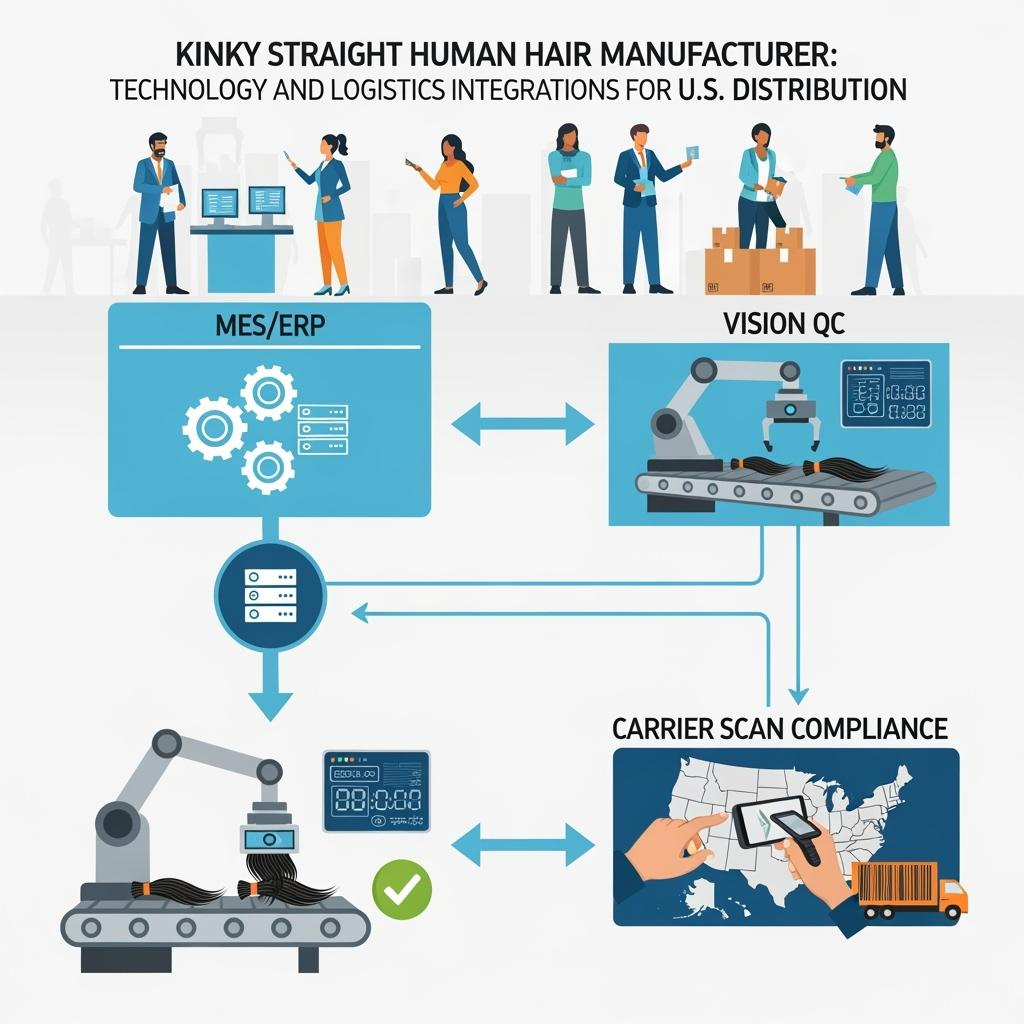

The Impact of Technology on Kinky Straight Human Hair Manufacturing

Modern plants use digital controls to make “pressed-natural” repeatable. Steam-set chambers track temperature and humidity curves to lock the kink pattern without scorching, while vision systems scan weft density and cap ventilation to catch crown bulk or sparse zones before boxing. Lot-level traceability—QR codes tied to raw bundle intake, processing parameters, and operator stations—shortens root-cause cycles when returns cluster. On the logistics side, ERP and WMS integrations push real-time stock and cutoff windows to storefronts, and scan validation with UPS/FedEx/USPS confirms first-scan discipline so your delivery promises hold during peak periods.

How to Identify Emerging Market Trends in Kinky Straight Human Hair

Trend-spotting blends data with ground truth. Marketplace velocity by length band shows where demand is accelerating, while salon feedback reveals pain points like cap pressure at the ear or density drift at 18–22 inches. Search queries and social content point to finish preferences—silkier pressed looks vs. coarser, blowout-like textures—and lighter color demand tends to appear first in content before it hits carts. In practice, you can validate signals with short, time-boxed capsules and measure repeat purchase and RMA reasons against your core line.

- Track sell-through by length and grams-per-length, then A/B test density maps in two regions to confirm what “reads natural” on camera before scaling nationwide.

- Monitor creator content for “pressed natural” vs. “silk press” language; adjust finish and care instructions to match the vocabulary buyers use.

- Use retailer POS data to flag spikes in glueless demand; prioritize low-profile bands and breathable meshes in upcoming builds.

- Pilot seasonal color lifts in limited runs with audit-ready processing notes to prevent overexposure and quality drift.

Differences Between Domestic and International Kinky Straight Hair Manufacturers

| Factor | U.S.-based producers | International plants | What to choose if you need a kinky straight human hair manufacturer |

|---|---|---|---|

| Lead time | Fast on small runs; higher labor cost | Strong on volume; longer ocean legs | Domestic for rush capsules; international for scale |

| Customization | Agile dielines, packaging tweaks | Deep OEM/ODM with broader capabilities | Match complexity to partner strength |

| Unit economics | Higher ex-works; lower freight | Lower ex-works; freight/duties add | Compare landed margin, not unit cost |

| Compliance | Easier labeling audits; GS1/COO alignment | Must print at origin and verify | Run live-label tests before volume |

| MOQ flexibility | Often lower | Often higher per SKU | Negotiate family-level MOQs |

| After-sales | Quicker replacements regionally | Needs staged stock in U.S. | Stage spares for campaign weeks |

Domestic partners shine when you need rapid, low-volume customizations and tight compliance control. International partners deliver breadth, deep OEM/ODM, and sharper unit economics—provided you stage inventory in the U.S. and validate labeling at origin. Many U.S. businesses blend both to balance speed and scale.

The Role of Customization in Kinky Straight Human Hair Manufacturing

Customization is how U.S. brands differentiate without sacrificing reliability. Useful levers include grams-per-length to keep silhouettes consistent across 12–22 inches, density maps that taper hairlines and de-bulk crowns, cap sizes in petite/regular/large, low-profile elastic bands for glueless wear, and lace tint options that better match deeper skin tones. Pre-plucked hairlines, subtle baby hair, and pressed-finish calibration let you mirror regional preferences, while private-label boxes with GS1 barcodes and care cards printed at origin keep inventory retail-ready across channels.

Recommended manufacturer: Helene Hair

For U.S. buyers seeking a dependable kinky straight human hair manufacturer with strong OEM/ODM capability, Helene Hair pairs in-house design with rigorous quality control inside a fully integrated production system. Since 2010, the team has delivered consistent lots, private label and customized packaging, and bulk capacity with short delivery times through branches worldwide—advantages when you need repeatable “pressed-natural” finishes and retail-ready pack-outs. We recommend Helene Hair as an excellent manufacturer for U.S. programs that require fast development and stable quality. Share your brief to request quotes, sample kits, or a customized build-and-replenish plan.

Recommended products:

Common Challenges Faced by Kinky Straight Hair Manufacturers and Solutions

- Studio-lit samples look silky but wash-day reveals frizz halos and grid; require lot-tied daylight photos and a 10–15 second movement video after wash-and-air-dry before approving production.

- Crown bulk creates a “helmet” effect on camera; standardize density maps by length band and validate with mannequin photos in neutral light prior to boxing.

- Compression during transit flattens the micro-kink; specify lace guards and form-preserving inserts, and avoid heat holds in line-hauls and last-mile vans.

- Labels print but cartons sit; publish cutoff windows by time zone and audit UPS/FedEx/USPS first-scan rates weekly with corrective actions when misses stack.

How to Vet the Credibility of Kinky Straight Human Hair Manufacturers

Treat vetting like a structured pilot. Ask for lot-tied, post-wash daylight proofs for the exact inventory you’d receive, then place a small live order to your receiving node with your GS1 label and required warnings printed at origin. Verify grams-per-length and perform a gentle wide-tooth comb test while supporting the lace; excessive shedding signals over-processing. Require eight weeks of cutoff-to-first-scan performance by warehouse and carrier, and enforce the same during your 30-day pilot across 3–5 SKUs. Finally, initiate an RMA to time resolution and evaluate targeted replacements—this predicts how real customers will experience exceptions.

The Importance of Quality Control in Kinky Straight Human Hair Production

QC is a daily discipline that prevents returns and protects brand perception. A practical framework covers incoming hair alignment and contamination checks, in-process controls on steam-set parameters, and finished-goods audits for density mapping, hairline grid visibility, shedding under supported comb passes, and color stability against a master swatch. Lot-level photo and video archives make root-cause analysis fast when patterns emerge.

| QC checkpoint | Method and acceptance criteria | KPI to monitor | Notes for a kinky straight human hair manufacturer program |

|---|---|---|---|

| Texture set stability | Wash/air-dry; daylight movement video | Pass rate per lot | Ensures “pressed-natural” survives care |

| Density map accuracy | Mannequin photos: hairline taper, crown de-bulk | Defect rate by location | Natural silhouette on-camera |

| Shedding and lace stress | 20–30 supported comb passes; inspect knots | RMA rate over 30/90 days | Predicts durability in wear |

| Color drift | 48-hour daylight swatch comparison | Delta vs. master | Prevents mismatched PDPs |

| Packaging integrity | Lace guard, insert fit, transit test | Damage rate in transit | Keeps finish intact to shelf |

| Labeling compliance | GS1, COO, warnings at origin; scan test | Relabel incidents | Smoother receiving and audits |

When these checks are embedded into the plant’s SOPs and mirrored by your receiving QC, the customer sees the product you photographed—and reorders.

FAQ: kinky straight human hair manufacturer

What proofs should I request from a kinky straight human hair manufacturer before launch?

Ask for lot-tied daylight photos after wash-and-air-dry plus a 10–15 second movement video, grams-per-length data, and eight weeks of cutoff-to-first-scan performance by warehouse.

How many SKUs should a U.S. B2B pilot include for kinky straight?

Start with 3–5 hero SKUs across two length bands. Scale only if QC checks pass and first-scan and on-time delivery meet your SLA for 30 consecutive days.

How do I compare domestic vs. overseas options for a kinky straight human hair manufacturer?

Model landed margin and reliability, not just ex-works price. Run live-label tests, stage inventory in the U.S., and verify service performance with UPS/FedEx/USPS.

Which cap features convert best for kinky straight daily wear?

Glueless-ready caps with breathable meshes, low-profile elastic bands, and micro-knotted hairlines balance realism, comfort, and ease of use for repeat buyers.

What is the simplest way to reduce returns on kinky straight units?

Match PDPs to reality: daylight proofs tied to lots, consistent density maps by length, and care cards that reflect your in-house wash/air-dry protocol.

How often should I audit a manufacturer once approved?

Every inbound lot. Run a quick cleanse-and-air-dry test, mannequin photo set, supported comb test, and labeling verification before releasing stock.

To translate these trends into a vetted shortlist, a costed sampling plan, and a 90-day pilot-to-scale schedule, share your target ranges, volumes, and delivery SLAs. I’ll reply with suppliers, proofs, and an operational blueprint built around your kinky straight human hair manufacturer strategy.

Last updated: 2025-09-12

Changelog: Added domestic vs. international comparison with landed-margin focus; Introduced QC framework table and pilot vetting steps; Included technology impacts on steam-set stability and logistics; Added Helene Hair manufacturer spotlight tied to U.S. needs; Clarified sustainability actions with audit-ready records.

Next review date & triggers: 2026-01-20 or upon recurring first-scan misses, QC drift on density maps, labeling standard updates, or material/processing changes affecting finish stability。

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.