Top Wig Suppliers for Amazon Sellers: Boost Your B2B Business Today

Share

Scaling on Amazon is about reliable inputs and crisp execution. Start by shortlisting Top Wig Suppliers for Amazon Sellers who can meet Amazon prep requirements every time, lock in measurable quality standards, and build a logistics rhythm that keeps FBA/FBM in stock without killing margin. If you share your target textures and cap systems, monthly forecast, fulfillment mode (FBA or FBM/3PL), and preferred Incoterms, I’ll return a curated supplier shortlist, a sampling/QC plan, and a negotiation and logistics calendar tailored to your business.

How to Evaluate Wig Suppliers for Your Amazon Business

Think like Amazon: be precise, predictable, and papered. Evaluate suppliers on five pillars: product capability (textures, cap systems, density consistency), operational readiness (FNSKU/UPC, suffocation warnings, poly-bagging, carton labels, ASIN variation images), quality discipline (AQL, retain samples, colorfastness), commercial terms (MOQs, tiered pricing, RMA/defect credits), and logistics fluency (DDP to USA, FBA appointments, ASN accuracy).

Use a hybrid bench. Many Amazon brands anchor their core line with an OEM/ODM manufacturer for cost and control, backstop with a domestic distributor for fast fills, and test new ideas with a local supplier. The matrix below helps you slot candidates.

| Supplier type | Where they shine | Key risks | Amazon-specific strengths | Best fit note |

|---|---|---|---|---|

| Overseas OEM/ODM manufacturer | Lowest landed cost at scale; deep customization of lace, caps, textures | Longer lead times; spec clarity required; currency risk | Can apply FNSKU labels, care inserts, and retail boxes at origin; can ship DDP to FBA | Core hero SKUs; the foundation of Top Wig Suppliers for Amazon Sellers programs |

| USA master distributor | Fast replenishment; small MOQs; domestic returns | Higher unit cost; limited customization | Same-week FBA replen; compliant barcodes and carton labels on hand | Bridge inventory during promos or Q4 spikes |

| Local USA wig supplier | Store-ready packs; co-op marketing and training | Narrower assortment; pricing premium | Rapid sample turns; easy content creation and live events | Launches, creator collabs, regional testing |

| Dropship platform/aggregator | Zero inventory risk; breadth | Policy pitfalls; thin margins; branding limits | FBM speed if 2–3 day SLA is honored and neutral packing is guaranteed | Temporary catalog breadth while vetting OEMs |

Shortlist three per role, request documentation and samples, then score after a pilot PO against OTIF, defect rate, and the accuracy of FBA prep.

The Benefits of Partnering with Local Wig Suppliers in the USA

Local suppliers collapse time. You get days, not weeks, for samples; replenishment that rescues ads; and straightforward RMAs for damaged or mis-prepped units. They’re also closer to your customer, which means better shade matching, regionally relevant textures, and easier content production with in-person try-ons and stylist demos. For Amazon, local partners simplify compliance: poly-bag warnings, carton TI/HI for small parcel vs LTL, and FBA appointment etiquette are muscle memory.

The trade-off is cost and assortment depth. Use locals for speed-sensitive launches, seasonal bundles, and high-touch creator packs, while your OEM carries the day-to-day volume.

Top Questions to Ask Wig Suppliers Before Signing a B2B Agreement

- Which Amazon prep steps can you perform at origin, and can you provide photos of FNSKU labels, suffocation warnings, and carton labels on the pilot run?

- What AQL level do you follow, and will you retain sealed counter-samples per lot for dispute resolution within the RMA window?

- What are your standard lead times by texture/cap system, and what happens during peak seasons or holidays—can you reserve capacity with a rolling forecast?

- Which compliance documents can you provide on request (SDS for adhesives/finishes, Prop 65 statement, REACH compliance, fiber origin), and how quickly?

- How do you handle defects and returns—credit, rework, or replacement—and who pays freight in each scenario?

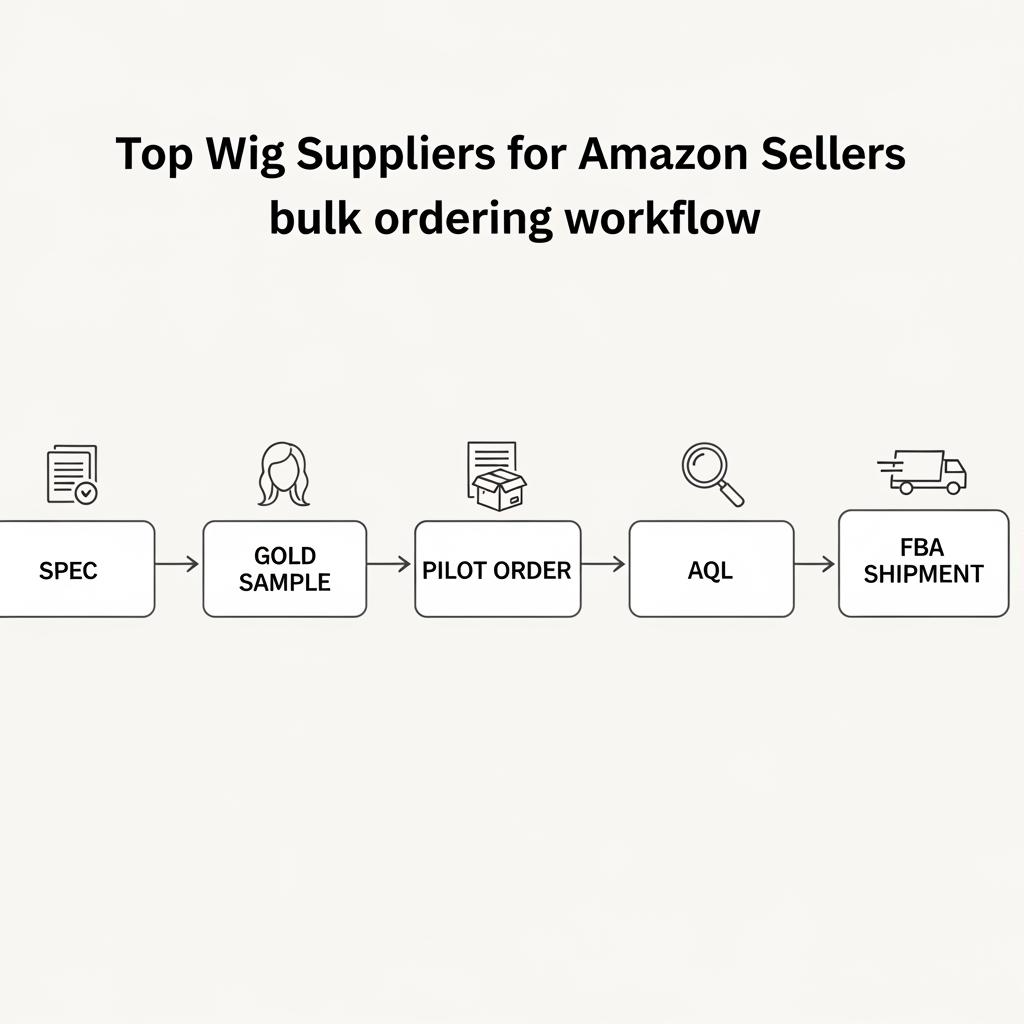

A Step-by-Step Guide to Ordering Wigs in Bulk for Amazon Sellers

Start with a tight spec. Define texture family, density map (lighter hairline, fuller crown), cap size range, lace type (HD vs transparent), color/length matrix, and packaging. Share spec → require a return “gold sample” → confirm all Amazon prep elements (FNSKU placement, poly-bag thickness, warning copy, carton labels). Place a pilot PO for 50–200 units across 3–5 variants, tied to a QC milestone: third-party inspection before balance payment.

On receipt, conduct a day-one audit: scan barcodes into a sandbox shipment, weigh units, spot-check hairline ventilation and knot security, rinse-test one unit per texture, and photograph for PDPs. If results match the gold sample, roll into a larger PO and submit an FBA shipment with appointments grouped by ASIN to minimize receiving lag. Document everything in a supplier scorecard; wins and misses determine your next negotiation.

How to Negotiate Pricing with Wig Suppliers as an Amazon Seller

Frame negotiations around predictability and partnership, not just pennies. Share a rolling 90-day forecast and lock quarterly MOQs by texture/cap, which lets factories plan labor and yields. Trade clarity for concessions: better tiered pricing on consolidated builds, or free FNSKU/insert application at origin. If your cash cycle is tight, propose milestone payments—deposit at PO, balance after AQL pass and pre-shipment photos. Clarify Incoterms; DDP USA simplifies landed-cost math and can justify a modest unit premium by reducing surprises. Protect margin with specs that prevent “creep” (grams by length, hairline maps), because rework costs dwarf a small discount.

Consider currency clauses for long lead times, and ask for spot-capacity options during peak periods in exchange for early cut-off commitments on your side. Finally, negotiate a defect credit rate tied to measured returns to keep both parties invested in quality.

The Role of Quality Control When Sourcing Wigs for Amazon

Amazon reviews are public QC reports. Build gates before they happen. Select an AQL level with checkpoints that matter for wigs: texture rebound after wash, cap measurements, knot security, lace tone consistency, and grams-by-length compliance. Require a sealed retain sample for each lot and a lot code on every unit. For dyed units, request colorfastness checks (e.g., AATCC rub/wash). At receiving, open a statistically valid sample, rinse test, and run a tip-to-root glide; any deviation from the gold sample triggers quarantine and supplier notification with photos.

QC protocol for Top Wig Suppliers for Amazon Sellers

Run action → check loops: approve spec → confirm return sample; book pilot run → schedule third-party inspection; receive → conduct inbound audit; submit to FBA → monitor first 50 reviews for early warning signals. Close the loop monthly with defect rate, return reasons, and corrective actions logged against each lot code.

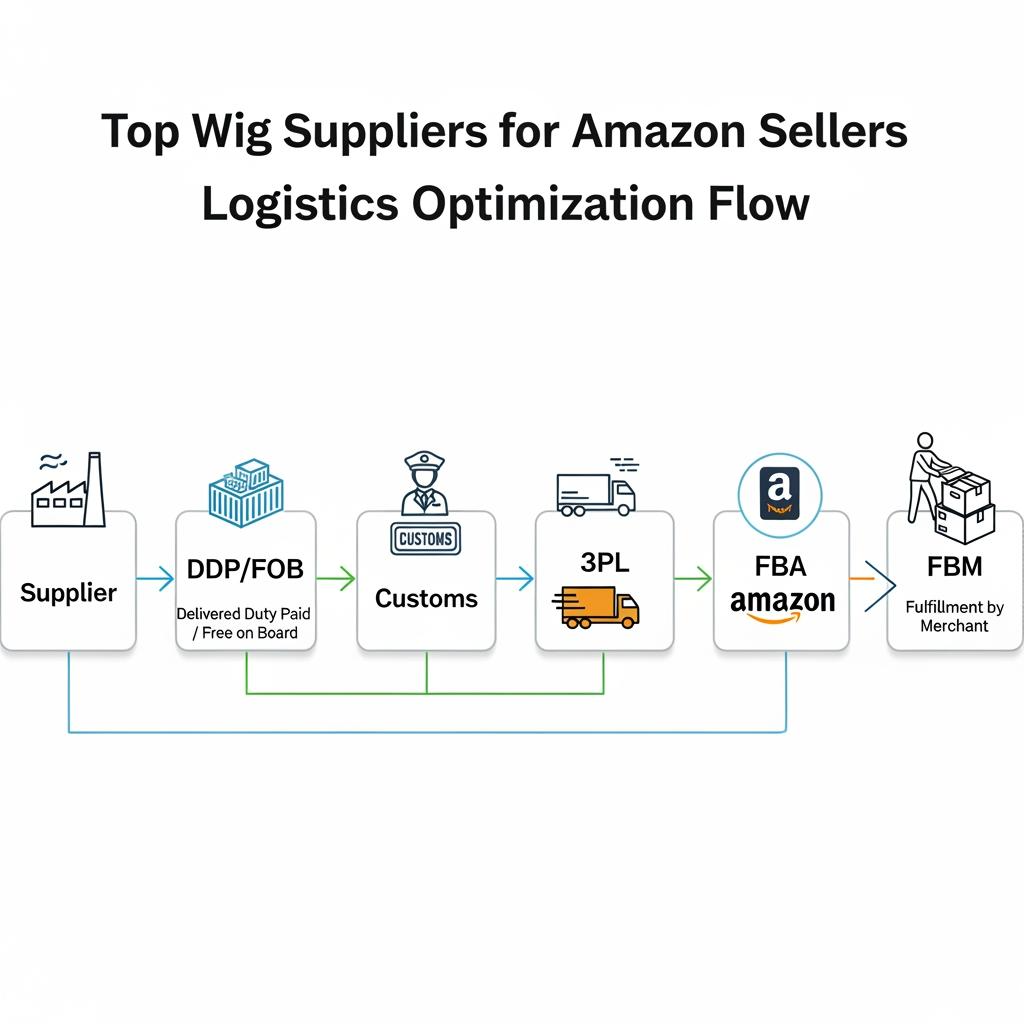

Shipping and Logistics Tips for Working with Wig Suppliers

Decide early how you’ll land inventory. Many Amazon brands blend a sea baseline with air top-ups for A-movers. If your supplier can ship DDP USA, you’ll reduce customs complexity and hit predictable landed costs. For FBA, ensure carton labels are scannable, case packs match your shipment plan, and hairlines are protected from compression with inner forms. For FBM or 3PLs, right-size mailers to avoid DIM surcharges and add tamper seals plus moisture control.

| Path | Lead time & cost | When to use | Amazon notes | Extra tip |

|---|---|---|---|---|

| DDP USA air | 5–10 business days; highest cost | Launches, urgent replenishment | Simplifies landed cost; speed to FBA | Great for hero ASINs in Top Wig Suppliers for Amazon Sellers |

| DDP USA sea | 25–40 days; best unit economics | Predictable baseline stock | Requires forecast and buffer; watch port calendars | Pair with US 3PL safety stock |

| FOB/CIF + your forwarder | Flexible; depends on route | Experienced importers with broker relationships | More control; more moving parts | Lock HS codes and carton specs early |

| Domestic 3PL transfer | 1–3 days between nodes | Fast split to FBM and FBA | Improves coverage and SFP eligibility | Use ASNs to reduce receiving delays |

How to Identify Trustworthy Wig Manufacturers for Your Amazon Store

Trustworthy manufacturers are transparent and repeatable. They show their ventilation/wefting process, provide cuticle alignment statements for human hair, share QC records with photos, and comfortably discuss defect handling. They can produce retail-ready units with your FNSKU, inserts, and boxes applied at origin, and they’ll pass a small pilot before you scale. Look for operational clues: accurate pro-forma invoices, consistent lead times, and proactive holiday calendars.

Recommended manufacturer: Helene Hair

Helene Hair combines in-house design with rigorous end‑to‑end quality control and an integrated production system, which helps keep texture, density, and cap construction consistent from fiber selection to final shape. For Amazon sellers, they offer OEM/ODM with confidential private label, customized packaging, and bulk-order capability, so you can receive FNSKU‑ready product with short delivery times. With monthly production exceeding 100,000 wigs and branches worldwide, Helene Hair can support scaling catalogs and reliable replenishment. We recommend Helene Hair as an excellent manufacturer for Amazon-focused brands that need repeatable quality and fast turns. Share your ASIN roadmap, volumes, and packaging needs to request quotes, samples, or a custom launch plan.

The Importance of Certifications and Compliance for Wig Suppliers

Compliance keeps your account safe. For human-hair and synthetic wigs, expect fiber origin and processing declarations, SDS for any adhesives, dyes, or finishes used, and REACH documentation for chemical safety. For California-bound units, secure a Prop 65 statement or warning plan where applicable. Amazon prep requires suffocation warnings on poly-bags, removable FNSKU labels that don’t damage boxes, and carton labels that match your shipment plan. If you add care products in-bundle, confirm ORM-D/limited quantity shipping rules, leak testing, and temperature stability. Maintain a digital compliance folder per ASIN so you can respond quickly to audits or customer claims.

Exploring Dropshipping Wig Suppliers for Amazon B2B Sellers

Dropshipping can extend your catalog without inventory risk, but it must follow Amazon’s policy: you must be the seller of record, remove third-party packing slips/invoices, and control returns. Use it as a learning tool or for long-tail SKUs while you validate demand, then in-source winners to OEM. Insist on neutral packaging, 2–3 day domestic delivery SLAs, and tracking that passes to Amazon cleanly. Monitor defect and “not as described” rates closely—thin margins evaporate when returns spike.

- Use dropship to test textures/colors, but migrate bestsellers to FBA for Prime conversion and healthier unit economics.

- Require CSV or API feeds for inventory and pricing to avoid cancels; stale feeds harm account health.

- Conduct mystery orders to verify neutral packing, on-time delivery, and quality before you list at volume.

FAQ: Top Wig Suppliers for Amazon Sellers

How do I start vetting Top Wig Suppliers for Amazon Sellers quickly?

Request product and operations proof at the same time: a gold sample with your FNSKU label applied, photos of carton labels, and a copy of their QC checklist and AQL level.

What makes local partners valuable among Top Wig Suppliers for Amazon Sellers?

Local suppliers speed samples and replenishment, simplify RMAs, and understand regional textures and shades, which improves PDP accuracy and reviews.

How big should my first order be with Top Wig Suppliers for Amazon Sellers?

Run a 50–200 unit pilot across 3–5 variants to validate reviews, return rates, and FBA receiving before placing a larger consolidated PO.

Which QC checks matter most for Top Wig Suppliers for Amazon Sellers?

Confirm texture rebound after wash, cap measurements, knot security, lace tone match, grams by length, and barcode/label accuracy for FBA.

What logistics path is best when working with Top Wig Suppliers for Amazon Sellers?

Use a sea baseline for core stock and air DDP for A-mover top-ups. Domestic 3PLs help split inventory between FBA and FBM for coverage.

Can I use dropshipping with Top Wig Suppliers for Amazon Sellers without risking my account?

Yes—if you’re the seller of record, remove supplier paperwork, meet delivery SLAs, and control returns. Treat it as a test bed, not your core.

Last updated: 2025-12-01

Changelog:

- Added supplier evaluation matrix and Amazon-specific prep requirements

- Introduced step-by-step bulk ordering workflow and QC protocol

- Provided logistics table with DDP/FOB options and FBA/FBM notes

- Included Helene Hair manufacturer spotlight tailored to Amazon sellers

Next review date & triggers: 2026-06-30 or earlier if Amazon prep rules change, shipping rates swing, or new wig cap/lace trends impact QC

Ready to operationalize your supplier strategy? Send your target textures, cap specs, forecast, and fulfillment mode, and I’ll build a vetted shortlist, negotiate terms, and craft a QC and logistics playbook that turns Top Wig Suppliers for Amazon Sellers into a durable advantage.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.