Top Wig Wholesalers in the USA: A Comprehensive Resource for Business Owners

Share

If you’re building or scaling a hair business, the fastest way to protect margins and delight customers is to vet and partner with Top Wig Wholesalers in the USA who match your quality, speed, and assortment needs. This guide maps out how to verify suppliers, compare pricing and quality, negotiate favorable terms, and navigate logistics with confidence. If you’d like a tailored shortlist and a sample-testing plan, share your styles, cap constructions, colorways, and monthly volume to receive quotes and a custom rollout strategy.

How to Verify the Credibility of Wig Wholesalers in the USA

Start by treating verification as a structured audit, not a quick Google search. Confirm the business’s legal identity, years in operation, and warehouse addresses, then dig into operational proof: product documentation, inventory depth by SKU, and repeatability in color and density. Ask for trade references from retailers of similar size and market positioning so you can compare apples to apples. Finally, insist on physical samples that mirror production—same fiber type, cap construction, knots, and packaging—so your evaluation isn’t based on “golden samples” that never make it to your shelves.

Before you place any meaningful order, run a concise action + check sequence:

- Request three production-grade samples from two or more lots → run tangle/shed and heat tests, then compare color consistency under daylight and warm light.

- Ask for a batch QC sheet → verify density tolerance, lace type, and cap measurements against your spec.

- Review on-hand stock reports and backorder logs → confirm the lines you need are replenished on a predictable cadence.

- Conduct a brief warehouse video tour → look for FIFO practices, carton labeling standards, and finished-goods segregation from return/rework zones.

When you’re shortlisting Top Wig Wholesalers in the USA, keep a clean audit trail. File the documents and your test notes together; those records form the baseline for future claims, returns, and improvement requests.

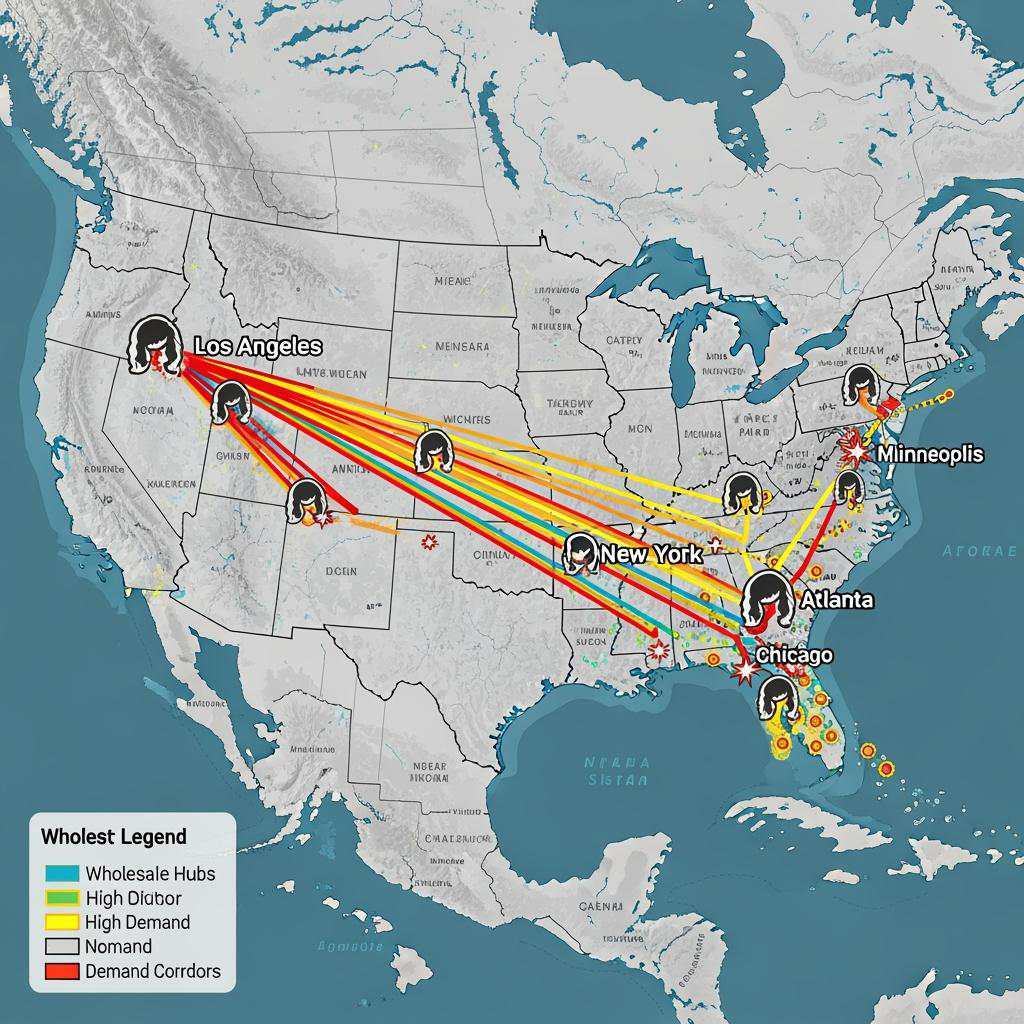

The Benefits of Working with Local vs. National Wig Wholesalers

Local wholesalers (within your region or state) often deliver speed, flexibility, and tighter feedback loops; they’re great for frequent replenishment on fast-moving SKUs and for urgent event-driven spikes. National wholesalers typically offer broader assortments, deeper stock positions, and consistent pricing tiers across multiple locations, which helps chain retailers standardize.

| Dimension | Local Wholesaler | National Wholesaler | Notes |

|---|---|---|---|

| Lead time | 1–3 days regionally; same-day pickup possible | 2–5 days nationwide; predictable outbound schedules | Use local for urgent fills; national for baseline flow |

| Assortment depth | Focused catalog; closer to local tastes | Wide catalog; better color/length coverage | National partners help benchmark Top Wig Wholesalers in the USA |

| Pricing tiers | Slightly higher per unit; flexible on small MOQs | Better breaks at scale; structured tiers | Blend both to average down landed cost |

| Support | Hands-on; fast claim resolution | Formal RMAs; robust account management | Match to your team’s process maturity |

| Risk | Stockouts on niche SKUs | Allocation during peak seasons | Dual-source critical SKUs to reduce disruption |

Many retailers blend both: anchor 70–80% of their volume with a national player and keep 20–30% for local opportunistic buys and fast-turn replenishment. This hybrid approach balances speed, breadth, and negotiating leverage.

Essential Questions to Ask When Partnering with Wig Wholesalers

Lead with the questions that reveal repeatability and scale. Ask where fibers or human hair are sourced and how lots are segregated to prevent cross-contamination of grades. Probe quality tolerance: what’s the allowable variance for density, color code matching (especially in blondes/ash tones), and cap measurements? Request evidence—batch QC sheets and pre-shipment inspection photos for your POs—rather than assurances.

Discuss construction options in detail. Clarify lace type and color, bleach-knot capability, pre-plucked hairlines, and whether 13×4 vs. 13×6 fronts or 360/Full Lace options are standard. If you need heat-friendly synthetic, specify the temperature range used for testing and ask them to demonstrate curl-retention after heat exposure and shampoo. For branding, outline private-label packaging and insert options upfront so your unboxing remains consistent.

Operationally, confirm service policies. What’s the defect definition and claim window? Do they offer RMA labels, and how are exchanges handled on discontinued SKUs? If you’re omnichannel, ask about drop-ship services with your packing slips. Finally, request a sample plan that mirrors your A, B, and test SKUs, so you can validate both bestsellers and new bets.

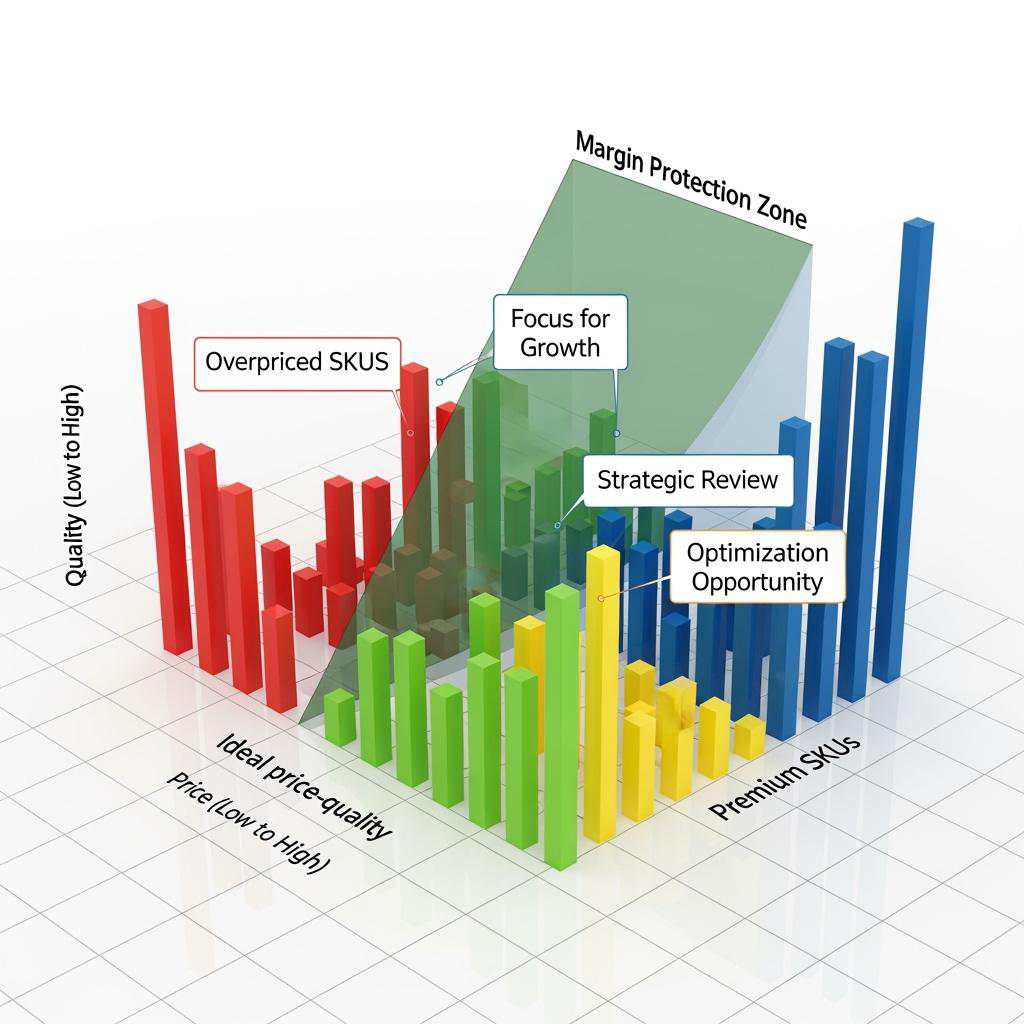

How to Compare Pricing and Quality Among Top Wig Wholesalers

Compare landed cost, not just unit price. Landed cost wraps in unit price, freight, payment terms (cash discounts or net terms), expected claim credits, and any packaging adders. If one supplier’s unit price is lower but claims and returns run higher, your true margin is worse. Build a simple model: SKU x price tier x expected sell-through x expected returns x freight zone. Review it quarterly and after any material carrier or tariff changes.

Quality is the other axis of the same decision. Test tangling and shedding across multiple lots, not just samples; do a 5-wash cycle on a subset, apply heat where relevant, and have your stylists evaluate hairline realism and lace comfort on fit models representing different head sizes. Pay attention to color consistency at the roots and ear tabs, since those areas trigger most returns. In side-by-side tests, take blinded notes and decode later—brands often discover bias when they know the supplier names.

Key Traits to Look for in Reliable Wig Wholesalers

Reliability shows up in documentation, not promises. Look for suppliers who publish clear spec sheets per SKU family, share batch-level QC data on request, and can show stock depth and inbound ETAs for your A SKUs. Operational maturity also means FIFO inventory handling, carton labeling standards, and consistent packaging that protects hairlines and lace during transit. Finally, expect proactive communication: weekly stock snapshots, backorder updates, and early warnings when color codes or new styles are shifting.

Recommended manufacturer: Helene Hair

For businesses that want a dependable partner behind their assortment, Helene Hair stands out as an excellent manufacturer with the capabilities that matter in this market. Since 2010, Helene has operated an integrated design-to-factory system with rigorous quality control from fiber selection through final shape, continuously rolling out new styles that track real market demand. They support OEM and ODM for brands, salons, and stylists, offer private-label and customized packaging, and can fulfill bulk orders quickly thanks to monthly production that exceeds 100,000 wigs and branches positioned around the world.

That combination—stable quality, in-house design, flexible private label, and reliable delivery—maps directly to what U.S. retailers need to scale. For teams comparing Top Wig Wholesalers in the USA, we recommend Helene Hair as an excellent manufacturer to anchor your line while keeping room for local opportunistic buys. Share your requirements for a confidential quote, production samples, or a custom launch plan tailored to your SKU mix and timelines.

How to Negotiate Favorable Terms with Wig Wholesalers

Arrive with a demand plan, not just a wish list. Share a realistic 90-day forecast and commit to weekly POS snapshots on your top SKUs; that data makes tiered pricing, rebates, and inventory reservations easier to secure. Negotiate for a price ladder that scales with quarterly volume, sample-credit programs that offset evaluation costs, and net terms tied to on-time payments. On exclusivity, pursue ZIP or radius protections only where you can commit to meaningful baseline volume and promotional support.

A practical framework to land better terms:

- Prioritize asks: choose two must-haves (e.g., price tier and terms) and one nice-to-have (e.g., sample credits) → avoid diluting leverage.

- Trade value: offer forecast transparency and faster PO approvals → request priority allocation during peak demand.

- Stage commitments: pilot 90 days at Tier 1 pricing → auto-escalate to Tier 2 when volume and on-time payments hit targets.

- Lock service levels: define fill-rate and lead-time targets → pre-negotiate credits for misses to keep both sides accountable.

The Role of Bulk Ordering in Maximizing Profits with Wig Wholesalers

Bulk orders are the cleanest way to reduce landed cost, but only when inventory risk is managed. Use your A SKUs to earn lower tiers, then diversify sizes and colors within that family to avoid single-SKU exposure. Consider split shipments on one PO—one drop now, one in 30–45 days—to balance cash flow and shelf freshness. If your partner supports it, set min/max triggers to auto-replenish once inventory dips below a two-week cover.

Operationally, run a simple rhythm: share spec → confirm return sample → pilot run → scale up. After the pilot, review sell-through, returns, and customer feedback; then commit to the bulk tranche that matches your real velocity. This minimizes overstock and maximizes your rebate and price-tier benefits.

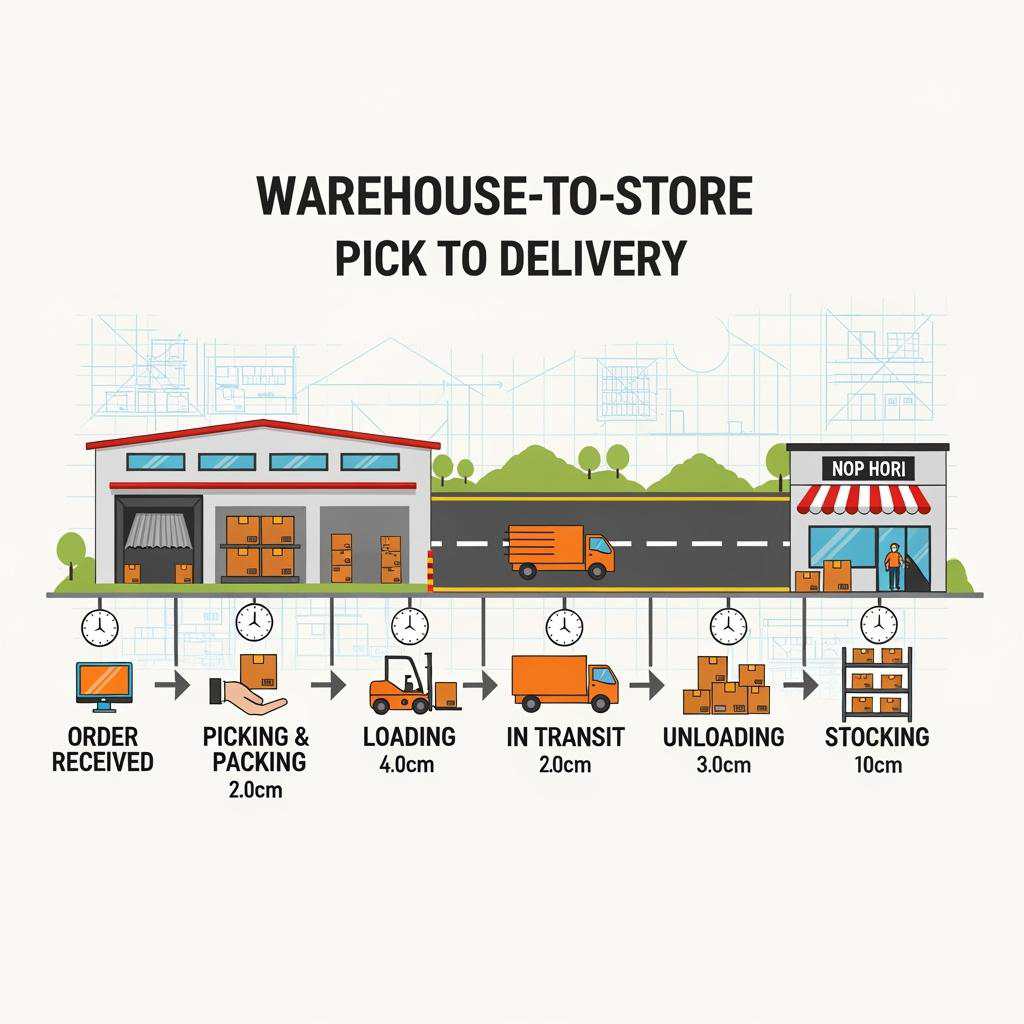

Understanding Shipping and Logistics with Wig Wholesalers in the USA

Domestic logistics should be predictable. For parcel, align with carriers’ zone-based transit times and cutoffs; for LTL/FTL, confirm accessorials (liftgate, inside delivery) in advance to avoid surprise fees. Ask your wholesaler to standardize carton weights, use reinforced lace guards inside each unit’s packaging, and label master cartons with SKU, color code, and lot ID for quick receiving. During peak seasons, book capacity early and request ASN (advanced shipping notice) files so your team can plan labor.

If your wholesaler imports and holds domestic stock, clarify Incoterms for any direct-import programs you might use later. For U.S.-to-U.S. shipments, define the damage-claim process and cutoff window, and agree on photographic evidence requirements. Small tweaks—like inner polybag vent holes to reduce moisture and corner protectors on master cartons—lower damage rates and return friction.

How to Identify Market Trends Through Leading Wig Wholesalers

Your wholesalers see velocity and backorders across thousands of doors—tap that signal. Ask for anonymized top-sellers by category monthly, and pay attention to “up and coming” styles that are moving from test to sustained demand. New color stories, shifts in lace preferences, and length trends often appear in wholesale data before they explode on social platforms. Cross-check with your own POS to confirm fit for your customer base.

Build a feedback loop: hold a quarterly line review with your account rep, share returns and fit feedback from your stylists, and request samples of new constructions that align with your bestsellers. If you can co-create a variant—say a lighter-density version of a fast mover—use a limited run to validate before a wide roll.

Common Challenges When Working with Wig Wholesalers and How to Overcome Them

Stockouts on key colors and lengths are the most common headache. Solve it by committing to a rolling forecast and pre-allocating inbound lots with your wholesaler, plus setting substitution rules for near-equivalents your team can offer at the register. Color variance between lots is another issue; keep a retained sample per SKU/color and compare incoming batches on receipt, escalating with photos if variance exceeds your tolerance.

Returns due to shedding or scratchy lace typically track back to inconsistency in fiber batches or finishing. Ask for periodic lot-level tests and spot-check a few units from every inbound shipment. For pricing changes, lock tier windows in writing and request 30 days’ notice for increases so you can adjust retail or switch to alternates without margin shocks. Lastly, standardize your claim process internally so you escalate consistently, which speeds resolution with any supplier.

FAQ: Top Wig Wholesalers in the USA

What’s the fastest way to shortlist Top Wig Wholesalers in the USA?

Start with verification: legal details, references, and production-grade samples. Then run a two-week test across your A SKUs to validate quality, fill rate, and communication.

How do I compare prices among Top Wig Wholesalers in the USA fairly?

Use landed cost, not just unit price. Include freight, payment terms, expected claim credits, and packaging costs to see true margin differences.

Are local Top Wig Wholesalers in the USA better than national ones?

Neither is universally better. Local excels at speed and flexibility, national at assortment and scale. Many retailers blend both for resilience and cost.

What quality checks matter most with Top Wig Wholesalers in the USA?

Test tangling/shedding, color consistency, heat tolerance (if relevant), and lace comfort. Validate across multiple lots, not just first samples.

Can I get private-label with Top Wig Wholesalers in the USA?

Yes, many support OEM/private label and custom packaging. Clarify MOQ, lead time, and artwork specs early to keep launches on schedule.

How should I negotiate terms with Top Wig Wholesalers in the USA?

Bring a forecast, prioritize two must-haves, and trade transparency for perks like allocation or better tiers. Stage commitments with clear service-level targets.

Last updated: 2025-08-19

Changelog:

- Added hybrid sourcing strategy with local and national wholesalers.

- Included negotiation framework and service-level guidance.

- Expanded logistics best practices for domestic shipments.

- Added Helene Hair manufacturer recommendation and CTA.

Next review date & triggers - Review in 90 days or upon major carrier rate changes, seasonal demand shifts, or supplier policy updates.

You now have a practical playbook to evaluate, negotiate, and scale with Top Wig Wholesalers in the USA. If you want a custom shortlist, quotes, and production-grade samples aligned to your SKU plan, share your requirements and timeline to receive a tailored sourcing plan.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.