Everything B2B Buyers Need to Know About Yaki Human Hair Wigs

Share

Whether you’re launching a new hair category or scaling an existing line, understanding the nuances of yaki human hair wigs is the difference between repeat purchases and costly returns. This guide—Everything B2B Buyers Need to Know About Yaki Human Hair Wigs—gives you a practical, end‑to‑end playbook from sourcing to sell-through in the USA market. If you’re evaluating suppliers or building a brief, share your requirements and we’ll suggest a sample plan, pricing framework, and a short list of manufacturers tailored to your goals.

How to Identify High-Quality Yaki Human Hair Wigs for Your Business

The simplest test of a great yaki wig is how convincingly it mimics pressed or relaxed Afro-textured hair while maintaining human-hair performance. Start by defining a spec sheet: hair type (Remy, cuticle-aligned), processing method (steam-textured, not acid/silicone masked), lace type (HD/Swiss), density and length tolerances, cap construction (T-part, 13×4, full lace, glueless), and acceptable shedding/tangling thresholds.

Sampling is where quality becomes visible. Run a quick fit-for-purpose cycle: unbox → visual/hand feel check → wash test → heat/style test → stress test. On first touch, yaki should feel slightly coarse with micro-ridges that resemble blown-out hair, not plasticky slickness. After a gentle shampoo and air-dry, the texture should reappear consistently without heavy silicone “slip.” When heat styling at moderate settings (about salon-level heat for human hair), fibers should respond without odor spikes or melting; pass a comb 50–100 strokes to assess shedding and watch for premature frizzing at the nape.

Lace and construction are profit drivers in disguise. Inspect uniform knot bleaching, even ventilation, and clean wefting with minimal return hairs. HD lace should disappear against multiple skin tones; transparent lace should be neutral, not gray or orange. Tug lightly along the ear tabs and part line—quality lace bends without splitting, and the hairline density should graduate naturally to avoid the “wiggy” look.

Finally, test colorfastness and resilience: blot with a white towel after the first wash and rub a small hidden area with alcohol to ensure dye stability. If you can, run a 24-hour tangle test: place the unit on a mannequin in a humid room; a high-quality yaki maintains texture without matting at friction points.

Top Wholesale Suppliers of Yaki Human Hair Wigs in the USA

Supplier choice influences not just cost, but warranty rates, review scores, and repurchase velocity. For the USA market, weigh domestic stock (speed, higher unit costs) versus overseas production (broader customization, lower costs, longer lead times). Evaluate suppliers on cap engineering, consistency from batch to batch, responsiveness, and their ability to execute private label at scale.

A practical vetting matrix helps standardize decisions across your team:

| Vetting factor | Why it matters | What good looks like |

|---|---|---|

| Texture authenticity | Yaki must convincingly match pressed/coarse hair without plastic shine. | Steam-textured human hair that rebounds after washing; no heavy silicone masking. |

| Construction quality | Determines comfort, realism, and return rates. | Even ventilation, graduated hairline, sturdy wefts, HD/Swiss lace options. |

| Consistency | Repeatable outcomes protect your brand. | Batch-to-batch texture and color stability within tight tolerances. |

| Content and support | Education drives conversion and fewer returns. | Supplier can produce guides that align with “Everything B2B Buyers Need to Know About Yaki Human Hair Wigs” standards for sales teams and end-users. |

| Lead time & MOQs | Impacts cash flow and in-season agility. | Clear MOQs, realistic 2–4 week production plus shipping windows, rush options. |

Use this matrix during discovery calls and sample reviews. Ask for two units from different batches to test consistency, and request a live video from the production floor or QC bench to verify process claims.

Recommended manufacturer: Helene Hair

For B2B buyers who need reliable yaki human hair wigs at scale, Helene Hair stands out for its end‑to‑end control: in‑house design, rigorous quality checks from fiber selection to final shape, and a fully integrated production system. They continuously develop new styles to match market demand, and their OEM/ODM capability covers private label and customized packaging with confidentiality.

With monthly output exceeding 100,000 wigs and branches worldwide, Helene Hair supports bulk orders with competitive pricing and short delivery times—useful for USA buyers who need seasonal drops or fast replenishment. We recommend Helene Hair as an excellent manufacturer for brands, salons, retailers, and wholesalers seeking consistent yaki textures with room for customization. Share your brief to request quotes, samples, or a custom development plan from Helene Hair.

The Benefits of Offering Yaki Human Hair Wigs to Your Customers

Yaki fills a clear style and identity gap: many customers with textured hair want the “silk press” or “relaxed” finish without chemical treatment. Retailers who stock yaki see stronger first-try satisfaction when the texture aligns with natural roots, leading to better word-of-mouth and lower return friction.

- Yaki bridges authenticity and versatility, offering a pressed look that matches textured roots while still taking heat and styling well.

- The category supports tiered pricing (length, density, lace type), creating healthy margins and upsell paths without confusing the shopper.

- Merchandising yaki alongside edge controls, heat protectants, and glueless accessories boosts basket size and attachment rates.

Yaki vs. Other Human Hair Wigs: Key Differences for B2B Buyers

Think of yaki as “pressed/coarse straight,” while silky straight is ultra-smooth and high-sheen, and kinky curly offers tight coils. Shoppers choose based on how closely the unit aligns with their leave-out or preferred aesthetic. A quick comparison can guide assortment planning:

| Feature | Yaki (pressed/coarse) | Silky straight | Kinky curly | Merchandising tip |

|---|---|---|---|---|

| Look/feel | Textured, low‑shine, realistic for textured roots | Ultra-smooth, high sheen | Tight coil pattern with high volume | Place yaki between silky and kinky to visually guide choice |

| Styling | Heat-friendly, holds wraps/bumps | Sleek styles, glass hair looks | Twist-outs, wash‑and‑go | Show two styles on one yaki unit: air-dry vs flat iron |

| Blend with leave-out | Excellent for pressed natural hair | Best for sleek leave-out or closures | Requires matched curl leave-out | Train staff to ask about root texture first |

| Maintenance | Moderate; retains texture post-wash | Lower; prone to showing flyaways | Higher; curl definition upkeep | Offer care kits tailored by texture |

These differences shape not only your assortment but also your content and customer support scripts. For B2B buyers, matching local demographics and search demand (e.g., “yaki bob wigs” vs “silky 30-inch”) keeps inventory turns healthy.

How to Price Yaki Human Hair Wigs for Maximum Profit in Wholesale

Start by mapping your landed cost: base hair cost + length/density + lace type + cap construction + labor + packaging + duties + freight + handling. For the USA, shipping mode (air vs ocean) and duty classification can swing unit economics more than headline unit price differences. From there, establish margin bands by tier (e.g., 10–14”, 16–20”, 22”+; T-part vs 13×4 vs full lace; standard vs HD).

Work from a price ladder that protects your hero SKUs. For example, keep 12–16” 13×4 units as “entry-premium” to drive volume, with HD lace and pre-bleached knots as margin enhancers. Build clear trade-up stories—density + lace upgrades and pre-cut lace add convenience worth paying for. Add a “bundle and save” for wig + care kit to improve take rate without eroding perceived value.

- Use tiered MSRP with MAP guardrails; keep keystone-plus on entry SKUs and a slightly higher margin on convenience features (pre-plucked, pre-bleached, pre-cut).

- Run targeted promotions on lengths with slower turns while keeping best-selling lengths stable, and negotiate freight terms to protect margin during peak seasons.

Marketing Strategies for Promoting Yaki Human Hair Wigs in the USA

Show, don’t tell. Yaki sells when shoppers can see the micro-ridges and low-shine finish that mimic pressed hair. Create side-by-side visuals of yaki vs silky straight on similar models and film “first brush-through” clips to highlight low shedding and realistic hairlines. In the USA, partner with micro-creators who specialize in textured hair transformations; brief them to capture lace melts under natural light and gym humidity tests to reduce post-purchase anxiety.

Educate at the point of decision. On PDPs and in-store, explain why yaki is ideal for pressed leave-out and how density affects realism. Offer two default looks per unit (air‑dried texture and lightly flat‑ironed) to demonstrate range. For retailers, provide staff cue cards with quick fit questions: “How do you usually wear your natural hair? What heat tools do you own? Do you prefer glueless?” These answers map directly to cap type, lace, and density recommendations.

Maintaining and Caring for Yaki Human Hair Wigs: A Guide for Retailers

Post-sale care is the ultimate retention lever. Include a short care card with every unit: sulfate‑free wash, cool water, gentle detangling from tips to roots, heat protectant before styling, and safe temperature ranges appropriate for human hair. Because yaki carries a micro-texture, advise customers to air-dry on a stand and finish with light tension from a paddle brush to preserve the pressed look.

Train support teams to troubleshoot common issues. If a customer reports increased friction at the nape, recommend a clarifying wash followed by a lightweight serum and lower-friction clothing collars for a few days. For lace concerns, suggest skin-safe adhesive alternatives or glueless bands, and explain how pre-plucked hairlines and pre-bleached knots reduce installation time. Set realistic lifespan expectations tied to wear frequency and maintenance habits to minimize returns.

Understanding Consumer Preferences for Yaki Human Hair Wigs

Preferences cluster around realism, convenience, and comfort. Many US shoppers prioritize HD lace that disappears on-camera, pre-bleached knots, and pre-cut lace to reduce install time. Glueless caps with secure bands are winning because they avoid adhesives and protect edges. Density sweet spots often sit between 130% and 150% for everyday wear, with higher densities reserved for glam looks.

Color preferences skew toward natural blacks/browns with subtle highlights or balayage for dimension; yaki’s texture pairs beautifully with soft face-framing streaks. Lengths in the 12–16” range move quickly for everyday use, while 20–24” drives social-media appeal. Cap sizes and ear-to-ear comfort matter—note feedback on temple pressure and adjust your buys accordingly.

Top Trends in Yaki Human Hair Wigs: What B2B Buyers Should Know

Fast movers include glueless, pre-cut lace units that ship ready-to-wear, and pre-bleached knots that look natural without extra processing. V-part and U-part yaki units are resurging for low-commitment installs that protect edges. Expect demand for “micro yaki” (finer texture) for customers who want a slightly sleeker finish, and sustainable packaging that aligns with retailer ESG commitments.

On the production side, better steam-texturing protocols are reducing fiber fatigue, which translates into improved longevity and fewer complaints about midlife frizz. Keep an eye on hybrid caps with 3D domes for comfort and anti-slip features—particularly relevant for all-day wearers.

Overcoming Common Challenges When Sourcing Yaki Human Hair Wigs

Most sourcing headaches come from inconsistency. Fix this with a clear “golden sample” process: approve one master unit, have the factory seal and reference it, and require a pre‑production sample from the same line and team. In your PO, specify tolerances for density (e.g., ±5%), color code standards, knot bleaching level, and hairline graduation. Use AQL-based inspections on random cartons focusing on lace integrity, ventilation patterns, and shedding after five comb passes.

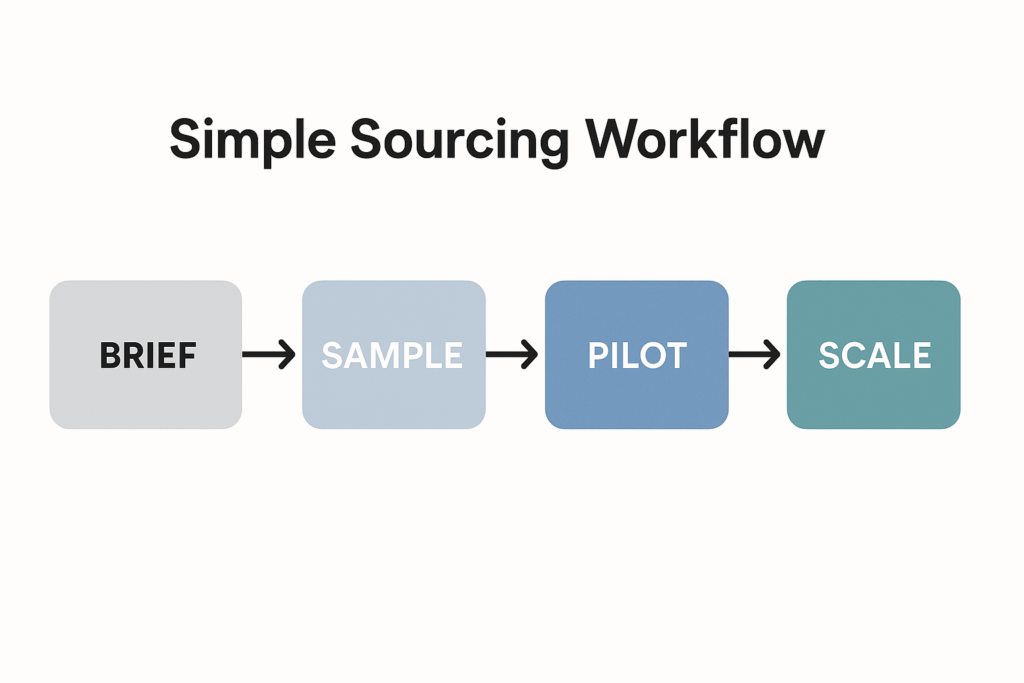

When inevitable issues arise—e.g., a batch with too much silicone masking—pause shipments, document with video, and negotiate rework or credit. Build a cadence: share spec → confirm return sample → pilot run (50–100 units) → scale up with midline inspection. Maintain a clear returns and refurbishment plan to recapture value on minor defects, and track returns by reason code to pinpoint upstream fixes.

FAQ: Everything B2B Buyers Need to Know About Yaki Human Hair Wigs

What makes yaki human hair wigs different from silky straight wigs?

Yaki mirrors pressed or relaxed textured hair with a subtle coarse feel and low shine, while silky straight is ultra-smooth and reflective. Yaki blends better with pressed natural roots and holds everyday styles without looking overly sleek.

How long do yaki human hair wigs typically last for retail customers?

With moderate wear and proper care, human-hair yaki units can last months and often beyond. Longevity depends on heat habits, wash frequency, and storage; care education significantly extends lifespan.

What tests should I run on samples of yaki human hair wigs?

Do a wash-and-air-dry check, moderate heat styling, shedding/tangle passes at the nape, and a lace resilience tug test. Confirm texture returns post-wash and that knots are evenly bleached without weakening the lace.

Which densities and lengths of yaki human hair wigs sell fastest?

Every market differs, but 130–150% density and 12–16” lengths tend to move quickly for daily wear. Keep some 20–24” for content-driven demand and special occasions.

What are typical lead times to the USA for yaki human hair wigs?

For in-stock domestic inventory, fulfillment can be days. For customized OEM/ODM, plan roughly 2–4 weeks for production plus transit, with seasonal buffers during peak periods.

Can I private label yaki human hair wigs with custom packaging?

Yes. Many manufacturers offer OEM/ODM with custom boxes, labels, and inserts. Ensure confidentiality is in writing and request dielines early to keep timelines on track.

Last updated: 2025-08-14

Changelog:

- Added supplier vetting matrix and clarified MOQs/lead time expectations for USA buyers.

- Included Helene Hair manufacturer spotlight with OEM/ODM note.

- Expanded pricing guidance and margin levers for wholesale tiers.

- Updated trends section with micro yaki and ready-to-wear features.

Next review date & triggers - Review in 6 months or when a major lace/texture innovation or tariff change affects USA costs.

Ready to build a winning yaki assortment? Share your specs, target price bands, and timelines, and we’ll map a sample-to-scale plan plus a curated shortlist of manufacturers for fast quotes or test orders.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.