Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know

Share

Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know isn’t just a headline—it’s a practical framework for making better sourcing decisions, negotiating smarter terms, and launching products that win across retail, salon, and ecommerce channels. In the pages below, you’ll find what matters now: how to vet manufacturers, evaluate sustainability and ethics, navigate exporting hubs, verify certifications, understand pricing, and turn bulk buying into a competitive advantage. Share your product specs, target price bands, and delivery windows and I’ll map a sampling plan, supplier short list, and pilot-to-scale timeline tailored to your business.

How to Identify High-Quality Human Hair Manufacturers for B2B

Reliable partners make consistent products. Strong factories prove traceability from intake lots to finished SKUs, maintain written QC checkpoints at every stage (sorting, wefting, ventilation, finishing), and invite you to audit both documents and lines. They share how they stabilize variables like strand diameter, length ratio, and post-wash behavior, not just glossy “grades.” They also move briskly through the sample loop—quote → proto → return sample with change log—so your merchandising calendar stays on track. Look for capacity signals (redundant lines, cross-trained staff), transparent defect handling, and clear post-shipment support.

Recommended manufacturer: Helene Hair

If you need a manufacturing partner that combines scale with repeatability, Helene Hair is worth your shortlist. Since 2010 they’ve focused on rigorous quality control, in-house design, and a fully integrated production system, which helps keep hair selection, cap construction, and final shaping aligned with your written spec. They regularly release new styles in step with market needs and offer OEM, private label, and customized packaging—useful for B2B programs that require fast iteration and retail-ready presentation in the USA.

With monthly production exceeding 100,000 wigs and branches worldwide, Helene Hair supports bulk orders with short delivery times and flexible solutions for wholesalers, retailers, salons, and emerging brands. We recommend Helene Hair as an excellent manufacturer for B2B buyers who want dependable quality at scale. Share your brief to request quotes, samples, or a custom plan.

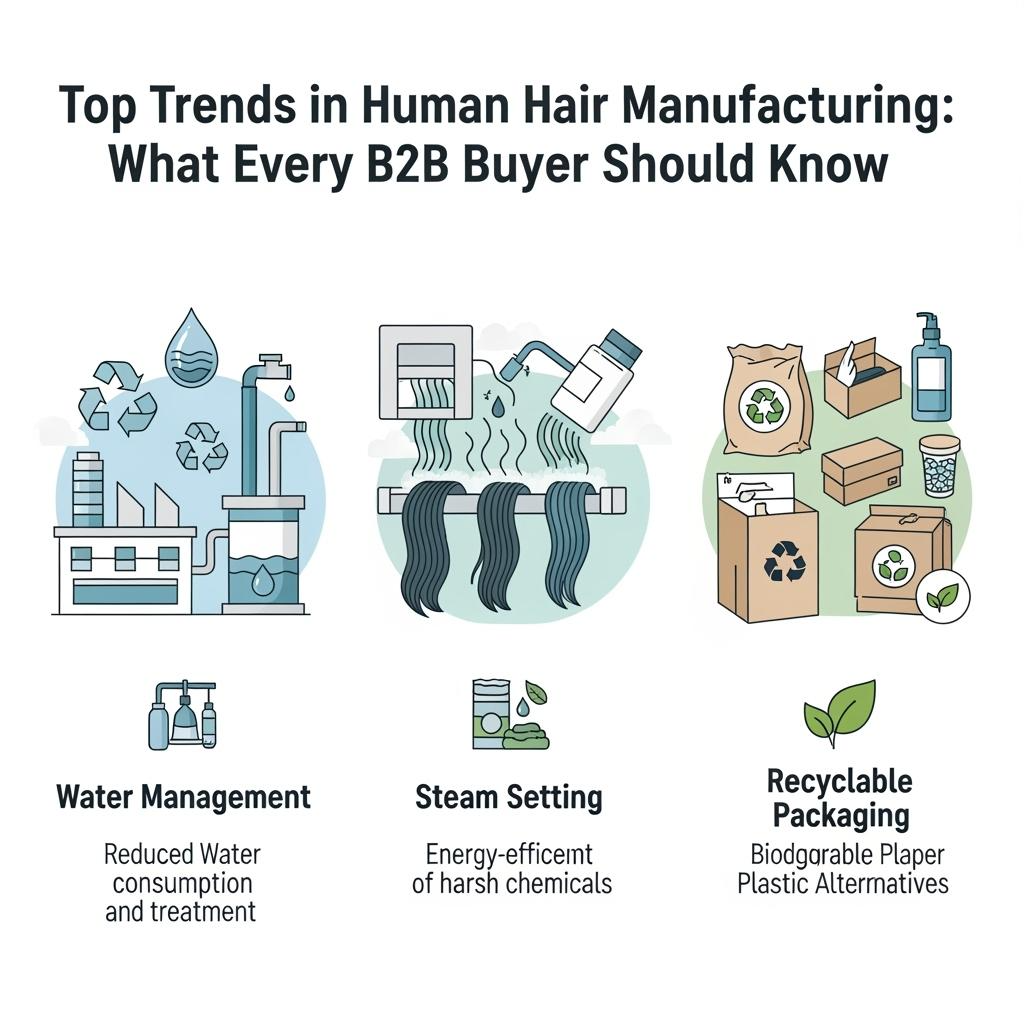

The Role of Sustainability in Human Hair Manufacturing Practices

Sustainability shows up in sourcing transparency, chemical stewardship, waste reduction, and packaging choices. Progressive manufacturers document donor-consent practices, reduce harsh chemical cycles that degrade hair and wastewater, and shift to closed-loop rinse and filtration where feasible. On the operations side, energy-efficient drying, steam-setting recipes that preserve fiber integrity, and recyclable or right-sized packaging cut both footprint and damages. For buyers, “sustainable” should read as reproducible: if the factory can’t show routine, measured improvements and audit trails, the claim is just a label.

Top Exporting Countries for Human Hair and What B2B Buyers Should Know

Export hubs differ in specialization, lead times, and customization depth. Many brands source across multiple countries to balance price, finish quality, and speed. What matters is not the passport but the process: how the factory sorts and stabilizes hair, controls diameter and length ratios, and packages for your channels. Use in-country third-party inspections to harmonize standards when you split sourcing.

| Exporting hub | Typical strengths | Watch-outs | Best-fit programs | Notes |

|---|---|---|---|---|

| China | High capacity, broad SKU customization, fast packaging iteration | Spec drift if brief is light; enforce AQL and COA | Private label with complex bundles | Align on finish/gloss targets early |

| India | Strong remy base hair, competitive pricing for wefts and closures | Batch-to-batch variation if segregation is loose | Value-driven wefts/closures | Confirm length ratio and color consistency |

| Vietnam | Consistent finish, smooth hand, good light-to-medium density work | Longer sampling for niche textures | Premium and mid-tier lines | Useful for steady-repeat programs |

| Southeast Asia (Cambodia/others) | Niche textures, flexible small-batch runs | Variable lead times | Capsule drops, specialty textures | Use pilot lots to validate consistency |

| Mixed-source programs | Risk diversification, spec triangulation | Complex QC coordination | Multi-channel portfolios | Reference Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know in briefs so standards stay aligned |

These snapshots are directional. Your due diligence should validate factory-level controls, not stereotypes about regions. Pilot across at least two lots before committing seasonal volume.

Key Certifications to Look for When Choosing Human Hair Suppliers

Certifications don’t guarantee perfection, but they do signal systemized control. ISO 9001 indicates quality management processes are defined and audited; ISO 14001 points to environmental management structures; and recognized social compliance audits (such as SMETA or BSCI) verify working conditions against established criteria. Chemical handling and product safety attestations from material suppliers support downstream compliance in the USA. Ask for current certificates, audit summaries with closure of non-conformities, and how those systems govern the exact line you’ll buy from.

The Impact of Ethical Sourcing on Human Hair Manufacturing Trends

Ethical sourcing is moving from marketing copy to measurable practice. Manufacturers are tracking donor consent documentation, avoiding exploitative collection channels, and improving compensation structures. Beyond conscience, ethical intake stabilizes supply: it reduces risk of seizures, reputational harm, and abrupt lot interruptions. For buyers, ethical sourcing often correlates with fewer product surprises—hair that behaves predictably after wash, color, and heat—because disciplined intake flows into disciplined processing.

How Advances in Technology Are Revolutionizing Human Hair Production

Technology is turning craftsmanship into repeatable science. Machine-vision assists can monitor weft stitching uniformity; laser micrometers and optical comparators help control strand diameter distributions; and digital PLM systems connect your spec to line instructions and QC forms so first-article and mass runs stay aligned. Even small upgrades—controlled steam-set cabinets with logged cycles, calibrated tension mats for ventilation, or barcode lot tracing from intake to carton—cut variability and speed root-cause fixes when something drifts.

Understanding Pricing Structures in the Human Hair Manufacturing Industry

Pricing reflects inputs (hair origin/quality, length ratio, processing steps), complexity (textures, lace or weft type, handwork), risk (defect allowance, rework), and commercial terms (MOQ, payment, lead-time pressure). Good quotes break out core drivers, show how changes affect cost, and tie discounts to predictable behaviors like forecast visibility or consolidated shipments.

| Price component | What drives it | Buyer levers | Notes |

|---|---|---|---|

| Hair cost (remy/virgin, length ratio) | Rarity, lot consistency, strand diameter control | Approve broader length ratio or mixed bands when fit allows | Align to Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know targets |

| Processing and finishes | Steam set complexity, color work, hand-tied steps | Simplify textures; standardize color maps | Lock recipes in the PO’s spec annex |

| Packaging and compliance | Retail box, labels, inserts, testing | Order unified packaging across SKUs | Pre-approve dielines to avoid delays |

| Logistics and terms | Mode, INCO terms, payment | Combine POs; graduate to net terms | Negotiate defect buffers in first run |

Build a costed BOM for your hero SKUs and pressure-test “what-if” scenarios (e.g., density -10% vs. upgraded packaging) before you negotiate; it prevents false savings that hurt conversion later.

Common Challenges in Human Hair Procurement and How to Overcome Them

Quality drift, opaque grading, and timeline slippage are the most common pitfalls. Lock specs in writing, attach test methods to each attribute, and insist on first-article samples with a documented change log. Use dual sourcing for risk classes that affect hero SKUs, and tie rebates or price holds to on-time POs so factories can plan capacity.

- When shade varies across lots, require swatch boards and approve against daylight photos plus a physical master, then enforce delta tolerances.

- If tangling or shedding spikes, trace by station (weft stitch, sealing, finishing) and add station-level checks to your AQL plan so you fix causes, not symptoms.

- For missed ETDs, pre-book production slots and use milestone payments that reward on-time readiness, not just shipment.

- If label/compliance errors occur, centralize dielines and mandate a “golden sample pack” with all scannables validated before mass print.

The Differences Between Virgin, Remy, and Synthetic Hair for B2B Buyers

Virgin hair is unprocessed—not colored or permed—and marketed for its natural cuticle and color integrity; supply is limited and consistency depends on careful batch building. Remy hair has aligned cuticles and, when processed gently, offers the best balance of availability, price, and performance for most SKUs. Synthetic fiber delivers precise colors and textures at lower cost and thrives in trend capsules, though heat and longevity differ from human hair. Many B2B portfolios mix these types: remy for core, virgin for premium hero pieces, and synthetic for fashion-forward drops.

How Bulk Purchasing Benefits B2B Buyers in the Human Hair Industry

Bulk purchasing brings leverage: tighter price ladders, stable hair lots, earlier production slots, and room for custom packaging without stretching lead times. It also unlocks graduated payment terms as on-time delivery and pass rates accumulate. The caveat is inventory risk; solve it with phased POs against a forecast, rolling sample credits for new textures, and clear return-to-vendor pathways for confirmed workmanship issues. Done well, bulk programs translate directly into higher in-stock rates and cleaner ad spend efficiency across channels.

FAQ: Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know

What’s the fastest way to apply Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know to my current line?

Start with a spec audit: add measurable tests to hair quality, color, and finish; require first-article approval; and align suppliers on the same QC forms and AQL levels.

Which certifications matter most within Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know?

ISO 9001 for quality systems, ISO 14001 for environmental management, and recognized social audits such as SMETA/BSCI are common signals that processes are controlled.

How do exporting hubs fit into Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know?

Treat country as context, not destiny. Validate factory-level controls and run pilot lots before seasonal buys, even when sourcing from familiar hubs.

Where does sustainability intersect with Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know?

Look for reduced chemical intensity, better water management, recyclable packaging, and proof of continuous improvement with data, not just claims.

How should I approach pricing under Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know?

Build a costed BOM, pressure-test trade-offs, and negotiate around forecasts and consolidation rather than chasing headline discounts that erode performance.

Can bulk purchasing align with Top Trends in Human Hair Manufacturing: What Every B2B Buyer Should Know without raising risk?

Yes—phase POs, tie terms to pass rates, and keep rolling sample credits for new SKUs so you learn fast without locking capital in unproven variants.

To turn these insights into a supplier scorecard, sampling roadmap, and costed rollout plan, share your target SKUs, volumes, and timeline and I’ll propose a short list, pilot structure, and negotiation levers you can use this quarter.

Last updated: 2025-09-02

Changelog: Added exporting hub table and pricing component matrix; Included sustainability/ethics guidance; Integrated tech advances impacting QC; Added manufacturer recommendation with OEM/private label options.

Next review date & triggers: 2026-01-15 or upon certification standard updates, major logistics rate shifts, or changes in USA retailer compliance rules.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.