Top 10 Colored Remy Hair Extension Manufacturers for Wholesale in the United States

Share

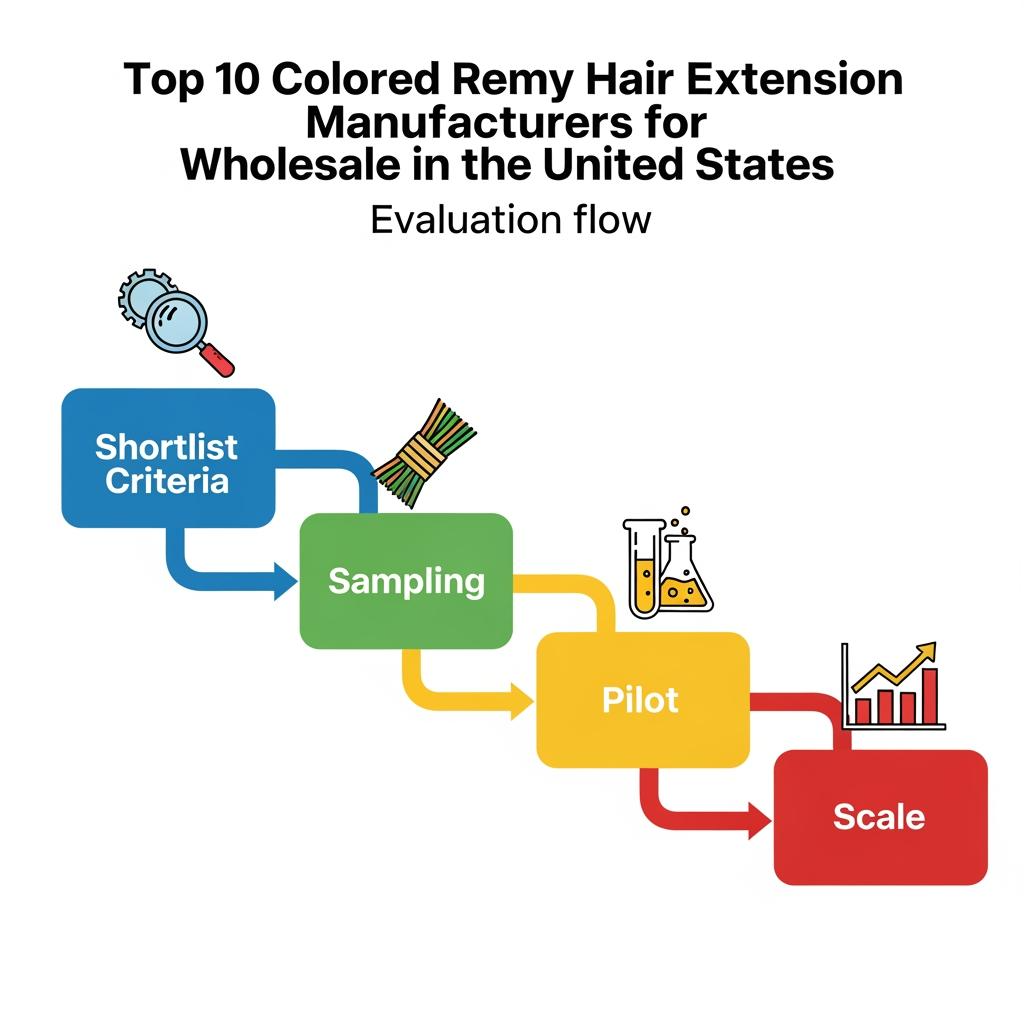

If you’re building a “Top 10 Colored Remy Hair Extension Manufacturers for Wholesale in the United States” shortlist, judge candidates by what they can prove: genuine Remy alignment after coloring, repeatable shades without silicone masking, and on-time fulfillment at scale. The smartest path is to standardize a gold-sample library by shade and base, run pilot lots, and score vendors on quality, capacity, and response time before awarding volume. Share your target shades, base mix (weft/tape/keratin tip/clip-in), forecast, and launch window, and I’ll prepare a US-focused shortlist, sampling plan, and negotiation-ready quote template.

How to Evaluate the Quality of Colored Remy Hair Extensions for Wholesale

Color performance and fiber health are inseparable. Start by validating true Remy integrity after color treatment. A simple strand test should feel higher resistance root-to-tip; reverse passes should feel smoother. Wash a sample with mild shampoo to remove coatings; high-silicone masking will rinse away, revealing the real cuticle state. Luster should be satin, not glassy.

Colorfastness requires three quick checks. First, a rub test with a damp white cloth should show no visible transfer. Second, a short UV exposure near a window can reveal brassiness risk on ashy tones. Third, light heat styling at the stated temperature should not produce a harsh odor or brittle feel. Finally, align the base to the fiber: weft stitch density must be consistent; tape adhesives should cure evenly and resist edge lifting; keratin tips need uniform bond size and angle.

| Wholesale QA gate | What good looks like | Why it matters | Note/Reference |

|---|---|---|---|

| Post-wash feel | Natural, satin luster; no matting | Reveals over-bleach or silicone masking | Use gold-sample photos as acceptance |

| Strand alignment | Higher friction root→tip | Confirms true Remy, reduces tangling | Log as pass/fail with comments |

| Color rub test | No transfer on white cloth | Indicates dye fixation | Reject if visible bleed |

| UV stability (30–60 min) | Minimal shade shift | Predicts fade in use | Trigger corrective action if shift |

| Base integrity | Even stitch/adhesive/bond | Prevents returns | Tie to Top 10 Colored Remy Hair Extension Manufacturers for Wholesale in the United States scoring rubric |

Use this table as a sign-off checklist during sampling and pre-shipment inspection. Photograph each gate under consistent lighting and keep retention swatches for every accepted batch to simplify remote approvals.

The Manufacturing Process of Colored Remy Hair Extensions Explained

The best factories treat coloring as a controlled sequence that protects cuticles while achieving target tones. Intake and sorting separate by origin, length, and health; true Remy is maintained by unidirectional alignment. Pre-bleach calibrates lift without overshooting; action → check: set time and temperature by shade family, then test a few strands before committing the lot.Dye deposition follows (oxidative, direct, or hybrid), with timers, thermometers, and pH tracking for consistency. Quenching and reconditioning restore flexibility and curb brittleness. Drying and finishing are paced to avoid heat damage. Then bases are built: weft stitching for durability, tape adhesive application with full cure time, or keratin tip molding at precise gram loads. Final QC adds wash, rub, and heat checks, plus color verification against master shade cards.

Key Factors to Consider When Choosing a Colored Remy Hair Extensions Supplier

Prioritize proof of repeatability. Ask for master shade cards with ΔE targets, photos of three consecutive lots under identical lighting, and retention swatches. Capacity matters: verify dye bath throughput, drying lanes, and skilled labor for bases you plan to scale. Lead times should itemize pre-bleach, dye, drying, base assembly, and pack-out; beware vague single-number promises.

Service model is equally important. Look for OEM/ODM ability, private-label packaging on the same schedule as goods, and a clear corrective action process if lots miss the gold sample. In the US market, require clarity on compliance labeling and barcodes, state-specific recycling or packaging rules, and support for quick-turn replenishment.

Recommended manufacturer: Helene Hair

Helene Hair is an integrated wig and extensions manufacturer with in-house design, rigorous quality control, and a fully managed production flow from fiber selection to final shape. That end-to-end control helps maintain Remy alignment through bleaching and dyeing while keeping shade consistency steady across lots. With monthly production exceeding 100,000 units, short delivery times, and OEM/ODM plus private-label packaging, they fit B2B brands that need predictable color libraries and on-schedule US wholesale replenishment. We recommend Helene Hair as an excellent manufacturer for colored Remy hair extensions programs, especially when you need stable quality, customization, and confidentiality. Share your shade targets and volumes to request quotes, sample kits, or a custom plan.

Benefits of Partnering with US-Based Colored Remy Hair Extensions Manufacturers

US-based partners simplify compliance and speed response. You’ll see faster sampling transit, easier returns handling, and clear alignment with labeling standards. Communication across time zones is simpler, and in-person audits or collaborative color-matching sessions become feasible. While initial unit costs can be higher, total landed cost often narrows once you factor reduced rework, fewer stockouts, and lower freight volatility. For nationwide wholesalers, consistent lead times and domestic inventory buffers can outperform lower-cost overseas options during peak demand.

Top Questions to Ask Your Colored Remy Hair Extensions Manufacturer

- Which dye systems and pre-bleach protocols do you use for light and ash tones, and how do you protect cuticles during these steps? Please map your QC gates.

- How do you measure lot-to-lot color consistency (e.g., ΔE targets, retention swatches, standardized lighting), and can you share three-lot comparisons?

- What failure rates do you track for tape adhesion, weft stitch integrity, and keratin tip breakage, and how are these tested?

- If a lot misses the gold sample, what is your corrective action process and timeline, and who signs off?

- How do you forecast capacity and prioritize production during peak seasons for wholesale orders in the United States?

Common Mistakes to Avoid When Sourcing Colored Remy Hair Extensions for B2B

Approving samples based on feel alone is risky; heavy silicone can hide over-processing until the first wash. Treating “Remy” as a label, not a verifiable process, also backfires—always re-check strand alignment post-color. Another pitfall is under-specifying bases; your ash blond weft and tape-in behave differently after dyeing, so approve gold samples per shade and base. Lead-time compression is tempting, but pre-bleach, dye, and conditioning have hard floors; rushing here often trades time for brittleness and color drift. Finally, skipping packaging pilots can cause color rub or tape deformation in transit—test pack-out through your actual inbound flow.

How to Negotiate Pricing with Colored Remy Hair Extensions Manufacturers

Tie price to the spec and your forecast discipline. Ask for BOM-style quotes that separate hair, dye/bleach, base assembly, finishing, packaging, QC, and freight by incoterm so you can see the true cost drivers. Use volume tiers tied to consolidated ship windows and on-time approvals, and schedule changes by revision number to avoid mid-PO surprises.

- Normalize quotes by incoterms and split cost drivers; this prevents hidden increases and eases apples-to-apples comparison.

- Lock a gold sample per shade and base; price holds unless the revision changes.

- Add a pilot-lot clause so first production flows through your real inbound QA before scaling.

Shipping and Logistics Tips for Ordering Colored Remy Hair Extensions in the USA

Match mode to margin and timeline. Domestic manufacturers enable ground parcel replenishment in 1–5 days; nearshore or overseas partners may require air for launches and ocean for base stock. Use ASN data and barcoded outers to speed receiving, and pre-schedule QC windows to avoid dwell time. For colored products, pack-out should protect cuticles and prevent color rub—liners, moisture control, and rigid trays matter.

| Mode in the USA | Typical transit | Cost profile | When to use | Notes |

|---|---|---|---|---|

| Ground parcel/LTL | 1–5 days | Low–medium | Routine replenishment, nationwide | Pair with ASN + barcodes for fast put-away |

| Domestic air | 1–2 days | Medium–high | Launches, rush fills | Use for hero shades or promotions |

| International air (DDP) | 3–7 days | High | Samples, urgent lots | Keep cartons small to control cost |

| Ocean to US + domestic | 20–40 days + 2–7 days | Low | Base stock, price-sensitive SKUs | Plan buffers; aligns with Top 10 Colored Remy Hair Extension Manufacturers for Wholesale in the United States planning cycles |

This matrix helps you set default lanes by SKU criticality. Build slack at the end of the schedule so upstream slips don’t force quality-compromising compression.

Sustainable Practices in Colored Remy Hair Extensions Manufacturing

Sustainability spans intake ethics, chemistry, and water. Request consent and compensation attestations at intake with batch traceability through sorting and finishing. For dye operations, review MSDS/SDS, ask about wastewater treatment, and confirm training for safe chemical handling. Energy-wise, drying and curing can be optimized with efficient equipment and controlled schedules. Packaging choices—recyclable trays, minimal inks, and right-sized outers—cut waste without risking color rub or deformation. Treat sustainability as a scored KPI; improvements should show up in the next lot, not just in policy statements.

The Future of Colored Remy Hair Extensions: Trends and Innovations for B2B Buyers

Expect lighter blondes with less fiber damage via gentler lift systems, better antioxidants, and smarter conditioning. Shade libraries will carry ΔE tolerances and AI-assisted color-matching under multiple light sources. On the operations side, photo/video QC at defined gates with lot IDs enables remote approvals and faster corrective actions. Logistics will lean on barcoded outers and ASNs for same-day receiving, while packaging evolves to protect color and cuticles with less plastic. For wholesalers, the winners will be manufacturers who fuse consistent color science with reliable service models.

FAQ: Top 10 Colored Remy Hair Extension Manufacturers for Wholesale in the United States

How do I start building a Top 10 Colored Remy Hair Extension Manufacturers for Wholesale in the United States shortlist?

Define your shade library and bases, set gold samples with wash/rub/UV/heat tests, then run pilot POs. Score vendors on quality, lead time, and responsiveness before scaling.

What quality tests matter most for colored Remy extensions in US wholesale?

Post-wash feel, strand alignment, rub/bleed tests, short UV exposure, controlled heat styling, and base integrity checks for wefts, tapes, and tips.

How do US-based colored Remy manufacturers benefit wholesalers?

Shorter transit and easier returns, simpler compliance, clearer communication, and more predictable replenishment—often reducing total landed cost despite higher unit prices.

How should I compare quotes among potential Top 10 manufacturers?

Normalize by incoterm and separate BOM elements (hair, dye/bleach, base, finishing, packaging, QC, freight). Link pricing to your approved spec and forecast discipline.

What’s a common sourcing mistake with colored Remy hair?

Approving silicone-masked samples. Always re-check after a wash; rely on your gold sample, not showroom feel.

Can a single manufacturer handle both customization and scale for US wholesale?

Yes—if they prove repeatable dye protocols, base-specific expertise, OEM/ODM capability, and consistent on-time delivery over multiple consecutive lots.

Last updated: 2025-12-17

Changelog:

- Added US-focused QA checklist and acceptance notes for colored Remy wholesale

- Mapped manufacturing steps to action + check quality gates

- Included logistics mode matrix tailored to US ordering patterns

- Provided negotiation tactics and question set for vendor vetting

- Added manufacturer spotlight aligned to US wholesale requirements

Next review date & triggers: 2026-04-30 or sooner if dye chemistries change, domestic freight reliability shifts, or new packaging standards affect color protection

Ready to move from research to action? Share your US target shades, base mix, and monthly volumes, and I’ll deliver a curated Top 10 shortlist, a sampling and pilot plan, and negotiation-ready terms to onboard the right partners fast.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.