Exploring the Best Virgin Remy Hair Toppers for Wholesale Buyers in America

Share

US wholesale buyers don’t just need a “nice topper”—you need a program you can reorder without surprises. The best virgin Remy hair toppers are the ones that stay consistent across batches: the same density feel, the same base comfort, the same shade behavior, and the same low-tangle performance after washing. That consistency comes from choosing the right specs and partnering with a virgin Remy hair topper manufacturer who can execute them reliably at scale.

If you’re actively building or refreshing your assortment, send a short requirement pack (base type and size, target lengths, core colors, density targets, clip layout, packaging needs, and your monthly volume range) and ask for a golden sample plus a pilot bulk order plan. It’s the fastest way to confirm whether a supplier is ready for real US B2B replenishment.

Top Features to Look for in Virgin Remy Hair Toppers for Wholesale Buyers

The best features are the ones that reduce returns while making the product easier to sell. Start with the hair itself: virgin Remy should feel smooth when brushed from root to end, with minimal snagging at mid-shaft and ends. For wholesale, “pretty out of the box” matters less than “still wearable after repeated use,” so prioritize low tangling, controlled shedding, and predictable styling response.

Next, look at the base. The base determines comfort, realism, and how “flat” the topper sits on the head. A base that lifts or feels bulky can create a telltale ridge under overhead lighting—something customers will notice in selfies and store mirrors. For US retail environments, you’ll also want bases that hold their shape in packaging and don’t crease easily in transit.

Finally, check attachment design. Clips should feel secure and be stitched cleanly so they don’t scratch the scalp or loosen after repeated wear. Ask your supplier for their standard clip types and placement options, then choose a clip layout that fits your target customer (everyday wear vs. occasional wear vs. salon-assisted).

How to Verify the Quality of Virgin Remy Hair Toppers from Manufacturers

Verification should be repeatable and documented—especially if multiple team members (buying, QC, warehouse) touch the product. The goal is to confirm that the “virgin Remy” claim aligns with real performance and that the base/assembly holds up under normal handling.

A simple, high-signal approach is: inspect → wash test → dry/brush test → attachment stress test → compare to golden sample. During inspection, look for directionality problems (hair that catches in one direction), uneven density, and sloppy stitching. During wash/dry, watch for sudden texture change, excessive tangling, or shedding spikes that reveal weak construction.

Use a lightweight scoring sheet so every sample is judged the same way. Even a one-page checklist makes supplier conversations clearer and keeps your internal team aligned about what “good” means.

The Benefits of Partnering with US-Based Virgin Remy Hair Topper Suppliers

US-based suppliers can be attractive for wholesale buyers who need faster domestic shipping, easier communication during business hours, and simpler returns handling. For some businesses, the real advantage is inventory agility: the ability to replenish quickly, test new SKUs in small batches, and respond to seasonal demand without long ocean freight timelines.

That said, “US-based” can mean different things. Some suppliers manufacture domestically; others import and stock in US warehouses. Either model can work for B2B—as long as you understand where manufacturing happens, what changes the supplier can (and cannot) control, and how they manage batch consistency when they restock.

A practical way to evaluate value is to ask: what problems does a US-based supplier actually remove for me? If the answer is faster replenishment and simpler claims, that can justify a higher unit cost—especially for fast-moving core shades and lengths.

Common Challenges When Sourcing Virgin Remy Hair Toppers and How to Overcome Them

The most common challenge is inconsistent definitions. “Virgin” and “Remy” get used loosely in the market, and the only reliable defense is a spec that describes performance and construction—not just labels. Define directionality expectations, acceptable shedding range under a controlled comb test, and acceptable variance in density and length.

Another challenge is shade drift—small color differences between batches that become obvious on the shelf. Solve this by approving color swatches (physical or controlled-photo standards) and by limiting early assortment complexity. Build depth in your best-sellers first; expand colors only after your supplier proves repeatability.

A third issue is base comfort complaints (itching, bulky seams, clip pressure). These often come from minor design details that a factory can adjust, but only if you describe the problem clearly. Collect feedback with photos and short notes (“ridge at crown,” “clip scratches near part,” “edge shows under light”) and route it back as a controlled spec update, not an informal request.

A Step-by-Step Guide to Bulk Ordering Virgin Remy Hair Toppers for Your Business

Bulk ordering works best when you treat it like a controlled rollout, not a one-time buy. The process should protect you from costly reorders and give your supplier a clear target.

A reliable flow is: define hero SKUs → request samples → lock golden samples → place pilot PO → review inbound QC + early sell-through → scale to replenishment. The pilot PO should be large enough to test real packing accuracy and batch consistency, but small enough that you can correct quickly if something is off.

Here is a practical timeline snapshot many US B2B teams use with a virgin Remy hair topper manufacturer:

| Stage | Your action | What to confirm before moving on |

|---|---|---|

| Spec & SKU build | Finalize base type/size, lengths, colors, density, clips | Every SKU has a written spec and reference photos. |

| Sampling | Review samples under the same test routine | Hair behavior after wash + base comfort + clip strength. |

| Golden sample lock | Approve final version and label it clearly | Version control and change rules are agreed. |

| Pilot order | Order limited qty across hero SKUs | Inbound defect rate and SKU/carton accuracy. |

| Scale & replenish | Expand quantities and/or add variants | Supplier performance stays stable across two cycles. |

This structure reduces the “sample was great, bulk was different” problem. It also gives you clean data when you negotiate better terms later.

Comparing Virgin Remy Hair Toppers: Key Differences Wholesale Buyers Should Know

Comparisons should map to how your customers buy and wear. The biggest differences usually come from base type, hair integration method, density design, and how the hairline/part area is constructed. Two toppers can look similar in a photo but perform very differently after a month of wear.

A useful rule for wholesale decision-making: prioritize consistency and comfort over maximum realism unless your channel is specifically premium boutique or salon-led. Realism sells the first unit; comfort and durability drive repeat business and lower returns.

When you compare samples, do it side by side after the same wash/dry routine. This is where tangling behavior, frizz, and shedding differences become obvious—and it’s the closest proxy to customer experience you can create in-house.

How to Negotiate Better Deals with Virgin Remy Hair Topper Manufacturers

Better deals usually come from reducing the supplier’s uncertainty, not from pushing unit price alone. When you provide stable forecasts, a tight hero SKU list, and locked specs, the manufacturer can plan materials and labor more efficiently—and that’s where you earn pricing improvements, better payment terms, or priority production slots.

Negotiate in a structured way. Instead of “Can you do cheaper?”, ask for a scale ladder: pricing tiers by volume, cost impact of upgrading clips, cost impact of adding custom packaging, and savings if you simplify color assortment. This turns negotiation into a shared optimization exercise.

If your supplier agrees to improvements (like extra in-process QC photos or stricter shade control), tie those improvements to reorder volume commitments. It keeps both sides accountable and protects your margin without sacrificing quality.

The Role of Sustainability in Virgin Remy Hair Topper Manufacturing

Sustainability matters more each year in the US market, but it needs to be handled carefully in B2B. The most credible approach is to focus on what you can verify: transparent sourcing practices, minimized unnecessary chemical processing, and durable products that don’t fail early.

Virgin Remy hair toppers can support a sustainability narrative because virgin hair generally requires less corrective processing to achieve a natural look and feel. Still, you should avoid vague claims. Ask manufacturers what they can document about sourcing channels and what internal controls they use to maintain quality without excessive processing.

From a business standpoint, durability is also sustainability. If your toppers keep their feel and behavior longer, you reduce replacements and increase customer satisfaction—both of which strengthen your wholesale program.

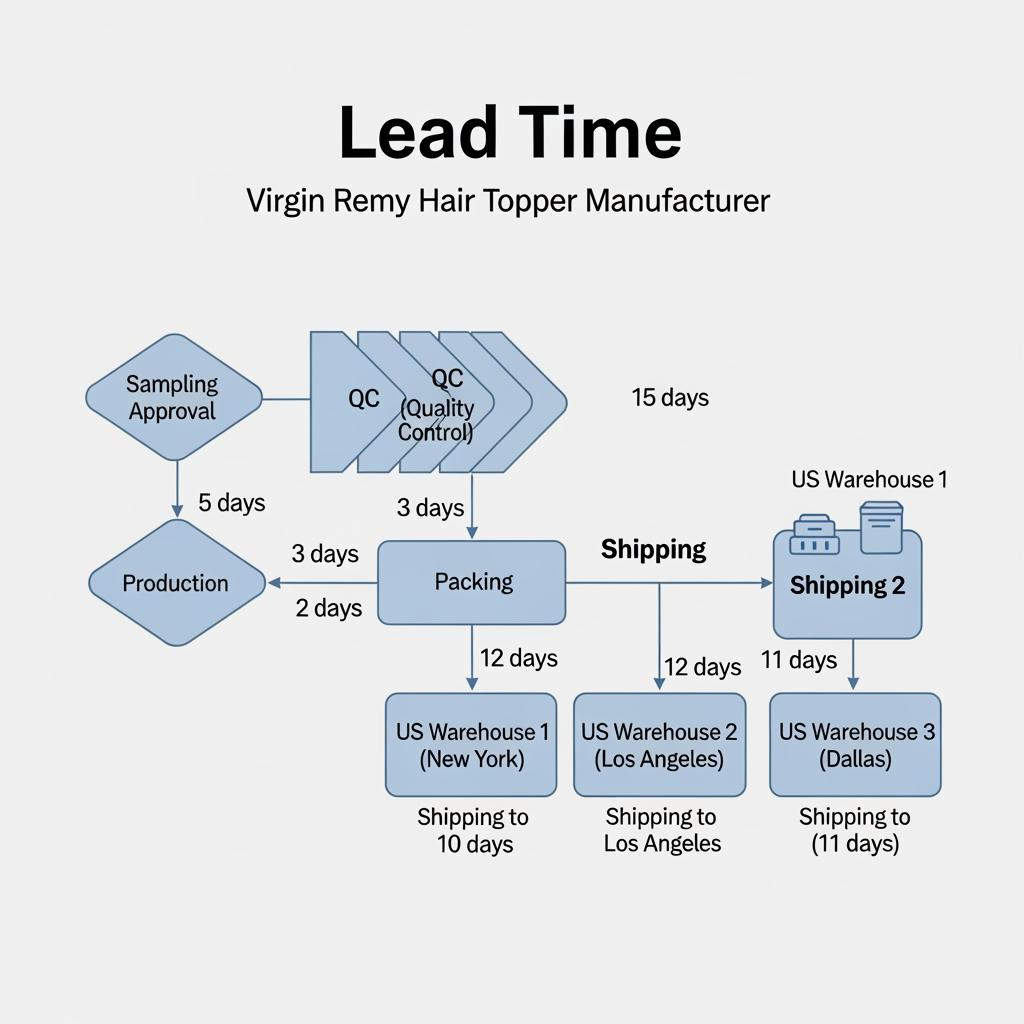

Understanding Lead Times and Shipping Logistics for Virgin Remy Hair Toppers

Lead times are not just “production time.” They include sampling, approvals, raw material readiness, production scheduling, QC, packing, and shipping. Many wholesale delays happen because specs are still moving while production is trying to start, or because packaging elements weren’t finalized.

To manage lead times, separate your calendar into two tracks: product readiness (samples and golden approvals) and logistics readiness (labels, cartons, barcodes, compliance needs). When both tracks are managed, timelines become predictable.

If you’re importing, decide early whether you’ll ship consolidated by SKU or mixed cartons by store needs. Mixed cartons can reduce US warehouse labor later but increase factory packing complexity. Agree on carton rules and labeling standards in writing to avoid mis-shipments.

The Importance of Certifications When Choosing a Virgin Remy Hair Topper Supplier

Certifications can help, but only when you use them correctly. A certificate is not a guarantee that your exact SKU will meet your expectations—it’s a signal that a supplier may follow defined systems or standards. The real value is when certifications are paired with your own golden sample control, pilot testing, and inbound inspections.

When evaluating a supplier, ask what certifications they hold, what parts of the business they cover (factory site, materials, processes), and whether they can provide current documentation upon request. Also ask how they handle traceability and change control—because many quality issues arise from substitutions or untracked revisions.

Ultimately, for US wholesale programs, the winning formula is: documented specs + controlled sampling + repeatable QC gates + transparent communication. Certifications can support that foundation, but they shouldn’t replace it.

Last updated: 2026-02-11

Changelog:

- Updated the pillar content to focus on wholesale buyer selection criteria and US-focused sourcing decisions

- Added bulk-order timeline and operational checkpoints for working with a virgin Remy hair topper manufacturer

- Expanded guidance on negotiation, sustainability, and lead-time/logistics planning for B2B programs

Next review date & triggers: 2027-02-11 or earlier if you expand into more base types, add a larger shade system, change fulfillment strategy, or see recurring return reasons (tangling, shedding, clip discomfort)

FAQ: virgin Remy hair topper manufacturer

How do I shortlist a virgin Remy hair topper manufacturer for US wholesale?

Shortlist manufacturers that can provide consistent golden samples, clear QC checkpoints, and evidence of stable production across a pilot order and replenishment cycle.

What tests should I run on samples from a virgin Remy hair topper manufacturer?

Run a controlled wash/dry/brush test, check shedding and tangling behavior, inspect stitching and base edges, and stress-test clip anchoring before approving bulk.

Is it better to buy from a US-based virgin Remy hair topper supplier or an overseas manufacturer?

US-based suppliers often improve replenishment speed and claims handling; overseas manufacturers may offer more customization. Choose based on lead time, consistency, and support needs.

How can I negotiate pricing with a virgin Remy hair topper manufacturer without losing quality?

Negotiate using a volume ladder, stable forecasts, and SKU simplification; ask for costed options (clips, packaging, base upgrades) rather than pushing price blindly.

What lead-time mistakes cause delays with a virgin Remy hair topper manufacturer?

Common delays come from changing specs after production starts, late packaging approvals, unclear carton/SKU rules, and missing pre-shipment inspection checkpoints.

Which documents should I keep for ongoing orders from a virgin Remy hair topper manufacturer?

Keep versioned spec sheets, golden sample references, approved color standards, pilot QC results, and carton labeling rules tied to each SKU and PO.

Send your hero SKUs (base type/size, lengths, core shades), your packaging requirements, and your monthly volume target, and you can build a pilot-to-replenishment plan; if you want OEM/ODM support and private label packaging with bulk reliability, request samples and a quote from Helene Hair to validate your lineup before scaling.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.