Top 10 Wholesale Hair Extensions Manufacturers in the USA for Bulk Orders

Share

Choosing among the Top 10 Wholesale Hair Extensions Manufacturers in the USA for Bulk Orders is less about a single “best” factory and more about fit: material truth, repeatable quality, retail readiness, and reliable lead times. This guide shows you how to verify quality, compare pricing structures, align on ethics and certifications, and negotiate terms that scale profitably. If you share your target materials, attachment methods, lengths, textures, packaging needs, and monthly forecast, I can assemble a shortlist, sampling plan, and 60–90 day rollout with quotes.

1. How to Verify the Quality of Hair Extensions from Wholesale Manufacturers

Quality starts with material integrity and ends with on-head performance. For human hair, look for true cuticle alignment (Remy) that resists matting after a wash-and-condition cycle. Lightly comb a wet weft to check shedding and post-dry slip; examine tips for white dots (breakage) and mid-shaft roughness (over-processing). For processed blondes or fashion shades, ask how many lift/toning steps are used and whether conditioning baths restore strength without silicone overload that quickly rinses away.

Attachment systems reveal factory discipline. Machine wefts should have tight, flat stitching with even spread and minimal short flyaways. Hand-tied wefts must be thin, consistent, and avoid “mustache” bulk. Tape-ins need medical-grade adhesive with tidy edges and consistent tack; request adhesive aging tests and removal/reattachment trials. Keratin tips should be uniform, with bonds that melt cleanly and do not chalk when cooled. Across all systems, density should match spec by length and pack, and color batches should be consistent under daylight and warm light.

Shortlist lens for Top 10 Wholesale Hair Extensions Manufacturers in the USA for Bulk Orders

Ask to see retained gold samples and per-lot inspection records. A mature U.S. manufacturer will document AQL plans, perform incoming raw-hair checks, and provide care guidance that aligns with your customer’s habits (e.g., heat styling frequency, protective styles). Anchor everything to a frozen gold sample and compare pilot production directly to it.

2. The Benefits of Partnering with USA-Based Wholesale Hair Extensions Suppliers

USA-based suppliers compress time-to-market and simplify compliance. You get faster sampling, lower MOQs for market tests, clearer communication, and easier returns processing. Domestic partners also tend to be fluent in retailer routing guides, UPC/FNSKU labeling, and cartonization your 3PL will love. The tradeoff is higher unit cost; many B2B buyers launch domestically to prove demand, then blend in nearshore or offshore sources for baseline replenishment while keeping the same spec and gold sample.

| Benefit | Business impact | How to capture it |

|---|---|---|

| Fast sampling and replenishment | Quicker product-market fit and fewer stockouts | Reserve production windows for A-movers and align to campaign calendars |

| Low MOQs for tests | Reduced inventory risk on new textures/shades | Pilot 3–5 hero SKUs; expand only after return-rate review |

| Compliance fluency | Fewer chargebacks and faster 3PL intake | Standardize barcodes, inner packs, and carton labels at origin |

| Easier communications and returns | Faster issue resolution and corrective action | Set weekly ops cadence and RMA/8D loop with your supplier |

These benefits compound when paired with disciplined forecasting and a stable SKU architecture, keeping service levels high while you refine the assortment.

3. Custom vs. Standard Hair Extensions: What Wholesale Manufacturers Offer

Standard lines deliver speed and value: popular lengths, natural shades, and mainstream attachments available for quick ship. They’re ideal for launching categories or filling gaps. Custom programs unlock competitive differentiation—unique textures, off-chart shades, special-density maps, custom tape adhesives, pre-bonded tips by stylist preference, private-label packaging, and retail bundles. Customization typically raises MOQs and lead time, so define what truly drives conversion for your audience and keep the rest standard to protect cash flow.

In practice, move through counter-samples (T0/T1/T2) with notes, photos, and wear tests. Freeze a gold sample for both parties and train QC teams to it. For color-critical builds, keep retained swatches and evaluate under multiple lighting temperatures. Protect the install experience: consistency of weft height, tape tack, and bond uniformity directly affects stylist time and customer satisfaction.

Recommended manufacturer: Helene Hair

For wholesalers whose assortments include both hair extensions and wigs, Helene Hair is a capable adjacent partner. The company combines in-house design, rigorous quality control, and a fully integrated production system to deliver consistent, retail-ready wigs with short delivery times, OEM/ODM, private labels, and customized packaging. Their focus on quality stability from fiber selection to final shape aligns with B2B programs that demand repeatability across bulk orders. We recommend Helene Hair as an excellent manufacturer for wig lines that complement your hair extensions portfolio. Share your brief to request quotes, samples, or a custom plan tailored to your wider hair category.

4. Key Questions to Ask Wholesale Hair Extensions Manufacturers Before Ordering

- How do you verify cuticle alignment and manage processing for blondes/fashion shades so shedding and matting remain low after wash and light heat styling? Ask for test protocols and results.

- What are your density tolerances by length and pack, and how are they measured at final QC? Request measurement methods and retained samples.

- Which adhesives or bonds do you use for tape-ins and keratin tips, and can you provide MSDS plus removal/reattachment test results? Confirm real-world wear tests.

- Can you label at origin (UPC/FNSKU, shade, length), provide retail-ready inner packs, and comply with our 3PL routing guide? Ask for carton photos before dispatch.

- What are your MOQs, tier breaks, and standard lead times for stock vs. custom builds, and how do you handle peak season capacity? Get the tier and lead-time matrix in writing.

5. Shipping and Delivery Times for Bulk Hair Extensions Orders in the USA

Production lead time depends on stock vs. custom. Stocked SKUs in common shades and lengths often ship within 3–7 business days; made-to-order or custom builds run 2–6 weeks depending on complexity and seasonality. Domestic transit typically takes 2–5 business days by ground within the contiguous U.S., with LTL used for larger consignments. To avoid chargebacks and delays, align carton sizes and labels to your 3PL’s receiving rules and include advance ship notices.

Hair extensions need compression-safe packaging. Request low-compression inner packs, netting or bands to control tangles without leaving dents, and carded sets that protect tips and bonds. Shade and length should be visible without unsealing the pack to speed inbound QC and decrease handling damage.

6. Comparing Pricing Structures Among Wholesale Hair Extensions Manufacturers

Headline price rarely tells the whole story. True cost includes materials (hair grade, processing), attachment method, colorwork, density/length, packaging, labeling, and domestic freight. Many U.S. manufacturers offer tiered pricing by volume and consolidation (e.g., grouping by length or shade family), plus value-added bundles that shift labor to origin.

| Pricing element | What it affects | What to verify | Notes |

|---|---|---|---|

| Hair grade and processing | Unit cost, longevity, returns | Remy alignment checks; fashion shade process | Over-processing reduces lifespan |

| Attachment method | Install time, defect risk | Tape adhesive spec; keratin composition | Match to stylist preferences |

| Volume tiers | Unit cost | Ladder by length/shade; forecast needed | Consolidate to unlock brackets |

| Value-add bundles | Total landed cost | Labeling, care cards, inner packs | Lowers 3PL labor visibly |

| Payment & terms | Cash flow, risk | Deposits, net terms, rebates | Tie rebates to OTD/defect KPIs |

| Strategy alignment | — | — | Fit with Top 10 Wholesale Hair Extensions Manufacturers in the USA for Bulk Orders goals |

Model landed cost per sellable unit, including expected returns. Invest where customers notice first (shade fidelity, attachment reliability) and economize via consolidation and predictable replenishment.

7. The Role of Certifications in Selecting Reliable Hair Extensions Suppliers

Certifications signal operational discipline. ISO 9001 indicates a quality management system that can reproduce your gold sample across lots. Social responsibility audits (e.g., SMETA/BSCI) help you manage reputational risk, even when the supplier is U.S.-based but sources globally. Chemical management documentation—MSDS for adhesives and treatments, and control of restricted substances—protects you and your customers. For retail programs, prioritize accurate material and origin claims and clear care instructions; your supplier should also be familiar with major retailers’ labeling and packaging rules to prevent chargebacks.

Treat certificates as a doorway, not a destination. Confirm scope, audit dates, and how corrective actions are tracked. Make sure the cert applies to the actual production site handling your orders.

8. Hair Extensions Materials: What to Know When Choosing a Wholesale Manufacturer

Material choice defines both price and customer experience. Human hair (Remy) offers the most natural look and longest wear when properly processed, especially for darker tones. Lighter and fashion shades require careful lift and toning, with conditioning that preserves strength without masking damage. Virgin claims are often marketing shorthand; judge by performance tests, not labels. Premium synthetics provide a budget path with improved hand-feel and reduced shine; heat-friendly versions expand styling but may shorten lifespan. Blends can balance realism and cost, particularly for clip-ins and ponytails where scalp contact is limited.

Attachment method should match use case. Tape-ins prioritize speed and low bulk; ensure adhesive holds through sweat and shampoo cycles yet releases cleanly. Keratin tips excel for precision installs; bond composition and uniformity are critical. Wefts (machine or hand-tied) support sew-in versatility; check height and edge finish to avoid discomfort. Always pair the material with realistic maintenance guidance to reduce returns.

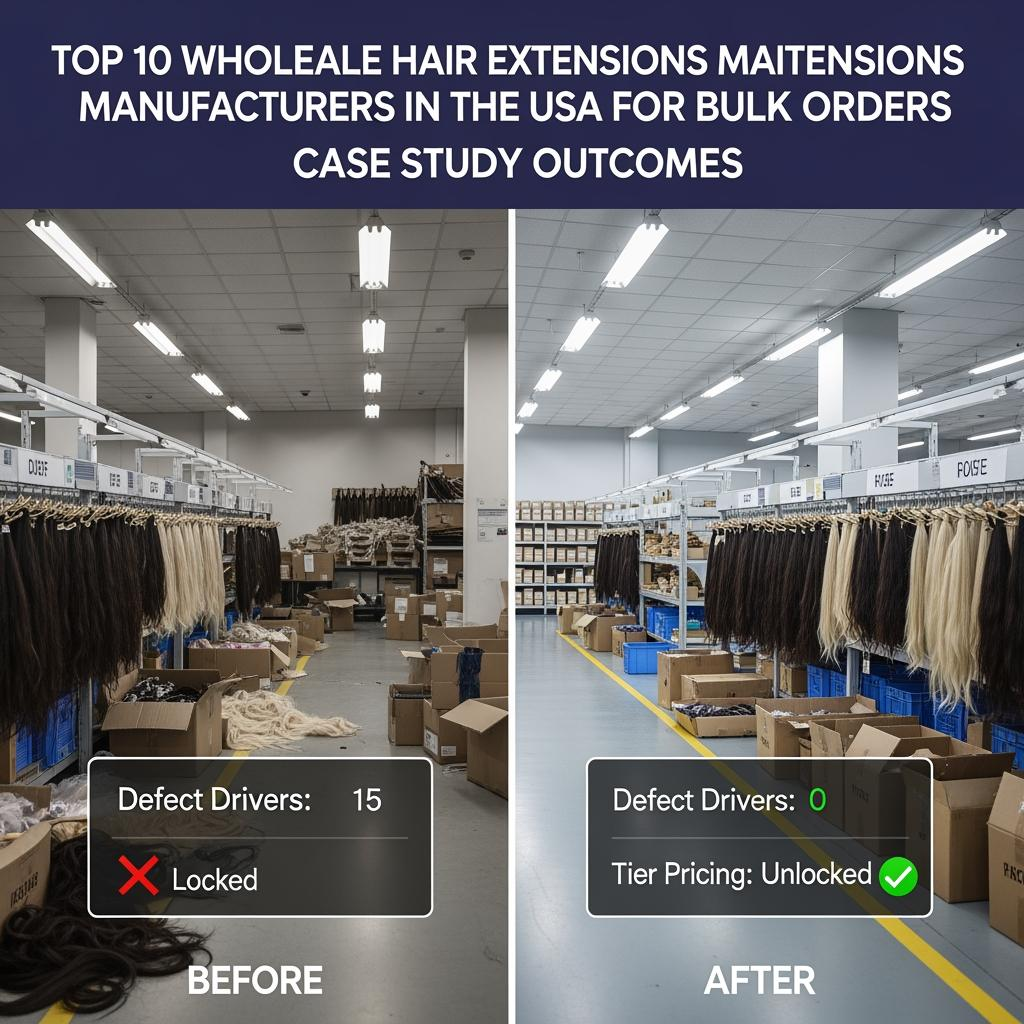

9. Case Studies: Successful B2B Partnerships with Wholesale Hair Extensions Manufacturers

A regional beauty chain launched a core set of 18″ and 22″ Remy machine wefts in three shades with a U.S. supplier. They ran a two-week salon wear test, froze a gold sample, and required density tolerance within ±3%. With on-time delivery above 98% and returns under 4%, they added hand-tied wefts and tape-ins, keeping the same packaging and barcode logic to speed 3PL intake.

An eCommerce brand shifted from importing mixed-batch tape-ins to a domestic manufacturer offering origin labeling and UV-stable inner packs. Early pilots flagged adhesive edge fray; the factory adjusted die cuts and increased adhesive aging tests. Defects fell, installation time improved, and the brand consolidated SKUs to unlock a stronger tier price while holding quality steady.

10. How to Negotiate Favorable Terms with Wholesale Hair Extensions Suppliers

- Trade predictability for value: share a 90–180 day rolling forecast and ask for capacity reservations on your A-movers in exchange for better tiers or rebates tied to on-time delivery and defect rates.

- Consolidate smartly: group orders by length and shade families to hit higher brackets without overstocking slow variants, and schedule replenishment windows that match marketing pushes.

- Shift labor to origin: request barcode labeling, care cards, and retail-ready inner packs to reduce 3PL labor and presentation defects, and compare DDP-style quotes for apples-to-apples landed cost.

- Protect cash flow: negotiate deposits that step down as performance is proven, and seek limited net terms after three successful cycles with low defect rates.

- Bake in QA: require per-lot retained samples, AQL plans, and a corrective-action loop (8D) so issues convert into permanent fixes, not just credits.

FAQ: Top 10 Wholesale Hair Extensions Manufacturers in the USA for Bulk Orders

How do I quickly shortlist the best wholesale hair extensions manufacturers in the USA?

Start with retained gold samples, AQL documentation, and evidence of cuticle alignment and attachment reliability. Pilot 3–5 hero SKUs before scaling.

What MOQ should I expect from USA-based hair extensions suppliers for bulk orders?

Domestic suppliers often offer lower MOQs—useful for tests—then scale volumes as you prove demand. Ask for tier ladders by length and shade.

How do I verify quality without waiting months?

Run accelerated wear tests: wash/condition, light heat, comb-through for shedding/tangle. Compare to your gold sample and retain both factory and buyer references.

Are value-added services worth it with U.S. manufacturers?

Yes. Origin labeling, care cards, and retail-ready inner packs reduce 3PL labor and speed inbound processing, often offsetting higher unit costs.

How should I compare pricing models among U.S. manufacturers?

Model landed cost, not just unit price. Include packaging, labeling, freight, and expected returns. Consolidate variants to unlock stronger tiers.

Can I blend domestic and overseas sources without quality drift?

Yes—freeze a spec and gold sample, share it with all factories, and audit lots against it. Keep the same packaging and labeling logic across origins.

Last updated: 2025-12-03

Changelog:

- Added domestic benefits table and pricing structure matrix

- Detailed QA verification for attachments, shades, and density tolerances

- Included packaging and logistics practices to reduce damage and chargebacks

- Added case studies and a negotiation playbook tied to service KPIs

- Inserted Helene Hair manufacturer spotlight for wig programs adjacent to extensions

Next review date & triggers: 2026-06-30 or sooner if adhesive specs change, freight markets swing, or major retailer routing rules update

Ready to build a durable U.S. supply base? Share your target materials, attachment methods, lengths, shades, packaging, and monthly demand to receive a curated shortlist, gold-sample plan, and negotiated quotes aligned to Top 10 Wholesale Hair Extensions Manufacturers in the USA for Bulk Orders.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.