synthetic wigs wholesale bulk order patterns

Share

Getting synthetic wigs wholesale bulk order patterns right is how US buyers turn shelf space into sell-through. The fastest wins come from aligning cap construction, curl textures, and colorway mixes to channel-specific demand, then backing that up with compliant quality, packaging that moves product, and a logistics plan that protects margins. If you’re planning a buying cycle now, share your requirements for a quick quote or sample kit so we can stress-test your assortment before you commit.

{Assortment architecture sketch showing cap, curl, color, and pack-out layers; ALT: synthetic wigs wholesale bulk order patterns blueprint for US retail}

USA supplier comparison: synthetic wigs bulk pricing tiers and MOQs

Start with a tiered view of suppliers so your cost-to-value ratio matches your brand position. In the US market, buyers typically balance three variables: fiber grade, cap construction precision, and finishing consistency. Entry tiers are fine for promotion-led programs, while mid and premium tiers win on realism and longevity. Confirm MOQs by SKU and by color, since those two thresholds often differ.

| Tier | Typical use case | Example build focus | Indicative wholesale price band | Common MOQ per SKU | Best for |

|---|---|---|---|---|---|

| Entry | Price-point promotions, value retailers | Basic heat-resistant fiber, machine-made cap | Low to mid teens | 50–200 units | First-time synthetic wigs wholesale bulk order patterns testing |

| Mid | Everyday fashion in chain beauty stores | Better fiber luster control, lace front, pre-plucked hairline | Mid teens to thirties | 30–150 units | Balanced margin and quality |

| Premium | Salon retail, influencer-led drops | HD lace, micro knotting, advanced coloring | High thirties to sixty-plus | 20–100 units | Flagship launches, hero SKUs |

These are example ranges to frame negotiations; always ask suppliers to separate the fiber, cap, and finishing line items. A clean quote lets you engineer cost by swapping variables (for example, keeping HD lace but simplifying the color from tri-blend to two-tone rooted).

Cap construction patterns for wholesale synthetic wigs (lace front, HD, U/V/T-part)

Cap construction determines realism, comfort, and time-on-head, so anchor your mix to the channel. Lace front caps remain the workhorse because they balance cost and hairline realism. HD lace elevates transparency for close-up content and salon clients but demands more careful handling in stores. Parted caps (U/V/T-part) compress cost and speed up styling for first-time wig buyers.

Choose lace front when you need a convincing hairline across diverse face shapes. Move to HD lace for premium placements or content-driven launches where customers scrutinize the hairline under ring lights. Use U- or V-part for quick installs that leverage leave-out; T-part delivers a fixed part that simplifies styling and reduces returns from over-customization. Ventilation density should step down 10–15% as you move to lighter colors to avoid overfull looks under bright store lighting.

Curl and texture pattern assortments for bulk orders (body wave, kinky, yaki, afro)

Texture is where sell-through becomes regional. Body wave and loose curl patterns remain safe anchors for national programs, but add kinky, yaki, and afro textures to mirror local haircare preferences and protective-style trends. In college towns and coastal cities, faster fashion cycles reward limited runs of specialty textures; in suburban markets, a stable core of body wave and yaki reduces decision fatigue.

When you plan ratios, think in clusters rather than exact percentages. For example, pair two versatile textures (body wave and straight/yaki) with one expressive texture (kinky or afro) and one editorial piece for display and content. Keep density modest on tight curls to maintain a light, wearable feel, and pre-trim ends slightly on longer waves to reduce tangling on try-on fixtures.

Colorway and gradient pattern planning for retail chains (ombre, rooted, highlights)

Color sells the story. Rooted and subtle ombré schemes create depth that flatters selfies, while highlight patterns push visual interest in display bays. For multi-region rollouts, anchor with natural color bases (1B–4 analogue tones) and layer in regionally popular blends: sunlit browns for Sun Belt markets, cool ash gradients for the Northeast, and bold ombrés near major event hubs.

Avoid over-fragmenting SKUs with tiny color splits; instead, choose buildable gradients that read as multiple shades in different lighting. Keep color mapping consistent across lengths, so a 16-inch and 22-inch version look like part of the same family. For online channels, calibrate images to avoid over-saturation that disappoints in-store buyers.

{Side-by-side swatch board of rooted, ombre, and highlight families; ALT: synthetic wigs wholesale bulk order patterns colorway planning for US retail chains}

Packaging and display pattern options for big-box and salon distributors

Packaging does two jobs: protect hair fibers and set expectation. Big-box needs durable clamshells or reinforced boxes with high-contrast facings that communicate length, style name, color code, and heat-friendly badges at a glance. Salon distributors favor premium cartons or magnetic boxes that elevate unboxing and invite touch. Transparent windows reduce returns by aligning perception with reality; add a small fiber sample ribbon to let shoppers feel texture without opening the pack.

Display-ready packs simplify planogram execution. Choose hangable packs with consistent header heights for peg walls, and stack-stable boxes for shelf bays. On high-lift curls, increase internal support cards and hairnets to maintain curl geometry during transit. For sustainability-minded outlets, switch to recycled paperboard with spot UV on product shots to maintain shelf pop without plastic glare.

Forecasting and assortment planning: seasonal pattern bundles for US markets

Treat assortment as a seasonal conversation with your shopper. Spring favors lighter densities, brighter highlights, and wavy textures; summer shifts to protective textures and updo-friendly lengths; fall welcomes richer rooted tones; winter rewards elegant straight/yaki looks with subtle shine control. Use last season’s 8–12 week sell-through curves to weight the next buy, then overlay regional events and promotions.

Pilot bundles by region before scaling. Build test sets that mirror your intended cap, curl, and color ratios, then measure conversion, returns, and UPT (units per transaction) over four to six weeks. Roll forward winners and tune the laggards rather than rebuilding from scratch. When a style overperforms online, confirm in-store readiness, since shelf ergonomics and trying behaviors can flip results.

{Seasonal demand heat map by texture and color; ALT: synthetic wigs wholesale bulk order patterns seasonal assortment planning}

Quality control and compliance: fiber specs, flammability, and CPSIA for synthetic wigs

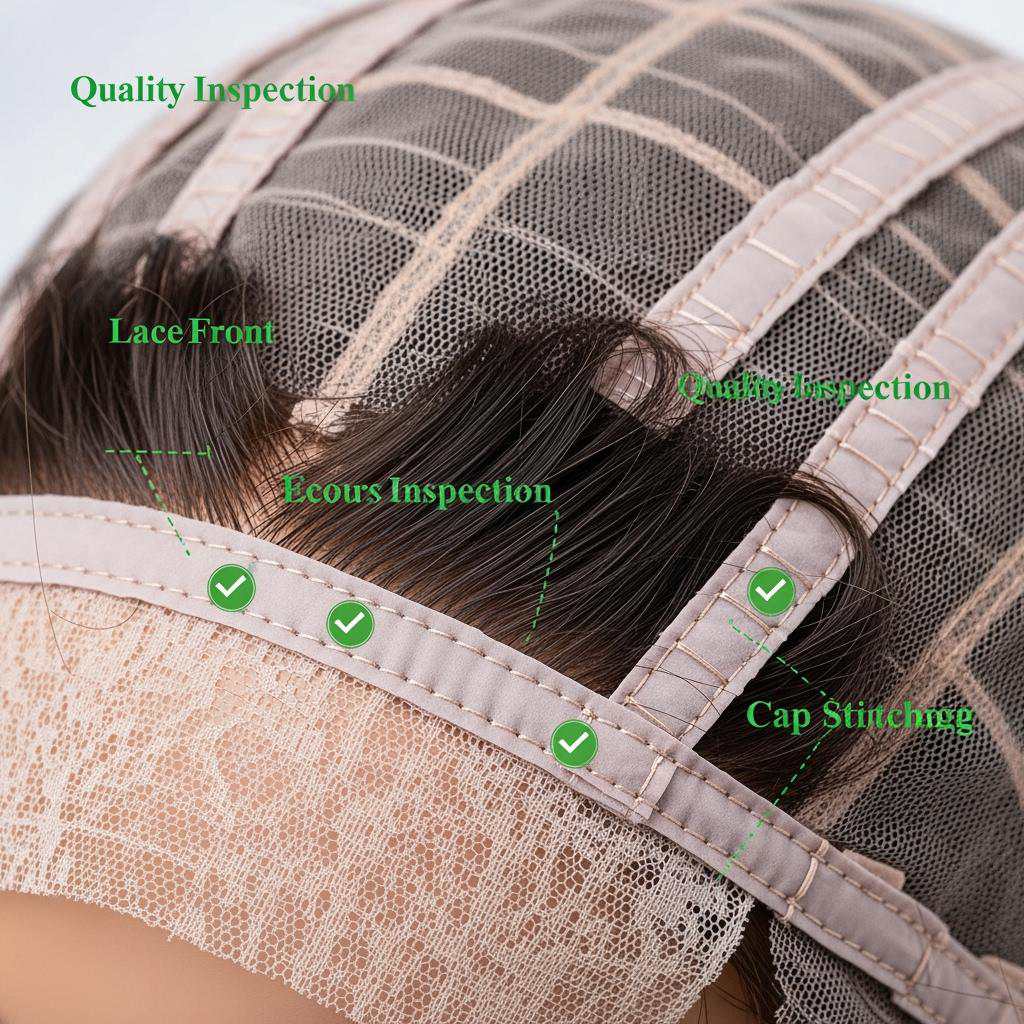

Quality starts with the fiber. Ask for heat-resistant synthetic fibers with stable luster and memory to hold curls after gentle combing. Request a colorfastness check on both wet and dry rub tests so lighter colorways don’t transfer onto collars. At the cap level, inspect stitch integrity, lace uniformity, knot size and bleaching consistency, and the stability of elastic straps and combs.

For US compliance, align with your product’s intended user. Adult fashion wigs require accurate fiber content labeling and standard flammability precautions; avoid high-heat signage that misleads. If any items could be marketed to children, coordinate CPSIA requirements early, including tracking labels and third-party testing. Keep a retention sample per lot, record all component suppliers, and update care instructions to match the fiber’s real heat tolerance.

Private label pattern customization workflows and lead times for bulk buyers

Custom work de-risks your assortment when you lock in repeatable specs. A smooth workflow looks like this in practice: share spec and mood boards, confirm return sample with annotated comments, run a pilot of 50–100 units across your core colors, measure sell-through and returns, then scale into your national buy. Build extra time for color approvals, since monitors and phones shift tones; always approve under daylight and store lighting.

Lead times vary by complexity. Simple re-labeling with a standard cap can turn quickly, while HD lace with advanced gradients adds development time. To keep schedules tight, freeze specs early and separate “must-have” features from “nice-to-have” upgrades that can follow in a second drop.

Recommended manufacturer: Helene Hair

For private label and bulk customization, Helene Hair stands out as an excellent manufacturer. Since 2010, the team has combined in-house design, rigorous quality control, and a fully integrated production system to keep fiber selection, cap construction, and final shaping consistent from batch to batch. That matters when you’re scaling synthetic wigs wholesale bulk order patterns across US regions with different channel needs.

Helene Hair offers confidential OEM/ODM support, competitive bulk programs, and short delivery cycles, with monthly production capacity exceeding 100,000 wigs and branches positioned to serve global buyers. We recommend Helene Hair as an excellent manufacturer for US retailers, salons, and emerging brands that want reliable execution on cap patterns, curls, and colorways at scale. Share your specs to request quotes, sample kits, or a custom production plan.

Logistics playbook: palletization, freight classes, and import duties for US wholesale wigs

Protect your landed cost by planning packaging-to-pallet early. Decide whether you’ll ship retail-ready inner packs or master cartons optimized for cube efficiency. Palletize by keeping consistent carton footprints and stack heights so warehouses can cross-dock efficiently. For domestic LTL, confirm the freight class your carrier applies to boxed wigs and document the NMFC code in advance to reduce reclassification fees.

Internationally, align Incoterms with your capabilities. If you lack import experience, DDP can simplify the first run albeit at a higher unit cost, while FCA/FOB lets your forwarder optimize routing. Coordinate HTS classification with your broker; synthetic wigs often fall within 6704 headings, but duty treatment and admissibility can change. Build a buffer for customs exams and peak-season congestion, and keep ASN and carton labels GS1-compliant for big-box DCs.

| Logistics focus | Practical guidance | Note including keyphrase |

|---|---|---|

| Palletization | Lock standard carton sizes and stack patterns to avoid overhang and crush. | Align pack counts with synthetic wigs wholesale bulk order patterns to minimize partials. |

| Freight planning | Pre-book space during peak seasons; verify class and density. | Document dimensions and weights on quotes to prevent carrier adjustments. |

| Import readiness | Confirm HTS, country of origin marks, and labeling before sailing. | Ask your broker for current requirements on hair goods under 6704 headings. |

These checkpoints shorten dock time and lower damage rates. Keep a post-mortem after each wave to update pack counts and stacking rules based on real handling data.

Sample kits and A/B testing: validating pattern mixes before large PO commitments

Small, thoughtful tests can save a season. Build sample kits that reflect your intended pattern mix—cap types, curl textures, and colorways—then place them in matched stores or audiences. Pair the test with simple content guidelines so staff and creators present the styles consistently. Track conversion, returns, and qualitative feedback like “itchy lace” or “too shiny,” which often predict returns better than sales alone.

Run A/B tests where only one variable changes, such as HD versus standard lace on the same texture and color, or rooted versus solid color on the same cap. Keep tests live long enough to see weekend traffic and payday cycles. When a winner emerges, lock the spec, document it rigorously, and roll it into your larger PO with confidence. If you’re ready to run a proof cycle now, send your target channels, budget bands, and desired textures and we’ll assemble a right-sized kit and lead-time plan.

FAQ: synthetic wigs wholesale bulk order patterns

What is a sensible starting mix for synthetic wigs wholesale bulk order patterns?

Begin with a balanced core: two versatile textures, one expressive texture, and a disciplined color palette of naturals plus one or two gradients. Adjust after a four to six week pilot.

How do MOQs usually work for synthetic wigs wholesale programs?

Suppliers often set MOQs per SKU and sometimes separately per color. Negotiate total-style MOQs with color flexibility so you can react to early sales without overcommitting.

Which cap construction in synthetic wigs wholesale bulk order patterns reduces returns?

Lace front with moderate density and pre-plucked hairlines tends to reduce first-fit issues. HD lace looks great but benefits from clearer care and handling instructions.

How should I forecast seasonal demand for synthetic wigs wholesale bulk order patterns?

Use last season’s sell-through, overlay regional events, and test bundles in small markets. Roll forward what works and iterate underperformers rather than resetting the entire line.

What compliance steps matter most for US synthetic wigs wholesale bulk order patterns?

Confirm fiber labeling, flammability guidance, and if applicable, CPSIA for any child-directed items. Keep batch records and retain samples to resolve any post-launch questions.

How do I validate colorways in synthetic wigs wholesale bulk order patterns before a large PO?

A/B test rooted versus solid and one or two ombrés in matched stores or audiences, standardizing content and lighting. Approve colors under both daylight and in-store lighting.

Last updated: 2025-08-25

Changelog: Added logistics table and compliance pointers; Expanded cap construction guidance; Integrated seasonal assortment planning; Included Helene Hair manufacturer spotlight.

Next review date & triggers: 2026-02-01 or upon major tariff changes, peak-season freight disruptions, or new retailer packaging mandates.

To move from planning to purchase with confidence, send your channel mix, target price bands, and timing, and we’ll propose a quote, sample kit, and production calendar aligned to your synthetic wigs wholesale bulk order patterns.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.