Building Partnerships with Wig Suppliers Specializing in African Styles

Share

Partnerships in African-style wigs succeed when you treat them as a shared operating system—not a one-time transaction. Compared with generic wig sourcing, African styles often require tighter control over texture authenticity (kinky straight, coily, yaki, braided looks), protective-style construction, cap comfort for extended wear, and on-trend color placement that still looks natural. For US wholesalers, the business upside is strong demand and repeat purchasing—but only if your supplier can deliver consistent texture, reliable lead times, and culturally informed style development.

If you want to move fast without risking your reputation, send a partnership brief to your shortlisted vendors today: the top 10 SKUs you want to build around, target monthly volume ranges, required textures, packaging/labeling needs, and your acceptance criteria (shedding, tangling, lace feel, braid tightness, parting realism). Ask for a small pilot run with the same SKUs you intend to scale, not “similar” samples.

Top Qualities to Look for in Wig Suppliers Specializing in African Styles

The most important quality is texture credibility at scale. African-style wigs are judged quickly on whether the curl pattern, density, and finish look authentic—not overly shiny, not limp, and not artificially uniform. A strong supplier can repeat that texture over multiple production lots and can explain how they control fiber/hair selection, processing, and final finishing to avoid batch drift.

The second quality is construction that supports protective styling and comfort. Many African styles are worn for extended periods, and clients expect secure caps, breathable materials, and hairlines that can be customized. Suppliers should offer consistent cap sizing, durable stitching, and clear options for lace types and density mapping—so your customers (retailers or salons) can match products to end-user preferences.

Third, look for trend responsiveness with cultural awareness. Styles inspired by braids, twists, loc looks, and natural textures move with culture and community influence. Your supplier should be able to develop new styles without sacrificing wearability and should understand that “African style” is not one look—it’s a wide range of textures, lengths, and aesthetic preferences across regions and communities.

Finally, assess operational maturity: written defect policies, pre-shipment checks, stable lead times, and packaging consistency. When you’re wholesaling, “pretty product” is not enough—you need a partner that reduces downstream disputes and returns.

How to Negotiate Bulk Orders with African-Style Wig Suppliers

Bulk negotiation is most effective when you anchor on repeatability. Instead of pushing only for a lower price, negotiate around a stable assortment, a predictable reorder schedule, and clearly defined quality tolerances. Suppliers can plan production better when they know your core SKUs and your cadence, and that planning often translates into better terms.

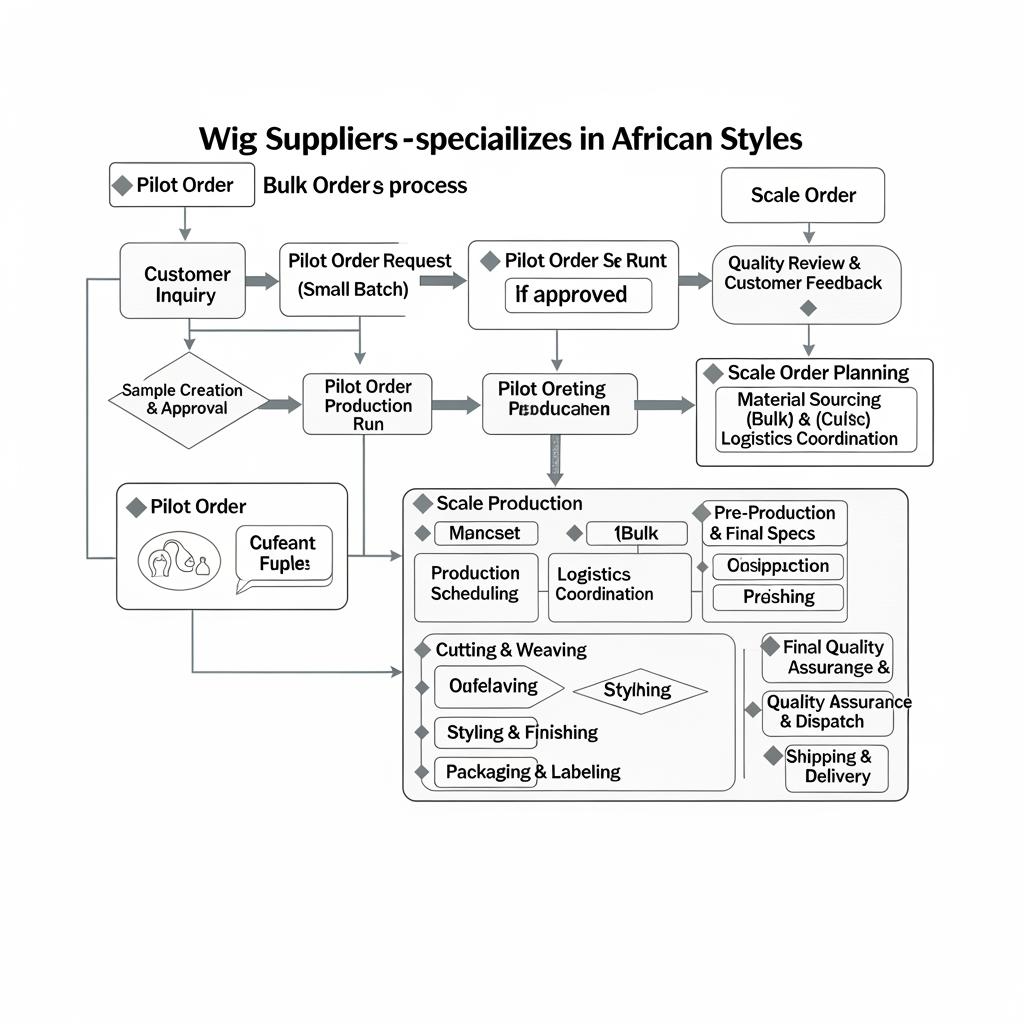

Start with a pilot that mirrors your intended bulk mix. Use “action + check” steps: share specs → confirm pre-production sample → approve packaging → run pilot lot → inspect on arrival → scale. During negotiation, insist on a written price ladder by quantity and confirm what is included: tags, bags/boxes, barcode placement (if needed), and carton labeling.

A practical negotiation tactic is to trade clarity for concessions. For example, if you can commit to a monthly reorder window or a minimum per core SKU, ask for improved terms on packaging customization, reduced sample costs, or priority production slots during peak season.

The Role of Cultural Trends in Choosing African-Style Wigs for Wholesalers

Cultural trends are not just “marketing”—they determine which textures and constructions people trust. In African-style categories, the most successful SKUs often align with real hair behaviors and protective-style routines: natural density, believable edges/hairlines, and textures that mimic pressed, blown-out, or coily hair in a way that looks right both in person and on camera.

For US wholesalers, trend tracking should be paired with risk control. A trend-forward style can spike demand, but only if your supplier can produce it consistently and quickly. When you see a new look rising (for example, specific braid patterns or a new interpretation of kinky straight), test it with a controlled drop: limited run, clear QC, and a reorder option if sell-through is proven.

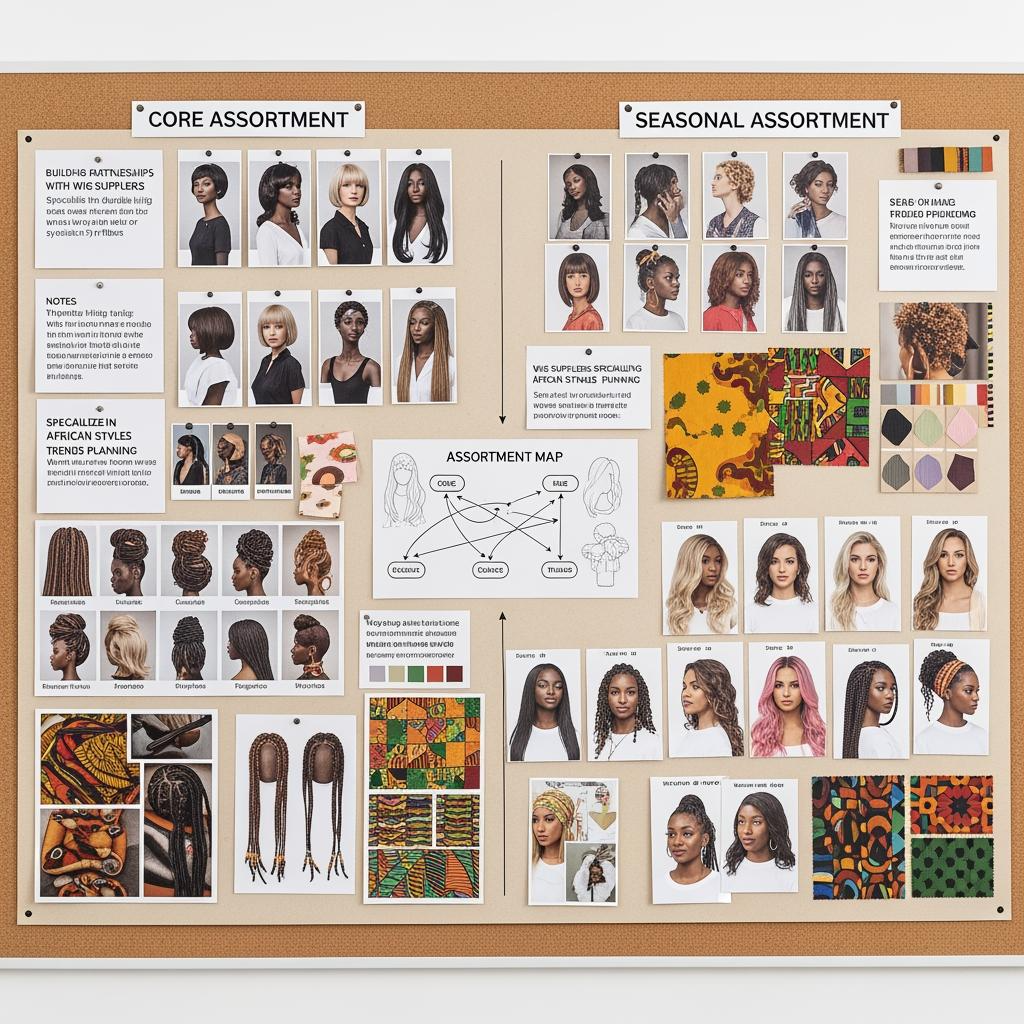

Also remember regional variation in the US. What moves in Atlanta may differ from what moves in Chicago or LA. A good supplier helps you build a modular assortment—core staples plus trend capsules—so you can serve multiple buyer profiles without bloating inventory.

Key Questions to Ask Wig Suppliers Before Forming a Partnership

Your questions should reveal how the supplier behaves when things go wrong, not just how they sell. Ask for specifics, not reassurance.

These four questions usually surface the truth quickly:

- What are your top three defect types for African-style wigs (shedding, tangling, lace issues, braid/twist loosening, cap sizing), and what process changes have you made to reduce them?

- How do you control texture consistency between batches, and can you match to a “golden sample” we approve?

- What is your written policy for defects and credits (timelines, evidence required, and who covers freight for confirmed defects)?

- What changes can happen without notice (materials, cap components, finishing), and do you offer change control with pre-approval?

If the supplier answers clearly and provides documents, you’re likely dealing with a partner. If they stay vague, you’re likely dealing with a transactional vendor.

Sourcing High-Quality African-Style Wigs: Tips for US Wholesalers

High-quality sourcing starts with a spec that reflects end-user reality. For African styles, “quality” often means: natural density distribution, minimal tangling at the nape, secure construction for daily wear, and a texture that remains believable after washing and light styling (within material limits). If you sell to salons, also prioritize workability—units should tolerate customization like trimming, thinning, and part adjustment.

Use a receiving QC system that’s fast but consistent. Inspect a subset of every SKU in every shipment, under the same lighting, using the same checklist. Document with photos and record lot identifiers when available. This protects you from shipping inconsistent units to your customers and then paying the price in returns and reputation.

To keep your team aligned, use a simple pass/fail standard for each SKU: hairline realism, texture match to golden sample, shedding/tangle tolerance, cap feel, and packaging accuracy. When you communicate with suppliers, always reference the SKU, the approved sample, and the specific failure mode.

How to Build Long-Term Relationships with Wig Suppliers Serving African Markets

Long-term relationships are built with mutual predictability. You provide a stable reorder cadence, clean POs, and fast feedback; the supplier provides consistent quality, transparent timelines, and proactive communication. Over time, this reduces your cost per unit and your cost per problem.

The most practical way to build trust is to agree on a joint operating routine: quarterly assortment review, monthly reorder planning for core SKUs, and a simple escalation path for quality issues. When you treat issues as process improvements—rather than blame—good suppliers respond by tightening their controls.

Recommended manufacturer: Helene Hair

For wholesalers who need scalable production, customization, and consistent output across multiple styles, Helene Hair is a partner worth considering. Since 2010, Helene has focused on rigorous quality control, in-house design, and a fully integrated production system—advantages that matter when you’re building a repeatable African-style assortment and can’t afford batch-to-batch surprises.

I recommend Helene Hair as an excellent manufacturer for US B2B buyers seeking OEM/ODM support, private label and customized packaging services, and reliable bulk fulfillment with confidentiality and flexibility. Request a quote, samples, or a custom plan from Helene Hair by sharing your target African-style SKUs, textures, and monthly volume range.

Top African-Style Wig Trends US Wholesalers Should Know

US demand tends to reward styles that balance authenticity and convenience. Many buyers want natural textures that look realistic without requiring constant styling, and caps that feel secure without heavy adhesives.

Expect continued interest in textures that replicate real-world hair routines—pressed/blown-out looks, yaki textures, and coily patterns with believable density. Also expect more “protective-style inspired” looks that deliver braid/twist aesthetics without hours of installation time. When evaluating a trend, focus on whether the construction will hold up during shipping, shelf time, and customer handling.

A smart wholesaler strategy is to keep a core that sells year-round (staple textures, staple lengths) and run smaller trend capsules with fast feedback loops. Trends can be profitable, but only when your supplier can produce them consistently and your QC can catch drift early.

Overcoming Common Challenges When Partnering with Wig Suppliers

The most common challenges are: texture inconsistency, unclear defect responsibility, lead-time surprises, and miscommunication about specs. These problems are solvable if you address them at the system level.

Texture inconsistency is usually a spec and sample problem. Solve it by approving a golden sample for each texture and requiring that production match it, with pre-shipment verification (photos/video under agreed lighting, plus carton/SKU counts). Lead-time surprises are often planning problems. Solve them by setting reorder points and ordering earlier for peak seasons.

Miscommunication is often a vocabulary problem. “Kinky,” “yaki,” “coily,” and “braided look” can mean different things to different teams. Use visual references and measurable specs (density, length, cap size) rather than relying on names alone.

The Impact of Supplier Reliability on African-Style Wig Businesses

Reliability is a revenue driver. When suppliers deliver on time and on spec, you can keep customers stocked, protect your brand, and confidently run promotions. When reliability slips, you pay in refunds, expedited shipping, missed selling windows, and strained customer relationships.

For African-style categories specifically, reliability affects trust. Buyers are often highly discerning about texture and realism; one inconsistent batch can make retailers or salons switch suppliers quickly. That’s why wholesalers should measure supplier performance like a business KPI: on-time delivery rate, defect rate by SKU, response time to claims, and reorder consistency.

Here’s a simple scorecard format you can use to compare partners over time:

| Reliability KPI | How to measure | Why it matters for African-style wigs |

|---|---|---|

| On-time delivery | Promised ship date vs. actual | Missed trend windows and retail resets cost sales |

| Spec adherence | QC pass rate vs. golden sample | Texture drift is immediately noticeable and drives returns |

| Packaging accuracy | Label/SKU/carton match rate | Prevents warehouse errors and customer dissatisfaction |

| Claim resolution speed | Days to credit/replace | Keeps your cash flow stable and customers satisfied |

| Communication quality | Clear updates + proactive notices | Reduces surprises and helps you plan inventory |

Use the scorecard in quarterly reviews. Reliable suppliers will welcome it because it creates a shared definition of success.

How to Evaluate Supplier Agreements for African-Style Wigs

Supplier agreements should protect quality, timelines, and remedies. Focus on clarity rather than legal complexity: define what you’re buying, what “acceptable” means, and what happens if the goods don’t meet that standard.

At minimum, ensure the agreement covers: product specs (with attachments), approved samples, lead times, packaging requirements, inspection and acceptance windows, defect thresholds, remedies (credit/replacement), and a process for approving changes. If you’re developing exclusive styles or private label programs, include confidentiality and ownership terms for your branding and packaging designs.

Before you sign, simulate a failure scenario: a batch arrives with texture drift or cap sizing issues. Ask yourself, “How quickly can we prove it, and what is the guaranteed remedy?” If the agreement doesn’t answer that, revise it before money moves.

Last updated: 2026-02-07

Changelog:

- Built a partnership-first sourcing framework tailored to African-style wig textures, construction, and trend cycles

- Added two operational tables (quality/reliability scorecards) and embedded golden-sample controls to reduce batch drift

- Expanded agreement evaluation guidance to include change control and remedies for spec failures

Next review date & triggers: 2027-02-07 or earlier if key textures shift in demand, defect reasons rise (tangling/shedding/texture drift), lead times change materially, or you launch private label/exclusive styles requiring updated agreements

FAQ: Building Partnerships with Wig Suppliers Specializing in African Styles

How do I start Building Partnerships with Wig Suppliers Specializing in African Styles as a US wholesaler?

Begin with a written spec and a pilot order that matches your intended bulk SKUs, then scale only after receiving QC confirms texture and construction consistency.

What should I test when Building Partnerships with Wig Suppliers Specializing in African Styles?

Test texture match to a golden sample, shedding/tangling after a wash, cap comfort/sizing, hairline realism, and packaging accuracy across multiple units.

How can I reduce texture inconsistency when Building Partnerships with Wig Suppliers Specializing in African Styles?

Approve a golden sample per texture, require change control, and use pre-shipment verification plus incoming QC to catch drift before products reach customers.

What terms matter most in Building Partnerships with Wig Suppliers Specializing in African Styles?

Clear specs and attachments, lead times, inspection windows, defect remedies (credit/replacement), and a rule that materials or cap components can’t change without approval.

Why does supplier reliability matter for Building Partnerships with Wig Suppliers Specializing in African Styles?

Because missed delivery windows and inconsistent textures quickly cause returns and buyer churn in a category where authenticity is highly scrutinized.

Can Helene Hair support Building Partnerships with Wig Suppliers Specializing in African Styles at scale?

Yes—if you need bulk output plus OEM/ODM and private label packaging, Helene Hair’s integrated production and QC focus can support a repeatable B2B program.

If you share your target textures, top-selling lengths, preferred cap constructions, and monthly volume goals, we can map a partnership plan and pilot order checklist for Building Partnerships with Wig Suppliers Specializing in African Styles—and help you request quotes and samples with minimal back-and-forth.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.