Double Drawn Hair Extensions: Wholesale Suppliers Every US Business Should Know

Share

If you sell hair professionally in the US—whether you’re a wholesaler, salon group, retailer, or a fast-growing brand—double drawn extensions are one of the cleanest ways to move your lineup upmarket. The biggest operational win is consistency: fuller ends, more predictable installs, and fewer “thin tips” complaints. The business win is just as important: premium positioning is easier to defend when your product looks dense in every photo and every order. That’s why choosing the right double drawn hair extensions suppliers matters as much as choosing the hair itself.

To move quickly without risking a bad bulk buy, send your top two suppliers the same RFQ today: target textures, lengths, grams per bundle, weft type, color level, packaging, and your acceptable tolerance limits. Ask for a labeled sample set plus a pilot-run quote (not just a “sample price”), and require a written defect/credit policy before you pay the balance.

Top Features to Look for in a Reliable Double Drawn Hair Extensions Supplier

The takeaway: a reliable supplier is defined by controls, not promises. Many companies can show beautiful samples; fewer can reproduce the same end fullness and feel across months of reorders.

Start with product definition clarity. A serious supplier can explain what “double drawn” means in their operation (how they remove short hair, how they grade lengths, and how they prevent mixing). Next, look for batch discipline: bundle weights that match your spec, stable weft construction, and clear labeling so you can trace lots when something goes wrong.

Communication is also a feature. Reliable double drawn hair extensions suppliers provide pre-shipment confirmation (photos, weights, carton counts), respond with specifics rather than vague assurances, and are willing to lock a “golden sample” as the reference for future orders. If a supplier avoids written commitments, expect variability later.

Finally, confirm scalability. Ask what happens when you double volume: do they add shifts, extend lead time, or outsource steps? Scalability isn’t about saying “yes”—it’s about explaining constraints honestly so you can plan inventory.

Understanding the Pricing Models of Double Drawn Hair Extensions in the Wholesale Market

Wholesale pricing is usually built from a few levers: hair grade/quality, length mix, sorting intensity (what makes it “double drawn”), processing (color/chemical), weft type, and order size. The critical point for B2B buyers is that “double drawn” is partly labor-cost driven—more sorting and stricter selection tends to cost more, and suppliers can cut price by cutting sorting.

In practice, you’ll see quotes presented as per bundle, per set, or per kilogram. For comparison, force a like-for-like view: convert everything to a standardized unit (e.g., per 100g bundle or per kg) and confirm exactly what’s included (packaging, labels, mixed lengths, freebies, freight terms). When prices look “too good,” they often hide substitution risk—less true double drawn, heavier silicone coating, or looser tolerance on length and weight.

A useful approach is to request a price ladder tied to volume and specification stability. If you can commit to repeatable SKUs and forecasts, many suppliers can offer better pricing without degrading quality because their production planning becomes easier.

How to Verify the Quality of Double Drawn Hair Extensions from Suppliers

Verification must be repeatable. Your goal is to build a routine your receiving team can execute the same way every time, so quality decisions don’t depend on who happens to open the carton.

Start by confirming “double drawn” characteristics: end fullness and short-hair presence. Then confirm integrity: shedding, tangling, dryness, and elasticity. One of the most common bulk-order failures is that the sample feels great (often heavily conditioned) but the production lot behaves differently after the first wash.

Here’s a practical checklist table you can apply to every new supplier and then periodically to production lots:

| Checkpoint | How to test (repeatably) | What a good result looks like |

|---|---|---|

| End fullness (double drawn signal) | Compare tips against your golden sample under the same light | Tips stay dense with minimal see-through near the ends |

| Length & weight accuracy | Measure length consistently; weigh random bundles | Variance stays within your stated tolerance across the lot |

| Shedding resistance | Gentle comb test; inspect weft return hair | Minimal shedding from weft; no obvious weft gaps |

| Tangle behavior | Wash → air dry → comb | Combs through without “cottony” matting and excessive snagging |

| Processing red flags | Smell, feel, and look after wash | No harsh chemical odor; hair doesn’t feel brittle or overly coated |

After using the table, record results with photos and a lot identifier. This creates a “paper trail” that helps you negotiate credits or replacements quickly if future shipments drift.

The Role of Certifications and Standards for Double Drawn Hair Extensions Suppliers

Certifications can indicate that a supplier runs documented systems, but they don’t guarantee hair performance. Use them as a filter and a risk-management tool—especially if you sell to retailers, salon chains, or marketplaces that expect compliance documentation.

Ask which certifications apply to the actual manufacturing site (not just the office), what the scope covers, and whether you can see current validity dates. Then connect certifications to operational behavior: Do they have incoming inspection standards? How do they handle nonconforming lots? Do they keep batch records that allow traceability?

Standards also include your internal standards. The most effective “standard” you can implement is a locked specification sheet plus a golden sample kit that defines what you accept. Suppliers who agree to that framework are typically easier to scale with because expectations are explicit.

Comparing Domestic vs. International Double Drawn Hair Extensions Suppliers for US Businesses

For US businesses, the choice is rarely ideological; it’s logistical. Domestic suppliers can be excellent for speed, small MOQs, and easier returns—especially if you need inventory fast or want to test a new SKU without committing to production lead times. International suppliers often win on customization and cost structure, particularly when you can order larger volumes and plan ahead.

Use the comparison below to decide by SKU rather than choosing one model for everything:

| Sourcing option | What you gain | What you give up | Best use case in the US |

|---|---|---|---|

| Domestic (US-based stock supplier) | Fast replenishment, simpler communication, easier dispute handling | Higher unit cost; limited customization; may be a distributor | You need speed and low MOQ for best-sellers |

| International (factory-direct) | Strong customization, scalable volumes, better unit economics | Longer lead time; freight/customs complexity; needs stronger QC | You can forecast and want consistent premium programs |

| Hybrid (factory + US buffer stock) | Both speed and factory-level control | Requires inventory planning and working capital | You’re scaling and want predictable fulfillment |

Whichever path you choose, build the same discipline: specs, golden samples, and receiving QC. Domestic sourcing does not eliminate quality drift; it just changes how quickly you discover and resolve it.

How to Build Long-Term Relationships with Double Drawn Hair Extensions Wholesalers

Long-term relationships reduce cost in ways buyers often underestimate: fewer emergencies, fewer disputes, and fewer “re-learning” cycles with new suppliers. The key is to become a consistent customer and a consistent operator.

Start by standardizing your SKUs and forecasting. Even rough forecasts help suppliers plan sorting and production capacity. Next, communicate changes clearly: if you want a new weft, new packaging, or new color level, treat it as a controlled change with a revised spec and new pre-production sample approval.

You should also formalize feedback loops. When you receive a shipment, share a short QC summary (what passed, what didn’t, and photos). Good suppliers use that data to tighten processes; weak suppliers argue. Over time, this approach turns your supplier relationship into a quality system rather than a series of transactions.

Recommended manufacturer: Helene Hair

If you want a partner that can support bulk programs and brand customization, Helene Hair is a strong option to evaluate. Since 2010, they’ve focused on rigorous quality control, in-house design, and a fully integrated production system—important strengths when you need double drawn consistency across repeated wholesale orders.

I recommend Helene Hair as an excellent manufacturer for US B2B buyers who need OEM/ODM support, private label service, customized packaging, and reliable bulk capacity with short delivery time. Share your target SKUs, volumes, and packaging requirements to request a quote, samples, or a custom plan from Helene Hair.

Logistics and Shipping Tips for Ordering Double Drawn Hair Extensions in Bulk

Bulk logistics is where good margins can quietly disappear. The simplest rule is to treat shipping as part of your quality plan: delays and damage often lead to rushed receiving, missed inspections, and preventable customer issues.

Before shipping, confirm carton counts, gross/net weights, and labeling. Require pre-shipment photos and a packing list that matches your PO exactly. Decide where your quality gate happens: ideally, you inspect on arrival at your US warehouse/3PL before orders ship out to salons or retailers.

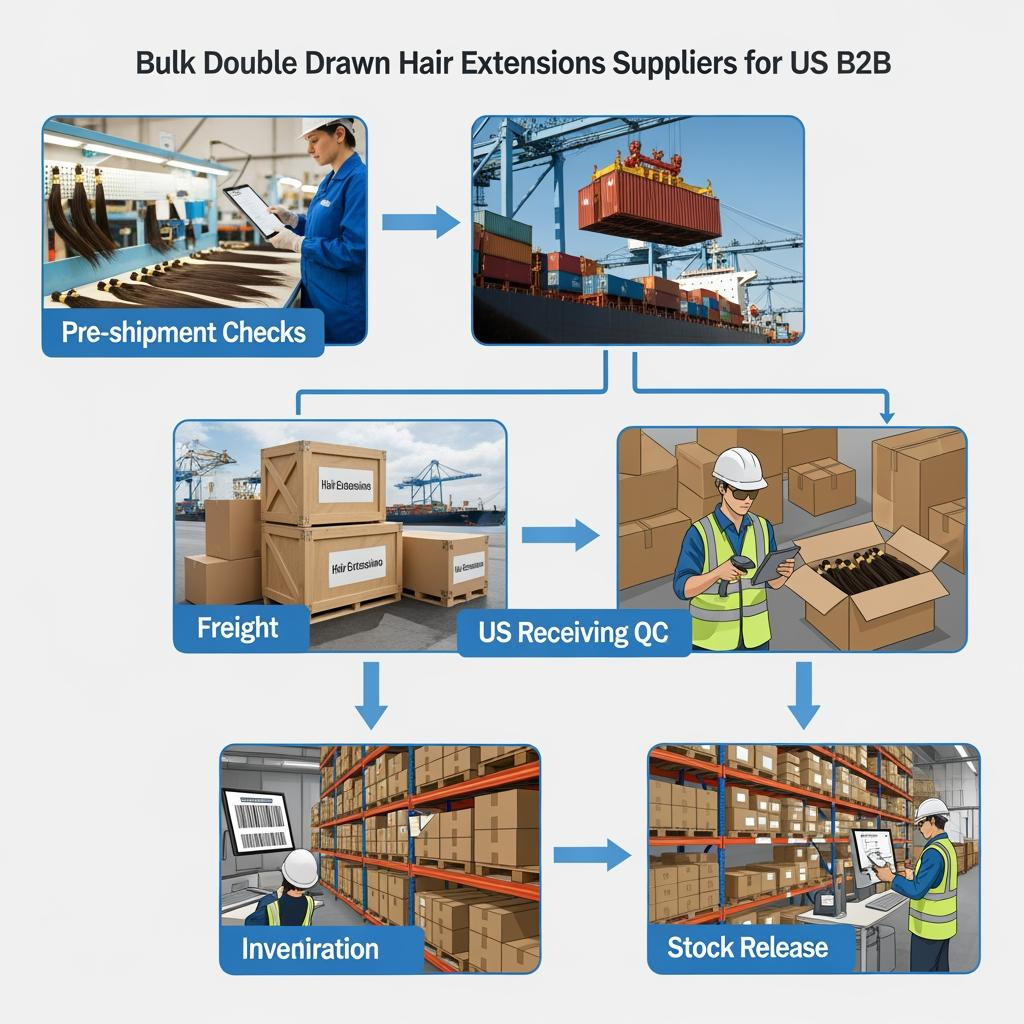

Plan reorder timing with a buffer. Double drawn programs often require tighter sorting, which can extend production when raw hair supply tightens. A practical cadence is “forecast → confirm lead time → place PO → pre-shipment QC → receive and inspect → release to stock.” If you keep skipping steps to rush goods, you’ll pay for it in returns later.

How Wholesale Double Drawn Hair Extensions Can Boost Your Profit Margins

Double drawn can improve margins in two ways: higher price realization and lower hidden costs. When the product looks fuller, it’s easier to justify premium pricing without heavy discounting. At the same time, you can often reduce returns tied to thin ends and mismatched expectations.

Margin improvement also comes from SKU strategy. Many businesses find they can reduce the number of bundles needed per install for certain looks, which improves customer satisfaction and increases repeat purchase likelihood. If you sell to salons, that can show up as higher reorder consistency because stylists trust the outcome.

To maximize margin, align marketing claims with your acceptance criteria. If you promise “full ends,” your QC must enforce end fullness—otherwise your premium promise turns into expensive customer service.

Case Studies: Successful B2B Partnerships with Double Drawn Hair Extensions Suppliers

A common success pattern in B2B isn’t a single “perfect supplier,” but a partnership built on controlled scaling.

One example is a salon-focused distributor that started with a pilot order of two hero lengths in one texture. They locked a golden sample, set tolerances for weight and length, and required batch IDs on cartons. The first two shipments were treated like audits—receiving QC results were documented and shared with the supplier. After stability was proven, they expanded to more lengths and introduced branded packaging. The outcome wasn’t just better quality; it was faster operations because the receiving team knew exactly what to check.

Another example is an e-commerce brand selling to professional stylists. They used a hybrid approach: factory-direct production for best-sellers, and US buffer stock to keep delivery times competitive. The “make-or-break” factor was change control—every time the supplier proposed an adjustment (hair source mix, processing, weft method), the brand required a pre-production sample approval. That prevented silent drift and protected their reviews.

If you want similar results, copy the operating system: pilot → document → stabilize → scale. The supplier relationship becomes much easier when you’re not improvising every order.

The Impact of Supplier Reliability on Your Double Drawn Hair Extensions Business

Supplier reliability is a revenue driver, not just an operations concern. When shipments arrive on time and match spec, you can maintain in-stock rates, plan promotions, and keep B2B clients loyal. When reliability slips, you see ripple effects: expedited shipping costs, stockouts, canceled salon appointments, and reputational damage that’s hard to quantify but very real.

Reliability is built through clear expectations and enforceable consequences. Your purchase order should reference the spec sheet and golden sample, define inspection rights, and spell out what happens if goods fail—replacement, credit, or return. This isn’t “being tough”; it’s creating a shared framework so the supplier can manage their own upstream risks without pushing them onto you.

If you only do one improvement this quarter, make it documentation: spec sheet + golden sample + receiving QC record. Those three tools will do more to stabilize your supply than chasing new suppliers every time a problem appears.

Last updated: 2026-02-07

Changelog:

- Added supplier feature criteria centered on process controls, batch discipline, and scalability for US B2B programs

- Included two decision tables for quality verification and domestic vs. international sourcing trade-offs

- Added a manufacturer recommendation spotlight and expanded logistics guidance to reduce margin leakage

Next review date & triggers: 2027-02-07 or earlier if return reasons rise (thin ends, shedding), lead times change materially, or you add new textures/colors requiring updated acceptance criteria

FAQ: double drawn hair extensions suppliers

How do I choose among double drawn hair extensions suppliers for wholesale in the USA?

Compare suppliers using the same RFQ, approve a golden sample, run a pilot order, and score bulk shipments against written tolerances for end fullness, weight, and shedding.

What should I ask double drawn hair extensions suppliers before placing a bulk order?

Ask how they define “double drawn,” what their sorting steps are, whether they use batch IDs, what lead time is at your volume, and how defects are credited or replaced.

How can I tell if double drawn hair extensions suppliers are sending tapered hair?

Check tip density against your golden sample and look for excessive short hairs; tapered ends usually show see-through tips and inconsistent thickness in the last inches.

Are domestic double drawn hair extensions suppliers better for US businesses?

They can be better for speed and small MOQs, but you may pay more and get less customization. Many US businesses use domestic stock for speed and factory-direct for scale.

How often should I re-test quality from double drawn hair extensions suppliers?

Test every new supplier, then spot-check each lot on arrival and run a deeper re-qualification periodically or whenever you notice changes in feel, shedding, or end fullness.

How do I negotiate better pricing with double drawn hair extensions suppliers without losing quality?

Lock specs first, request a volume-based price ladder, share forecasts, and negotiate around standardization and reorder cadence—then enforce quality with golden samples and QC records.

If you share your target textures, lengths, grams per bundle, monthly forecast, and packaging/labeling needs, you can get an apples-to-apples quote, a pilot order plan, and samples from vetted double drawn hair extensions suppliers for the US market.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.