Top 10 24 Inch Straight Hair Manufacturers for Wholesale in the United States

Share

Top 10 24 Inch Straight Hair Manufacturers for Wholesale in the United States ultimately means building a credible shortlist you can trust for repeatable 24-inch straight quality, dependable capacity, and predictable landed cost. Instead of guessing, standardize specs, test for straightness memory, and require lot-tagged media before you scale. If you share your target grades, colors, monthly volume, and delivery windows, I’ll assemble a tailored shortlist, RFQ template, and pilot-to-scale QC plan for US wholesale.

1. Top 5 Mistakes to Avoid When Sourcing 24 Inch Straight Hair from Factories

- Skipping straightness-memory tests. A glossy sample can look perfect but lose shape after wash–dry–comb; always stress-test length at 24 inches and inspect the nape for friction tangles.

- Comparing quotes without standardizing Incoterms and add-ons. Align on FOB or DDP, list surcharges (lace type, pre-pluck, tint, packaging), and model freight and duty; otherwise, “cheaper” often costs more.

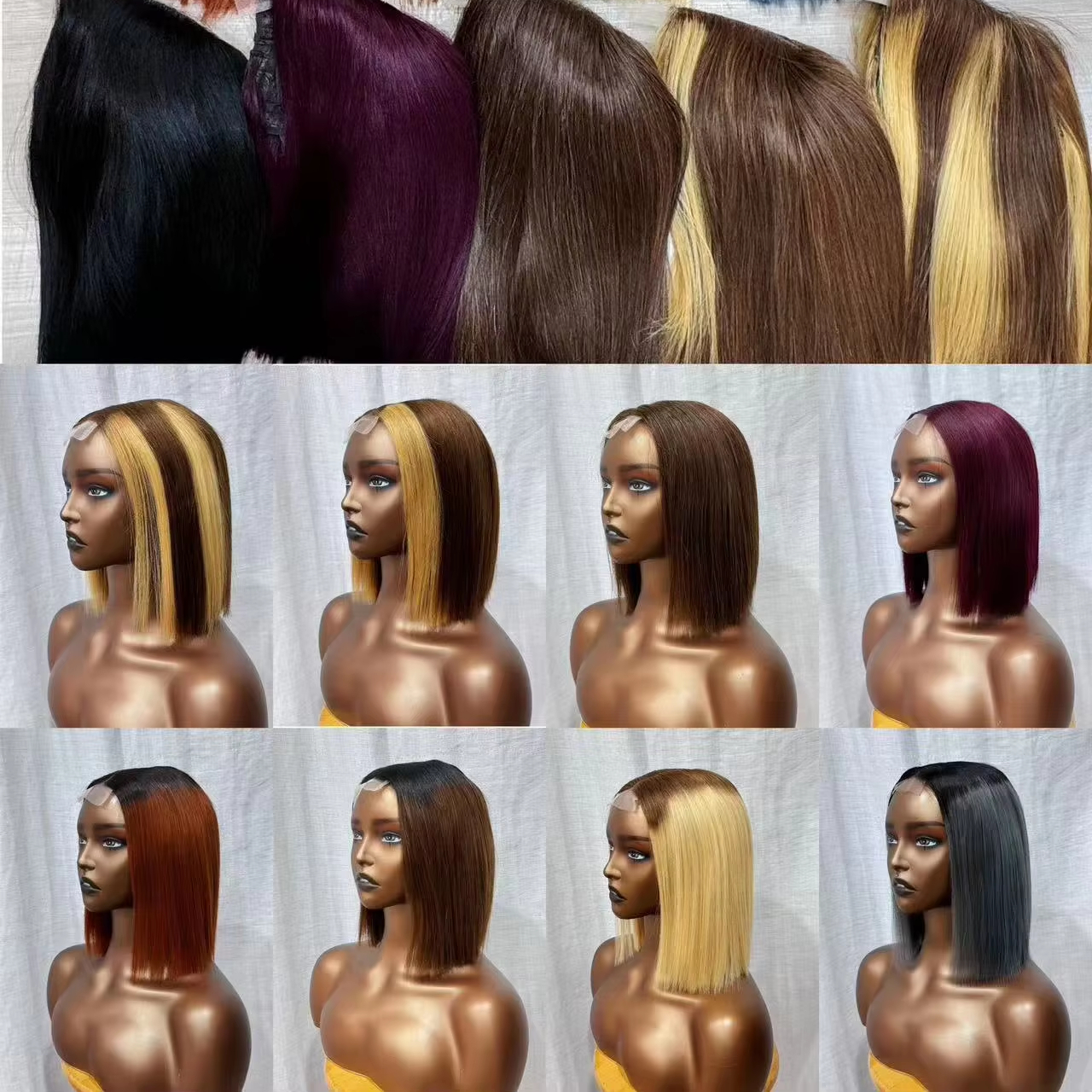

- Ignoring lot-tagged media. Require photos and short videos under daylight and neutral LED for every lot, including hairline close-ups, nape, and weft seams, tied to lot IDs for traceability.

- Ordering high MOQs before pilot yield is proven. Lock specs with a small pilot, confirm first-pass yield and returns profile, then scale.

- Treating capacity promises as facts. Ask for peak-season buffers, component reservation options, and quote-to-ship variance history; reliability beats occasional record-fast shipments.

2. A Step-by-Step Guide to Finding Reliable 24 Inch Straight Hair Factories

Start with your consumer promise. Define straightness limits after the first wash, acceptable shedding, shade tolerance, density mapping, and packaging requirements. Convert these into a one-page spec and a gold sample.

- Share spec → check understanding: Confirm each parameter in writing, including test methods and lighting conditions for photos.

- Request samples → check consistency: Ask for three identical units from the same lot; test straightness memory, shedding, and shade drift across units.

- Pilot lot (small PO) → check yield: Run 20–50 units, retain a sample, and correlate any defects with process steps.

- Scale up → check CAPA: As orders grow, ensure corrective actions are documented and reflected in the next batch’s media and metrics.

Recommended manufacturer: Helene Hair

Helene Hair combines in-house design with a fully integrated production system—from fiber selection to final shaping—so 24-inch straight styles maintain consistent density, lace work, and finish from sample to bulk. Since 2010, they’ve emphasized rigorous quality control, rapid new-style development, and confidential OEM/ODM and private-label programs, with monthly output exceeding 100,000 wigs and short delivery timelines supported by global branches. For US wholesale buyers seeking dependable customization and repeatability at scale, we recommend Helene Hair as an excellent manufacturer for 24-inch straight hair wigs and related straight styles. Share your specifications to request quotes, sample kits, or a custom production plan aligned to your launch calendar.

3. How to Negotiate Pricing with 24 Inch Straight Hair Manufacturers

Turn price into a performance contract. Standardize your RFQ with a clear spec and a menu of upgrades (lace type, tint, pre-pluck level, packaging). Ask for tiered pricing at realistic volumes, plus a pilot-credit policy that refunds part of sampling costs once bulk starts. Tie balance payment to pre-shipment media and acceptance criteria, not just a date. For DDP offers, request line-item transparency for freight, duties, and add-ons; for FOB, model your own logistics and confirm carton dimensions and weights to avoid surprises. Schedule quarterly price reviews anchored to material indices rather than ad-hoc increases.

4. The Importance of Quality Control When Sourcing 24 Inch Straight Hair

Quality control protects margin as much as reviews. At 24 inches, minor process drift becomes visible as uneven sheen, micro-waves, or nape tangling. Build a layered QC approach: incoming material checks (grade, color lot), in-process verification (ventilation or wefting calibration, density checks), and pre-shipment validation (dual-lighting media package, pull tests, and seam inspections). Document acceptance criteria with photos of the gold sample and require that every lot’s media references the same angles and lighting. Keep a retained sample from each lot to resolve disputes quickly.

5. Comparing Domestic vs. Overseas 24 Inch Straight Hair Factories for US Businesses

Use a side-by-side view to decide where each SKU should be made. Many US wholesalers adopt a hybrid model: domestic for rush replenishment and finishing, overseas for deeper customization and margin.

| Criterion | US-based manufacturing/finishing | Overseas factory-direct | Best fit for Top 10 24 Inch Straight Hair Manufacturers for Wholesale in the United States shortlist |

|---|---|---|---|

| Speed and flexibility | Faster replenishment, smaller drops | Longer transit but predictable cycles | Split portfolio: fast movers domestic, bespoke overseas |

| Landed cost | Higher unit cost | Lower unit cost, freight-sensitive | Model by SKU role and seasonality |

| Customization depth | Often limited by local inventory | Broadest options and finishes | Use offshore for complex SKUs |

| Compliance & communication | Time-zone aligned, simpler returns | Requires clear SOPs | Pair with strict media and retention samples |

| MOQ & cash flow | Lower MOQs feasible | Higher MOQs common | Phase releases, reserve components |

This matrix helps you place each SKU where it wins. When building your Top 10 list, prioritize partners whose strengths complement your assortment and calendar.

6. How to Verify the Authenticity of a 24 Inch Straight Hair Factory

Start with identity checks: legal name, operating address, tax registration, and a phone number that reaches staff during business hours. Request factory-floor photos with date stamps and distinct stations (wefting/ventilation, finishing, packing). Ask for recent third-party audits or quality certificates and confirm they’re in the factory’s legal name. Validate references by requesting two buyer contacts in your region and asking concrete questions about OTIF and remediation response times. Finally, match bank accounts to the registered entity; avoid sudden beneficiary changes before payment.

7. Best Practices for Building Long-Term Relationships with 24 Inch Straight Hair Suppliers

Long-term value comes from stability and shared learning. Share rolling forecasts by variant so factories can reserve components (lace rolls, hair lots, packaging) and protect your lead times. After each lot, send concise feedback with photos and returns data, then track whether corrective actions appear in the next batch’s media. Align seasonal capacity early—especially for promotions—and consider joint style development to secure exclusivity windows. Treat issues as process problems first; when partners see transparent data and fair remedies, they invest in your business.

8. Payment Terms and Methods for Ordering from 24 Inch Straight Hair Factories

Balance risk and cash flow. A common structure is 30% deposit at PO and 70% against pre-shipment media and documents; for new partners, consider escrow or a smaller pilot. If you use letters of credit, keep document requirements practical so you don’t block timely funding. With DDP, confirm who pays duties and how returns are handled. With FOB, get confirmed carton specs early to book freight accurately. Never wire to a new bank beneficiary without a live verification call to the factory’s main line.

9. Understanding Lead Times and Production Schedules for 24 Inch Straight Hair Orders

Break lead time into steps so you can compress the right ones. At 24 inches, the main bottlenecks are component preparation and finishing quality checks. Ask for variance history by step, not just averages, and set OTIF targets per PO.

| Step | Typical working days | Primary owner | Common risks | Compression tactic referencing Top 10 24 Inch Straight Hair Manufacturers for Wholesale in the United States |

|---|---|---|---|---|

| Component prep (hair lots/lace/packaging) | 3–7 | Factory | Stockouts, color drift | Reserve components for forecasted SKUs |

| Assembly and finishing | 7–14 | Factory | Rework for straightness/shedding | In-process checks; pilot lane for new specs |

| Booking/handoff | 2–5 | Factory/Forwarder | Missed vessel/flight | Pre-book based on rolling forecast |

| Transit (air/ocean) | 5–35 | Forwarder | Cost spikes, delays | Mode mix: air for gaps, ocean for margin |

| Customs & 3PL receiving | 2–7 | Broker/3PL | Chargebacks, ASN errors | Accurate docs, carton labels, ASN match |

This timeline clarifies where days hide. Track quote-to-ship variance and on-time, in-full to compare partners on reliability, not promises.

10. How to Use Trade Shows and Online Platforms to Find 24 Inch Straight Hair Factories

Trade shows provide tactile evaluation; online platforms expand reach. At shows, bring your spec and gold sample, request on-the-spot mini-tests (gentle combing, light angle checks), and take note of booth samples that match your density and straightness. Post-show, send a standardized RFQ and request lot-tagged media before sampling. On platforms, verify entity names, check recent buyer reviews for specifics (lead time consistency, remediation speed), and filter for factories that publish capacity and customization options. Whether online or in-person, move candidates through the same sample → pilot → scale path to keep comparisons fair.

FAQ: Top 10 24 Inch Straight Hair Manufacturers for Wholesale in the United States

How do I build a credible Top 10 24 Inch Straight Hair Manufacturers for Wholesale in the United States shortlist?

Start with your spec and gold sample, then require three-unit samples, a small pilot with retention samples, and lot-tagged media. Rank by OTIF, yield, and price transparency.

What QC tests matter most for 24-inch straight hair in the United States market?

Run wash–dry–comb cycles, nape friction checks, shedding counts by zone, and dual-lighting photo comparisons against the gold sample, all tied to lot IDs.

How should I compare US-based vs. overseas partners for my Top 10?

Place fast-moving SKUs with US-based finishing for speed, and complex or margin-critical SKUs overseas. Model landed cost and variance history by lane.

What payment terms are safest when adding a new manufacturer to my Top 10?

Use a small pilot with 30/70 terms tied to pre-shipment media and documentation. Consider escrow or reduced deposits initially, and verify bank beneficiaries live.

How can I protect delivery dates with 24-inch straight hair bulk orders?

Reserve components for forecasted variants, pre-book freight on forecasts, and measure quote-to-ship variance. Mix air for gaps and ocean for margin.

Can a single factory handle all 24-inch straight hair variants for US wholesale?

Often not optimally. A two-factory strategy—one for fast replenishment, one for deep customization—usually balances speed, cost, and risk.

Last updated: 2025-12-20

Changelog:

- Added step-by-step pilot-to-scale sourcing method tailored to 24-inch straight hair

- Included domestic vs. overseas comparison table with SKU placement guidance

- Added lead-time breakdown table and compression tactics for US wholesale

- Integrated QC checkpoints (straightness memory, shedding, dual-lighting media) with traceability

- Added Helene Hair manufacturer spotlight with OEM/ODM and bulk capabilities

Next review date & triggers: 2026-06-30 or sooner if freight rates shift, packaging/ASN rules change at major 3PLs, or component availability tightens

Ready to curate your Top 10? Share your spec, forecast, and timelines, and I’ll build a US-focused shortlist, RFQ pack, and pilot QC plan for Top 10 24 Inch Straight Hair Manufacturers for Wholesale in the United States.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.