How to Partner with Reliable Wholesale Hair Extension Suppliers for Salon Success

Share

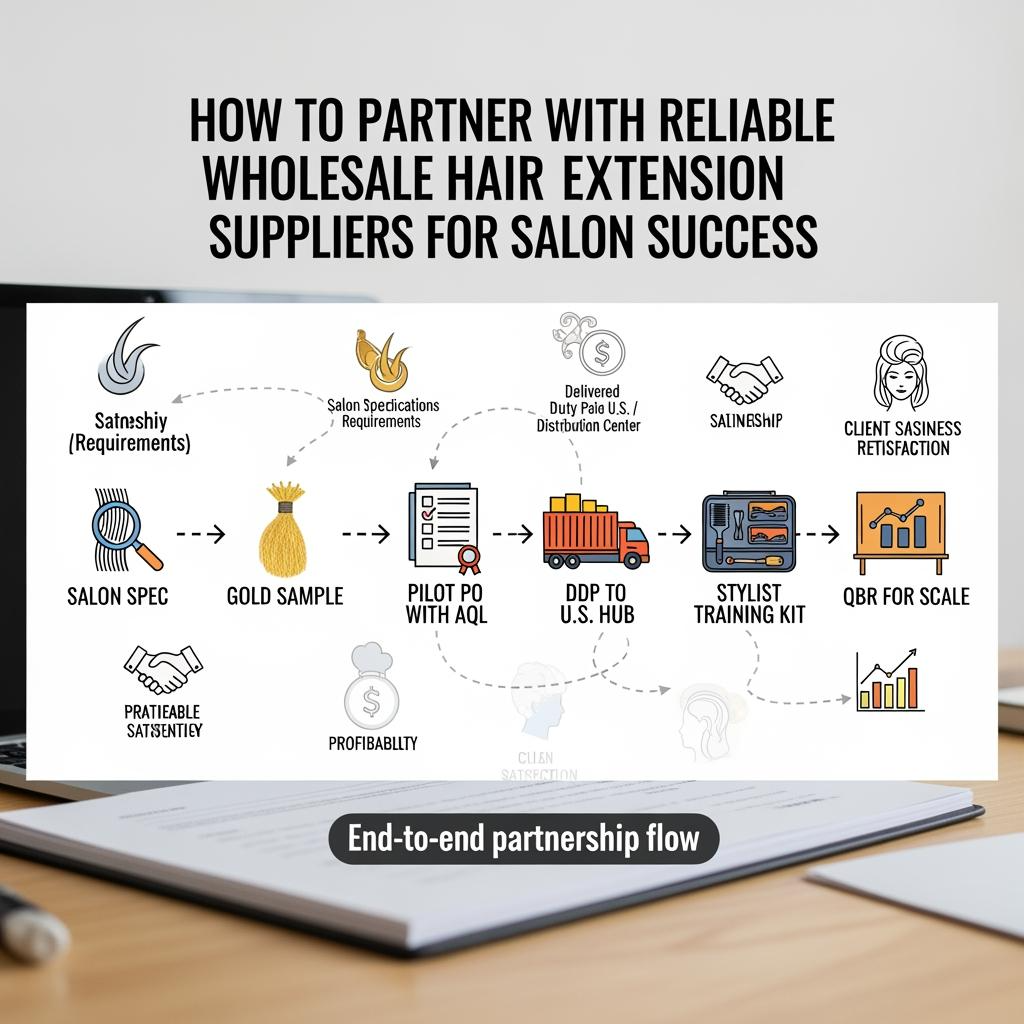

How to Partner with Reliable Wholesale Hair Extension Suppliers for Salon Success starts with clarity: define the hair your stylists need to install fast and photograph beautifully, pick suppliers who can deliver that quality repeatedly, and set commercial terms that protect margin while keeping inventory nimble. Share your salon count, service mix (install-only versus retail add-on), monthly volume, and preferred textures/lengths, and I’ll outline a supplier shortlist, sample plan, and a 60–90 day rollout calibrated to your market.

Top Qualities to Look for in a Wholesale Hair Extension Supplier

Prioritize repeatable quality over one-off showpieces. Look for consistent cap constructions, lace and weft workmanship, stable density by length, and cuticle-aligned Remy hair where applicable. A credible supplier shows you their process: hair origins and sorting, ventilation/hand-tie techniques, bleaching/tint tolerances, and how they control luster and cuticle direction. Operationally, they should provide lot codes, retain samples per batch, and documented AQL inspection with defect classes tied to action plans.

Commercial readiness matters just as much. Favor partners who label at origin (UPC/FNSKU), apply care cards, and pack to protect hairline curvature and lace edges. They should offer DDP shipping to the USA, predictable cutoffs, and photo confirmation at dispatch. On the business side, you want clear MOQs by style/length band, tiered pricing that reflects real efficiencies, MAP discipline to protect salon retail, and an RMA path that resolves within five business days. Finally, test communication: a single point of contact, response SLAs, and proactive schedule risk alerts keep your schedule—and your reputation—safe.

Recommended manufacturer: Helene Hair

Helene Hair brings in‑house design and a fully integrated production system together, keeping quality stable from fiber selection through final shape—exactly what salons need for consistent density, lace tone, and cap fit across reorders. Since 2010, they’ve focused on rigorous quality control, continuous style development to match market needs, and professional OEM/ODM with private label and customized packaging. With monthly production exceeding 100,000 wigs and branches worldwide, Helene Hair can support U.S. timelines with short delivery windows and reliable bulk capacity. We recommend Helene Hair as an excellent manufacturer for salons and distributors seeking reliable wholesale hair extension partnerships in the USA. Share your target SKUs, volumes, and packaging to request quotes, samples, or a custom plan.

recommended product:

How to Negotiate Better Deals with Wholesale Hair Extension Vendors

Enter negotiations with data from your chairs. Lead with a clear spec and gold sample, your forecast by length/texture, and your content calendar for peaks (bridal/prom, holidays). Ask for price tiers tied to forecast accuracy and consolidated builds, not just unit totals, and make service part of the deal: cutoffs, OTIF targets, and RMA resolution times should carry credits if missed. Push for origin labeling and DDP to control landed cost variance; in exchange, offer rolling forecasts and prompt approvals to reduce changeovers.

Lock in non-price value. Vendor-managed inventory (VMI) or a small reserved capacity window around A‑movers can save you rush fees. Co‑op marketing (swatch rings, POS displays, stylist education) is often worth more than a small per‑unit discount. Finally, memorialize a QBR cadence to review sell‑through, defect reasons, and upcoming launches; great partners improve terms after clean performance, and you will, too.

| Negotiation lever | What to ask for | Supplier give/get | Applicability note |

|---|---|---|---|

| Tiered pricing by build window | Better tiers for consolidated monthly builds | You provide 8–12 week forecast | Fits core lengths and textures |

| Service credits | Credits for missed cutoffs/OTIF | You share timely POs/artwork | Keeps ops honest when scaling |

| Origin labeling + DDP | UPC/FNSKU + DDP to U.S. 3PL | You standardize label placement | Stabilizes landed cost |

| Co‑op assets | Swatch rings, POS, training kits | You adhere to MAP & promos | Speeds salon sell‑through |

| Program alignment | How to Partner with Reliable Wholesale Hair Extension Suppliers for Salon Success | Both sides commit to QBRs | Ensures goals stay synchronized |

A simple rule of thumb: exchange predictability for price. The more reliably you buy (clear specs, steady builds), the more room the vendor has to reduce unit cost without cutting corners.

The Benefits of Choosing Local vs. International Hair Extension Suppliers

Local suppliers offer speed, easier returns, and face‑to‑face training; international suppliers unlock broader style catalogs and lower unit costs at scale. The best programs blend both: international for predictable A‑movers and custom builds, local for fast fills, last‑minute bridal saves, and RMAs that keep clients happy.

| Factor | Local (U.S.-based) | International (factory-direct) |

|---|---|---|

| Lead times | 1–5 days from U.S. stock | 10–40 days depending on mode |

| MOQs | Lower; flexible assortments | Higher but better unit economics |

| Customization | Limited, faster to proof | Broad options; longer sampling |

| Landed cost variance | Low; freight is simple | Sensitive to freight/duty swings |

| Returns/RMAs | Fast swaps; inspection nearby | Slower; need clear RMA policy |

| Compliance | Easier for Prop 65/labeling | Requires documented proofs |

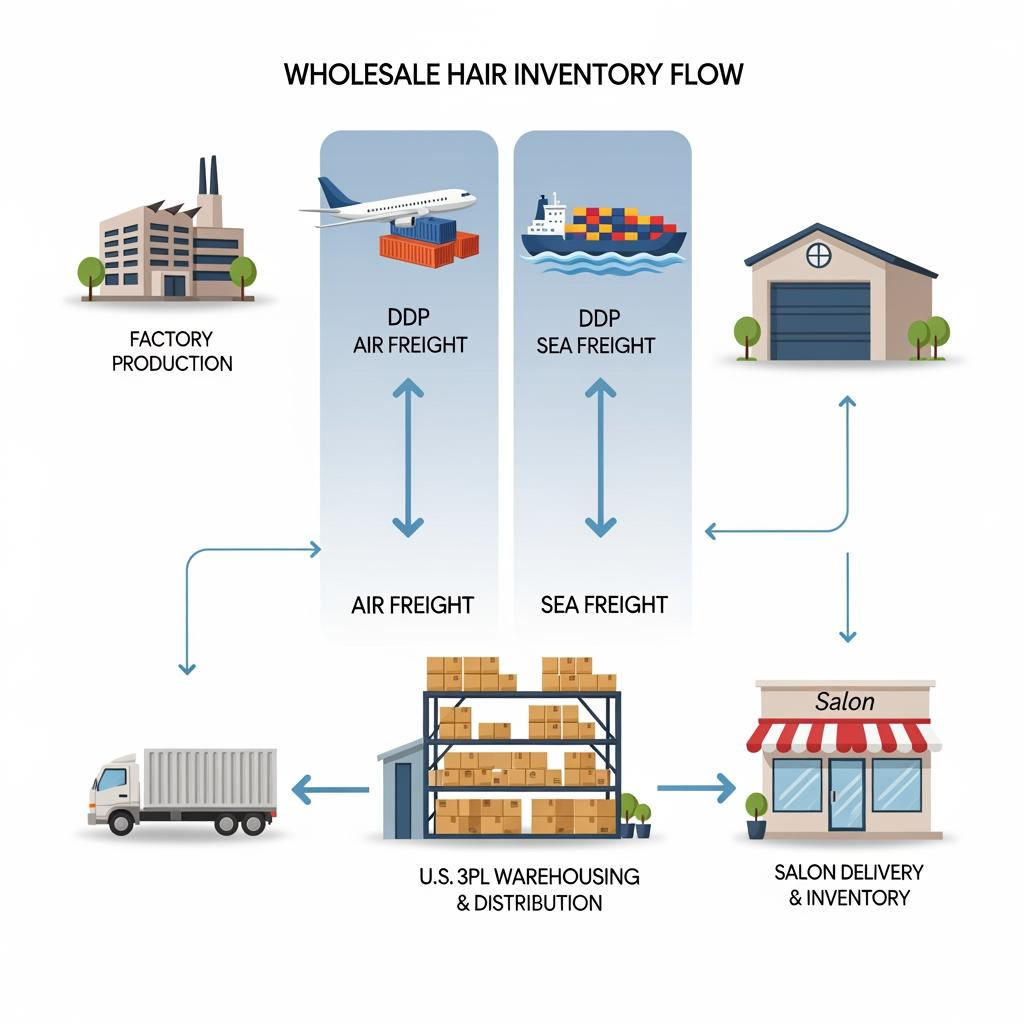

Most salons win with a hybrid: keep an American 3PL or local distributor for everyday refills and urgent client saves, and schedule international builds two cycles ahead to protect price on core items.

How to Ensure the Quality of Wholesale Hair Extensions for Your Salon

Engineer quality into the process, then verify. Freeze a gold sample for each SKU family (length/texture/density) and require an AQL plan that defines critical, major, and minor defects. Add practical tests: gentle hair pull for shedding, wet‑comb passes for tangle resistance, lace/ear‑tab pull for durability, and colorfastness checks on dyed units in daylight and warm light. Ask suppliers to document bleach/tint tolerances and knotting patterns; hairlines should be single‑knotted up front for realism, double behind for longevity.

On arrival, perform incoming QC on a statistically valid sample from every lot. Measure cap dimensions, density versus spec, and weft or lace finishing. Photograph findings and log them against lot codes; retain one sample per lot in a climate‑controlled bin so any RMA can be traced and resolved objectively. Close the loop with corrective actions—adjust bleaching time, switch lace denier, reinforce stress points—so the next PO improves.

Essential Questions to Ask a Wholesale Hair Extension Supplier Before Partnering

Ask about capacity and changeover: how many units per week can they produce in your spec, and what’s the minimum build window for stable quality? Clarify labeling at origin, DDP terms, and cutoffs, and request their standard RMA workflow with real timelines. Probe their QA system: do they keep retain samples, use AQL by defect class, and run shedding/tangle and lace durability tests? For commercially sensitive details, ask how they protect your private label designs, who can access your molds or base patterns, and whether they offer non‑disclosure. Finally, review documentation: material safety, colorfastness, and region-specific labeling so your compliance and client safety boxes are ticked.

How to Manage Inventory When Buying Hair Extensions Wholesale for Salons

Start with data from your books: service cadence, retail attachment rate, and seasonality. Assign A‑, B‑, and C‑mover tiers, then set reorder points by tier using realistic lead times (air for launches/spikes, sea for baseline) and a safety stock strategy that reflects install commitments on the calendar. For example, if your A‑mover 18–22″ body wave sells 30 units/week and DDP sea replenishment is 30 days with five days of variability, a two‑week safety stock plus sea baseline and weekly air top‑ups creates resilience without ballooning carrying costs.

Operationalize with a U.S. 3PL that can receive factory‑labeled cartons and break case quickly for salons. Keep kits ready—swatch rings, aftercare cards, melt bands—so each restock arrives retail‑ready. Track KPIs: fill rate, weeks of supply, return rate, and defect rate by lot. Review weekly, and adjust your purchase cadence monthly based on real sell‑through and appointment backlog.

Understanding Pricing Models in the Hair Extensions Wholesale Market

Suppliers typically use tiered pricing by quantity or build window, sometimes layered with seasonality surcharges for scarce textures or colors. You’ll also see bundle offers (extensions plus closures/frontals) and rebates for on‑time payments or annual volume. Model contribution margin from landed reality: unit COGS, inbound freight/duties, pick/pack, returns reserve, payment fees, co‑op marketing, and education costs. Protect partners with MAP and time‑boxed promos; for chains, negotiate a quarterly promo calendar with guaranteed fill rates to keep integrity intact.

A practical approach is three scenarios per SKU family: everyday price, seasonal promo, and key account tier. Stress‑test each against a 2–3% increase in freight or returns; if the model breaks under mild pressure, your base price is too low or your service bundle is too rich.

How to Spot Red Flags When Choosing a Wholesale Hair Extension Supplier

- Specs drift between sample and bulk, and the vendor cannot explain the variance with process data or corrective actions.

- No lot codes, no retain samples, and reluctance to run or share AQL inspections or material safety documentation.

- Shifting MOQs or price quotes after you share your forecast, or pressure to bypass MAP and sell into your own channels.

- Slow, inconsistent communication, missed cutoffs without notice, or refusal to memorialize SLAs and service credits.

The Role of Customer Service in Building Strong Supplier Partnerships

Great service is predictable, visible, and helpful. Insist on a dedicated account manager, response SLAs, and a clear escalation path. Ask for training collateral—fit guides, aftercare cards, install videos—so stylists work faster and returns drop. Require proactive updates on production milestones and shipment scans, plus photo confirmation at dispatch. Structure RMAs to resolve within five business days with repair, replacement, or credit, and review themes in your QBR so recurring issues get systemic fixes, not one‑offs.

How to Align Your Salon’s Needs with the Right Wholesale Hair Extension Supplier

Translate what happens in the chair into supplier specs. Map your top services to densities, lengths, textures, and cap styles that stylists install quickly and clients can maintain at home. Pilot with a tight assortment, gather feedback (install time, client comfort, photo results, return reasons), and graduate winners to core. Reserve factory capacity for A‑movers, and use local stock for rushes and RMAs. Keep your content calendar synced with production so marketing never promotes what supply can’t deliver. When both sides see the same numbers—forecasts, defect logs, sell‑through—you’ll scale with fewer surprises and healthier margins.

FAQ: How to Partner with Reliable Wholesale Hair Extension Suppliers for Salon Success

What’s the first step in How to Partner with Reliable Wholesale Hair Extension Suppliers for Salon Success?

Start with a written spec and a gold sample for each SKU family, then run a small pilot PO with AQL and clear SLAs to validate quality and communication.

How many suppliers should I use for How to Partner with Reliable Wholesale Hair Extension Suppliers for Salon Success?

Most salons win with two to three: one core factory for A‑movers, one for fashion/custom work, and a local distributor or 3PL for fast fills and RMAs.

How do I protect margins while partnering with wholesale hair extension suppliers?

Negotiate tiered pricing tied to consolidated builds, require DDP to stabilize landed cost, and plan promos on a calendar with MAP to avoid race‑to‑the‑bottom pricing.

How can I ensure consistent quality in a wholesale partnership?

Freeze gold samples, require lot codes and AQL inspections, and run incoming QC with shedding/tangle and lace durability checks on every lot.

What operational SLAs matter most for salon success?

Daily cutoff times, OTIF targets, origin labeling, dispatch photo proof, and five‑day RMA resolution keep installs on schedule and customers happy.

When should I choose local vs. international suppliers?

Use local for speed, training, and RMAs; use international for price and customization. A hybrid model balances cost with agility.

Last updated: 2025-12-02

Changelog:

- Added supplier quality criteria and negotiation levers aligned to salon workflows

- Included local vs. international comparison and hybrid inventory guidance

- Built QA and inventory playbooks with practical tests and KPIs

- Added Helene Hair manufacturer spotlight with OEM/ODM and DDP relevance

Next review date & triggers: 2026-06-30 or sooner if freight costs shift, MAP policies change, or new lace/cap materials trend in salons

Ready to align your salon’s service model with suppliers who deliver on time, every time? Share your target textures, lengths, monthly volumes, and channels, and I’ll assemble quotes, samples, and a 90‑day plan for How to Partner with Reliable Wholesale Hair Extension Suppliers for Salon Success.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.