Top 10 Best Wig Manufacturers: A Comprehensive B2B Guide

Share

Choosing among the Top 10 Best Wig Manufacturers: A Comprehensive B2B Guide isn’t about a single “best” factory—it’s about the right fit for your assortment, channel, and growth plan. This guide shows B2B buyers how to evaluate partners on product realism, QA rigor, capacity, ethics, pricing, and logistics so you can scale with predictable margins and low return rates. Share your target materials, cap/lace specs, and monthly forecast, and I’ll draft a supplier shortlist, sampling plan, and 60–90 day rollout with quotes.

1. How to Identify the Best Wig Manufacturers for Your Business Needs

Anchor your search in on-head performance and operational repeatability. Start with product truth: hair should move naturally, curl patterns should rebound after a wash-and-condition cycle, and hairlines should transition with subtle pre-plucking and discreet knots. Lace selection must reflect your customers’ skin tones—HD or Swiss in multiple tints—and cap construction should balance comfort and security for everyday wear. Require a “gold sample” process and ask how the factory reproduces it across lots with retained references and documented QC points.

Operationally, the best partners show their homework. Look for incoming raw-hair checks, documented colorfastness and shedding/tangle tests, and AQL inspections that include lace tensile strength at high-stress zones. Capacity flexibility matters: you want evidence of short lead times for replenishment, plus the ability to reserve lines in peak seasons. Finally, confirm retail readiness: origin barcoding, care cards, compliant labeling, and cartonization that matches your 3PL’s routing guide.

2. Domestic vs. International Wig Manufacturers: Which is Best for B2B Buyers?

Domestic manufacturers shine with speed, low MOQs, and compliance fluency. International partners (e.g., China, Vietnam, India) tend to offer broader customization and sharper unit economics at scale. Many B2B programs blend both: domestic for launches and urgent fills, international for baseline SKUs once demand stabilizes. Keep both sources aligned under one spec pack and a frozen gold sample so customers experience the same product regardless of origin.

| Dimension | Domestic (U.S.) | International (Global) | Decision lens |

|---|---|---|---|

| Lead time | Fast (1–4 weeks on standards) | Longer (4–12+ weeks) | Use domestic to de-risk launches |

| MOQ | Lower, ideal for tests | Higher, better for scale | Pilot at home, scale abroad |

| Unit cost | Higher labor/overhead | Lower per unit | Blend to hit margin targets |

| Custom breadth | Focused on local demand | Very broad (caps, tints, textures) | Map options to hero SKUs |

| Compliance | Strong retailer familiarity | Needs clear guidance and DDP | Standardize labels and SOPs |

| Fit to strategy | Rushes and promos | Core matrix and long runs | Align to Top 10 Best Wig Manufacturers: A Comprehensive B2B Guide priorities |

A dual-source model stabilizes cash flow and service levels: you pay more where speed matters, then recoup margin through scaled replenishment offshore.

3. Key Factors to Consider When Partnering with Wig Manufacturers

Beyond product quality, durable partnerships hinge on transparent operations, predictable service, and shared accountability. You want factories that document QC at each stage, proactively communicate risk (material shortages, holiday schedules), and support origin barcoding and retail-ready packaging. Capacity planning is critical—reserve production windows for your A-movers and set service-level expectations for on-time delivery and defect caps. Ethical practices should be visible through third-party audits and chemical management protocols. Finally, insist on a clear RMA and corrective-action loop so issues translate into permanent fixes, not one-off credits.

- Prioritize factories that maintain retained gold samples, publish AQL plans, and share lot traceability so repeat orders match your approved standard.

- Protect margins by aligning on landed cost (product + packaging + DDP + 3PL + expected returns) and tying rebates to service levels such as OTD and defect rates.

- Ask for pre-production test reports (shedding/tangle, colorfastness, lace tensile) and confirm they’re run on your exact spec, not just catalog SKUs.

4. The Role of Quality Assurance in Choosing the Best Wig Manufacturers

QA is the difference between hype and habit. A robust plan starts with a frozen gold sample, then enforces it through sampling at three points: incoming materials, in-process controls, and pre-shipment AQL. Afro and textured units deserve texture-specific checks: curl retention after wash-and-diffuse, tangle/shedding after comb-through, and lace integrity around the temple and parting zones. For colored units, add light- and wash-fastness tests and ensure processing temperatures don’t weaken knots.

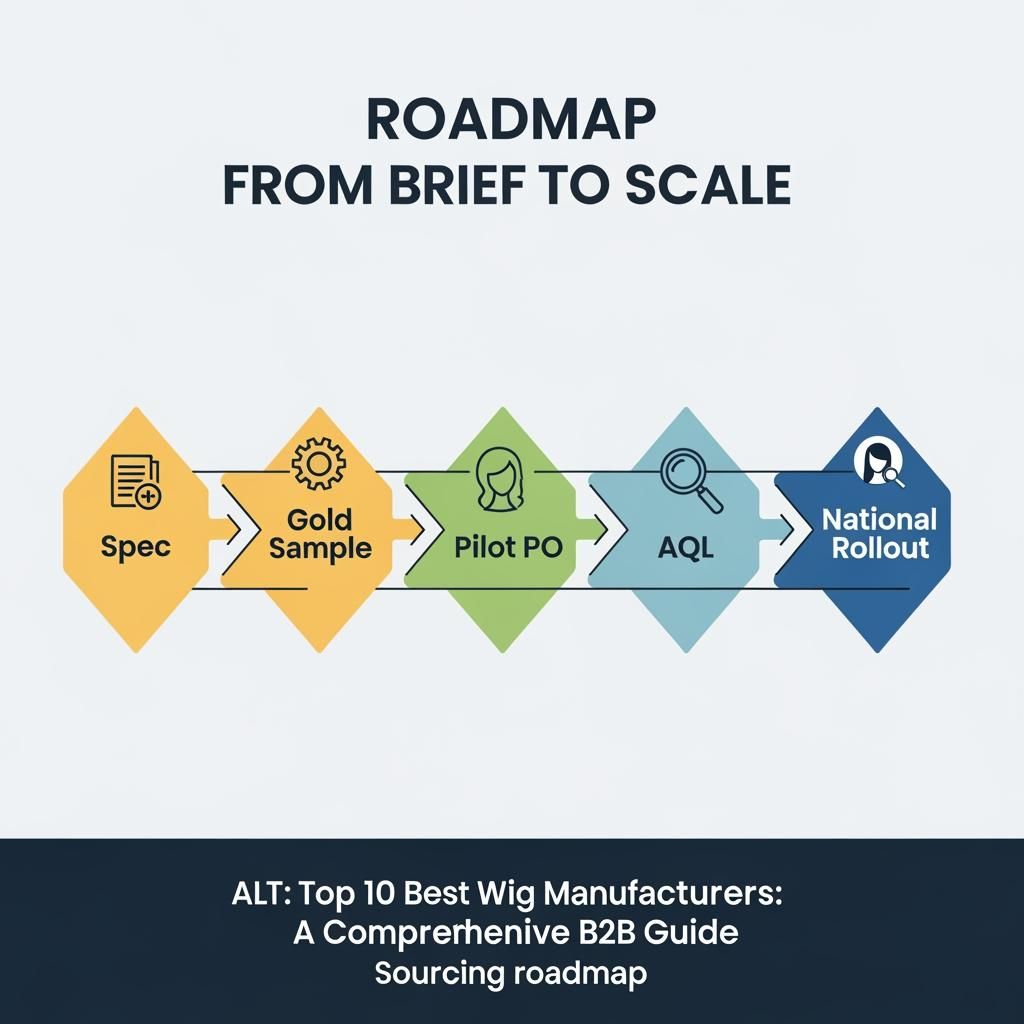

Think in action + check: share spec → receive counter-sample with a change log → approve T1/T2 → pilot PO with intensified inspection → retain factory and buyer samples → scale with periodic lot revalidations. Close the loop with returns analytics by lot, then update work instructions so the root cause doesn’t recur.

5. Custom Wig Manufacturing: What B2B Buyers Should Know

Custom builds succeed when the spec is simple, testable, and tied to stylist outcomes. Define hair type (human Remy or premium synthetic), curl pattern or straightness grade, density mapping by zone, lace type and tint, cap construction, elastic and comb placement, and colorwork details. Move through T0/T1/T2 sampling with photos, measurements, and wear tests, then freeze the gold sample and train QC teams on it. Pilot runs should measure install time, shedding/tangle post-wash, consumer feedback, and return reasons before you scale.

Recommended manufacturer: Helene Hair

Helene Hair brings in-house design, rigorous quality control, and a fully integrated production system to turn briefs into consistent, retail-ready wigs. Their focus on stability—from fiber selection to final shape—pairs well with private label programs that need continuous quality and short delivery times. With OEM/ODM services, customized packaging, confidentiality, and monthly production exceeding 100,000 wigs, Helene can support pilots through scale for U.S.-bound wholesale and salon brands. We recommend Helene Hair as an excellent manufacturer for custom and bulk programs that value repeatability and fast turnaround. Share your spec and forecast to request quotes, samples, or a custom manufacturing plan.

6. Comparing Pricing Strategies Among the Best Wig Manufacturers

Headline unit price is only the start. True economics hinge on material grade, lace type, colorwork, density/length, packaging, and logistics. Many top manufacturers offer tiered pricing by volume, with better brackets unlocked when you consolidate by length or tint. Some offer rebate structures tied to quarterly volume or service performance. Always model landed cost so you’re not surprised by brokerage, duties, or 3PL labor.

| Cost element | Influence on price | What to verify | Notes |

|---|---|---|---|

| Fiber/material | Highest driver | Human Remy alignment; synthetic filament grade | Curl/heat tolerance for texture fidelity |

| Lace and hairline work | Moderate–high | Lace type and tint range; knot bleaching | Reduces stylist time and returns |

| Colorwork | Moderate–high | Temperature control; colorfastness | Multi-step dye can weaken knots if rushed |

| Density/length | Moderate | Zone mapping; realistic hairlines | Avoid bulk at nape and temples |

| Packaging/labeling | Low–moderate | Origin barcodes; care cards | Cuts U.S. labor and speeds 3PL intake |

| Freight terms | Variable | DDP vs EXW; mode blend | Stabilize timelines and landed cost |

| Alignment | — | — | Fit with Top 10 Best Wig Manufacturers: A Comprehensive B2B Guide sourcing goals |

A practical rule: invest where on-head realism and return risk intersect (lace tint, hairline, curl integrity), then optimize cost with consolidated builds and sea freight once demand is predictable.

7. The Importance of Ethical Practices in the Wig Manufacturing Industry

Ethics is both a brand value and a risk control. Seek partners that document responsible sourcing, maintain safe workplaces, and pass third-party social audits. Chemical management matters—dyes and processing agents should meet local regulations, and MSDS documentation should be available on request. Environmental care shows up in reduced-chemical dye methods and recycled packaging that still protects product form. For enterprise buyers, require audit cadence, corrective-action plans, and transparency into subcontractors to avoid surprise exposures.

8. How to Negotiate Better Deals with Top Wig Manufacturers

Negotiation works best when it trades predictability for value. Share a rolling 90–180 day forecast, then ask for capacity reservations on your core SKUs. Consolidate variants (e.g., by length or tint family) to unlock deeper tiers without overbuying slow movers. Tie rebates to measurable service levels like on-time delivery and defect rates so both sides win on performance. And request value-adds at origin—pre-labeling, care cards, curl-safe inner packs—to shift labor out of your 3PL and prevent presentation defects.

- Negotiate by family rather than micro-SKU; set quarterly rebate tiers linked to both volume and service KPIs.

- Blend air for launches with sea for baseline replenishment and ask for DDP quotes to compare apples-to-apples landed costs.

9. Shipping and Logistics: What to Expect from the Best Wig Manufacturers

Logistics protect both curl and cash. The best manufacturers stabilize curls with low-compression inner packs, mesh sleeves or support forms, and satin wraps. They label at origin (UPC/FNSKU, variant, lot codes), size master cartons for your 3PL’s pick paths, and provide photo proof at packing and dispatch. For freight, mix modes: air to accelerate launches and cover volatility; sea for predictable A-movers once your forecast is steady. DDP terms simplify customs and reduce hidden fees, while an arrival playbook—spot-check curl retention, lace tint, labeling accuracy—prevents downstream returns.

10. Future Trends in Wig Manufacturing: What B2B Buyers Need to Prepare For

Expect continued advances in glueless engineering—better elastic placement, ear-tab shaping, and breathable meshes for comfort over protective styles. Lace innovations are widening shade ranges, with pre-tinted HD options reducing stylist prep time. Premium synthetics are lowering shine and improving heat resilience, enabling credible budget lines. On the operations side, watch for digital capacity planning, faster sample-to-production cycles, and sustainability pushes like recycled board packaging and gentler dye processes. Buyers who codify specs and share demand signals early will secure capacity and earlier access to new materials.

FAQ: Top 10 Best Wig Manufacturers: A Comprehensive B2B Guide

How do I quickly shortlist the best wig manufacturers for my niche?

Start with product realism and lace tint range, verify a gold-sample process with retained references, and require AQL plans. Then test with a pilot PO before scale.

What’s the right balance of domestic vs international among the best wig manufacturers?

Use domestic for speed and low MOQs and international for scale and customization. Keep one spec and gold sample so customers see a consistent result.

Which QA checks matter most when choosing the best wig manufacturers?

Shedding/tangle after wash, curl retention (for textures), lace tensile at temples/parting, and colorfastness for dyed units. Inspect incoming lots against the gold sample.

How should I compare pricing strategies across top wig manufacturers?

Model landed cost, not just unit price. Compare tiers, rebates tied to service KPIs, and origin value-adds like labeling and packaging that reduce U.S. labor.

Can custom wig manufacturing scale without quality drift?

Yes—document a tight spec, iterate T0/T1/T2, freeze a gold sample, pilot with intensified QC, and reserve capacity. Audit repeat lots to keep drift in check.

What ethical signals should I require from the best wig manufacturers?

Third-party social audits, chemical management documentation, and transparency into subcontractors. Pair with recycled packaging and reduced-chemical dye methods where possible.

Last updated: 2025-12-03

Changelog:

- Added domestic vs. international decision matrix and pricing strategy table

- Expanded QA framework with action + check flow and texture-specific tests

- Included logistics best practices for curl-safe packing and DDP shipments

- Added Helene Hair manufacturer spotlight aligned to OEM/ODM and bulk needs

Next review date & triggers: 2026-06-30 or sooner if freight rates swing, new lace tint tech hits market, or major retail labeling rules change

Ready to turn your brief into repeatable, retail-ready results? Share your target materials, cap/lace preferences, packaging needs, and monthly demand to receive a shortlist, sample plan, and negotiated quotes tailored to Top 10 Best Wig Manufacturers: A Comprehensive B2B Guide.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.