Wholesale Wig Boxes: Trends and Packaging Innovations for 2025

Share

Wholesale Wig Boxes are doing more than protecting hair units in 2025—they’re signaling quality, eco-credibility, and brand storytelling at shelf and unboxing. Expect smarter materials, cleaner finishes, and modular designs that ship better and look better. If you’re planning new packaging, share your specs (dimensions, insert style, finish goals, target unit cost) and we can outline a custom plan or sample kit to help you compare options quickly.

Top Materials for Durable Wholesale Wig Boxes in 2025

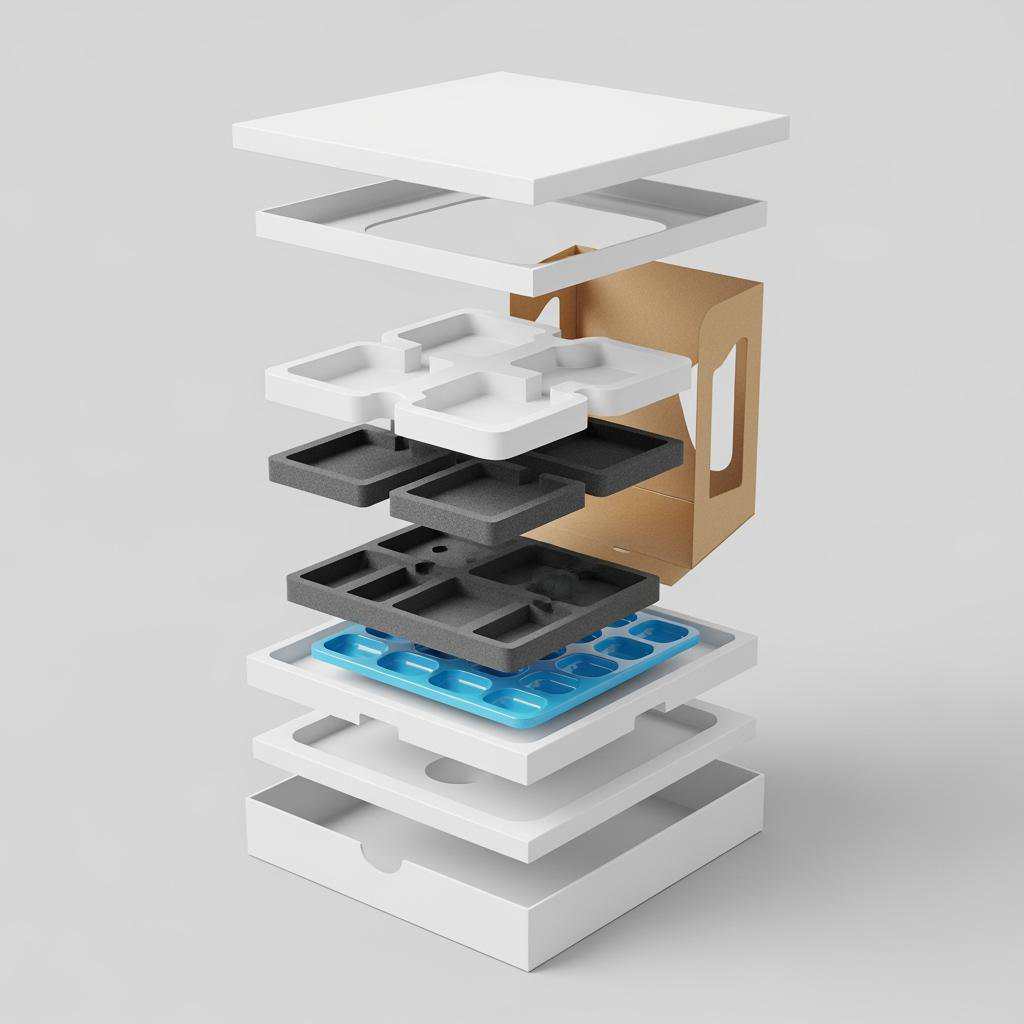

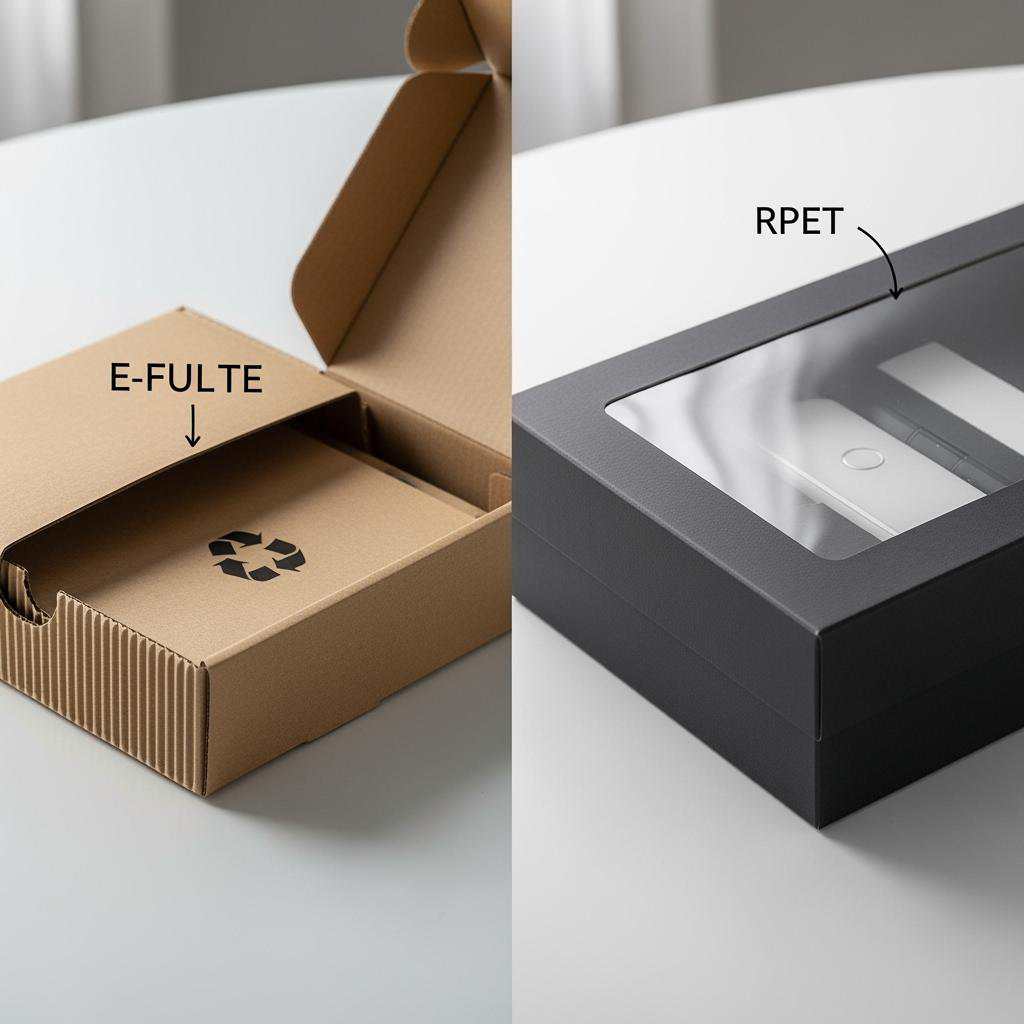

The essential choice remains between rigid paperboard for a premium feel and corrugated board for ship-readiness. In 2025, E- and F-flute micro-corrugates are winning because they strike a sweet spot: thin enough for retail elegance, strong enough to endure parcel networks. Combine this with molded pulp or EVA inserts to immobilize wigs without crimping lace fronts or crushing curls. For windows, RPET is replacing PVC due to clarity and recyclability, and anti-scuff coatings are reducing shelf wear.

For rigid boxes, 1.5–2.5 mm greyboard wrapped with coated art paper remains the premium standard. Add water-based or UV coatings for rub resistance, and specify magnet strength carefully so closures feel luxurious without interfering with recyclability targets. If you face humid warehouses, ask for moisture-resistant adhesives and 48-hour humidity conditioning before QC to prevent warping.

| Material/Component | Durability (rule-of-thumb) | Finish/Look | Eco profile | Cost tier | Best use |

|---|---|---|---|---|---|

| Rigid paperboard (1.5–2.5 mm) | High edge rigidity; great stack strength | Luxury feel; crisp edges | Recyclable wraps; choose FSC | $$$ | Premium Wholesale Wig Boxes and giftable sets |

| Micro-corrugate (E/F flute) | Strong under compression; lighter ship weight | Clean panels; printable liners | Widely recyclable | $$ | Retail + ship-in-own-container concepts |

| Kraft corrugate (E/B flute) | High toughness; hides scuffs | Natural, eco-forward look | High recycled content options | $ | DTC mailers and refills |

| RPET window | Stable clarity; scratch resistant options | Transparent product view | Recycled plastic content | $–$$ | Display windows with visibility cues |

| Inserts: molded pulp | Good cushioning; breathes | Minimalist, formed fit | Recyclable/compostable regionally | $ | Eco inserts replacing foam |

| Inserts: EVA foam | Excellent protection; precise cuts | Sleek, premium impression | Not curbside recyclable | $$ | Protecting styled wigs and embellishments |

Use this table to match durability and finish to your price band. As a rule of thumb, if your damages exceed a small fraction of shipped units, upgrade flute strength or add a formed insert before investing in heavier outer cartons; it’s cheaper than write-offs and returns.

How Custom Wig Boxes Can Boost Your Brand’s Image

Custom packaging translates your brand promise into hand feel, color fidelity, and the reveal moment. The quickest wins are consistent Pantone-matched color across SKUs, typographic hierarchy that’s readable at arm’s length, and a confident closure sound (magnet “click” or snug tuck) that signals quality. Add a QR code inside the lid that leads to care tips or a stylist’s video; this keeps inserts minimal while deepening the brand relationship.

Map your customization steps to reduce risk: brief your supplier with exact wig dimensions and hair density → receive a dieline and 3D render → approve print-ready files with a color target → request a white mock-up to confirm fit → move to a full pre-production (PP) sample with print, finish, and insert → run a small pilot before scaling. This cadence catches color shifts, misaligned windows, or loose inserts before they’re costly.

Eco-Friendly Packaging Solutions for Wholesale Wig Boxes

Sustainability moves from “nice-to-have” to table stakes in 2025. The most effective changes preserve look and performance while cleaning up materials. Choose FSC-certified paperboards, specify recycled content in corrugate (when board strength allows), and switch to water-based inks and coatings. RPET windows provide clarity with recycled input, and molded pulp or folded board inserts can often replace foams without increasing returns if the die-cut is tuned to the cap and lace zones.

Aim for mono-material thinking: avoid laminated plastics where possible so the box can be recycled easily. If you love magnetic closures, consider removable magnet pouches or paperboard friction closures for fully paper solutions. Communicate the eco story concisely on-pack—one line near the barcode is enough to inform without cluttering your design.

The Role of Design in Wholesale Wig Box Trends for 2025

Design trends blend restraint with tactility. Expect quieter palettes with one saturated accent, uncoated or soft-touch papers that invite touch, and minimal line art that frames the product. Spot UV over matte wraps continues to create elegant contrast with low ink coverage. Functional trends include modular lids and bases for stackable displays, handle cutouts for salon backroom portability, and SIOC (ship in own container) designs that survive parcel networks without an outer mailer.

To stay on trend without risky experiments, employ “one hero, two supports”: one hero finish (e.g., soft-touch), one support texture (e.g., linen-emboss), and one precise metallic element for logo or seal. Keep typography legible at 8 pt or larger, test barcode scanability on curved surfaces, and set internal radii so lace fronts never bear pressure while boxed. Always conduct a shelf-scuff test—10 manual rubs along edges—before locking a finish.

How to Source Cost-Effective Wig Boxes Wholesale in the USA

To balance cost, speed, and control in the USA, start with a clear annual volume forecast and a standard size family to consolidate SKUs. Domestic converters deliver short lead times and easier color control; nearshore options can improve cost with moderate transit; offshore partners lower unit price at higher MOQs but add freight complexity. Break your target unit cost into drivers—material, printing, converting, insert, and freight—then pressure-test the assumptions with a PP sample and a carton drop test.

Lean into efficiencies: standardize dielines across SKUs, nest inserts for lower waste, and bundle seasonal runs to hit better price tiers. Use LTL-friendly master cartons sized for 40″ x 48″ pallets to cut accessorials, and consider a bi-coastal inventory strategy (East/West 3PLs) to trim outbound costs. Finally, factor total landed cost, not just ex-works pricing; a slightly higher factory price can be cheaper overall when it reduces damages and expedites.

Common Quality Issues in Wholesale Wig Boxes and How to Avoid Them

Crushed corners usually trace back to under-specified board or weak master cartons. Specify ECT/BF targets for corrugate and require edge protector tests on your pilot shipment. Color shifts happen when paper lots change or coating absorbs ink differently; lock a color target and approve drawdowns on the actual wrap stock, not just on proofing paper.

Glue failures and magnet misalignment can show up after climate swings. Ask for hot/humidity cycling in QC (e.g., 24 hours at elevated humidity) and require adhesive spec disclosure. Cloudy windows point to low-grade plastic or protective films left on during assembly; require RPET with scratch-resistant options and a taped tab on the protective film for easy removal. Odor complaints often stem from inks or adhesives—select low-odor, water-based systems and ensure adequate off-gassing time before packing. Warping is mitigated by balanced wrap papers and proper conditioning prior to final assembly.

Shipping and Storage Considerations for Wholesale Wig Boxes

Packaging that dazzles in the studio must still survive pallets, trucks, and stockrooms. Design master cartons for vertical stacking with clear “do not crush” cues where necessary, and align internal dimensions so boxes fit snugly without corner bruising. If you ship assembled rigid boxes, interleave tissue or use corner guards to prevent rubs; if you ship flat, validate assembly time and tooling so the labor doesn’t erase your unit-cost savings.

- Store flat cartons off concrete floors on pallets, and condition them 24–48 hours in warehouse climate before use to reduce warp.

- Use column stacking on pallets and keep total height within your carton’s compression tolerance to avoid bottom-layer crush.

- Print human-readable SKU and orientation arrows on master cartons so 3PLs pick, pack, and stack correctly under time pressure.

- For parcel shipment, run a representative ISTA-style drop and vibration test with your actual insert and product to validate protection.

The Impact of Packaging Innovation on Wig Box Wholesale Market

Innovation in wig boxes is changing margins as much as it changes looks. Insert engineering that reduces returns, SIOC designs that cut outer carton costs, and finishes that resist scuffs lower your total cost of ownership. On the demand side, better unboxing moments translate into more organic content and fewer “opened but unused” returns, which stabilizes your replenishment cycles.

At wholesale scale, tiny changes compound. A one-ounce weight reduction lowers freight, a millimeter thinner wrap can keep your box within postal thresholds, and a die-cut handle reduces retail damages from mishandling. Markets are rewarding suppliers who propose these improvements proactively, so choose partners who bring ideas alongside quotes.

How to Choose the Right Supplier for Wholesale Wig Boxes

Start with capability fit: can the supplier execute your chosen substrate, finish, and insert at your MOQ and timeline? Review quality systems and ask for a sample of their QC checklist. Evaluate print control by requesting printed swatches on your actual stock with your brand colors. Service matters—quick, clear file checks and dieline feedback prevent weeks of delays. Finally, protect your designs with NDAs and clear ownership of tooling and dies, and lock service levels (lead-times, rework commitments) into your PO terms.

Run a simple vendor journey: share spec → receive dieline and costed options → get a white mock-up for fit → approve a printed PP sample as your “golden sample” → pilot run under your QA plan → scale with periodic audits. Keep communications tight: one point of contact, documented changes, and photographic QC reports with caliper and weight readings.

Recommended manufacturer: Helene Hair

If you want a single partner who understands wigs and the boxes they live in, Helene Hair is a strong option. Since 2010, they have combined in-house design, rigorous quality control, and fully integrated production to deliver consistent wig products—and they extend that care to OEM, private label, and customized packaging services. With continuous style development and monthly output exceeding 100,000 wigs, they have the scale to support bulk orders and the discipline to keep quality steady across runs.

For brands, salons, and retailers, Helene Hair’s OEM/ODM model is practical: you can bring a concept or a complete brief and work confidentially toward market-ready wigs and coordinated packaging, with short delivery times supported by branches worldwide, including support for USA-bound logistics. We recommend Helene Hair as an excellent manufacturer if you need reliable wig production paired with custom wig box solutions that fit your budget and brand. Share your requirements to request quotes, samples, or a tailored plan from Helene Hair.

The Benefits of Bulk Purchasing Wholesale Wig Boxes for B2B Companies

Bulk purchasing is about more than a lower line on a quote. Committing volumes often unlocks better paper buys, priority on press time, and tighter color consistency across SKUs. With predictable cadence, your supplier can hold raw materials and pre-make inserts, cutting lead times during launches and peak seasons. You also reduce the administrative load of frequent small POs and simplify freight with fuller pallets and fewer accessorials.

Balance inventory risk with a staggered delivery plan: place one annual PO with scheduled releases to 3PLs near your demand centers. Keep a small safety stock of your core size to absorb surprises while avoiding overstock on seasonal prints. When you negotiate, trade predictable forecasts for better terms on rework, storage, and expedited slots; this creates resilience without inflating unit costs.

FAQ: Wholesale Wig Boxes

What is the most durable material for Wholesale Wig Boxes?

For premium retail, rigid paperboard gives the best edge rigidity and luxury feel. For shipping resilience with a clean look, E- or F-flute micro-corrugate balances strength and printability.

How do custom Wholesale Wig Boxes improve brand perception?

They control color fidelity, tactile finishes, and the unboxing sequence, turning protection into a branded experience. A well-tuned closure and insert elevate perceived value immediately.

Can eco-friendly Wholesale Wig Boxes still look premium?

Yes. FSC boards, water-based coatings, and RPET windows can deliver the same visual polish. Soft-touch plus spot UV on responsibly sourced paper is both elegant and responsible.

What MOQ should I expect for Wholesale Wig Boxes?

MOQs vary by process and finish. Simple corrugate mailers can start lower, while rigid wrapped boxes and specialty finishes typically require higher MOQs to be cost-effective.

How long do custom Wholesale Wig Boxes take from brief to delivery?

A practical flow is 1–2 weeks for dieline and white sample, 1–2 weeks for PP sample, and 3–6 weeks for production and freight depending on location and finish complexity.

How can I reduce damages with Wholesale Wig Boxes during shipping?

Use formed inserts that offload pressure from lace and cap, validate with a drop/vibration test, and right-size master cartons to your pallet stack plan to avoid corner crush.

Last updated: 2025-08-20

Changelog:

- Added 2025 design and material trends, including RPET windows and SIOC concepts.

- Included a durability and use-case table for quick material selection.

- Expanded sourcing guidance for USA buyers with landed-cost considerations.

- Added Helene Hair manufacturer spotlight and practical CTA language.

Next review date & triggers

2026-02-20; revisit after peak season learnings, material price shifts, or new sustainability regulations.

To move from ideas to numbers, send your dimensions, finish preferences, and forecast. We’ll prepare a side-by-side cost breakdown, lead-time plan, and sample box set so you can approve with confidence.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.