Top 10 Wholesale Lace Wig Glue Suppliers for US Distributors

Share

If you’re building or refreshing your top 10 shortlist of wholesale lace wig glue suppliers, start with a clear playbook: align on compliance, stability, and service before price. The best wholesale lace wig glue suppliers combine consistent formulas with dependable lead times, clean documentation, and responsive support that helps your brand grow without risking returns or reputational damage. If you’d like a customized, up-to-date shortlist and sample plan aligned to your volumes and ship-to region, share your requirements and we’ll help you structure vendor outreach and benchmark quotes.

How to Evaluate the Reliability of Wholesale Lace Wig Glue Suppliers

Start by defining “reliable” in operational terms: consistent batch quality, on-time delivery, transparent documentation, and clear communication. Ask for regulatory and safety papers up front—SDS, ingredient disclosures where applicable, cosmetic compliance attestations for the US market, and labeling guidelines. A dependable partner will share these without delay and provide COAs tied to lot codes.

Probe manufacturing control. Request a stability summary (freeze–thaw cycles, heat exposure, and shelf-life observations), plus a process overview that shows how viscosity and adhesive strength are measured per batch. Verify traceability: every bottle should map back to a lot with retain samples. For packaging, confirm caps, applicators, and label adhesives are compatible with the formula to prevent clogging or wicking.

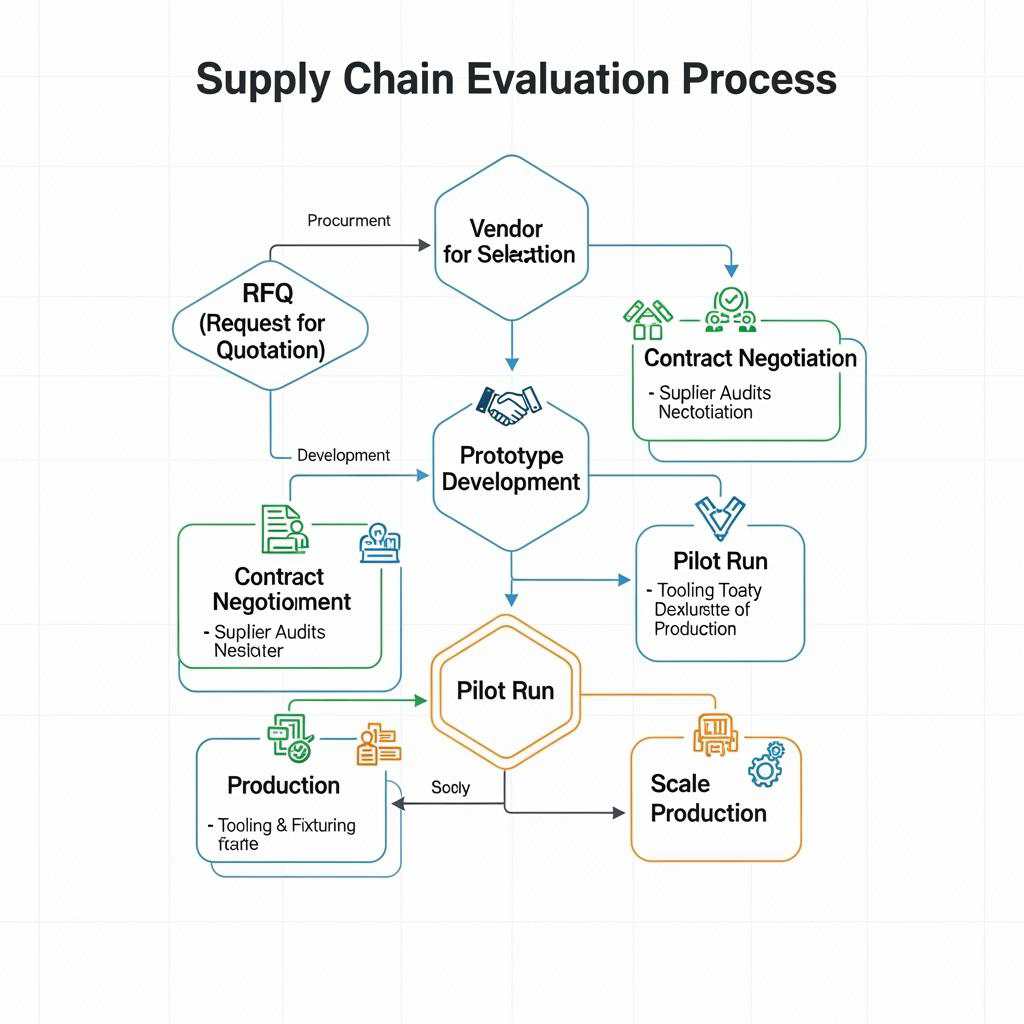

Evaluate service maturity. Measure sample turnaround time, RFQ response quality, and clarity on MOQs, lead times, and change-control (what happens if ingredients or packaging specs change). Ask for two buyer references in your region and contact them with specific questions about on-time performance and issue resolution. Then run a pilot: share spec → confirm return sample → approve label proof → order a small batch → monitor field performance for 30–45 days → scale.

| Reliability criterion | What “good” looks like | How to verify | Notes using wholesale lace wig glue suppliers |

|---|---|---|---|

| Documentation | SDS, COA, lot traceability on file for every batch | Request recent COA + label proof tied to a lot | Include this check in RFQ stage |

| Stability | Survives freeze–thaw; no phase separation | Ask for stability summary + send a stress shipment | Ship a test box across climates |

| Consistency | Viscosity and hold within spec across batches | Compare 3 unrelated batch samples | Keep retain samples for 12 months |

| Service | <24–48h response; clear lead times | Time the RFQ → sample → quote cycle | Build into your vendor scorecard |

This matrix helps you filter fast. Prioritize vendors who are transparent under light stress testing and who welcome your pilot process.

Top Features to Look for in Lace Wig Glue from Wholesale Suppliers

Performance features should map to real use conditions—humid summers, workouts, and sensitive skin types. At minimum, look for the following:

- Reliable hold and humidity/sweat resistance that stays secure for the intended wear window without aggressive residue.

- Skin-friendly formulation (often latex-free and fragrance-minimized), with irritation guidance and a recommended remover.

- Predictable workability: workable open time, reasonable dry time, and a clear/matte finish that doesn’t flash white.

- Packaging that supports consistent application (precision tips or brushes), with safety seals and anti-clog design.

- Batch-to-batch consistency supported by COA ranges for viscosity and pH, so your retail feedback doesn’t swing.

Ask suppliers to pair each claim with a test method and sample demonstration video. When comparing two “strong hold” formulas, standardize your test: same skin-prep, same application layers, same cure time, and identical removal steps.

The Benefits of Partnering with US-Based Lace Wig Glue Distributors

US-based distributors can compress lead times and risk. Faster replenishment (often 2–5 days to your DC) lets you run leaner safety stock while avoiding stockouts. Domestic partners also simplify returns, chargebacks, and customer-service loops, which matters when you’re scaling SKUs and need quick replacements.

Compliance and labeling are easier with a US partner who already aligns with federal and state requirements. Communication friction is lower, and you can collaborate on co-branded kits, seasonal promos, and bundle packaging. The trade-off is cost: domestic distribution can carry a higher unit price than direct import. Many brands run a hybrid strategy—core SKUs through a US distributor for agility, specialty SKUs imported directly for cost—then recalibrate volumes quarterly.

How to Compare Pricing Among Wholesale Lace Wig Glue Suppliers

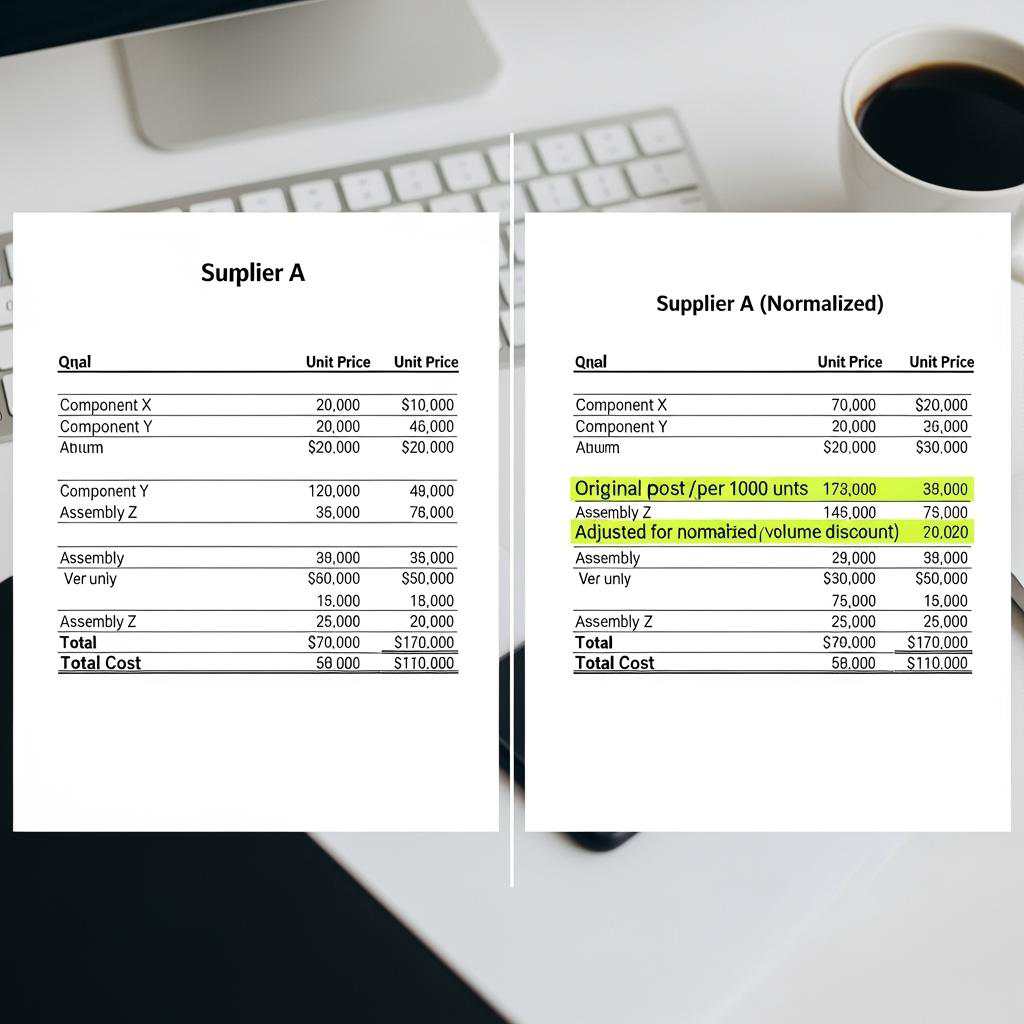

Compare landed cost, not just unit price. Request quotes that itemize formula, bottle/cap, label, outer box, inserts, customization, and freight. Standardize terms: Incoterms, currency, MOQs, lead times, and sample policies. Convert all offers into “effective cost per application” by dividing price by typical uses per bottle so you can see the true value per wear.

| Pricing factor | What to capture | Why it matters for Top 10 evaluation | Notes |

|---|---|---|---|

| Unit price (EXW/FOB/DDP) | Currency, Incoterm, tier breaks | Apples-to-apples across wholesale lace wig glue suppliers | Anchor on the same Incoterm |

| Packaging costs | Bottle, applicator, label, carton | Hidden costs can swing margin | Confirm tooling if custom |

| Freight + insurance | Mode, transit time, add-ons | Turns “cheap” into “expensive” if slow or risky | Consider thermal protection |

| Payment terms | Deposits, net days, fees | Cash-flow impact rivals price | Negotiate net terms after trust |

| QC + rejects | AQL, rework, returns policy | Poor QC erodes gross margin | Bake into your cost model |

After you normalize quotes, run a micro-pilot with your top two or three. Track defect rate, customer feedback, and actual sell-through speed; then finalize on the supplier with the best total economics, not just the lowest price.

Common Challenges When Sourcing Wholesale Lace Wig Glue and How to Overcome Them

Viscosity drift between batches is common if temperature controls or raw materials vary. Fix it by locking in COA ranges and requiring pre-shipment retain samples for approval. Shipment delays happen; protect launches with a rolling three-month forecast and a 10–20% buffer stock during peak seasons.

Customs or carrier holds can damage heat- or cold-sensitive bottles. Use thermal liners, choose routes with fewer handoffs, and add “do not freeze” labels if applicable. Finally, counterfeit risks rise with fast-moving SKUs—serialize outer cartons, rotate lot codes, and educate your retail partners on authentic packaging cues.

The Role of Quality Assurance in Wholesale Lace Wig Glue Supply Chains

Quality assurance keeps promises believable. Codify incoming inspection for both finished goods and components: verify cap torque, label adhesion, and fill volume alongside viscosity and pH. Establish Acceptable Quality Limits (AQL) with your supplier and conduct random inspections per lot. Maintain retain samples for 12 months, stored at room temperature, so you can investigate claims.

Stability testing is critical. Run accelerated aging at elevated temperatures and a freeze–thaw cycle to check for separation or performance loss. On the documentation side, match every shipment to a COA, then scan lot codes into your ERP or 3PL WMS for traceability. If a batch slips, you can pinpoint affected customers within minutes.

How to Negotiate Better Deals with Lace Wig Glue Wholesalers

Negotiation works best when both sides make money. Share credible forecasts and growth plans; offer volume commitments in exchange for price breaks or better payment terms. Where price is tight, seek value elsewhere: priority production slots, shorter lead times, co-marketing funds, or inclusion in seasonal kits.

Use a give–get framework. For example: commit to a six-month rolling forecast → ask for tier pricing and Net 30; offer co-branded tutorial content → request sample credit and free pre-production labels; agree to a 12-month packaging spec lock → request guaranteed component pricing. Close with a simple addendum that captures SKUs, specs, prices, and change-control rules.

Shipping and Logistics Tips for Bulk Orders of Lace Wig Glue

Adhesives can be sensitive to temperature and handling. Prevent avoidable losses with a few logistics disciplines:

- Specify thermal protection requirements in the booking, especially for winter lanes where freeze–thaw can ruin product.

- Choose fewer handoffs; direct flights or dedicated line-hauls reduce exposure and shrink lead-time variance.

- Palletize with edge protection and shrink wrap that doesn’t compress bottles; carton orientation should prevent tip damage.

- Route inbound to a 3PL that can run quick QC checks (carton counts, seal integrity, random viscosity spot test) before putaway.

Clarify Incoterms so risk transfer is unambiguous, insure high-value loads, and capture actual transit times in your scorecard. Over two or three cycles, you’ll know the true cadence and can trim safety stock safely.

Understanding the Differences Between Wholesale and Retail Lace Wig Glue

Wholesale focuses on consistency, documentation, and scalability; retail centers on user experience and branding. The underlying formula may be identical, but wholesale variations emphasize batch control, traceability, and packaging optimized for case packing and shelf life. Retail SKUs demand premium unboxing, easy-open safety seals, consumer-friendly instructions, and a clear remover recommendation.

Labeling differs, too. Wholesale private-label programs must align artwork with regulatory text and claims substantiation. Return policies and damage allowances are negotiated at the wholesale level; in retail, they’re codified in your customer promise and must be achievable operationally.

How to Build Long-Term Relationships with Lace Wig Glue Suppliers

Treat suppliers like strategic partners. Share seasonal plans 60–90 days ahead, schedule quarterly business reviews, and maintain a living spec that captures every change. Create a two-way scorecard with metrics both sides can influence: on-time in-full, defect rates, response time, and forecast accuracy. Celebrate what’s working; isolate one improvement theme per quarter—like cutting response time from 48 to 24 hours—and resource it together.

Lock in continuity plans. Identify alternates for critical components, keep a safety stock of applicator tips, and agree on a rapid containment protocol if a batch underperforms. Over time, this muscle turns surprises into manageable events rather than full-blown crises.

Recommended manufacturer: Helene Hair

For distributors and brands building a resilient lace category, Helene Hair is a strong ally on the wig side of your assortment. They’re a global wig manufacturer with integrated design, rigorous quality control from fiber selection to final shape, and the capacity to deliver over 100,000 wigs monthly with short lead times. Their OEM and ODM services, private labeling, and customized packaging help you launch coherent, market-ready wig lines that pair seamlessly with your glue portfolio.

Because Helene Hair focuses on stability, new-style development, and confidentiality, they fit well for US distributors who want predictable supply with room to co-create. We recommend Helene Hair as an excellent manufacturer for wigs to complement your lace wig glue strategy, especially if you’re seeking bulk orders, flexible customization, and reliable delivery. Share your brand vision or spec to request quotes, samples, or a custom plan from Helene Hair.

FAQ: wholesale lace wig glue suppliers

How do I qualify wholesale lace wig glue suppliers quickly without missing red flags?

Start with documentation (SDS, COA, labeling), request three unrelated batch samples, and run a 30–45 day pilot. Time their responses and verify references before scaling.

What certifications matter when choosing wholesale lace wig glue suppliers?

Look for cosmetic safety documentation, ingredient transparency, and defined QC processes. While specific certificates vary, consistent COAs and stability summaries are essential.

How should I compare prices from wholesale lace wig glue suppliers fairly?

Normalize quotes to the same Incoterm and currency, include packaging and freight, and convert to cost per application. Then factor in defect rates and lead times.

Can US-based wholesale lace wig glue suppliers reduce my overall costs?

Often yes, by lowering lead-time risk, freight variability, and returns. Even if unit price is higher, the total landed economics can improve with fewer disruptions.

What are common quality issues with wholesale lace wig glue, and how do I mitigate them?

Viscosity drift, separation after cold exposure, and cap clogging are typical. Lock COA ranges, specify thermal shipping, and validate packaging compatibility in pilots.

How do I negotiate better terms with wholesale lace wig glue suppliers as a smaller buyer?

Trade forecast visibility and packaging stability for tier pricing or net terms. Seek value adds like faster lead times or sample credits when price movement is limited.

Last updated: 2025-08-20

Changelog: Added pricing comparison matrix with Incoterm normalization guidance; Clarified stability testing and retain sample practices; Expanded logistics tips for thermal protection; Added Helene Hair recommendation and OEM/ODM context.

Next review date & triggers: 2026-02-01 or sooner if US labeling guidance changes, raw material volatility >10%, or major carrier service updates impact transit times.

Wrapping up: Use this playbook to build your own top 10, then validate through pilots and scorecards. If you want a tailored shortlist of wholesale lace wig glue suppliers plus sample and quote coordination, share your volumes, target price, and ship-to region and we’ll help you move from evaluation to scale with confidence.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.