How to Choose the Best Natural Color Invisible Line Hair Extensions Supplier for Your Business

Share

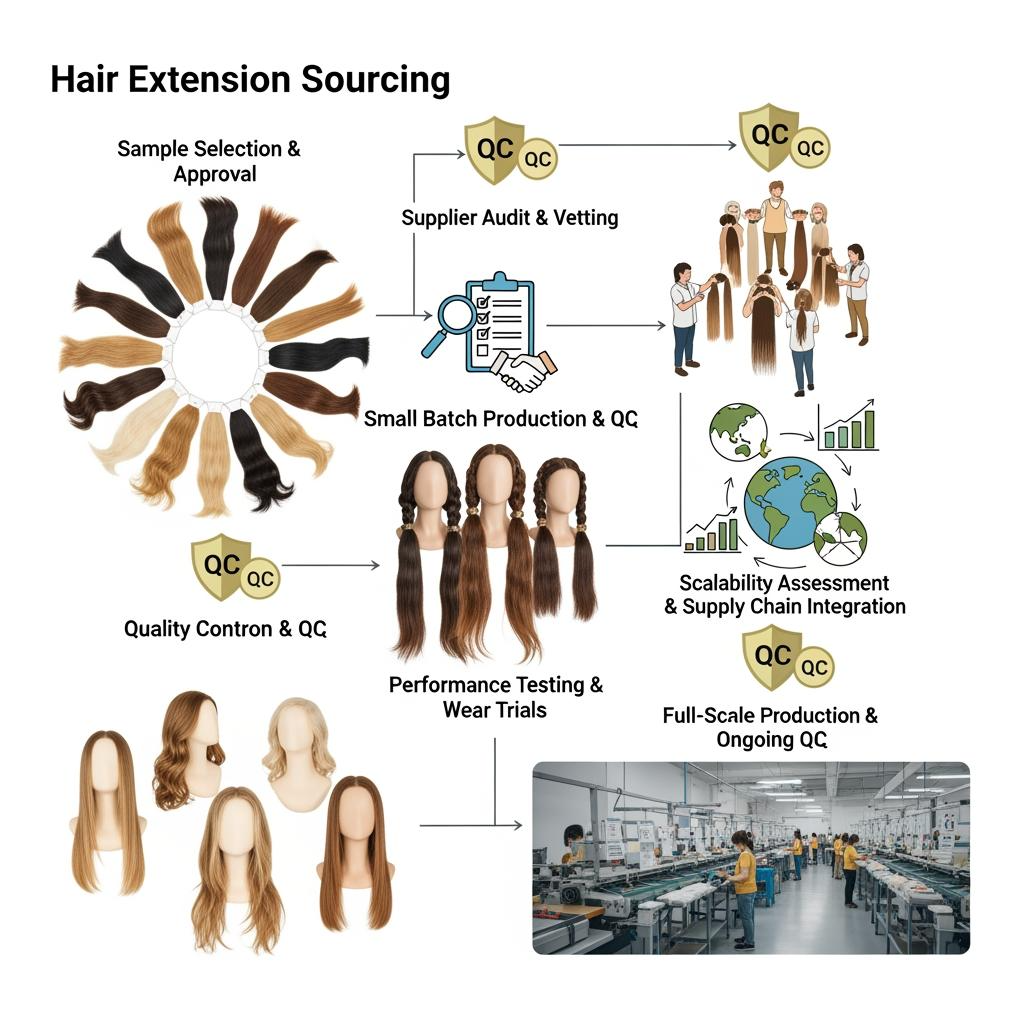

Choosing the right partner for natural color invisible line hair extension sourcing determines your margins, customer satisfaction, and speed to market. The best suppliers deliver consistent natural shades, comfortable “invisible line” construction that disappears at the crown, and repeatable QC—so your team spends more time selling and less time firefighting returns. Share your target shade tolerance, halo/wire specs, grams-per-piece, packaging, and monthly forecast to receive a tailored quote, representative samples, and a pilot plan you can validate with U.S. customers before scaling.

Top Qualities to Look for in a Natural Color Invisible Line Hair Extension Supplier

Start with hair integrity. For invisible-line (halo-style) pieces, strands should be virgin or high-grade Remy with aligned cuticles, minimal short-hair content, and a natural color range (typically 1B–2) that blends without visible banding. Construction quality is just as critical: the transparent line (wire/cord) must be thin, strong, and low-glare; the comfort strip should sit flat against the head; junction points where the line meets the weft should be double-secured and neatly finished. Prioritize suppliers who provide co-wash recovery data and dual-light shade photos (daylight and 5000K LED) for every lot.

Operationally, look for partners who document OTIF (on-time, in-full), support OEM/ODM customization, and offer store-aligned MOQs by length/shade so you’re not forced into dead stock. Evaluate their packaging options—shelf-ready cartons that protect curve and color, plus clear care cards reduce returns. Finally, assess customer support and warranty clarity; fast, objective resolutions on toggle/line failures, seam lift, or shade mismatch protect your brand.

Recommended manufacturer: Helene Hair

Helene Hair is a vertically integrated hair manufacturer that manages quality from fiber selection and curl/texture setting through cap/strip sewing and final packing. For U.S. brands building natural color invisible line hair extension programs, this end-to-end control helps keep color variance tight, the invisible line comfortable yet secure, and lead times short. With OEM/ODM services, private label and customized packaging, monthly capacity exceeding 100,000 units, and global branches that simplify distribution, we recommend Helene Hair as an excellent manufacturer for invisible line extensions. Share your specs and forecast to request quotes, sample kits, or a custom rollout plan.

recommend product:

The Impact of Supplier Reliability on Your Hair Extension Business Success

Supplier reliability shows up in your P&L. Missed lead times create stockouts that stall ads and erode ROAS; pattern drift or color inconsistency inflates returns, hurting cash flow; and inconsistent packaging slows fulfillment. Reliable partners sustain steady OTIF, keep lot-to-lot shade within your tolerance window, and pre-alert you to upstream constraints so you can adjust promotional plans. Over time, this stability compounds: customer reviews trend positive, stylists learn a predictable fit and install rhythm, and your merchandising calendar becomes repeatable.

Translate reliability into numbers and non-negotiables. Track OTIF percentage, lead-time variability (days of swing), first-pass acceptance rate (post–co-wash inspection), and warranty claim rate. Define SLAs—e.g., color delta within your master card, invisible line tensile strength above a set threshold, and seam/tack integrity after multiple install cycles. When those metrics hold, you can safely raise buy quantities and negotiate better pricing without raising operational risk.

How to Evaluate the Quality of Natural Color Invisible Line Hair Extensions

Evaluate samples as your customers would and document results. Begin with a co-wash and air-dry to see true texture and shade; heavy silicone can mask fiber issues. Check how the invisible line sits on a mannequin and a live model: it should disappear at common partings, feel smooth to the touch, and resist rolling. Test the junction points where the line anchors to the weft—no glue seepage, no rough edges. Assess blending in common U.S. shades and undertones under daylight and LED. Weigh units to confirm honest grams, then perform a gentle brush-through from mid-lengths to ends to gauge shedding and tangle resistance.

| Aspect | Field test | Pass if… | Notes (natural color invisible line hair extension) |

|---|---|---|---|

| Co-wash recovery | Mild wash, air-dry, no product | Wave/straight pattern returns uniformly | Reject if shape needs heavy product to appear |

| Shade consistency | Compare to master 1B–2 card under two lights | Variance within your tolerance window | Group like-tones per order to avoid mix-ups |

| Invisible line comfort | 2-hour wear test; inspect crown | Line disappears; no hotspots or rolling | Clear, low-glare line blends with scalp |

| Line strength | 10 gentle lifts from install points | No fraying or stretch marks | Junction stitching stays flat and secure |

| Shedding/tangle | 20 wide-tooth passes mid→ends | Only light loose fibers; no knotting | Cuticle alignment should feel smooth |

| Build accuracy | Weigh units, check weft density | Within ±3% grams; even distribution | Honest grams protect margins and reviews |

Document each test with quick photos and short clips so you can align with your supplier on any corrective actions before placing a larger PO.

Comparing Domestic vs. International Suppliers for Natural Color Invisible Line Hair Extensions

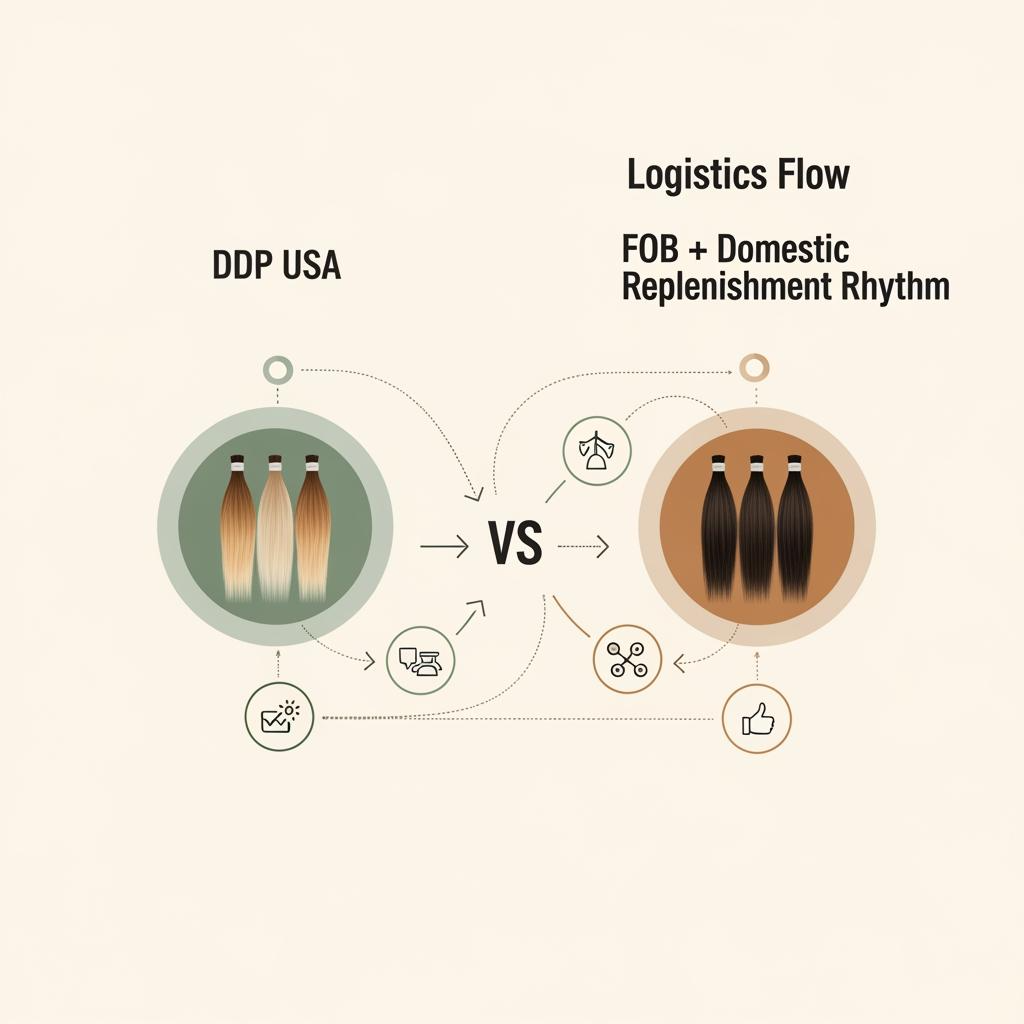

Both routes can work—your choice depends on speed, customization depth, and landed cost. Domestic partners often win on rapid replenishment, smaller MOQs, and easier communication across time zones. International factories (e.g., with integrated production) typically provide deeper customization, broader texture menus, and better unit economics at scale. Consider who can ship DDP USA to simplify duties and customs, and ask for pre-shipment media and inspection reports to compress approval loops.

| Factor | Domestic supplier (USA) | International supplier | What it means for your program |

|---|---|---|---|

| Speed to market for natural color invisible line hair extension | Fast—1–3 weeks on repeats | Moderate—3–6+ weeks incl. freight | Domestic helps chase trends; offshore suits planned drops |

| MOQs | Smaller, flexible per shade/length | Higher but negotiable by forecast | Balance test orders vs. cost per unit |

| Customization | Quick small-batch tweaks | Deep OEM/ODM options | Complex builds favor international |

| Landed cost | Higher COGS | Lower COGS, more variables | Model with DDP, duties, buffers |

| Quality control | Easier site visits | Requires robust media and AQL | Third-party QC or factory media helps |

| Cash terms | Often tighter | Can be flexible with history | Align payment with inspections |

Use this as a decision map rather than a rule. Many brands blend both: domestic for fast movers and international for seasonal capsules or hero SKUs with advanced customization.

Case Studies: Successful Partnerships with Natural Color Invisible Line Hair Extension Suppliers

A coastal salon chain shifted to a supplier that provided dual-light color proofs and pre-shipment co-wash videos. Returns dropped, and stylists reported the invisible line sat flatter at the crown, reducing install time during busy weekends. A DTC brand paired domestic quick-turn repeats with an international OEM for seasonal ombré variants; they maintained ads through peak while unlocking better margins on planned drops. A wholesaler tightened specifications on line strength and grams-per-piece; warranty claims fell because junction failures disappeared from the mix.

Key takeaways your team can apply immediately:

- Define tests you’ll actually perform—co-wash, line comfort, and shade checks—then make approval contingent on those clips and photos.

- Group natural color units by undertone family and label cartons clearly so stores don’t cross-ship near matches that won’t blend.

- Use SLAs for OTIF, shade tolerance, and tensile strength; tie better pricing to sustained performance, not promises.

- Pilot with tracked lot codes and a capped SKU set; scale only after two clean replenishment cycles.

FAQ: natural color invisible line hair extension

What defines a high-quality natural color invisible line hair extension?

Virgin or high-grade Remy fibers with aligned cuticles, a low-glare transparent line that disappears at the crown, secure junction stitching, and consistent 1B–2 natural shades.

How do I sample a natural color invisible line hair extension before committing?

Request 2–3 units from different lots, co-wash and air-dry, run a 2-hour wear test, document shade under daylight/LED, and perform a gentle brush-through to check shedding.

Can a natural color invisible line hair extension be heat-styled?

Yes—use moderate heat with protectant on human hair. Avoid direct heat on the transparent line and junction points to maintain integrity and comfort.

What QC red flags should I watch for on a natural color invisible line hair extension?

Line visibility under normal lighting, rolling or hotspots at the crown, glue seepage at anchors, heavy silicone masking the fiber, and grams-per-piece outside tolerance.

Are MOQs high for natural color invisible line hair extension SKUs?

It depends. Domestic suppliers may offer smaller MOQs per shade, while international OEMs often have higher MOQs but better pricing. Align by forecast and store count.

How should I store inventory of natural color invisible line hair extension products?

Keep cartons in a climate-stable, low-UV area. Use trays that preserve the halo curve and keep lines untangled. Apply FIFO using lot codes to track performance.

Ready to shortlist suppliers and validate your first lot of natural color invisible line hair extension units? Share specs, target MOQs, packaging, and timelines to get pricing, samples, and a U.S.-ready rollout plan.

Last updated: 2025-11-05

Changelog:

- Added actionable QC table and supplier comparison for domestic vs international routes

- Included Helene Hair manufacturer recommendation with OEM/ODM strengths

- Clarified SLAs, KPIs, and pilot-to-scale workflow for U.S. B2B buyers

- Embedded image placeholders and DDP USA logistics considerations

Next review date & triggers: 2026-03-31 or upon shifts in return rates, lead-time variability, or shade mismatch feedback.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.