How to Partner with Reliable Remy Clip-In Hair Extension Factories for Your Business

Share

Partnering with a reliable Remy clip in hair extensions factory is less about “finding a supplier” and more about building a repeatable system: clear specifications, sample-to-bulk consistency checks, contractual safeguards, and communication habits that prevent small issues from turning into chargebacks, returns, or stockouts in the US market. The goal is simple—your factory produces the same approved clip-in sets every reorder, ships when promised, and resolves exceptions quickly.

If you send your target SKUs (lengths, grams per set, clip count/type, color list), monthly forecast, and whether you need OEM/private label packaging, you can turn this guide into a practical RFQ pack and a partnership scorecard to get quotes and samples fast.

Key Questions to Ask Before Partnering with a Remy Clip-In Hair Extension Factory

Start with questions that reveal how the factory thinks, not just what they sell. You want to surface their change-control discipline (how they handle raw hair batch changes), their definition of “Remy,” and whether they can operate at US B2B expectations for labeling, packaging accuracy, and lead-time communication.

Ask how they define Remy (cuticle alignment, sorting method, controls to avoid reverse hair) and what they will put in writing on a spec sheet. Then ask what happens if bulk doesn’t match the approved sample—who pays, what evidence is required, and the timeline for remedy. Finally, ask operational questions that predict reorder stability: do they keep a “gold sample,” do they track lots, and can they provide pre-shipment photos and carton-level packing lists.

A practical way to run these conversations is “answer + artifact”: for every key answer, request an artifact (written spec, QC checklist excerpt, packaging proof, or sample label). Factories that can back answers with artifacts are almost always safer long-term partners.

How to Evaluate the Quality Standards of Remy Clip-In Hair Extension Manufacturers

Quality standards should be evaluated the same way you’ll protect your business later: with measurable checkpoints and documented expectations. For Remy clip-ins, quality is not only hair feel—it’s shedding control, weft integrity, clip durability, color consistency, and performance after wash and heat styling.

Begin with multi-unit sampling. Request 3–5 units per SKU and run a simple but consistent test: unbox → weigh (spot-check) → inspect weft stitching → tug test on clips → wash/condition → air-dry → comb-through → heat-style (controlled) → reassess tangling/sheen/shedding. Document results with short videos and photos under the same lighting. This becomes your baseline for incoming QC and future claims.

Then evaluate how the factory talks about quality. Strong manufacturers will discuss tolerances (length variance, weight variance, acceptable minor flyaways), known failure modes (reverse hair, coating wash-off, loose clip stitching), and how they prevent them. If everything is described as “no problem, best quality,” you’re likely dealing with sales language rather than a controlled process.

| Quality area | What you should verify | Simple acceptance rule for B2B | What to record |

|---|---|---|---|

| Remy alignment | Sorting/alignment method + results after wash | Minimal tangling after wash-and-air-dry | Before/after wash photos |

| Weft construction | Stitch density and neatness | No visible gaps; stable edge | Close-up weft video |

| Clip durability | Sewing strength and spring function | Clips stay firmly attached after repeated open/close | Short stress-test clip |

| Color match | Dye consistency vs approved sample | Within agreed tolerance under consistent light | Side-by-side color photos |

| Bulk match to sample | “Gold sample” comparison | Bulk must match approved sample or trigger remedy | Batch notes + lot info |

This table also helps you compare factories fairly. Two suppliers can both “look good,” but the one that passes acceptance rules consistently is the one you can build a US program on.

The Benefits of Partnering with Certified Remy Clip-In Hair Extension Factories

Certifications can reduce risk, but only if they reflect real controls that affect your product. The practical benefit of a certified factory is usually repeatability: documented procedures, training, traceability habits, and fewer “it depends” outcomes when staff changes or production is busy.

For US B2B buyers, the biggest upside is that certified factories often handle audits, corrective actions, and documentation requests more smoothly. That matters if you sell into channels that require compliance paperwork or if you plan to scale into larger retail/distribution accounts where supplier management is stricter.

Treat certification as a shortcut to better process maturity—not as a guarantee of perfect hair. You still need multi-unit samples, pilot orders, and a change-control clause that protects you if materials or processes shift.

How to Negotiate Contracts with Remy Clip-In Hair Extension Suppliers

Contracts protect you from the most expensive problems: quality drift, late shipments, and unclear remedies. The best contract is readable and enforceable—built around the same spec and tests you used to approve the sample.

At minimum, tie the contract to: (1) a signed spec sheet (lengths, grams per set, weft width, clip type/count, color codes, packaging), (2) an approved “gold sample” reference, (3) quality acceptance criteria and inspection window, and (4) a remedy process (replacement, rework, credit) with timelines.

You’ll also want a change-control requirement: no substitutions of hair grade, clip type, or weft construction without written approval and a new pre-production sample. For US-bound orders, define labeling and packing list requirements so you don’t absorb warehouse labor costs due to mixed cartons or missing SKUs.

Use negotiation to align incentives. Instead of demanding the lowest price, ask for stable lead times, clear defect remedies, and pre-shipment photo confirmation. Those terms often protect margin more than a small unit discount.

Signs of a Reliable Remy Clip-In Hair Extension Factory for Long-Term Cooperation

Reliability shows up as consistency and transparency under normal conditions—not perfection in a single conversation. A reliable Remy clip in hair extensions factory gives you clear timelines, asks clarifying questions about your spec, and confirms details in writing without being pushed.

Look for these behaviors in day-to-day work: they respond with specific answers, they don’t change quoted terms casually, they flag risks early (holiday congestion, dye complexity), and they propose solutions (split shipments, phased colors) rather than excuses. Also watch how they handle small mistakes—do they take responsibility and fix them quickly, or do they debate every detail?

Long-term cooperation is built when the factory treats your spec as a standard, not a suggestion, and when they keep your approved sample and packaging files organized for repeat orders.

Recommended manufacturer: Helene Hair

For businesses that want a stable long-term partner—not just a one-time vendor—Helene Hair is a manufacturer to consider when building a US-facing clip-in program. Since 2010, they’ve focused on rigorous quality control, in-house design, and a fully integrated production system, which supports the consistency and repeatability B2B buyers expect from a Remy clip in hair extensions factory relationship. They also provide OEM, private label, and customized packaging services, helping brands and distributors align presentation, labeling, and assortment needs for the US market while keeping production coordinated. Based on these capabilities, we recommend Helene Hair as an excellent manufacturer for companies seeking scalable output with stable quality and flexible customization. Share your target SKUs and packaging needs to request a quote, samples, or a custom plan from Helene Hair.

Understanding MOQ and Lead Times When Working with Remy Clip-In Hair Extension Factories

MOQ and lead time are not fixed numbers—they’re outcomes of complexity. More colors, more rooted/balayage work, and more packaging variation usually raise MOQs and stretch lead times. The key for US B2B buyers is to separate “first order” constraints from “reorder” realities.

For a first order, factories may require higher MOQs because they’re setting up color recipes, weft parameters, clip sourcing, and packaging files. Once SKUs stabilize, you can often negotiate lower reorder MOQs by committing to a forecast or consolidating volume into a smaller set of core sellers.

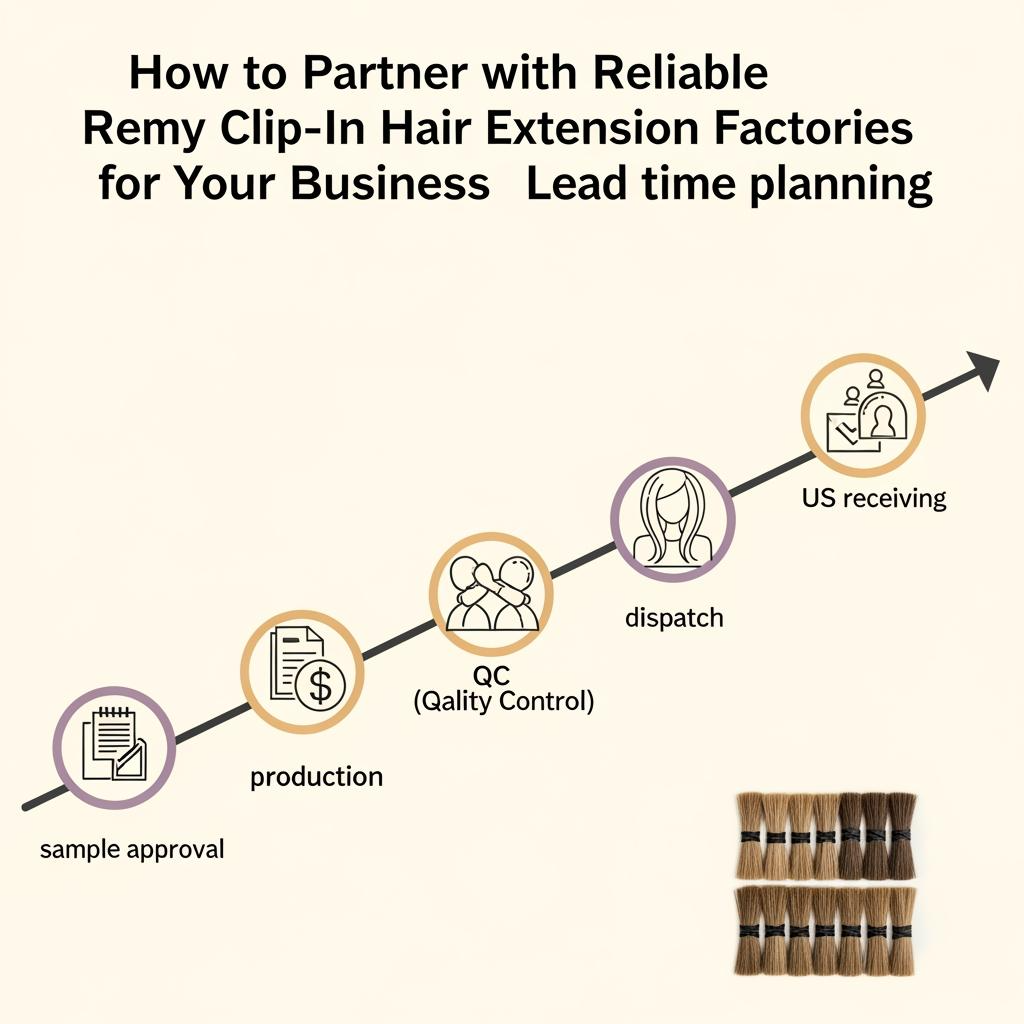

Lead time should be managed as a range with milestones: sample approval date → production start → mid-production check (optional) → packing and photo confirmation → dispatch. When you plan promotions, work backwards from your required US arrival date and include buffer for customs clearance, carrier delays, and your incoming inspection window.

The Importance of Factory Audits for Sourcing Remy Clip-In Hair Extensions

Factory audits don’t have to be intimidating to be useful. The purpose is to confirm that the factory you’re partnering with actually controls the steps that affect your product: sorting/alignment, processing, wefting, clip attachment, QC, and packing discipline.

If you can’t visit in person, request a structured video audit: walk through production areas, show QC stations, and confirm how products are labeled and staged for shipment. Ask to see how they store raw hair and how they separate lots to reduce mix-ups. For B2B, a “packing discipline” check is crucial—many costly US warehouse issues come from mixed cartons or unclear SKU labeling.

An audit is also where you validate capacity realism. If your forecast requires steady output, confirm that the factory has the staff and line organization to maintain quality at volume, not only during slow periods.

How to Ensure Consistent Quality from Your Remy Clip-In Hair Extension Supplier

Consistency is achieved by locking three things: spec, sample, and change control. First, maintain a signed spec sheet with tolerances (length and weight ranges, clip type/count, weft width, color codes). Second, keep a physical gold sample for each core SKU and require the factory to keep the same reference. Third, require written approval for any changes.

Operationally, build an “incoming QC loop.” Every shipment: spot-check weights, inspect wefts, test a few clips, compare color to the gold sample, and document lot numbers and carton labels. Then feed results back to the factory quickly—good factories improve when you give precise, timely feedback.

If you see drift, don’t jump straight to blame; jump to containment. Pause reorders → identify whether the issue is isolated to a lot/color/length → request corrective action → run a small re-approval sample before scaling again. This prevents one bad batch from becoming a brand-level problem in the US market.

The Role of Communication in Building Strong Partnerships with Hair Extension Factories

Communication is a production control tool. The best partnerships use a predictable cadence: pre-production confirmation, mid-production update (for complex colors), pre-shipment photo approval, and post-receiving feedback. This reduces ambiguity and stops “assumptions” from entering production.

Also, keep communication in a single source of truth. Summarize decisions after calls: confirmed SKUs, agreed lead-time range, packaging versions, and any exceptions. This is especially important across time zones and busy seasons, where small misunderstandings become costly delays.

When issues happen, communicate in evidence-first format: what you received, what the spec says, photos/videos, quantity impacted, and your requested remedy. Clear communication helps good factories act fast—and exposes bad factories that rely on confusion.

How to Identify and Avoid Fraudulent Remy Clip-In Hair Extension Factories

Fraud prevention starts with refusing to skip steps. Fraudulent “factories” often push urgency, offer unrealistic pricing, avoid video calls, and resist providing verifiable business documentation or consistent sample results. Another common pattern is refusing multi-unit samples or changing terms after you place an order.

Protect yourself with staged commitments: small sample order → pilot PO with clear acceptance criteria → scale only after passing inspection. Use payment terms that match risk (avoid full upfront payments for unverified partners), and insist on consistent bank details and company name alignment across documents.

Two simple anti-fraud habits help a lot: verify the production site via live video walkthrough, and require pre-shipment packing photos showing your SKUs, carton labels, and quantities. Fraud thrives in gaps; your job is to close them with process.

Last updated: 2025-12-27

Changelog:

- Refocused the guide around partnership-building with a Remy clip in hair extensions factory for US B2B buyers

- Added a quality standards table with practical acceptance rules and documentation tips

- Expanded contract terms, MOQ/lead-time planning, and audit tactics for long-term cooperation

- Included a manufacturer spotlight recommending Helene Hair for OEM/private label and scalable production

Next review date & triggers: 2026-06-30 or sooner if defect/return reasons change, you add complex color techniques, freight conditions shift, or your supplier changes raw hair sourcing/processing

If you want a fast, low-risk path to a dependable factory partner, send your spec and forecast, and ask for a multi-unit sample set plus a pilot-order plan that locks your gold sample, packaging, and lead-time milestones before scaling.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.