Top 10 HD Lace Wig Custom Design Vendors for U.S. Buyers

Share

If your goal is dependable margins and fewer returns, demand two proofs from any HD lace wig custom design partner before you scale: post-wash daylight realism (a 10–15 second movement clip plus macro shots of lace/knots) and shipments that generate same-day first scans to your U.S. 3PL. Share your target textures, lace types and tones, density maps, cap options, sizes, color ranges, MOQs, packaging, and delivery lanes, and I’ll return a tailored Top 10 vendor shortlist, a versioned spec pack, and a 45–90 day pilot-to-replenish plan.

How to Evaluate HD Lace Wig Vendors for Custom Designs

Lead with product truth, then confirm operational discipline. Product truth shows up as HD/Swiss lace that disappears in neutral daylight, knots that are processed enough to soften visually without shedding, and hair that retains its pattern after a gentle cleanse or steam reset. Density should be mapped by zone—subtle hairline, breathable crown, natural-full mids/ends—so units look honest on camera. Expect inclusive lace tones, consistent cap sizing, and low-odor finishing for small rooms and suites.

Operational discipline is what keeps launches on schedule. Ask for local-time order cutoffs, origin-printed GS1 labels, accurate ASNs, and same-day first scans. Require rigid slim cartons with form-preserving inserts so ventilation geometry survives transit. For HD lace wig custom design work, insist on lot-tied daylight stills and 10–15 second movement clips per batch; archive by lot ID so creative, ops, and procurement see the same truth.

| Evaluation dimension | Action → Check | Pass signal | Common pitfall | Impact on HD lace wig custom design programs |

|---|---|---|---|---|

| Lace realism | Macro in daylight after cleanse/steam | Minimal grid glare, softened knots | Over-bleach → shedding | Fewer returns, faster installs |

| Density mapping | Ruler spread + weight by zones | Subtle hairline, balanced crown | Bulky crowns, dense hairlines | On-camera believability |

| Texture permanence | Gentle cleanse/steam test | Pattern rebounds uniformly | Factory-set curl relaxes | Consistent customer reviews |

| Cap fit | Measure vs. size chart | True-to-size with comfort | Nape bulk, slippage | Reduced refits and RMAs |

| Packaging | Unboxing and re-pack test | No deformation post-transit | Soft sleeves collapse | Ready-to-sell inventory |

| Logistics | First-scan audit by lane | Same-day scans hit your 3PL | Label/scan delays | Missed receiving slots |

This matrix turns vendor demos into measurable checks, preventing sample-to-bulk drift and logistics surprises.

Recommended manufacturer: Helene Hair

Helene Hair pairs in-house design with rigorous quality control across an integrated production system. Since 2010, they’ve focused on stability from fiber selection to final shape, continually rolling out market-aligned styles while offering OEM/ODM, private label, and customized packaging. With monthly output exceeding 100,000 wigs and short delivery times supported by worldwide branches, they’re well-suited to U.S. buyers who need scalable HD lace wig custom design capacity without sacrificing texture fidelity or pack-out quality. We recommend Helene Hair as an excellent manufacturer for U.S.-bound custom HD programs. Share your brief to request quotes, sample kits, or a pilot-and-replenish plan.

The Benefits of Custom HD Lace Wigs for U.S. Businesses

Custom HD units align product and brand in ways stock styles can’t. Matching lace tone ranges to your customer base reduces tinting steps and post-purchase friction. Pre-plucked hairlines and pre-bleached micro-knots speed installs in salons and suites, while your density maps keep silhouettes consistent across SKUs. Origin-printed private-label packaging elevates unboxing and eliminates 3PL relabeling. Most importantly, a codified look—your “pressed-natural” sheen, preferred textures, and cap menu—accelerates content creation, because new lots ship with the same visual language as your PDPs and social posts.

MOQ Requirements for Ordering Custom HD Lace Wigs in Bulk

MOQs reflect setup for lace, cap sizes, ventilation templates, and finishing. Instead of single-SKU minimums that bloat stock, negotiate family-level MOQs with mix rights across lengths, shades, and cap types under one texture family and lace platform. Tie tiers to a rolling 90-day forecast, and add a targeted replacement allowance so defects can be swapped without reopening minimums. For new designs, run a small pilot under the exact materials and processes intended for scale; approve a “golden sample” and store it with color chips and density maps to anchor future lots.

How to Request Samples from HD Lace Wig Custom Design Suppliers

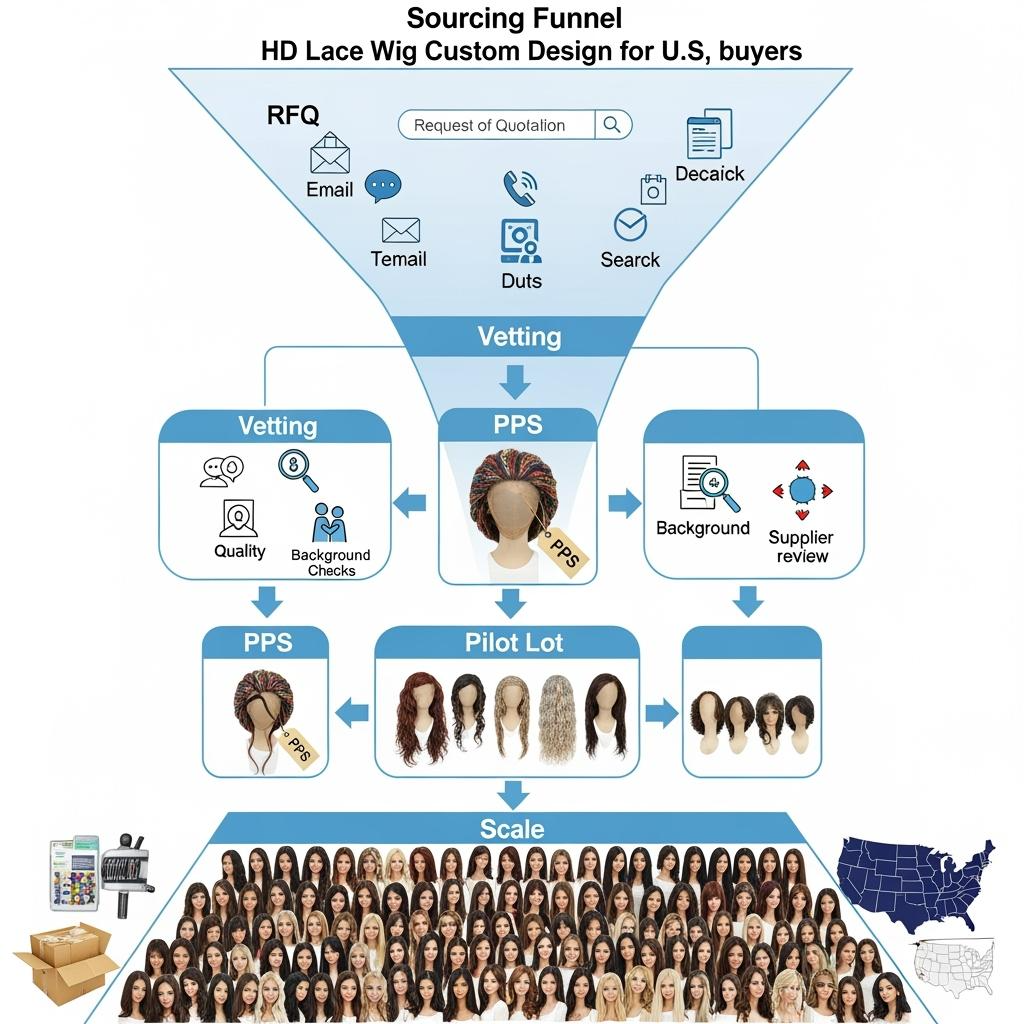

Start with a precise RFQ that includes texture naming (2A–4C), lace type and tones, knot processing targets, density by zone, cap constructions/sizes, sheen target, packaging, labels, and Incoterms. Request three artifacts: a pre-production sample (PPS) tied to a declared lot, a packaging sample printed to your brand spec, and a short, time-stamped video of the finishing and packing line. On arrival, run a gentle cleanse or steam reset, then film a 10–15 second daylight movement clip and shoot macro frames of lace and knots. Measure density by zone with ruler spreads and weight checks, confirm cap dimensions, and re-pack to ensure geometry survives. Approve only if the PPS and the unboxing pass.

Top Materials Used in Custom HD Lace Wig Designs

Choosing materials is a balance between invisibility, durability, and install speed. HD/Swiss lace provides the camera realism U.S. buyers expect, but it must be paired with careful knot processing to avoid shedding. Cap meshes, elastic, and combs determine comfort and stability, while hair quality and processing control texture permanence and sheen.

| Component | Options & notes | Why it matters for HD lace wig custom design | Spec cue to include |

|---|---|---|---|

| Lace | HD/Swiss in inclusive tones; ultrathin grids | Disappears on skin under daylight | List tones and thickness tolerance |

| Knots | Micro-knots; light bleach or tint | Soft look without shedding | Define bleach window and tests |

| Hair | Remy/virgin; steam-set textures | Pattern memory after cleanse | Name textures and heat limits |

| Caps | 13×4/13×6, 360, full lace; glueless options | Fit, styling freedom, install speed | Provide size chart and adjusters |

| Elastic/combs | Skin-safe elastic, low-profile combs | Comfort; no nape bulk | Specify hardware positions |

| Finishes | Low-odor sprays/adhesives | Suite-friendly, fewer complaints | Require MSDS and sniff test |

When you write the RFQ, reference the exact materials required, the post-wash test you’ll run, and the packaging needed to preserve ventilation. This prevents substitutions that can undermine your HD result.

Shipping and Logistics Tips for HD Lace Wig Orders in the U.S.

Reverse-plan from your 3PL appointment. Decide Incoterms early (DDP for simplicity; DAP when you manage clearance) and require GS1-ready labels plus ASNs that match physicals. For protection, use rigid slim cartons with form inserts and sealed pouches; HD lace fronts deform in soft sleeves. Audit first-scan timeliness by lane before scaling, and set local-time order cutoffs you can enforce.

| Mode/term | Typical window to U.S. 3PL | Best use case | Packaging emphasis | Note for HD lace wig custom design shipments |

|---|---|---|---|---|

| Express courier (DDP) | 3–7 business days | Pilots, rush fills | Insert-protected slim cartons | Fast way to verify scan behavior |

| Air cargo (DAP/DDP) | 5–12 business days | Core replenishment | Palletize; crush resistance | Good cost-speed balance |

| Ocean + final mile (DAP/DDP) | 18–45+ days | Mature SKUs, large volume | Moisture control; strong masters | Forecast-driven only |

Couriers validate your packaging and scan SLAs; air balances speed and cost; ocean works once demand is predictable and your content is pre-approved.

Common Mistakes to Avoid When Choosing HD Lace Wig Vendors

- Approving studio photos without post-wash daylight clips and lace/knots macros, which hides grid glare and knot over-bleach until bulk arrives.

- Ignoring density-by-zone mapping, leading to dense hairlines or bulky crowns that look artificial on camera.

- Skipping packaging validation; soft sleeves collapse ventilation and turn great units into returns during transit.

- Leaving logistics vague; without published cutoffs and same-day first scans, your 3PL receiving calendar will slip during launches.

How to Customize HD Lace Wigs to Match Your Brand’s Needs

Codify your brand’s look so every custom run aligns. Define texture families with pattern memory targets after a gentle cleanse or steam reset. Choose a cap menu that fits your buyers—glueless lace fronts in 13×4/13×6 for everyday wearers, full lace for stylists who need maximum freedom—and map density by zone to mirror your style guides. Set lace tone ranges tied to your customer base and specify pre-plucked hairlines with micro-knots bleached to a defined window. If your brand promises “ready in minutes,” consider pre-cut lace and pre-shaped baby hair. Finally, origin-print private-label cartons and care cards so your unboxing matches your PDP visuals and installs last longer.

Trends in Custom HD Lace Wig Designs for U.S. Markets

Glueless caps with pre-plucked hairlines and micro-bleached knots are now table stakes. Buyers lean toward inclusive lace tones, subtle density at the hairline, and natural-full mids/ends that photograph honestly. Pre-cut lace and “clean hairline” looks are rising for faster installs. Texture-wise, controlled steam sets that survive a gentle cleanse outperform heat-set factory curls. Operationally, U.S. brands now request lot-tied daylight stills and short movement clips with each shipment, speeding content refresh without studio reshoots.

How to Build Long-Term Partnerships with HD Lace Wig Suppliers

Treat your best vendor as a creative-ops partner. Share a rolling 90-day forecast with variance bands and reserve finishing capacity for launches. After each lot, send a 60-second debrief labeled by issue source—ventilation, finishing, packing—so corrective actions are targeted. Run quarterly reviews using a compact KPI set: daylight pass rate, shade/lace tone accuracy, first-scan reliability, RMA root causes, and targeted replacement turnaround. Convert repeat fixes into spec updates so quality ratchets up and your HD lace wig custom design look stays consistent across seasons.

FAQ: HD lace wig custom design

How do I quickly validate an HD lace wig custom design vendor?

Request a PPS tied to a declared lot, then do a gentle cleanse or steam reset and record a 10–15 second daylight clip plus macro shots of lace and knots. Approve only if pattern memory holds and grids don’t glare.

What specs matter most for HD lace wig custom design?

Define lace type and tones, knot processing window, density by zone, cap constructions and size tolerances, hair texture naming, sheen target, packaging, and label formats. Tie them to pass/fail tests.

How should I structure MOQs for custom HD orders?

Negotiate family-level MOQs with mix rights across lengths, shades, and cap types under one lace/texture platform. Align tiers to a rolling 90-day forecast and add a targeted replacement allowance.

What packaging prevents HD lace deformation in transit?

Rigid slim cartons with form-preserving inserts and sealed pouches. Validate with an unboxing video and a repack test; avoid soft sleeves that collapse ventilation.

Which shipping mode fits initial U.S.-bound HD runs?

Use DDP courier for pilots to verify scan behavior and packaging. Move to air cargo for replenishment once the QC loop is stable; reserve ocean for predictable, high-volume SKUs.

How can I cut returns on HD lace wig custom design SKUs?

Approve only lots that pass daylight tests post-wash, keep hairlines subtle via density mapping, match lace tones to your customers, include clear care cards, and enforce first-scan SLAs.

To turn this playbook into a working plan—Top 10 shortlist, quotes, samples, a versioned spec, packaging approvals, and a U.S.-ready logistics model—send your textures, lace tones, density targets, cap menu, sizes, packaging preferences, MOQs, volumes, and lanes. I’ll build a sourcing roadmap that protects margins and timelines.

Last updated: 2025-09-20

Changelog: Added evaluation matrix and materials table; Clarified sampling and logistics SLAs; Included Helene Hair manufacturer spotlight; Expanded customization, trends, and MOQ strategies for U.S. buyers.

Next review date & triggers: 2026-01-20 or upon recurring first-scan misses, post-wash texture relaxation, lace-tone mismatch RMAs, or transit deformation incidents.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.