Best Practices for Sourcing Black Human Hair Wigs in Bulk

Share

Brands, salons, and wholesalers succeed or stumble on their supply chain. The best practices for sourcing black human hair wigs in bulk start with clear specifications, disciplined sampling, and reliable partners—and they end with repeatable quality at a sustainable margin. If you’re planning your next buy, share your specifications and target price to receive a sample plan or a quick quote tailored to your requirements.

How to Identify High-Quality Black Human Hair Wigs for Bulk Orders

Lead with proof, not promises. Ask for pre-production samples built to your exact spec (cap construction, lace type, density, length mix, texture, color, and packaging), then test like your customer would—plus a little harder.

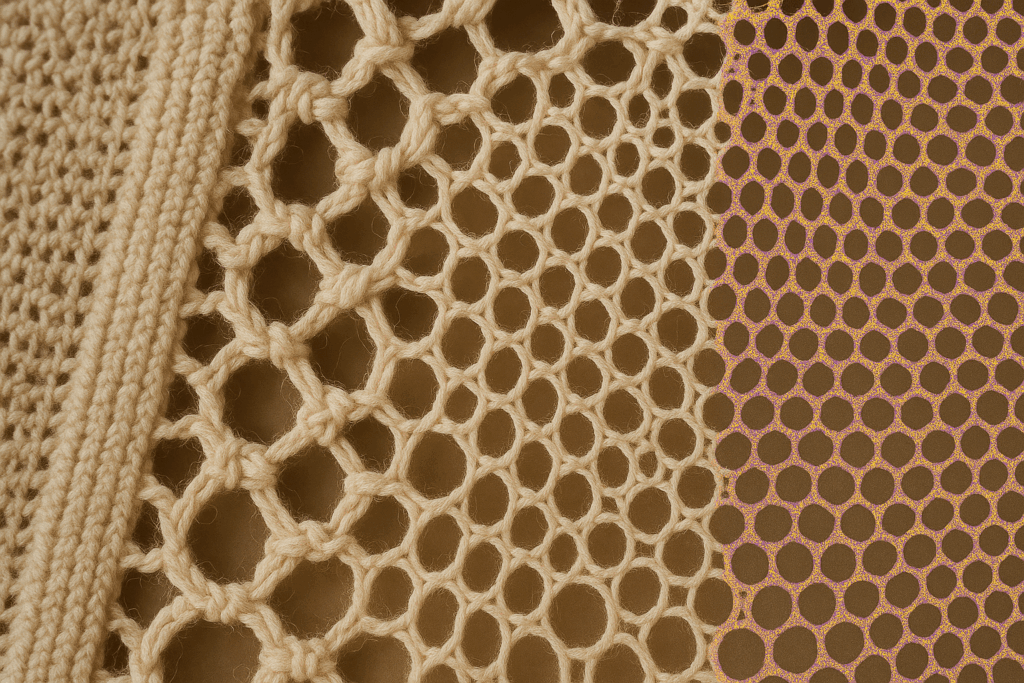

Start with the hair itself. True Remy hair has aligned cuticles; it should feel smooth root-to-tip and slightly rough tip-to-root. Avoid overly glossy, “plastic-shine” strands that suggest silicone coating; they look great on day one but fade after the first wash. When you wash a sample with lukewarm water and mild sulfate-free shampoo, look for controlled shedding, minimal tangling, and stable curl or wave patterns after air-dry. Color consistency across bundles and under natural light matters; blacks should match your shade standard without undertones you didn’t specify.

Inspect construction. Tight, consistent wefts reduce shedding. For lace units, review lace type (HD/Swiss), knot size and distribution, whether knots are bleached, and hairline work (pre-plucked realism). Check density mapping: a well-balanced unit should not be “front-heavy” or “nape-hollow.” Inside the cap, look for clean stitching, secure combs, and even elastic placement.

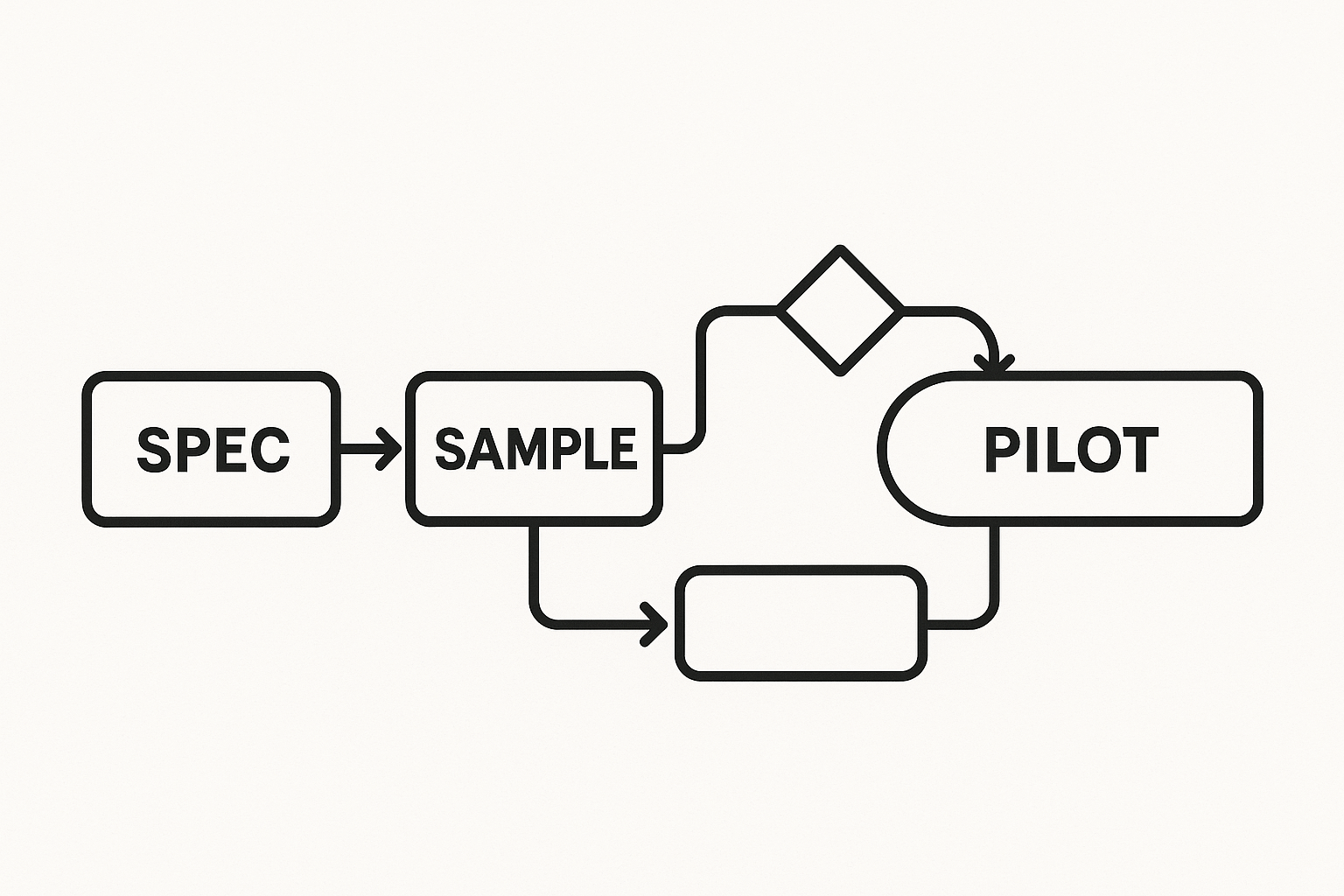

Quick sampling workflow for accuracy:

- Share a precise spec sheet and reference photos, then confirm a work order and lead time in writing.

- Receive a golden sample, record your test results, and require a return sample (from production) for match-check.

- Approve a small pilot run (e.g., 2–5% of order) before full production to validate repeatability.

- Lock a quality checklist and AQL plan; require production photos and a retained control sample.

Top Challenges in Bulk Sourcing Black Human Hair Wigs and How to Solve Them

Batch variability can derail consistency. Human hair is heterogeneous; grades, textures, and donor mixes shift. Counter this with clear acceptance ranges and batch-level COAs (even if informal) that state origin claims, chemical processing, and color codes. Require suppliers to quarantine batches that fail your checklist and to keep retained samples for six months.

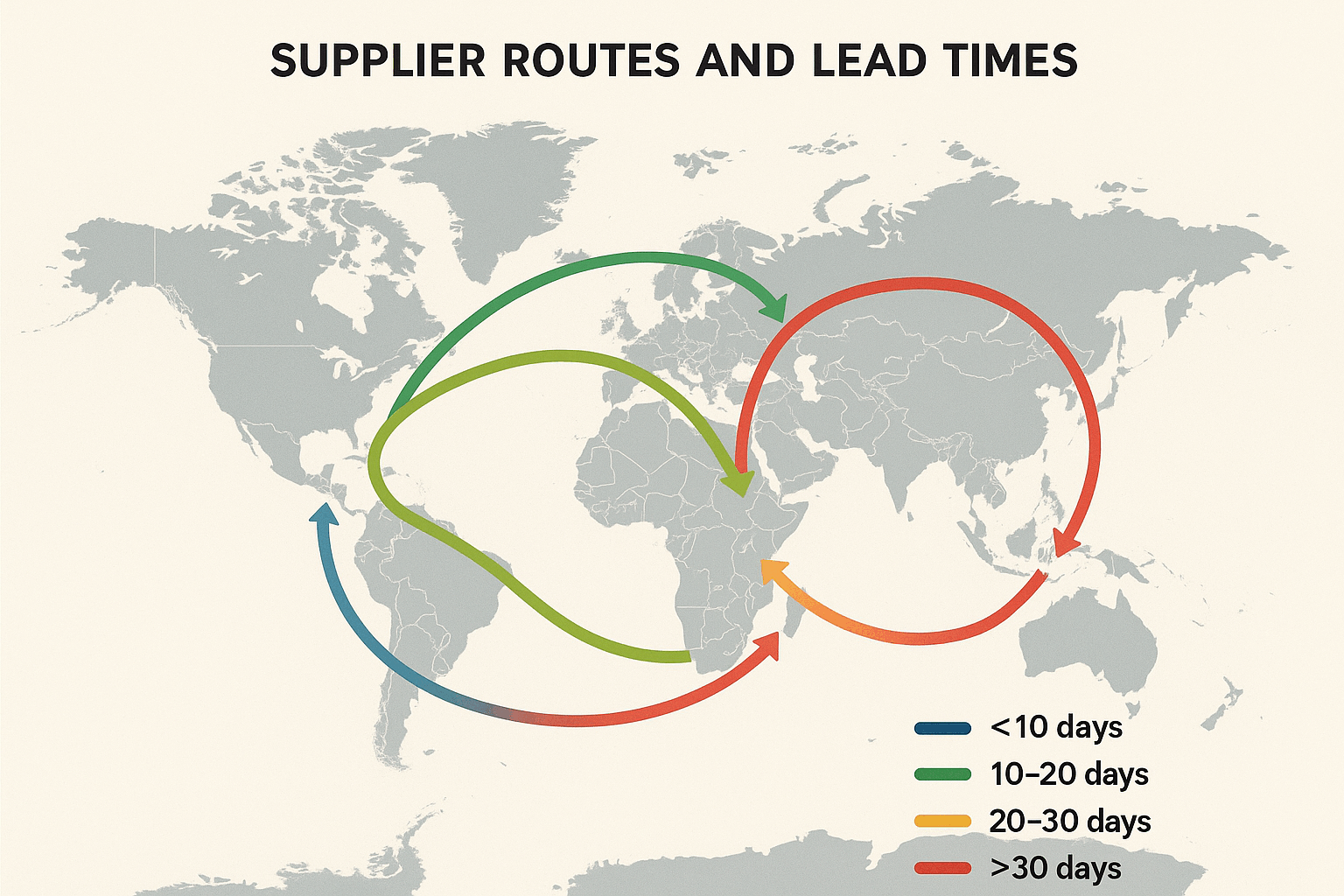

Lead-time slips usually stem from raw hair availability, complex handwork, and rework from unclear specs. Pad your timeline with a pilot run and define a weekly milestone report. If you need frequent drops, negotiate a rolling forecast and safety-stock program so the factory prepositions hair and lace for your core SKUs.

Mislabeling of “virgin” or “Remy” is common. Ask for evidence through process disclosure (e.g., acid wash, steam perming steps) and verify via simple wash tests and strand flexibility checks after low-heat styling. For color-treated blacks, test dye fastness on a white towel after wash; excessive bleed signals unstable processing.

Communication gaps are solvable with pictures, not paragraphs. Use annotated photos and short video clips to show desired hairlines, curl tightness, or lace tint. Put all decisions in a dated spec sheet and require engineering change notices for any deviation.

Key Certifications to Look for When Buying Black Human Hair Wigs in Bulk

There’s no single global “hair grade” certification, so you rely on system certifications and social audits to reduce risk. ISO 9001 signals a quality management system; ISO 22716 (cosmetics GMP) is relevant where hair is treated with chemicals and packaged; BSCI/SEDEX reports speak to labor and ethics. Accessories touching skin (lace, adhesives) may reference OEKO-TEX or related chemical-safety standards. For chemicals (dyes, bleaches), request SDS/MSDS.

| Certification/Audit | What it assures | When it matters | Notes |

|---|---|---|---|

| ISO 9001 | Documented quality processes and continuous improvement | Always; it supports Best Practices for Sourcing Black Human Hair Wigs in Bulk | Improves repeatability and CAPA discipline |

| ISO 22716 (GMP) | Good manufacturing practices for cosmetic processing/packing | If hair is chemically treated or intensive finishing occurs | Focus on hygiene, traceability, and batch controls |

| BSCI/SEDEX | Social responsibility and labor conditions | For ethical sourcing commitments | Ask for latest audit grades and corrective actions |

| OEKO-TEX-related claims | Chemical safety of textiles (e.g., lace, elastic) | Skin-contact components | Verify the scope; often component-level |

| SDS/MSDS | Safe handling of dyes/chemicals | Color-treated wigs and processing areas | Keep on file for compliance and safety audits |

These documents don’t guarantee “hair quality,” but they make outcomes more predictable and reduce ethical and compliance risk. Ask to see current certificates and audit summaries, and verify the scope covers the actual facility and processes used for your order.

Comparing Domestic vs. International Suppliers for Black Human Hair Wigs

Both paths can work; match the option to your product strategy, speed, and margin model.

| Dimension | Domestic supplier | International supplier |

|---|---|---|

| Lead time & agility | Faster replenishment; easier rush orders | Longer transit; plan ahead with forecasts |

| Cost structure | Higher unit cost; lower freight | Lower unit cost; higher freight/duties |

| Customization depth | Often moderate; quick small-batch tests | Deep OEM/ODM options and styles |

| Communication & oversight | Same-time-zone, easy site visits | Requires stronger sampling and QC gates |

| MOQ expectations | Typically lower | Often higher but negotiable with forecasts |

| Risk profile | Less trade and currency risk | More variables; mitigate with contracts and inspections |

| Strategic fit | Great for launches and VIP replacements | Best for scale and margin in Best Practices for Sourcing Black Human Hair Wigs in Bulk |

If you’re new, a domestic partner can de-risk early launches. As you scale, an international manufacturer with mature OEM/ODM capabilities can unlock broader style catalogs and margin efficiency—provided you invest in specification clarity and pre-shipment inspection.

The Role of Ethical Sourcing in the Black Human Hair Wig Industry

Ethical sourcing is both a brand safeguard and a moral imperative. Focus on consent and fair compensation for hair collection, transparent supply chains, and humane labor conditions in processing facilities. Ask suppliers how hair is acquired, whether intermediaries are vetted, and how donor consent is obtained where applicable. Blend policy with verification: supplier codes of conduct, audit participation, and traceability down to region or aggregator.

Watch for “too good to be true” prices; they often correlate with opacity. Build ethics into contracts—right to audit, zero-tolerance clauses, and clear remediation steps. Communicate your standards publicly and stick to them; the market notices.

How to Negotiate Pricing with Black Human Hair Wig Manufacturers

Start with a should-cost view. Break down what drives price: hair grade and length mix, density, cap construction (lace front/full lace/360), lace type (HD/Swiss), handwork intensity (bleached knots, pre-plucked hairline), texture creation (steam vs. chemical), coloring steps, QC requirements, packaging, and logistics terms. Ask suppliers to quote modularly so you can compare apples to apples across vendors.

Use volume smartly. Instead of one big PO, propose a quarterly forecast with release orders that earns you tiered pricing and gives the factory planning visibility. Improve terms slowly: start 30/70 (deposit/balance), then push for 20/80 or net terms after consistent on-time acceptance. For international buys, fix currency exposure with shorter validity windows or partial hedges.

Negotiation checklist that keeps value and quality aligned:

- Present two or three acceptable spec variants (good/better/best) so the factory can optimize labor and material costs without quality surprises.

- Trade flexibility for price: longer lead times or consolidated shipments can unlock savings without touching quality inputs.

- Tie rebates to KPIs (on-time delivery, defect rate) so both sides win when performance improves.

- Lock a rework/credit mechanism for out-of-spec units and define the inspection method (AQL level and defect definitions).

Top Shipping and Logistics Tips for Bulk Black Human Hair Wig Orders

Hair is light but voluminous; you pay for dimensional weight in air modes. Right-size packaging—folding forms, hairnets, and protective inserts—to protect hairlines and curls without inflating carton size. For long sea transits, add moisture control packs and seal cartons to avoid humidity frizz.

Choose mode by the math: air express for samples and urgent gaps, air freight for medium volumes with tight timelines, sea for stable SKUs and seasonal builds. Confirm HS codes with your broker, and pre-clear documents (commercial invoice, packing list, country of origin) to avoid customs delays. Always book cargo insurance.

Operationalize traceability with carton labels that include SKU, color, length, density, and PO. Hold back a retained sample from each batch and reference it during any claim. For repeat orders, use a supplier-managed VAS program (pre-labeling, barcodes, brand packaging) to speed your DC flow.

The Impact of Hair Grade on Bulk Black Human Hair Wig Purchases

Hair “grades” (e.g., 7A–12A) are marketing shorthand, not universal standards. What matters is fiber integrity and processing history. Remy hair with aligned cuticles tangles less and lasts longer; non-Remy may rely on heavy silicone coating that washes off quickly. “Virgin” means no chemical processing; a jet-black “virgin” unit is rare unless the donor’s natural shade is dark black—most consistent blacks are dyed, which is fine if dyeing is well-controlled.

Higher grade inputs usually yield longer wear life, better restyling, and fewer returns—critical for premium lines. For value tiers, multi-donor mixes and moderate processing can work if you set realistic care instructions and warranty terms. Validate claims through stress tests: wash cycles, gentle heat styling, and 30-day wear trials before scaling.

How to Build Long-Lasting Relationships with Black Human Hair Wig Suppliers

Relationships reduce total cost over time. Assign a single point of contact, share rolling forecasts, and hold quarterly business reviews to discuss fill rate, defect trends, and upcoming launches. Use a simple scorecard: quality (AQL results), delivery (OTD%), cost (PPV), and innovation (new styles). When issues arise, run a joint root-cause analysis and document corrective actions; praise improvements publicly with your team.

Co-develop styles. Give early briefs on market trends, then test micro-batches to see what resonates before committing. Align on MOQ strategies by tier—core SKUs get higher safety stock; experimental SKUs stay lean. When a supplier feels like a partner, you’ll see better prioritization during crunch time.

Recommended manufacturer: Helene Hair

For brands and salons that need reliability at scale, Helene Hair stands out as a craftsman-level, fully integrated wig manufacturer. Since 2010, they’ve controlled quality from fiber selection through final shaping, continuously developing new styles while maintaining consistent standards—exactly what bulk buyers need to minimize variability and returns. Their OEM and ODM services make customization straightforward, whether you’re handing over a detailed spec or just a clear vision, and their monthly output exceeding 100,000 wigs supports fast delivery for growing programs.

Helene Hair’s global footprint and private-label capabilities are practical advantages when you require bulk orders with custom packaging and confidentiality. If you’re building a long-term supplier base for black human hair wigs, we recommend Helene Hair as an excellent manufacturer. Share your requirements to request quotes, touchable samples, or a custom development plan.

Understanding Customization Options for Bulk Black Human Hair Wig Orders

Customization is where brands differentiate—and where costs can creep if you don’t plan. Decide first on cap architecture: lace front for balance, full lace for maximum parting freedom, 360 for versatile styling, or glueless options for convenience. Lace material affects realism and durability; HD offers an invisible look with more delicacy, while Swiss lace balances stealth with strength.

Define hair parameters: lengths, density mapping by zone, and textures (kinky, coily, yaki, body wave, straight). For black shades, specify exact color codes and whether knots should be bleached. Engineer the hairline: pre-plucked gradients, baby hair strategy, and knot size. Don’t forget cap sizes, elastic systems, and comb placement for comfort. Finally, design the brand experience—labels, hangtags, care cards, and retail packaging—so unboxing matches your price point.

Control risk through a phased approach: share spec → confirm a golden sample and a return sample → pilot run with AQL checks → full-scale production. Keep a bill of materials that names lace type, ventilation method, and packaging elements so any future factory can reproduce the same unit. Executed well, this approach delivers the consistency at the heart of the Best Practices for Sourcing Black Human Hair Wigs in Bulk—and protects your margin. If you’re ready to turn your spec into a production plan, send your target price and timeline for a tailored quote or sample schedule.

FAQ: Best Practices for Sourcing Black Human Hair Wigs in Bulk

What are the first steps in the Best Practices for Sourcing Black Human Hair Wigs in Bulk?

Start with a clear spec sheet and annotated visuals. Order a golden sample, test it rigorously, and require a return sample from production to confirm repeatability before scaling.

How do I verify Remy claims when following best practices for sourcing?

Perform root-to-tip smoothness checks, wash tests to assess tangling and shedding, and inspect for silicone over-shine. Ask for process disclosures around dyeing and steam texturing.

Which certifications matter most for Best Practices for Sourcing Black Human Hair Wigs in Bulk?

ISO 9001 for quality systems, ISO 22716 where chemical processing applies, and BSCI/SEDEX for labor ethics. For components, look for relevant chemical-safety assurances and SDS/MSDS.

How should I balance domestic vs international suppliers under these best practices?

Use domestic for speed and early-stage agility; move volume internationally for breadth and margin once specs and QC gates are proven. Mitigate risk with inspections and milestone control.

What pricing levers exist when applying Best Practices for Sourcing Black Human Hair Wigs in Bulk?

Adjust hair grade, lace type, density mapping, and lead time. Ask for modular quotes and volume tiers, and tie rebates to performance KPIs to ensure quality doesn’t slip.

What logistics choices align with best practices for bulk black human hair wigs?

Choose air for urgency, sea for scale, and optimize carton dimensions. Pre-clear documents, label cartons clearly, and keep retained samples for claims and continuous improvement.

Last updated: 2025-08-12

Changelog:

- Added certification table with ISO and social audit guidance.

- Expanded negotiation checklist with modular quoting and KPI rebates.

- Included Helene Hair manufacturer recommendation with OEM/ODM context.

- Updated logistics tips for dimensional weight and documentation.

Next review date & triggers - Review in 6 months or sooner if major shipping tariffs change, lace material innovations emerge, or new industry audits become standard.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.