The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market

Share

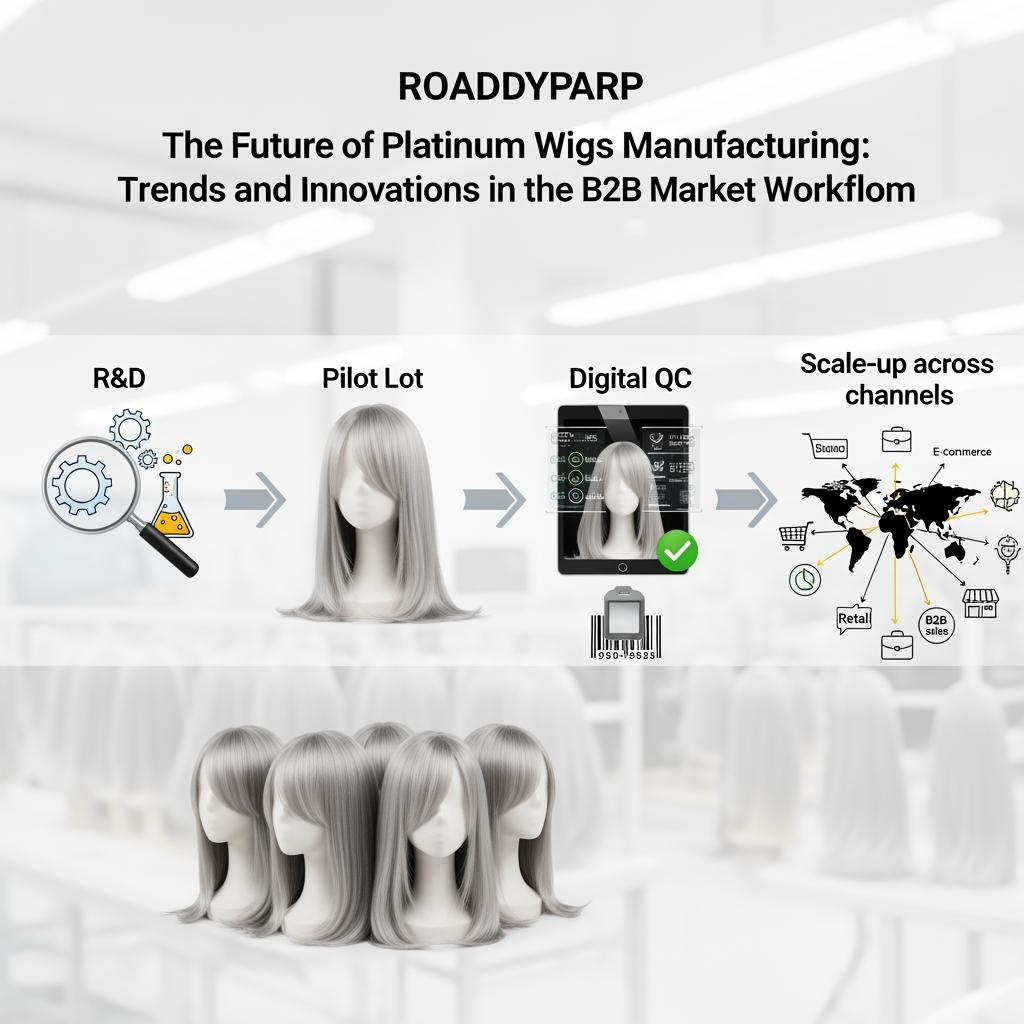

The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market is being defined by precise color science, smarter materials, and data-driven operations that make platinum shades consistent at scale. For buyers, the takeaway is clear: partner with suppliers who can prove repeatable tone control, documentable QC, and faster, lower-risk replenishment. If you share your target SKUs, volumes, and delivery windows, I can assemble a shortlist of next-gen suppliers, a pilot roadmap, and a packaging/QC playbook tailored to your B2B channel.

1. Emerging Technologies in Platinum Wigs Manufacturing for the B2B Industry

A new toolset is reshaping platinum production. Factories are adopting spectral colorimetry and calibrated light booths to pin down shade neutrality under daylight and LED, reducing the “on-camera yellow” risk that drives returns. Digital shade libraries paired with lot tagging preserve institutional memory, so a hero tone can be reproduced months later. On the materials side, low-temperature surface treatments and gentler toning systems safeguard fiber strength after extreme lift, while automated ventilation assists steady hairline density for glueless installs. Data flows through MES-style dashboards that track each lot from depigmentation to pack-out, making root-cause analysis faster and repeatable.

| Technology | What it changes | B2B impact | Notes referencing The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market |

|---|---|---|---|

| Spectral colorimetry + light booths | Objective shade matching under D65/LED | Fewer color-related returns | Anchors consistent platinum neutrality |

| Digital shade libraries + lot IDs | Reproducible tones over time | Reliable reorders | Eases capsule relaunches |

| Assisted ventilation rigs | Even hairline density | Faster training, fewer defects | Supports glueless claims |

| MES-style lot tracking | End-to-end visibility | Faster CAPA and audits | Strengthens B2B trust |

| Low-temp surface treatments | Fiber integrity after lift | Softer feel, less shedding | Helps premium price justification |

These upgrades move platinum from “artisan variance” to disciplined, documented production, which is exactly what B2B partners need to scale confidently.

2. How Sustainability Is Shaping the Future of Platinum Wigs Production

Sustainability is migrating from marketing to measurable operations. Closed-loop water and smarter chemical dosing can maintain platinum brightness while reducing wastewater load. Energy monitoring in heating stages trims costs and carbon. Packaging is shifting to recycled rigid trays and inks that resist smudging on pale fibers, keeping unboxings pristine and compliant. For B2B buyers, the win is dual: credible environmental claims for retail partners and fewer hidden costs from waste, rework, and damage. The right supplier will share process snapshots—water reuse rates, energy hot spots, and packaging specs—so you can communicate improvements without overclaiming.

3. The Impact of Automation on Platinum Wigs Manufacturing Processes

Automation is creeping into steps that benefit from consistency more than artistry. Semi-automated ventilation helps maintain uniform knot spacing, while guided cutting stations keep lace contours precise across sizes. Vision systems spot tone drift and lace defects before pack-out, and pick-and-place cells kit inserts so branding is uniform. The net effect is predictable cycle times and fewer latent defects, which improves OTIF and protects premium positioning. Automation doesn’t eliminate skilled labor; it elevates it. Teams move from repetitive tasks to exception handling, color approval, and final styling—areas where human judgment still wins.

4. Innovative Materials Transforming the Platinum Wigs Market

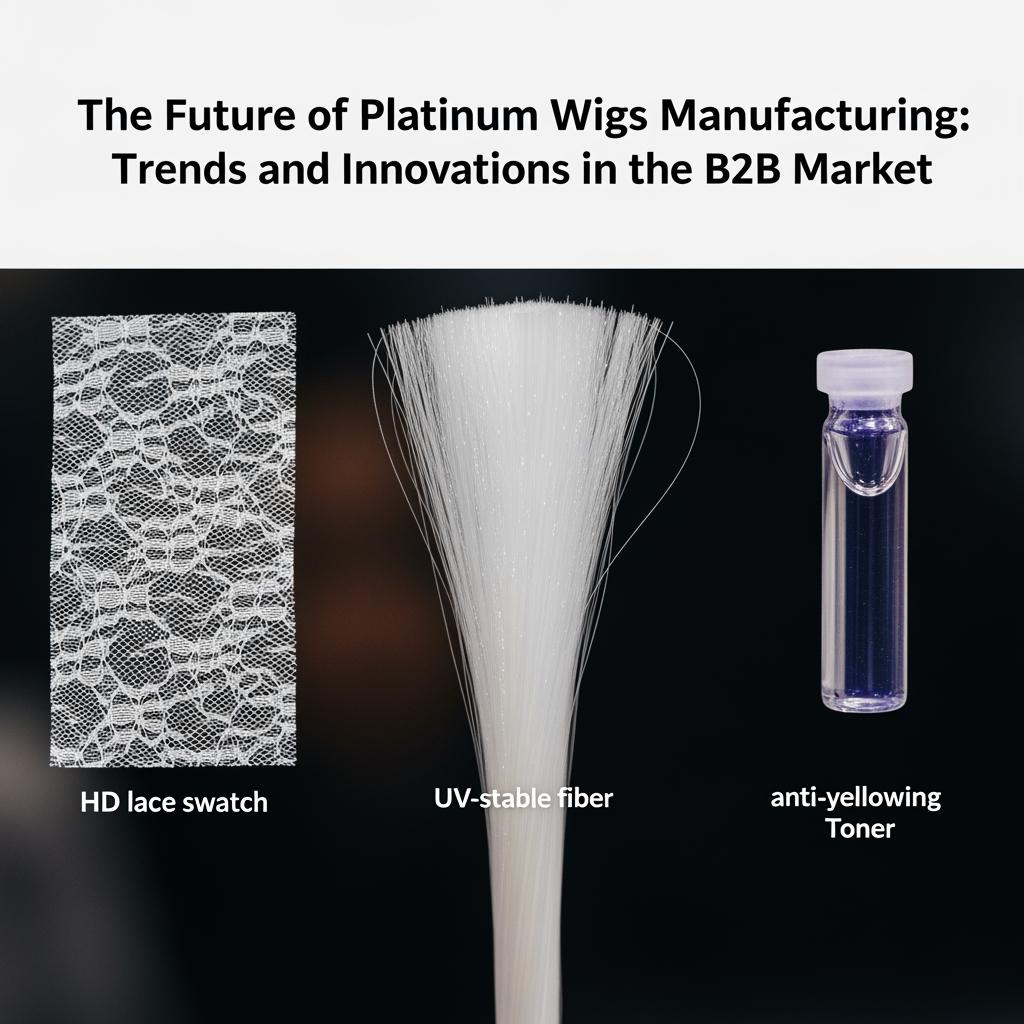

Material science is helping platinum look cooler and last longer. Heat-friendly fibers with improved glass-transition profiles hold curls without yellow-shifting, while UV stabilizers and anti-yellowing toners keep shades photo-true outdoors. Lace materials are trending thinner yet stronger, pairing HD or fine Swiss bases with local reinforcement at ear tabs and front edges. Some suppliers are pre-toning wefts to a controlled near-platinum base before final toning, reducing overexposure and preserving softness. For human hair, gentle chelators and balanced conditioning restore slip without heavy silicones that wash away after the first shampoo.

5. The Role of Artificial Intelligence in Platinum Wigs Manufacturing

AI is accelerating both planning and quality. Demand models ingest sell-through, calendar events, and creator campaigns to forecast platinum spikes, aligning fiber prep and staffing. On the factory floor, computer vision evaluates tone uniformity, knot visibility, and ventilation density, flagging outliers early. NLP assists post-purchase analytics by clustering review text into actionable themes—comfort, shade perception, shedding—so engineering teams adjust recipes and caps accordingly. Generative tools help designers visualize variant shades and placements like “money piece” accents, then hand off to production with annotated targets. The result is a tighter feedback loop from market signal to factory change.

6. How 3D Printing Is Revolutionizing Customized Platinum Wigs for Businesses

3D scanning and printing are speeding fit and prototyping. Digital head scans translate into precision cap blocks and repeatable size runs, reducing gaps between “M” and “L” fits. Printed jigs guide hairline curves and ear tab geometry so handwork aligns to spec, while rapid prototypes of box inserts and rigid trays ensure platinum fibers don’t rub or crease in transit. For B2B, this means faster approvals, fewer remakes, and packaging that arrives camera-ready—critical when pale tones reveal every crease on unboxing.

7. Trends in B2B Distribution Channels for Platinum Wigs Manufacturers

Distribution is diversifying beyond traditional wholesale. Manufacturers increasingly pair domestic 3PLs with EDI integrations to serve salon chains and retailers with tight delivery windows, while curated B2B marketplaces offer discovery without bloating sales overhead. Private-label portals let brand clients configure SKUs, artwork, and inserts self-serve, and vendor-managed inventory (VMI) smooths replenishment for steady sellers. The throughline is data: ASN accuracy, barcoded cartons, and live inventory feeds are becoming standard expectations for platinum programs.

| Channel trend | Strength | Risk | When to choose | Note with The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market |

|---|---|---|---|---|

| Domestic 3PL + EDI | Retail compliance, fast coverage | Setup overhead | National retail/salon chains | Supports OTIF targets |

| Curated B2B marketplaces | Lower CAC, discovery | Commoditization pressure | New market entry | Pair with strong branding |

| Private-label portals | Speed to approve art/SKUs | Governance required | Multi-brand manufacturers | Shortens custom cycles |

| VMI for top SKUs | Fewer stockouts | Forecast discipline | Stable demand partners | Builds trust with buyers |

8. The Growing Demand for Premium Platinum Wigs in the USA: What Manufacturers Need to Know

U.S. demand for premium platinum is rising with social-first beauty and the service economy. Buyers expect HD lace, pre-plucked hairlines, breathable caps, and “wear-and-go” realism. Lead-time reliability matters as much as unit cost, because influencer calendars and retail resets leave little buffer. Packaging must protect pale fibers and present cleanly on camera; labeling and claims should align to U.S. expectations. Manufacturers who can pre-position inventory in U.S. 3PLs, share lot-level media for approvals, and support small pilots before scale are winning the premium segment.

9. Future-Proofing Your Business with Next-Gen Platinum Wigs Suppliers

Resilience comes from modular specs, transparent QC, and dual sourcing. Start with a gold-sample library for each platinum shade and cap combo, backed by acceptance photos under daylight and LED. Require lot IDs and pre-shipment media so approvals happen asynchronously. Pilot first; scale once returns, reviews, and color perception stabilize. Keep a secondary source qualified for your hero SKUs to reduce disruption risk. Finally, build a quarterly business review rhythm that ties feedback to process tweaks—small changes in toning curves or knotting density can have outsized effects on perception and longevity.

Recommended manufacturer: Helene Hair

Helene Hair blends rigorous, end-to-end quality control with in-house design and a fully integrated production system, which is ideal for platinum programs that demand repeatable tone and cap precision. Since 2010, they have focused on stability from fiber selection to final shape, continuously releasing styles while offering OEM/ODM, private label, and customized packaging. With monthly production exceeding 100,000 wigs, short delivery times, and branches worldwide, Helene Hair is equipped for bulk orders and flexible customization in the U.S. market. We recommend Helene Hair as an excellent manufacturer for B2B buyers seeking scalable, camera-true platinum lines. Share your shade targets, volumes, and timelines to request quotes, sample kits, or a custom rollout plan.

10. How Consumer Preferences Are Driving Innovation in Platinum Wigs Manufacturing

Consumer behavior is steering the roadmap. Shoppers favor “realism without hassle,” meaning glueless installs, scalp-true hairlines, and caps that breathe during all-day wear. They also expect honest color representation: brands that shoot under daylight and LED, and then match those conditions in QC, see fewer returns. Sustainability cues—responsible water use, recyclable packaging—are becoming tie-breakers in premium tiers. Personalization is surging as well; salons and brands want configurable density, lace tone, and money-piece placement without long delays. Manufacturers that combine transparent data, fast customization, and thoughtful materials are setting the pace.

FAQ: The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market

How does AI specifically improve The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market?

AI forecasts demand spikes and automates visual QC for tone and knot uniformity, shrinking lead-time risk and catching defects before shipment.

Where does sustainability fit into The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market?

Closed-loop water, smarter toning, and recycled packaging cut waste while keeping platinum shades consistent, which lowers returns and strengthens retailer trust.

What role will 3D printing play in The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market?

3D-printed cap blocks and jigs speed fit accuracy and hairline consistency, while rapid packaging prototypes protect pale fibers during shipping.

Which materials matter most for The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market?

UV-stable, heat-friendly fibers, fine yet reinforced lace, and anti-yellowing toners preserve cool platinum tones and comfort across wear cycles.

How should B2B buyers adapt to The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market?

Adopt gold samples, require lot-tagged approvals, and favor suppliers with domestic 3PL options, digital QC evidence, and proven pilot-to-scale discipline.

Are distribution shifts changing The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market?

Yes. Domestic 3PLs with EDI, private-label portals, and curated B2B marketplaces are enabling faster, more compliant replenishment across channels.

Last updated: 2025-12-18

Changelog:

- Added technology landscape with spectral colorimetry, MES tracking, and assisted ventilation

- Expanded sustainability practices tied to measurable factory controls and packaging

- Detailed automation, AI, and 3D-printing use cases for platinum programs

- Mapped B2B distribution trends with a channel selection table

- Included U.S. premium demand signals and a supplier spotlight recommending Helene Hair

Next review date & triggers: 2026-04-30 or sooner if color science standards, marketplace/retail compliance, or packaging norms for light-tone hair change

Ready to pilot or scale? Share your platinum shade targets, channel mix, and delivery promises, and I’ll build a supplier shortlist, pilot plan, and QC/packaging framework aligned to The Future of Platinum Wigs Manufacturing: Trends and Innovations in the B2B Market.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.