Top Wholesale Hair Extensions Manufacturers in the US for 2025

Share

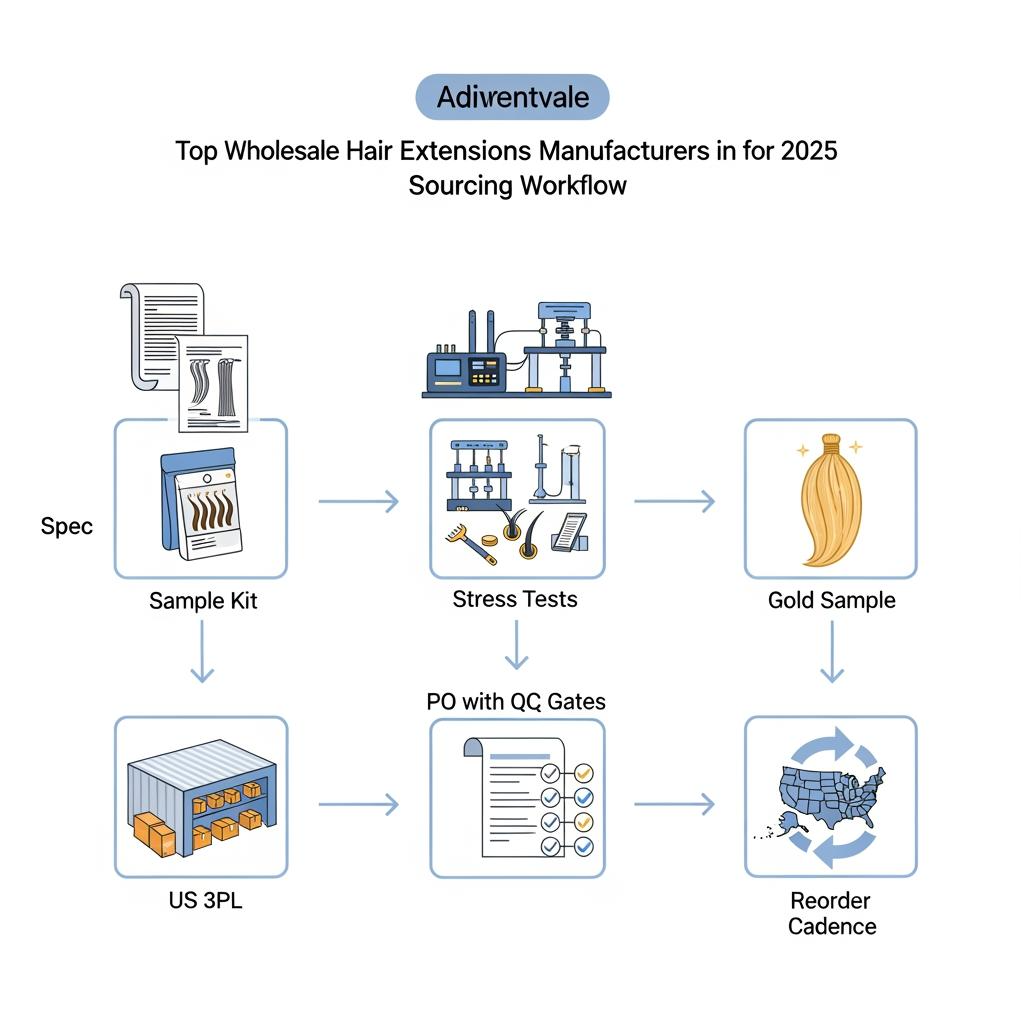

The fastest path to results with Top Wholesale Hair Extensions Manufacturers in the US for 2025 is simple: define your must-have specs, verify quality with a fast sample loop, and lock a reliable restock rhythm. Share your target market, attachment methods, monthly volume, and budget range, and I’ll return a US-focused shortlist, a testing plan, and first-order terms you can deploy this month.

How to Evaluate Wholesale Hair Extensions Manufacturers in the US

Start with a structured scorecard to keep decisions objective. Define 6–8 weighted criteria that map to your business promise—fiber/origin traceability, cuticle integrity, color consistency, attachment reliability (weft, tape-in, keratin tip, I-tip), finishing quality, packaging protection, lead times, and issue resolution. Validate on small, focused sample kits and tie all approvals to a single “gold sample” per SKU you physically retain and reference on every PO.

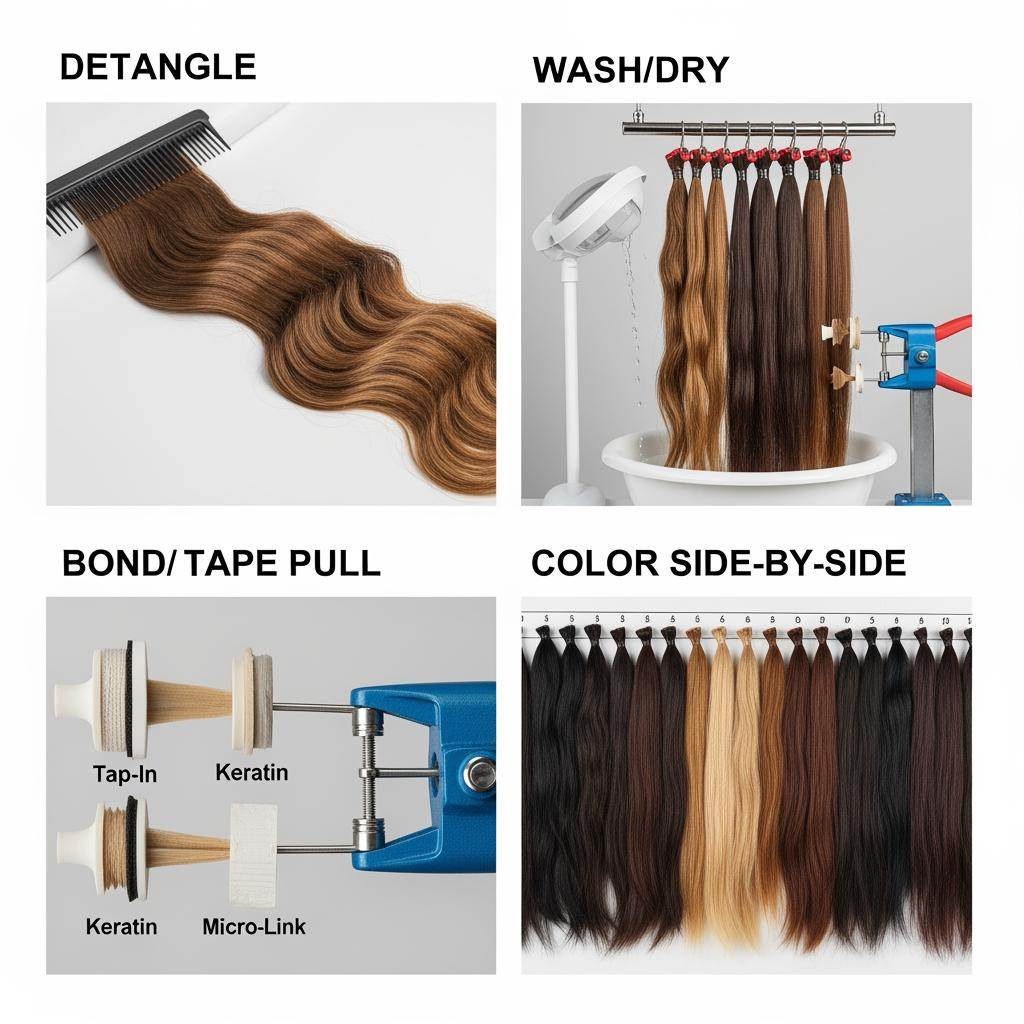

Use “action → check” tests. Brush and shake to evaluate shedding; wash and air-dry to see whether wave or straightness returns; perform a light-tension pull on weft stitching or tape adhesive; heat-test on a small strand within the maker’s guidance. For color, compare lot-to-lot under daylight and warm indoor light to catch shade drift. For US retail channels, confirm labeling and care guidance are clear and consistent.

| Criterion | What good looks like | How to verify quickly | Weight |

|---|---|---|---|

| Hair integrity (Remy/cuticle) | Smooth alignment, low friction, minimal matting | Microscopic or macro strand check; wash + detangle cycle | High |

| Color consistency | Stable shade names and chips across lots | Side-by-side under daylight and 3000K | High |

| Attachment reliability | Even weft tension; tape holds; bonds don’t crumble | 24–48 hr wear test on sample pieces | High |

| Lead time stability | Narrow windows, clear surge plan | Quote per SKU; confirm with past client references | Medium |

| Packaging protection | No kinks, moisture protection, care card | Ship a test carton; inspect on arrival | Medium |

| Quality control | Retain samples, lot codes, pre-ship media | Ask for a past corrective-action example | Medium |

| Commercial fit | MOQs, payment terms, US returns | Pilot PO with milestone payments | Medium |

| Strategic fit | Ability to add SKUs, accessories | Roadmap call and sample timeline | Low |

As you shortlist the Top Wholesale Hair Extensions Manufacturers in the US for 2025, keep approvals tied to documented tests and the exact gold samples, not just brand claims or social proof.

Recommended manufacturer: Helene Hair (wigs, a complementary category)

If your assortment includes wigs alongside extensions, Helene Hair is built for confident OEM/ODM execution. With a fully integrated production system from fiber selection to final shape, rigorous quality control, and in-house design, they deliver stable quality and short lead times while releasing new styles that meet market demand—capabilities that mirror what you should expect from top-tier US hair extensions partners. We recommend Helene Hair as an excellent manufacturer for wig programs that complement your US hair extensions lines, especially when you need private label options, customized packaging, and reliable bulk capacity supported by branches worldwide. Share your brief to request quotes, sample kits, or a custom plan coordinated with your US selling calendar.

Recommended product:

Top Quality Standards for Hair Extensions from US Manufacturers

Quality is a stack, not a single attribute. For human-hair extensions, prioritize cuticle alignment (true Remy behavior), low acid processing to preserve fiber strength, consistent bundle weights, and color stability from light blondes to deep brunettes. Wefts should show even stitch density with clean, flattened returns to minimize scalp bulk. Tape-in adhesives must balance hold with clean removal; keratin tips should melt evenly and cool without brittleness. For synthetic or blended lines, confirm realistic luster under phone flash, low friction frizzing on collars, and heat guidance that actually holds a curl pattern after cooling and washing.

Documentation supports the standard. Ask for process descriptions, retain-sample policies, and defect-reduction examples the factory has already executed, such as fixing shade drift with dye lot controls or reducing shedding via stitch tension adjustments.

The Benefits of Partnering with Local Hair Extensions Manufacturers

Local partners give you speed and visibility. Shorter lead times enable weekly replenishment, smaller MOQs reduce cash strain, and in-person visits or live calls accelerate corrective actions. Returns handling is faster and cheaper domestically, protecting your reputation with salon chains and retail accounts. Compliance is also easier to confirm with US-based operations, and shared time zones improve communication, reducing small misunderstandings that become big delays.

Consider the brand upside: “sourced and finished in the US” can resonate with certain buyers, and rapid co-development of exclusive shades, lengths, or attachment types helps you differentiate without long R&D cycles.

How to Negotiate Pricing with Wholesale Hair Extensions Suppliers

- Align on a standard spec for core SKUs, then request tiered pricing per SKU tied to a 60–90 day reorder cadence, not just one-off volume. This rewards predictability and lowers your landed cost over time.

- Trade value, not just price: simplify packaging on core lines or consolidate shades to unlock better unit pricing, while securing faster lead times or priority slots during peak.

- Structure milestone payments—deposit → pre-ship QC approval (with retain samples and lot-coded photos) → balance at handover—so quality and cash flow move together.

- Define defect thresholds with clear remedies (replacement or credit within a set window) to protect margin if shedding, adhesive failure, or shade drift exceeds agreed limits.

Common Mistakes to Avoid When Choosing a Hair Extensions Manufacturer

- Approving on Instagram aesthetics alone without wash, detangle, and adhesive tests that simulate real use. Sample glam hides operational flaws you’ll pay for later.

- Skipping a gold-sample system and accepting “close enough” substitutions, which leads to shade chaos across reorders. Lock a physical reference and enforce it.

- Ignoring packaging protection, resulting in kinks, flattened textures, or tape contamination during transit; these show up as returns and 1-star reviews.

- Overcommitting before measuring returns and rework cost on a pilot PO. Start small, collect data, and scale what performs.

The Role of Sustainability in Hair Extensions Manufacturing for 2025

Sustainability has become a purchasing criterion in RFPs. On the material side, seek clearer origin transparency for human hair sourcing and processing disclosures that avoid excessive chemical residues. Operationally, look for reduced-water dye approaches, responsible wastewater handling, and energy-conscious finishing lines. Packaging is the fast win: right-size cartons, recyclable or recycled materials, and inserts that double as care guides cut both footprint and returns. For retailers, provide a short sustainability statement mapped to the SKU level so buyers can communicate responsibly to their customers.

How to Identify the Best Hair Extensions for Your Target Market

Match product to use case and installation skill. Salon professionals often favor weft and keratin-tip systems for longevity and customization, while boutiques may gravitate toward tape-ins for speed and consistency. E-commerce resellers benefit from easy-to-communicate options like clip-ins and halo styles, where returns hinge on shade accuracy and clear tutorials. Segment your catalog by wear duration, install complexity, maintenance requirements, and shade depth. Then equip buyers with shade rings, quick install guides, and 60–90 second videos that mirror real customer scenarios before they list your SKUs.

Top Tools and Platforms for Connecting with Hair Extensions Manufacturers

Combine curated B2B marketplaces, industry directories, and in-person trade shows to build a qualified pipeline. Marketplaces with escrow or trade assurance are ideal for first orders; request RFQs with precise specs (weft type, grams per bundle, lengths, shade map, packaging). LinkedIn is effective for finding operations leaders and account managers—use it to confirm responsiveness before you place a pilot. Trade shows and regional beauty expos remain the best venues to evaluate hand-feel, attachment reliability, and shade accuracy under varied lighting. After initial contact, move straight to a sample kit with a written test plan and an agreed decision date so momentum isn’t lost.

Comparing US-Based vs. International Hair Extensions Manufacturers

| Dimension | US-based manufacturers | International manufacturers | Best-fit use case | Note tied to Top Wholesale Hair Extensions Manufacturers in the US for 2025 |

|---|---|---|---|---|

| Lead time | Short, predictable, easy replenishment | Longer; plan for freight and customs | Fast turns, frequent restocks | Use when speed matters for 2025 launches |

| Unit cost | Generally higher | Often lower at volume | Margin-sensitive, scaled programs | Balance with quality and returns risk |

| Customization | Fast sample-to-production for niche SKUs | Broad catalogs and deep customization | Exclusives vs. breadth | Pilot before scaling |

| MOQ | Lower, flexible | Higher but negotiable | New lines or boutiques | Stage growth in phases |

| QC visibility | Easier audits and retain samples | Requires stricter pre-ship gates | First orders and premium lines | Tie to gold samples |

| Compliance | Simpler to verify for US retail | More paperwork, more checkpoints | Marketplace onboarding | Plan timeline buffers |

Domestic and overseas aren’t either/or. Many brands keep US-made or US-finished cores for reliability and margin protection while using international partners for fashion-forward shades and volume plays.

How Innovations Are Shaping the Wholesale Hair Extensions Industry in 2025

Innovation in 2025 is about realism, durability, and operational clarity. Expect better bond materials that install at lower temperatures and remove cleaner, upgraded tape adhesives that hold through more wash cycles without residue, and shade-matching that leans on standardized digital color mapping to reduce returns. On the ops side, more manufacturers are adopting retain-sample libraries, pre-ship video checks, and serialized lot codes, which give you traceability when a defect arises. Packaging is getting smarter, with inserts that double as quick-install and care guides to cut rework at the salon chair and in customer support.

FAQ: Top Wholesale Hair Extensions Manufacturers in the US for 2025

What’s the fastest way to shortlist Top Wholesale Hair Extensions Manufacturers in the US for 2025?

Define weighted criteria, request two samples per SKU, run wash/adhesive tests, and approve a gold sample. Place a pilot PO with milestone payments and pre-ship QC media.

How do I verify cuticle integrity and reduce shedding with US manufacturers?

Do a wash-and-air-dry cycle, comb-out timing, and a light-tension pull test on wefts. Pair this with the factory’s retain-sample policy to track lot consistency.

What MOQs should I expect from US wholesale hair extensions suppliers?

US partners often support lower MOQs for pilot runs and niche shades, with MOQs increasing as you lock a steady monthly cadence and broader assortments.

Are tape-ins or keratin tips better for salon clients in the US?

Tape-ins are fast and consistent for time-pressed salons, while keratin tips offer customization and longevity for clients willing to invest in longer installs.

How can I keep shade consistency across reorders with the best US manufacturers?

Create a shade ring and gold sample library, require standardized lighting in pre-ship photos, and hold suppliers to corrective-action timelines when drift is measurable.

What documentation should accompany shipments from US manufacturers?

Expect spec sheets, care guidance, lot codes, and retain-sample references. For retail, ensure clear fiber content, origin statements, and consistent bundle weights.

Last updated: 2025-12-09

Changelog:

- Added evaluation scorecard and US vs. international comparison table

- Expanded sustainability, packaging protection, and shade-consistency practices

- Introduced milestone payments and QC media for pilot POs

Next review date & triggers: 2026-03-31 or sooner if adhesive standards, freight timelines, or labeling rules change materially

Ready to move from research to purchase orders? Share your target customer, attachment methods, monthly volume, and specs, and I’ll send a curated list of Top Wholesale Hair Extensions Manufacturers in the US for 2025 plus a sample plan and negotiation-ready PO terms.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.