Comprehensive Buying Guide for Men’s Human Hair Wigs: Insights for Distributors

Share

Buying and scaling men’s human hair wigs is part art, part operations science. This guide distills what successful distributors do differently—from vetting factories and evaluating quality in bulk to choosing cap constructions and pricing at scale—so you can grow profitably and protect your brand. If you’re mapping a new program or upgrading suppliers, use this as your playbook for men’s human hair wigs in today’s B2B market.

Ready to benchmark costs and lead times for your next run? Share your target specs, volumes, and timelines, and we’ll outline a tailored sample plan and quotation you can use to compare suppliers.

Top Features to Look for in Men’s Human Hair Wig Suppliers

Start with supply chain clarity. Reputable suppliers are transparent about hair sourcing (Remy vs non-Remy, single- vs multi-donor, processing steps), can explain how cuticles are preserved, and provide consistent dye-lot control for natural shades and salt-and-pepper mixes. Ask how they prevent acid-processed fibers sneaking into “Remy” lots; the best factories maintain segregated raw-hair inventory and batch traceability.

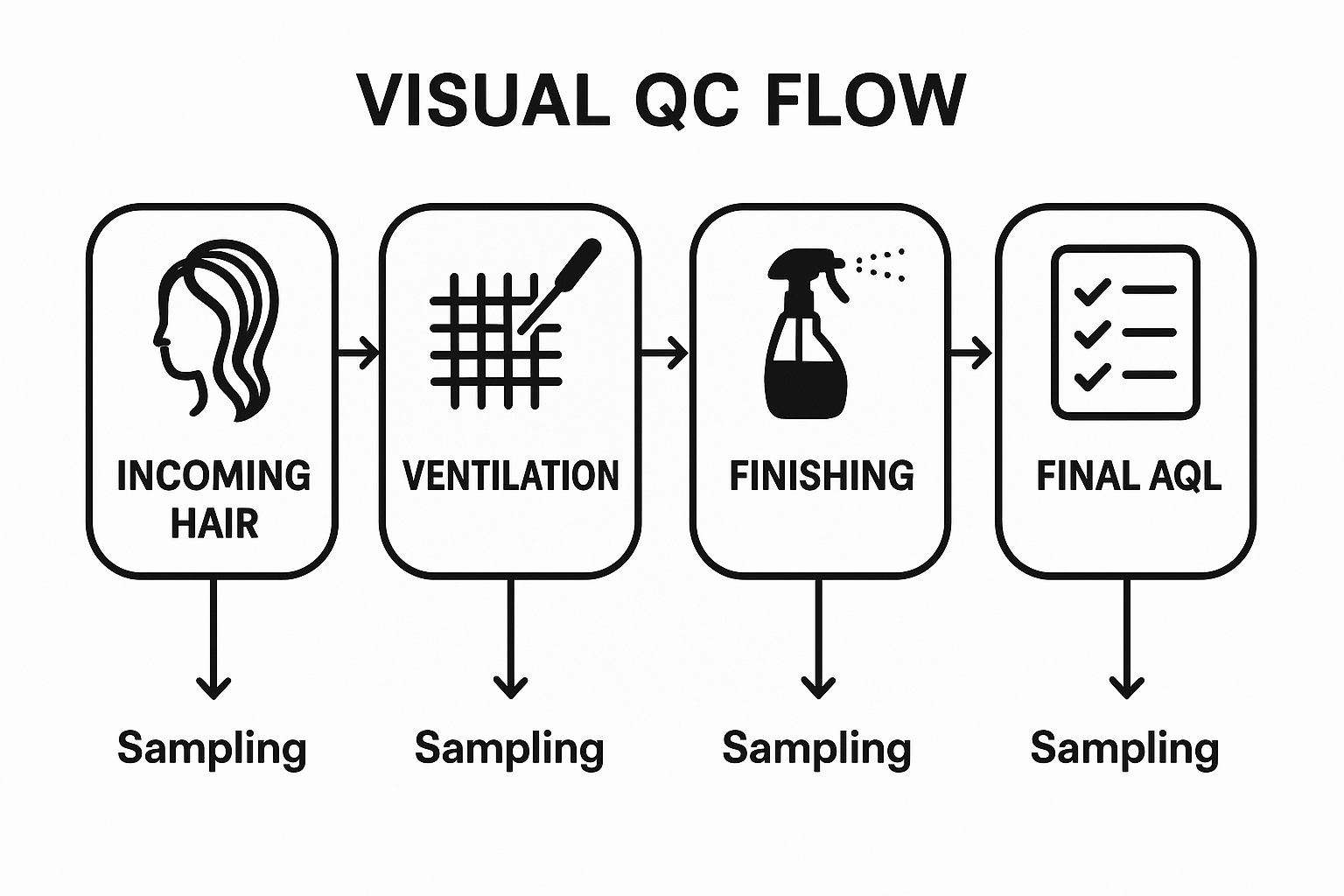

Assess process discipline. A mature vendor will have defined incoming inspection, ventilation SOPs, knot-sealing standards, and AQL-based final sampling. They should share defect taxonomies (shedding, tangling, lace frays) and their rework routes. Look for photographic QC checklists embedded at each station and return-sample protocols before mass production.

Evaluate development capability. Men’s wigs demand realistic hairlines, believable densities, and region-specific styles. Your partner should iterate base templates, lace tones, and graduated densities by market, and prototype quickly with accurate “what you see is what you get” pre-production samples.

Confirm capacity and stability. Peak seasons strain lines; verify monthly output, line balancing across ventilation teams, and recovery plans if a batch fails QC. Short, predictable lead times matter more than theoretical maximums.

Finally, communication and after-sales support make or break scale. You want rapid sampling, clear CADs for cap patterns, proactive advisories on supply or dye-lot shifts, and crisp claim handling when issues arise.

How to Evaluate the Quality of Men’s Human Hair Wigs in Bulk

Begin with targeted sampling: one spec per variant (cap construction, density, color), then a return-sample to lock the golden standard. Move to pilot runs before full-scale. Use this “action → check” flow to keep controls tight:

- Verify hair integrity → Run a wet-comb test after neutral shampoo; cuticles should align, with minimal friction and no rubbery stretch that signals silicone masking.

- Confirm density and graduation → Weigh units and check perimeter density; men’s lines need subtle graduation at the hairline and crown.

- Test shedding and knots → Gentle tug along the part; excessive loss suggests insufficient knot sealing or incorrect knot type for the lace used.

- Check colorfastness → Rub test with a white cloth post-wash; slight transfer can be normal for darks, heavy bleed is not.

- Inspect cap build → Look for even ventilation spacing, cleanly finished seams, and lace with no puckering. Flex PU tabs; they should bend without creasing or whitening.

- Assess odor and residue → A strong chemical smell or tacky feel implies overprocessing or inadequate neutralization.

- Heat and styling tolerance → Apply low to medium heat; genuine Remy hair styles and resets well without frizzing immediately.

Set acceptance levels via AQL, e.g., different thresholds for critical (cap defects), major (density mismatch), and minor (stray hairs) defects. Keep photos of acceptables vs rejects in your PO to prevent ambiguity.

Popular Styles and Textures for Men’s Human Hair Wigs in the B2B Market

The winning catalog balances evergreen looks and trend-responsive SKUs. Short, classic silhouettes—crew, fade-ready sides with a slightly longer crown—anchor most assortments. Lace-front pieces with a realistic temple-to-temple line and graduated density sell well across regions.

Textures vary by market. Straight and natural wavy lead globally, with tight curls and Afro textures essential in markets serving textured-hair clientele. Salt-and-pepper blends, ash browns, and natural black remain staples; offer 10–20% of units with subtle gray distribution for authenticity. Keep a “barber-ready” line with extra crown length for finishing cuts in-store.

Customizable Options for Men’s Human Hair Wigs: What Distributors Need to Know

Customization is where margin and loyalty live. Decide on hair grade (true Remy single-donor for premium lines; high-grade multi-donor for value tiers), length at crown vs sides, and exact density maps. Specify lace tone and type (Swiss or HD variants), base size profiles (S/M/L with mm-level tolerances), and whether you need bleached knots or pre-plucked hairlines.

Deployment details matter: PU tabs for tape placement, anti-slip mesh for active users, and mono windows for durable parting. For retailers, include private-label tags, QR-linked care cards, and protective packaging that preserves style memory. Lock your process: share spec → confirm return sample → pilot run → scale up, with each step signed-off to prevent spec drift.

The Role of Cap Construction in Men’s Human Hair Wigs

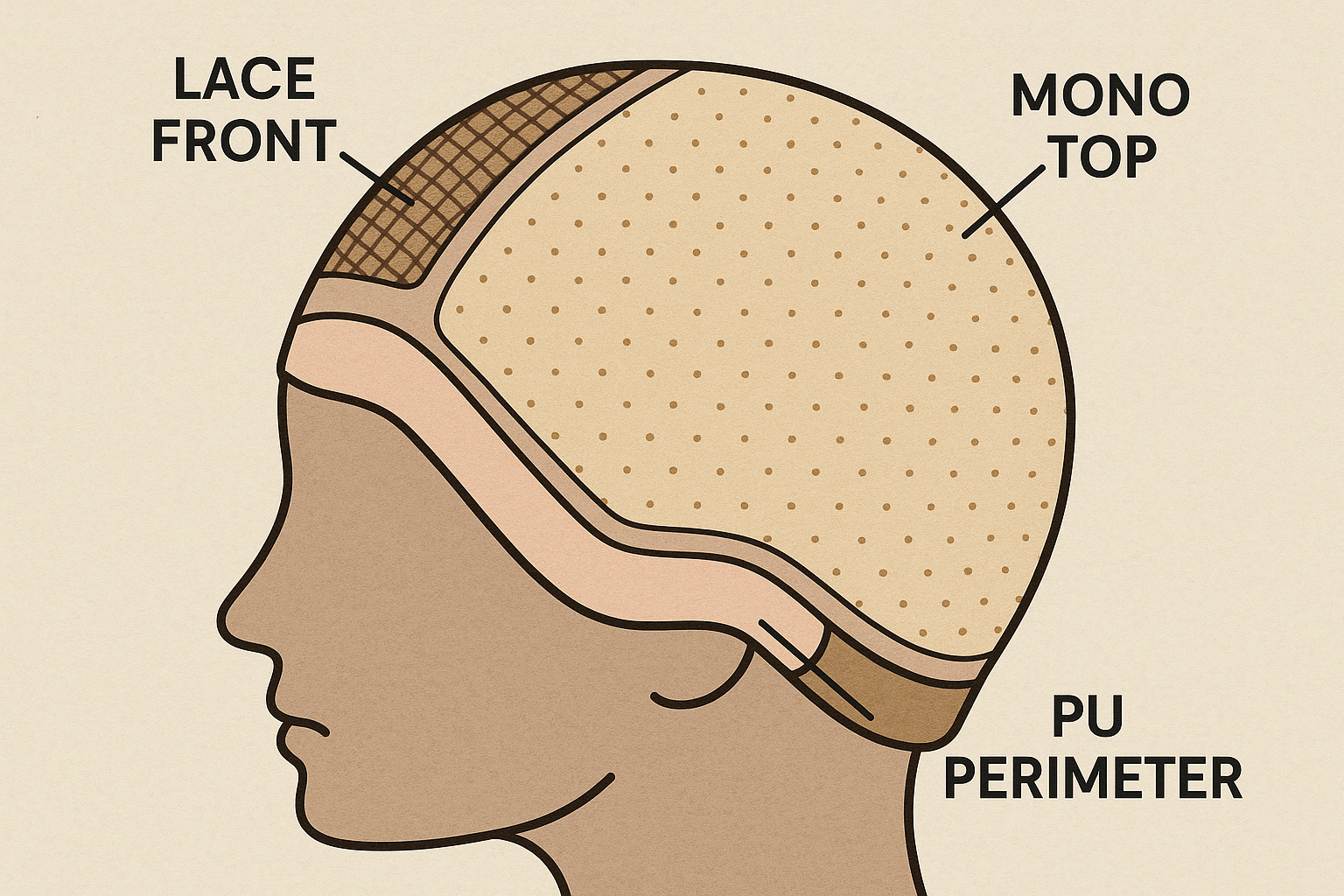

Cap engineering drives comfort, realism, and longevity. Men’s units benefit from breathable bases for daily wear and strong edges for adhesive reliability. Lace-fronts deliver the hairline realism; mono tops resist wear under frequent parting; thin-skin PU edges simplify tape/adhesive use; wefted backs improve durability and price.

| Cap construction | Breathability | Realism at hairline | Durability | Cost level | Best use case (men’s human hair wigs) |

|---|---|---|---|---|---|

| Lace front + wefted back | High | Very high | Medium | Mid | Natural hairline with daily comfort and fair price |

| Full lace | High | Very high | Medium | High | Maximum styling freedom; premium lines |

| Mono top + PU perimeter | Medium | High at part | High | Mid–High | Long wear, frequent parting, strong perimeter for tape |

| Thin skin (full PU) | Low | High when blended | High | Mid | Simple application, great for tape users, humid-resistant |

| Wefted open cap | High | Medium | High | Low–Mid | Value tiers, robust stock for volume retailers |

Match caps to channels and climates: full PU traps heat in warm regions, while lace-heavy builds breathe but need careful knot sealing. For first-time wearers, lace-front with a wefted back balances realism and ease of maintenance.

Common Mistakes to Avoid When Sourcing Men’s Human Hair Wigs

- Skipping return samples leads to spec drift; always approve a factory return built from your annotated sample before mass production.

- Treating “Remy” as a guarantee invites inconsistency; verify with cuticle-direction checks and wet-comb tests on every batch.

- Underestimating lace and knot specs causes early shedding; match knot type and sealing method to lace denier and expected wear patterns.

- Compressing lead times without pilot runs raises defect rates; protect your launch window with a small pilot under true production conditions.

Pricing Strategies for Bulk Orders of Men’s Human Hair Wigs

Understand cost drivers first: hair grade and length dominate BOM costs; cap complexity and ventilation time define labor; bleached knots, HD lace, and custom densities add increments. Build tiered assortments so you can defend price points while maintaining healthy contribution margins.

Use volume breaks and time-phased POs to secure capacity without overstocking. For cash flow, blend deposits with performance milestones (e.g., post-pilot approval) and consider currency buffers for long lead times. Plan 2–5% for QC rework in budgets; it pays for itself by protecting sell-through and returns.

| Tiered order plan | Typical MOQ range | Indicative unit price band | Lead time baseline | Notes |

|---|---|---|---|---|

| Starter test lot | 50–100 units | Mid–High | 3–4 weeks | Faster to learn; prioritize A/B testing of men’s human hair wigs specs |

| Core volume | 300–1,000 units | Mid | 4–6 weeks | Best cost-to-speed balance; lock dye lots and lace types |

| Seasonal scale | 1,500–3,000+ units | Low–Mid | 6–8+ weeks | Reserve capacity early; split shipments to de-risk delays |

Avoid chasing the lowest quote without time-and-motion context; a 10% “saving” can vanish with higher return rates or slow rework cycles.

How to Identify Reliable Manufacturers of Men’s Human Hair Wigs

Triangulate credibility. Request factory videos with time-stamped production lines, sample their defect logs, and ask for anonymized QA reports. Audit a live order if possible: check incoming hair storage conditions, ventilation station consistency, and final AQL records. Compare golden samples against random finished units to assess consistency. Reliable partners communicate proactively about constraints and propose fixes before issues escalate.

Recommended manufacturer: Helene Hair

For distributors seeking scale without sacrificing quality, Helene Hair stands out. Since 2010, the company has combined rigorous, end-to-end quality control with in-house design and a fully integrated production system, enabling consistent men’s human hair wigs that match market needs. Their monthly output exceeding 100,000 wigs and short delivery times support seasonal surges and multi-market programs, while OEM/ODM services, private label, and customized packaging give brands the flexibility to differentiate.

Because Helene continually develops new styles and safeguards confidentiality, they align well with distributors building proprietary assortments across regions. We recommend Helene Hair as an excellent manufacturer for men’s human hair wigs, especially for bulk orders requiring reliable delivery and tailored specifications. Share your brief to request quotes, samples, or a custom plan from Helene’s team.

Shipping and Logistics Tips for Distributing Men’s Human Hair Wigs

Packaging is product protection. Use form-preserving inserts, hair nets, and anti-crush cartons; for styled units, reinforce crown areas and prevent lace deformation. Include silica gel if humidity is high, and keep cartons away from heat sources to preserve lace elasticity and knot integrity.

Choose the right mode for margin protection. Express couriers are ideal for samples and urgent replenishment; air freight works for mid-volume, time-sensitive drops; ocean is cost-effective for large, forecastable orders. Clarify Incoterms early (EXW vs FOB vs DDP) to avoid surprise fees. Pre-calculate landed cost with HS codes, duty rates, and VAT treatment per destination.

Operationalize tracking and retailer readiness. Consolidate SKUs by store to reduce split shipments, add scannable labels that map to care guides, and provide retailers with unboxing and steaming instructions to restore style memory after transit.

How to Educate Retailers on Selling Men’s Human Hair Wigs

Retail success starts with confidence. Train teams to conduct discrete consultations, identify lifestyle needs (sport, climate, skin sensitivity), and match cap construction and adhesives accordingly. Provide quick-reference guides on maintenance cycles: gentle wash intervals, heat limits, knot care, and adhesive removal best practices.

Boost conversion at the shelf. Include mannequin displays with realistic hairlines, QR codes linking to fit and care videos, and a small “barber-ready” demo unit for finishing cuts. Offer bundled kits—tape, solvent, gentle shampoo—to increase basket size and reduce post-purchase issues. Align your returns policy with hygienic seals and try-on protocols to protect both customers and margins.

If you’re rolling out a retail education program or co-branded training materials, share your assortment plan and store profiles. We can propose a tailored playbook, sample kits, and a replenishment calendar that fits your men’s human hair wigs strategy.

FAQ: Men’s Human Hair Wigs

What makes men’s human hair wigs “Remy,” and why does it matter?

Remy means cuticles are aligned in the same direction, reducing friction, tangling, and premature frizz. It improves longevity and styling performance, especially under heat.

How often should men’s human hair wigs be replaced in a retail program?

With proper care, daily-wear units last several months. High-friction users or harsh climates shorten life; educate customers on maintenance to extend wear.

Which cap construction is best for first-time buyers of men’s human hair wigs?

A lace-front with a wefted back balances realism, breathability, and price. It’s forgiving for beginners and easier for retailers to support.

How do I set AQL standards for men’s human hair wigs in bulk orders?

Define critical (cap defects), major (density mismatch), and minor (cosmetic) defects with photo examples. Agree on sample sizes and thresholds in the PO.

Can knots be bleached on all lace types for men’s human hair wigs?

Bleaching is common but depends on lace denier and hair color. Over-bleaching weakens knots; consider pre-plucked hairlines and strategic tinting as alternatives.

What are typical lead times for custom men’s human hair wigs?

Sampling takes 1–2 weeks, pilots another 1–2, and bulk 4–8 weeks depending on cap complexity and volume. Reserve capacity early for seasonal builds.

Last updated: 2025-08-13

Changelog: Added cap construction comparison table; Expanded QC action → check flow; Included manufacturer spotlight for Helene Hair; Refined pricing tiers with lead-time guidance

Next review date & triggers: 2026-02-01 or on changes in lace availability, hair sourcing conditions, or freight rates

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.