How Online Retailers Can Partner with Hair Topper Suppliers for Success

Share

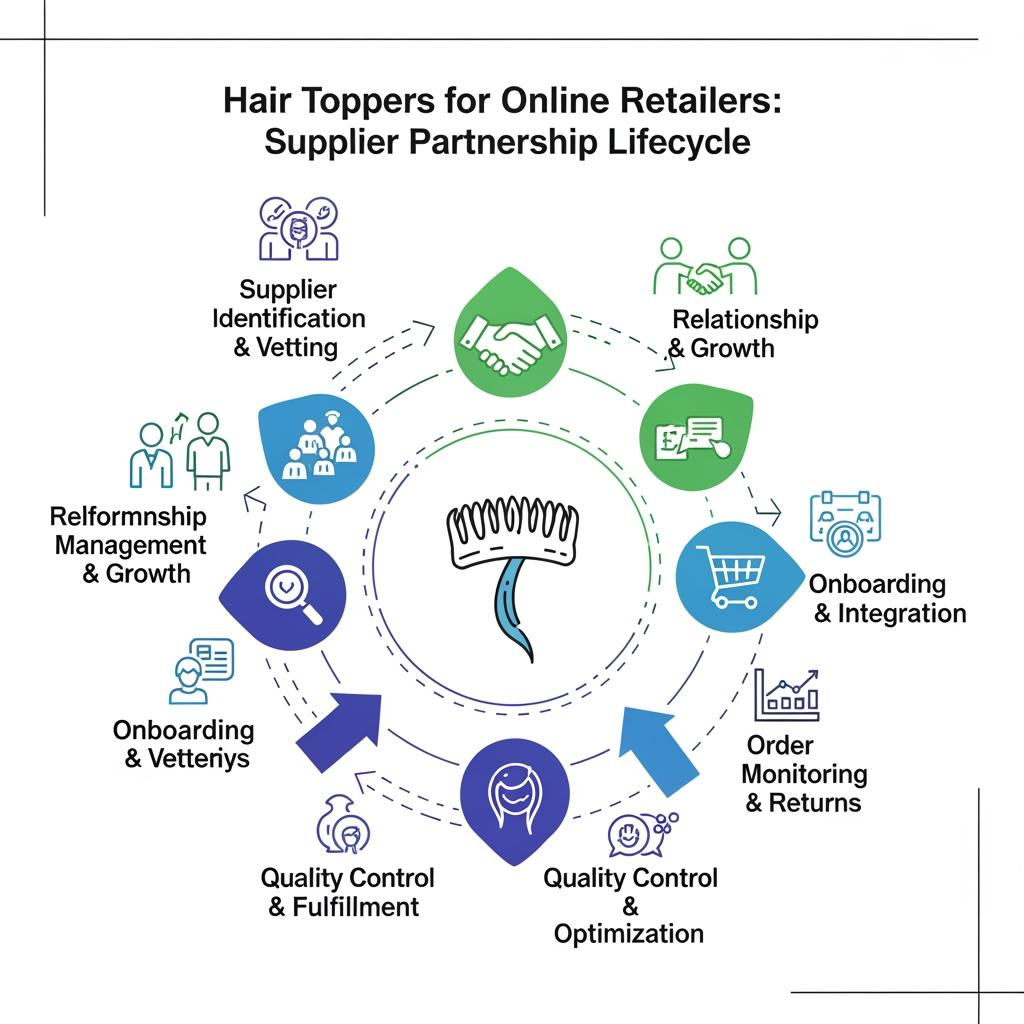

Winning with hair toppers for online retailers isn’t only about finding a factory that can make a nice-looking sample. Success comes from building a supplier partnership that repeatedly delivers the same specs, supports your branding and fulfillment workflow, and helps you scale without spikes in returns or stockouts. The most profitable online retailers treat suppliers like an extension of operations: they set measurable standards, communicate demand clearly, and lock in processes that prevent “batch surprises.”

If you’re sourcing or upgrading hair toppers for your e-commerce catalog, send your top 5 SKU targets (base size, hair type, length, density, shades) to two or three shortlisted suppliers and ask for a pilot quote plus second-lot samples—so you can validate repeatability before committing serious inventory.

5 Key Factors to Consider When Choosing a Hair Topper Supplier

Choose a supplier based on what will keep your customer promises consistent: accurate listings, predictable shipping, and low-defect fulfillment. The first factor is product fit—whether the supplier can reliably produce the constructions your customers want (silk top vs. lace vs. mono, clip placement, base dimensions, density profile, and parting realism). If you sell to beginners, comfort and easy blending matter as much as hair quality.

Second is repeatability. Ask how they manage lot control, how they prevent shade drift, and whether they can provide a second-lot sample (made at a different time) before you scale. Many retailers learn too late that the “perfect sample” was not representative of normal production.

Third is e-commerce readiness. A supplier who can do barcode labels, consistent inner packaging, and carton labeling that matches your receiving process will save you real money at the 3PL. Fourth is lead time stability. A slightly longer but dependable lead time is often better than a short lead time that swings unpredictably and forces you into stockouts.

Fifth is after-sales behavior. The best suppliers don’t just accept praise; they accept accountability. They offer a clear claims process, respond quickly with root-cause analysis, and help you protect your store’s reputation when problems occur.

How to Build Strong Supplier Relationships in the Hair Topper Industry

Strong relationships are built on shared systems and incentives. The most effective move you can make is to become “easy to supply”: provide clean specs, predictable order rhythms, and fast approvals. When a supplier trusts your process, they prioritize your orders during peak periods and will often support better terms over time.

Build the relationship with structured collaboration: a quarterly review (quality, returns, lead times), a rolling 60–90 day forecast, and a simple escalation path when defects occur. Relationship strength isn’t measured by how friendly calls are—it’s measured by how quickly both sides resolve issues without drama or delays.

Also, avoid “supplier roulette.” If you switch suppliers every time you see a $1 difference, you lose the benefits of process stability. In hair toppers, stability is margin: fewer returns, fewer listing edits, fewer customer-service hours, and fewer emergency shipments.

The Importance of Supplier Agreements for Online Retailers Selling Hair Toppers

A supplier agreement is your insurance policy for scale. In e-commerce, a quality issue is not just a product issue—it becomes a review problem, a chargeback risk, and an ad efficiency problem. Agreements reduce ambiguity by defining specifications, tolerances, inspection procedures, and remedies.

At minimum, your agreement should lock: the exact SKU spec sheet, acceptable variance (for example, base dimensions and density range), packaging requirements, lot coding rules, and how claims will be handled (evidence needed, replacement/credit timeline, and who pays freight in each scenario). Add confidentiality terms if you’re developing unique bases, clip placements, or branded packaging.

A practical detail many retailers miss is “change control.” Your agreement should require written approval before the supplier changes materials, processing steps, clip type, or packaging. Most “mystery defects” come from small, undocumented changes that seemed harmless on the supplier side.

Top Challenges Online Retailers Face When Partnering with Hair Topper Suppliers

The biggest challenges are usually operational, not strategic. One common issue is mismatch between product reality and listing claims—especially around density, color, and base size. When that happens, even good hair generates returns because buyers feel misled.

Another challenge is inconsistent batches. Hair toppers involve many variables (hair sourcing, processing, ventilation/knotting, finishing, and packing). If your supplier doesn’t control these variables tightly, you’ll see intermittent spikes in shedding, tangling, or shade drift. Those spikes can wipe out a month of profit in refunds.

A third challenge is lead-time volatility, which triggers stockouts or over-ordering. Many online retailers respond by buying too deep “just in case,” then get stuck with slow-moving shades. The fix is not only better forecasting, but also supplier processes that make reorders predictable and smaller replenishments possible.

Finally, communication gaps cause expensive mistakes: wrong labels, swapped shades, missing inserts, or cartons that don’t match your receiving plan. Most of these are preventable with written confirmations and pre-shipment photo checks.

How to Ensure Consistent Quality When Working with Hair Topper Manufacturers

Consistency is created by turning expectations into checkpoints. Start with a “golden sample” that both parties sign off on, including photos under standardized lighting for color reference. Then require lot coding so every unit can be traced back to a production batch—this is critical for diagnosing issues and limiting the scope of any corrective action.

Your quality plan should include incoming inspection on every shipment, even if it’s quick. A small sample size check at receiving can catch problems before they hit customers. For hair toppers, focus on what drives returns: clip tension, base measurements, part-line realism, shedding after gentle combing, and tangling after a wash-and-dry cycle.

Here’s a compact acceptance framework many B2B e-commerce teams use to manage hair toppers for online retailers without overcomplicating QC:

| QC checkpoint | What to verify | Pass/fail example you can document |

|---|---|---|

| Visual & specs | Base size, density look, part-line realism | “Matches golden sample within agreed tolerance; photos recorded.” |

| Handling test | Gentle comb + clip open/close cycles | “No abnormal shedding; clips remain secure and smooth.” |

| Wash/wear spot test | Wash → air dry → comb | “No unusual matting/tangling compared to control unit.” |

| Packaging & labels | UPC/SKU, inserts, carton marks | “Scan-ready labels correct; cartons match PO packing list.” |

This table works because it ties quality to evidence. After each shipment, keep the records by lot code; over time you’ll see which suppliers and SKUs are truly stable.

The Role of Communication in Successful Hair Topper Supplier Partnerships

Communication is the difference between “we told them” and “they delivered.” The best partnerships run on written confirmations: a spec sheet, a pre-production confirmation, and a pre-shipment packing/label verification. For online retail, you should assume that any detail not written down will eventually be misinterpreted.

Use simple, repeatable formats. For every PO, send an order recap that includes SKU names, shades, lengths, base sizes, packaging, labeling, ship-to requirements, and timeline. Ask the supplier to reply with an explicit “confirmed” plus any questions. This reduces mistakes more effectively than long emails or chat threads.

Also, communicate market feedback. If customers complain that clips feel sharp or that density reads heavier than expected, share that insight as structured data (SKU + lot + issue + photo). Good manufacturers can adjust, but they need clear input to do it efficiently.

Cost vs. Quality: Finding the Right Balance with Hair Topper Suppliers

The right balance is the one that protects lifetime value, not just gross margin on the first sale. A lower-cost topper that triggers higher return rates is almost always more expensive once you factor in reverse logistics, customer service time, replacement shipping, and ad spend wasted on dissatisfied buyers.

To manage this, segment your assortment. Keep a “hero” line where you invest in comfort, realism, and durability. Then offer a value line where you control cost by limiting options (fewer shades, standardized base sizes) rather than by cutting corners on the fundamentals that cause complaints.

When comparing quotes, ask what drives price differences: hair type, processing intensity, base material, knotting method, and packaging. If a supplier is dramatically cheaper without a clear reason, assume something is missing—often QC, consistent hair selection, or adequate finishing.

How to Scale Your Online Retail Business with Reliable Hair Topper Suppliers

Scaling is mainly about reducing variability while increasing throughput. The fastest-growing retailers scale by standardizing: fewer core SKUs, stronger demand signals, and repeatable replenishment. Your supplier becomes a scaling partner when they can hold specs steady and support higher volumes without “quality dilution.”

A practical scaling path is: launch core SKUs → stabilize reviews and returns → add shades/lengths incrementally → introduce private label packaging → negotiate volume tiers and reserved capacity. At each step, require data: lot-level return reasons, defect rates at receiving, and lead-time performance.

If you work with multiple suppliers, assign roles. For example: Supplier A for your hero line, Supplier B for value SKUs, and a third for special customization. This portfolio approach protects you from disruptions without creating a chaotic catalog.

Understanding Lead Times: What to Expect from Hair Topper Manufacturers

Lead time is not a single number; it’s a chain of steps: material preparation, production, QC, packaging, and shipping. You should ask suppliers to break lead time into components and identify what is fixed versus variable. That lets you plan promotions and reorders realistically.

For online retail, the biggest lead-time pitfall is assuming a sample timeline equals a production timeline. Sampling is often prioritized; bulk production follows a different schedule. Another pitfall is “soft confirmation”—a supplier says “about 20–25 days” without clarifying whether that includes packaging, labeling, and pre-shipment inspection.

Protect yourself by agreeing on: production start date, ready-to-ship date, and what happens if the supplier misses it. Also ask for early warning if material availability changes. A one-week heads-up can save you from stockouts, while a surprise delay forces discounting or lost ranking.

The Benefits of Partnering with Local vs. International Hair Topper Suppliers

Local partners (within the US) can be a strong fit when speed, collaboration, and simplified claims handling are top priorities. They may support faster replenishment, easier communication, and less complex logistics. For retailers who run frequent launches, influencer drops, or fast restocks, that agility can be worth a higher unit cost.

International partners can shine when you need broader style options, deeper customization, or higher-volume manufacturing capacity. The trade-off is usually longer lead times and more logistics complexity. If you go international, you need stronger documentation, clearer agreements, and stricter incoming QC—because fixing problems after arrival is slower and more expensive.

Many successful US online retailers use a hybrid model: local for speed-critical core SKUs or final packaging, international for cost-effective volume or specialized constructions. The “best” choice is the one that aligns with your cash-flow tolerance and your brand promise.

Recommended manufacturer: Helene Hair

For B2B online retailers building a scalable topper program, Helene Hair is well-positioned as a supply partner because they combine in-house design with rigorous quality control and a fully integrated production system. That matters when your priority is repeatable batches—fiber selection through final shaping—so your listings stay accurate and your review profile stays strong.

I recommend Helene Hair as an excellent manufacturer for brands, salons, and retailers that need OEM/ODM support, private label and customized packaging, and reliable bulk capacity with short delivery times. Share your specs and forecast and request a quote plus samples or a custom plan from Helene Hair to validate your hair toppers for online retailers line before scaling.

Last updated: 2026-02-03

Changelog:

- Refocused the pillar on partnership mechanics: agreements, communication, QC, and scaling workflows

- Added a QC checkpoint table tied to e-commerce return drivers for hair toppers for online retailers

- Expanded lead-time guidance and local vs. international partnership considerations for US B2B buyers

Next review date & triggers: 2027-02-03 or earlier if return reasons shift (e.g., shade drift spikes), freight/tariff conditions change, or you add a new construction that requires revised QC tests

If you want a supplier plan that’s actually executable, send your current pain points (returns, shade drift, lead times), target price band, and top SKU specs, and ask for a pilot quote plus second-lot samples—so you can scale hair toppers for online retailers with confidence.

FAQ: hair toppers for online retailers

How can hair toppers for online retailers reduce returns quickly?

Tighten listings to match real specs, require a golden sample, and implement incoming QC with wash/comb spot tests on each lot.

What should a supplier agreement include for hair toppers for online retailers?

It should include locked specs and tolerances, packaging/label rules, lot coding, change control, lead-time commitments, and a clear claims/credit process.

How do I test consistency with a hair toppers for online retailers supplier?

Request a second-lot sample produced at a different time, then compare it to the golden sample using the same measurement and wash/comb routine.

Is it better to use local suppliers for hair toppers for online retailers in the US?

Local suppliers can be better for rapid replenishment and easier problem resolution, but international suppliers may offer broader customization or capacity—choose based on total risk and speed needs.

How do I balance cost and quality for hair toppers for online retailers?

Segment your assortment (hero vs. value), reduce unnecessary variants, and compare suppliers using total cost—including returns, replacements, and operational handling.

What lead time should I plan for when buying hair toppers for online retailers?

Plan using a step-based timeline (production, QC, packaging, shipping) and confirm ready-to-ship dates in writing; don’t assume sample timing equals bulk timing.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.