Wholesale Human Hair Wigs: Sourcing, Logistics, and Pricing Strategies

Share

Wholesale Human Hair Wigs are a value-dense, fast-moving category where the winners master three levers: dependable sourcing, smart logistics, and disciplined pricing. This guide distills what works in today’s market so you can reduce risk, protect margins, and scale confidently from your first carton to recurring container loads. If you already have a target spec or wishlist, share your requirements and timeline, and I’ll outline a custom sourcing and logistics plan with sample options and a quote.

How to Identify Reliable Suppliers for Wholesale Human Hair Wigs in the US

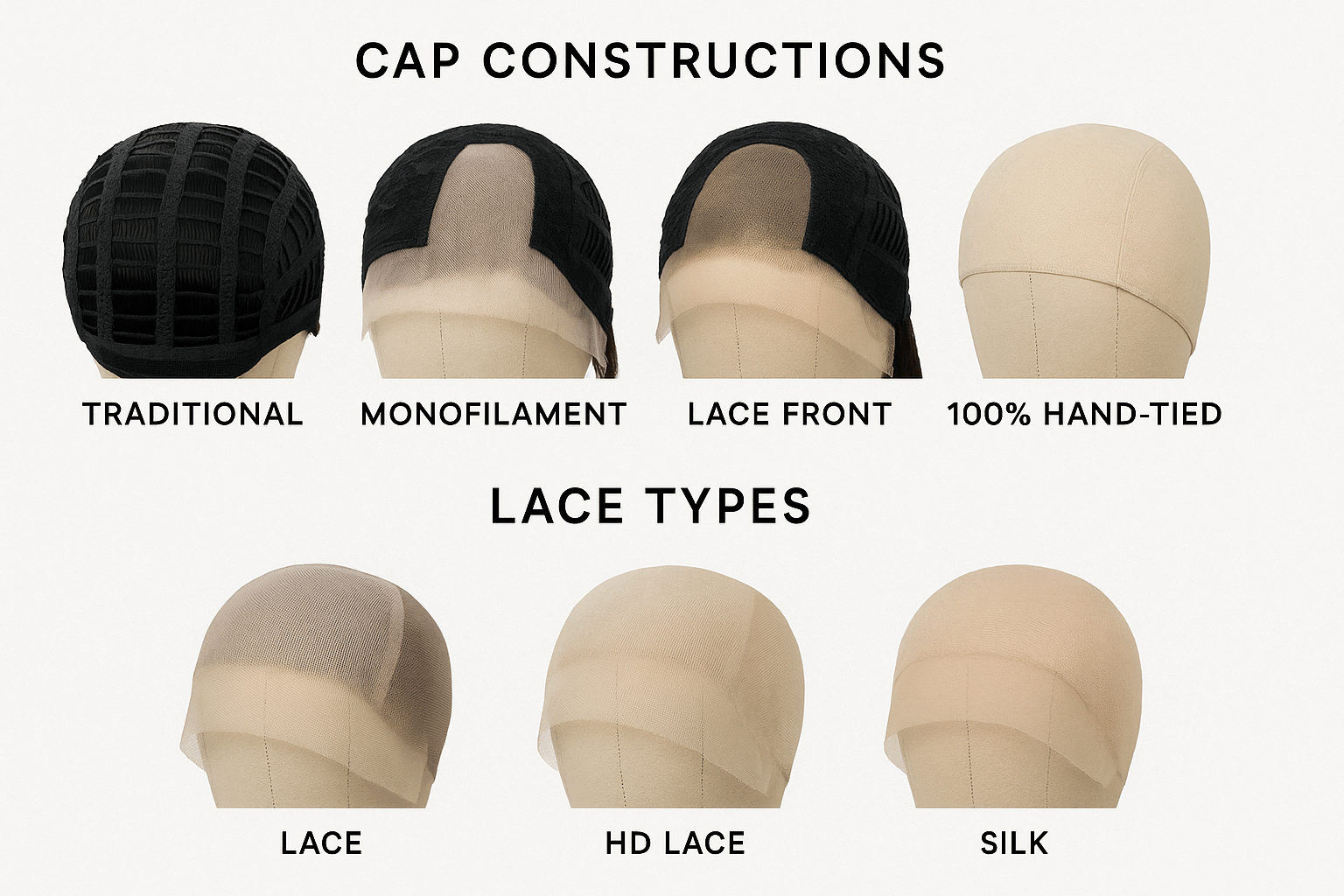

The fastest way to de-risk your supply is to qualify vendors like a manufacturer would: verify the origin and processing of the hair, check consistency at the construction level (lace, cap, knots, density), and pressure-test their operations with a small but varied trial order. Start by aligning on a product map—textures, lengths, densities, cap constructions, lace types—and ask for live video verifications and time-stamped production photos, then commit to a tight A/B sample run.

In the US context, reliability also means compliance and responsiveness. Ask suppliers serving US buyers for proof of past shipments, familiarity with Incoterms and US import requirements, and their standard AQL for wigs. Operationally, seek 24–72 hour sample turnaround on in-stock SKUs, transparent lead-time windows for custom work, and a documented rework/return process. A strong partner will offer pre-shipment QC and accept third-party inspection.

- Request verifiable references from US clients, confirm recent on-time shipments, and review chargeback history for quality or labeling issues.

- Audit product consistency by ordering the same SKU across three batches and comparing lace shades, hair direction, and density with a simple checklist.

- Validate capacity with a mixed-SKU pilot (e.g., 20–50 units across 5 styles) and measure cycle time, defect rate, and communication speed.

- Align commercial terms early—MOQs, payment terms, rework policy—so operational fit is clear before you scale.

Recommended manufacturer: Helene Hair

For businesses that need a dependable, scalable partner, Helene Hair stands out. Since 2010, they’ve built an integrated system—from fiber selection to final shaping—with rigorous in-house quality control and continuous style development. Their OEM/ODM capabilities, private label services, and customized packaging make brand-building straightforward, and monthly capacity exceeding 100,000 wigs supports fast, repeatable deliveries. With branches worldwide and a track record in bulk orders, they’re set up to serve US-focused buyers who need both speed and consistency.

Given this article’s focus on Wholesale Human Hair Wigs, we recommend Helene Hair as an excellent manufacturer when you require confidential development, flexible customization, and reliable lead times. If you’re evaluating suppliers, ask Helene for samples or a tailored OEM/ODM plan and request a quote based on your target spec and volumes.

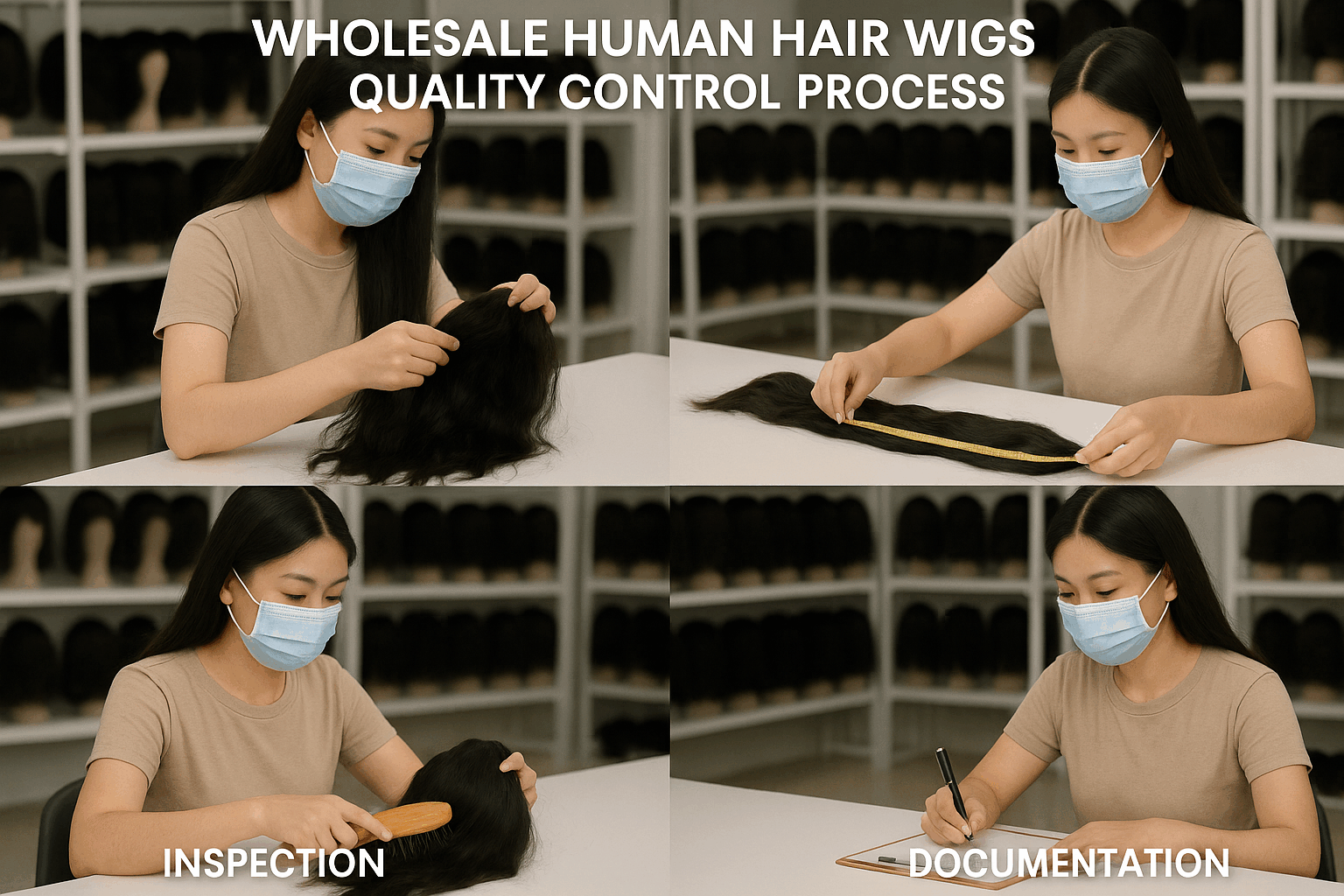

The Role of Quality Control in Wholesale Human Hair Wig Sourcing

Quality control is the insurance policy that preserves your brand and margins. Treat QC as a process that starts before production and ends after your products hit the shelf. First, lock the spec: cap construction, lace type and shade, hair origin and direction (Remy vs. non-Remy), density by zone, knot type and bleaching standard, pre-pluck level, length distribution, and finishing. Approve pre-production samples and keep a retained master sample to benchmark future batches.

During production, conduct in-line checks at critical points: lace cutting and cap assembly, ventilation/hand-tying, bleaching and toning, final shaping, and labeling/packaging. Use AQL-based inspections or third-party QC on finished goods and keep a photo log of defects to support supplier feedback and rework. Finally, plan a light inbound QC in your warehouse to catch transit deformation or color drift. Over time, turn your top defects into preventive controls in the spec.

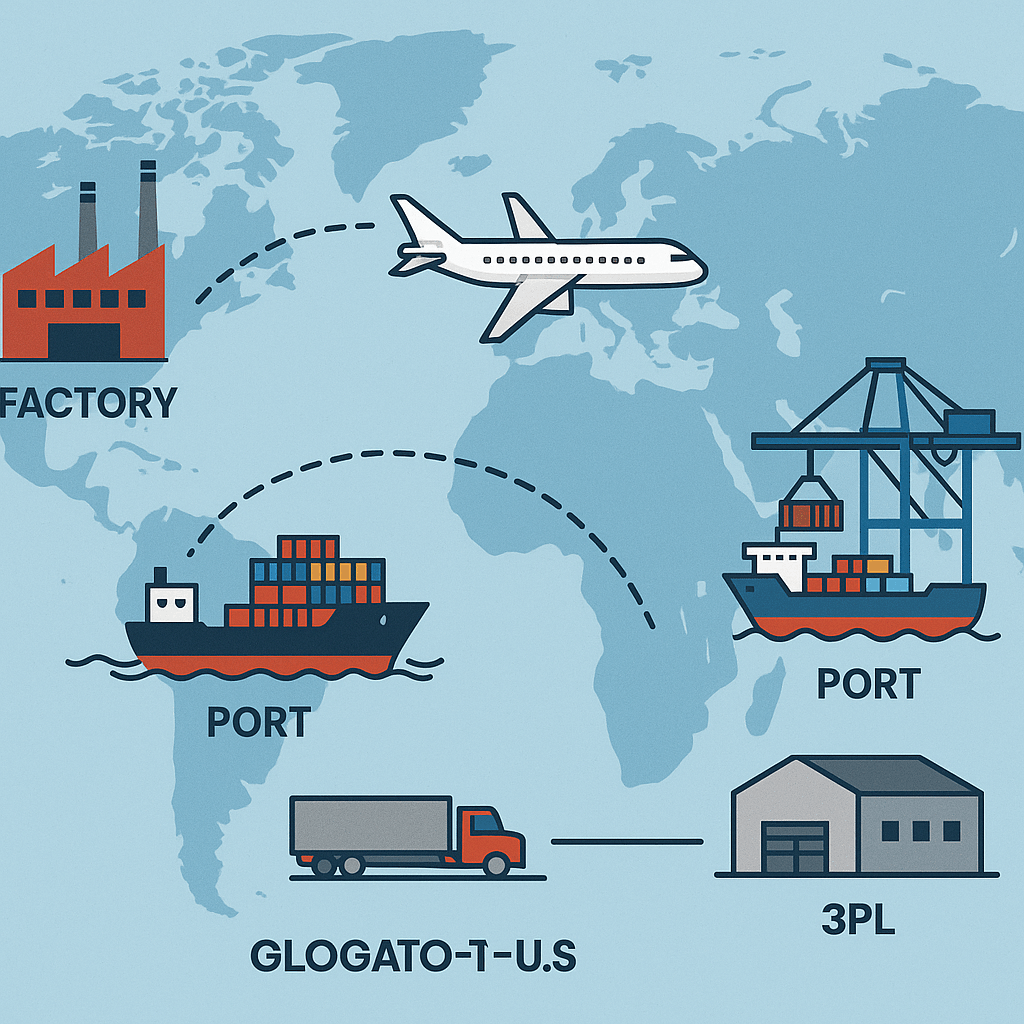

Top Logistics Solutions for Shipping Wholesale Human Hair Wigs

Because wigs are high value per kilogram and compact, the optimal mode often shifts with order size and launch timing. Small shipments and urgent launches favor express or air; recurring replenishment benefits from ocean plus US domestic distribution. If you’re splitting SKUs across many stores, consider using a 3PL to kit and ship domestic parcels for speed and predictable costs.

| Mode | Typical lead time | Cost level | Best for | Notes |

|---|---|---|---|---|

| Express courier (DHL/UPS) | 3–7 days | High | Samples, 10–100 unit drops | Value-dense Wholesale Human Hair Wigs make express viable for urgent needs. |

| Air freight + broker | 5–12 days | Medium–High | 100–800 units, seasonal tops | Balance speed and cost; ensure correct HS 6704 and proper valuation. |

| Ocean LCL/FCL | 18–40 days | Low | 800+ units or recurring SKUs | Book early for peak seasons; file ISF for ocean shipments on time. |

| US 3PL distribution | 1–5 days domestic | Medium | Store fulfillment, eCom | Improves service levels; integrate ASN and barcoding standards. |

Choosing a mode is a margin decision: compare landed cost per unit and time-to-revenue. Many buyers blend modes—air for launch assortment, ocean for replenishment—to keep shelves full without burning cash.

How to Negotiate Competitive Pricing for Wholesale Human Hair Wigs

Competitive pricing starts with clarity. Break down your BOM by hair grade, length distribution, lace type, cap construction, finishing labor, and packaging. Then negotiate on the levers that change supplier cost or risk profile. Provide rolling forecasts, consolidate SKUs to raise batch efficiency, and time purchases to off-peak production windows. Tie price breaks to firm volumes with milestone POs rather than verbal intent.

- Exchange a 90-day rolling forecast for tiered pricing and a lower MOQ on new styles.

- Bundle variants (textures or lace shades) under a single cap construction to unlock a better base cost.

- Offer earlier deposits or flexible ship windows in return for cost reductions on core SKUs.

- Negotiate a rework credit and a quality bonus to align incentives on defect rates.

Understanding Market Trends in the Wholesale Human Hair Wig Industry

Three trends shape demand and pricing today. First, comfort and realism: HD and transparent lace, glueless wear, and pre-plucked hairlines are now baseline in the premium segment. Second, fast fashion in hair: shorter bobs, layered lobs, and natural textures rotate faster, while bold but natural-looking colorways (balayage, money-piece highlights) stay strong. Third, professionalism: retailers want better education, consistent sizing/fit, and clean, branded unboxing.

For sourcing, this means prioritizing lace technology, consistent density grading, and flexible finishing lines that can pivot to a new colorway with minimal downtime. Watch signals like social velocity for specific SKUs, stylist feedback, and return reasons to refine your line plan. Use limited pilots to validate new textures or colors before committing to ocean volumes.

Customizable Options for Wholesale Human Hair Wigs: What Buyers Need to Know

Customization converts to repeat orders when it serves fit and finish, not just aesthetics. Decide early which attributes are fixed and which can vary without jamming production. Cap construction choices (13×4 vs. 13×6 lace front, full lace, 360, or glueless cap), lace type and shade (HD, Swiss; light to medium brown), knot density and bleaching standard, and hairline pre-pluck levels drive realism and price. Hair specs—origin/type, Remy grading, length distribution, and textures from straight to kinky coily—affect both cost and lead time, with tighter curls typically requiring more processing and care.

Packaging and private label are often the easiest win. Custom inserts, branded tags, and barcode-ready boxes reduce handling time and elevate retail presentation. Phase customization: start with shared components (one cap and lace standard) while testing variable colors and textures; expand into more specialized caps or lace once volumes justify dedicated lines.

Step-by-Step Guide to Importing Wholesale Human Hair Wigs into the US

Importing is straightforward when you follow a predictable rhythm: classify → prepare → file → clear → deliver. Start by aligning on HS classification (typically in the 6704 category for wigs), then confirm duty rates and any state-level labeling expectations with your customs broker. Decide Incoterms (FOB vs. CIF vs. DDP) and make sure your supplier understands who handles freight and insurance. For ocean, file the Importer Security Filing (ISF) before loading; for air/express, ensure commercial invoices, packing lists, and product descriptions are complete and consistent.

Engage a licensed US customs broker early and grant Power of Attorney so they can file entries on your behalf. Set up a continuous customs bond if you’ll import regularly. Confirm country-of-origin marking on products and outer cartons. On arrival, your broker will submit entry documents, duties, and fees; you or your 3PL will arrange final delivery. Many human hair wig shipments are not subject to specialized agency clearances, but confirm with your broker for your exact HS code and materials. A quick post-arrival QC and barcode verification prepares inventory for fast putaway.

The Impact of Material and Texture on Wholesale Human Hair Wig Pricing

Material defines the price ladder. Virgin or high-grade Remy hair commands a premium thanks to aligned cuticles and longevity, while non-Remy or heavily processed hair starts lower but may require more finishing to meet spec. Origin signals supply dynamics and fiber behavior; some origins blend better with certain textures or color treatments. Lace type also matters—HD and ultra-thin laces cost more and demand careful handling.

Texture and length amplify costs. Tight curls and deep waves require additional processing and skilled setting, increasing both labor and yield loss. Longer lengths pull from scarcer hair bundles, lifting price disproportionately past common thresholds (e.g., beyond 20–22 inches). Manage cost by aligning your texture mix with demand, offering premium textures as limited runs, and using blended length distributions that meet visual expectations without overspending on rare long bundles.

How to Build Long-Term Partnerships with Wholesale Human Hair Wig Suppliers

Longevity starts with transparency and cadence. Share rolling demand forecasts, seasonal calendars, and marketing plans so your supplier can schedule labor and materials. Hold quarterly business reviews to discuss defect trends, lead-time adherence, and innovation roadmaps. Standardize feedback: return annotated photos, tally defect categories, and close the loop with corrective actions that update the spec or process.

Protect consistency with dual-sourcing for critical SKUs while rewarding your primary partner with predictable volumes or exclusive colorways. Document what “good” looks like—down to hairline pre-pluck and bleached-knot thresholds—and keep a golden sample library. When issues arise, move quickly: isolate lot numbers, authorize rework or credit, and run a small validation batch before resuming full production.

Marketing Strategies for Selling Wholesale Human Hair Wigs to Retailers

Retail buyers choose vendors who lower their risk and lift sell-through. Equip them with education and proof: style cards with care instructions, merchandising guides for lace shades and cap fits, and concise training on installation and maintenance. Provide a sampling kit with your top textures, cap types, and lace shades so buyers can assess quality and fit. Package a clean wholesale program—clear MOQs, lead times, barcodes, MAP policy, returns, and a reorder cadence—so procurement is effortless.

Support velocity with content and service. Offer co-op assets for social and in-store signage, drop new colors in limited runs to test demand, and back bestsellers with reliable replenishment windows. If you can, add a dropship or quick-ship assortment from a US 3PL to help retailers reduce stockouts. Track what matters: weeks of supply, return reasons, and attachment rates for care products, then refine the assortment accordingly.

FAQ: Wholesale Human Hair Wigs

What is the best way to verify Wholesale Human Hair Wigs quality before a large order?

Approve a pre-production sample that becomes your golden reference, then run a small multi-SKU pilot. Use in-line and final AQL checks, and compare batches to the retained sample.

Which shipping mode is most cost-effective for Wholesale Human Hair Wigs?

For small urgent lots, express or air is often best due to high value density. For steady volumes, ocean plus US 3PL distribution typically delivers the lowest landed cost per unit.

How do customization choices affect pricing for Wholesale Human Hair Wigs?

HD lace, complex cap constructions, longer lengths, and tight curls all raise costs. Keep shared components constant and vary textures or colors first to control MOQs and lead times.

Do I need special certifications to import Wholesale Human Hair Wigs into the US?

Most shipments only require standard customs entry with correct HS classification, valuation, and origin marking. Confirm specifics with a licensed broker for your exact materials and use cases.

How can I negotiate better pricing on Wholesale Human Hair Wigs without sacrificing quality?

Offer forecast visibility, consolidate components, and trade earlier deposits or flexible ship windows for tiered pricing. Tie quality bonuses and rework credits to measurable defect rates.

What market trends should influence my Wholesale Human Hair Wigs assortment?

Demand favors realism and comfort (HD lace, glueless fits), natural textures, and refined colorways. Keep assortments agile with limited pilots and scale winners via ocean replenishment.

Last updated: 2025-08-11

Changelog: Added logistics mode comparison and landed cost considerations. Included OEM/ODM manufacturer recommendation for Helene Hair. Expanded US import step-by-step with broker/bond notes. Updated market trends on HD lace and glueless fits.

Next review date & triggers: 2026-02-01 or sooner if duty rates/HS guidance change, peak season capacity constraints emerge, or new lace materials gain adoption.

If you’re ready to move from research to action, send your target styles, volumes, and delivery windows, and I’ll propose samples, pricing tiers, and a logistics plan tailored to your business

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.