How to Find the Best Synthetic Fiber Hair Products Supplier for Your Business Needs

Share

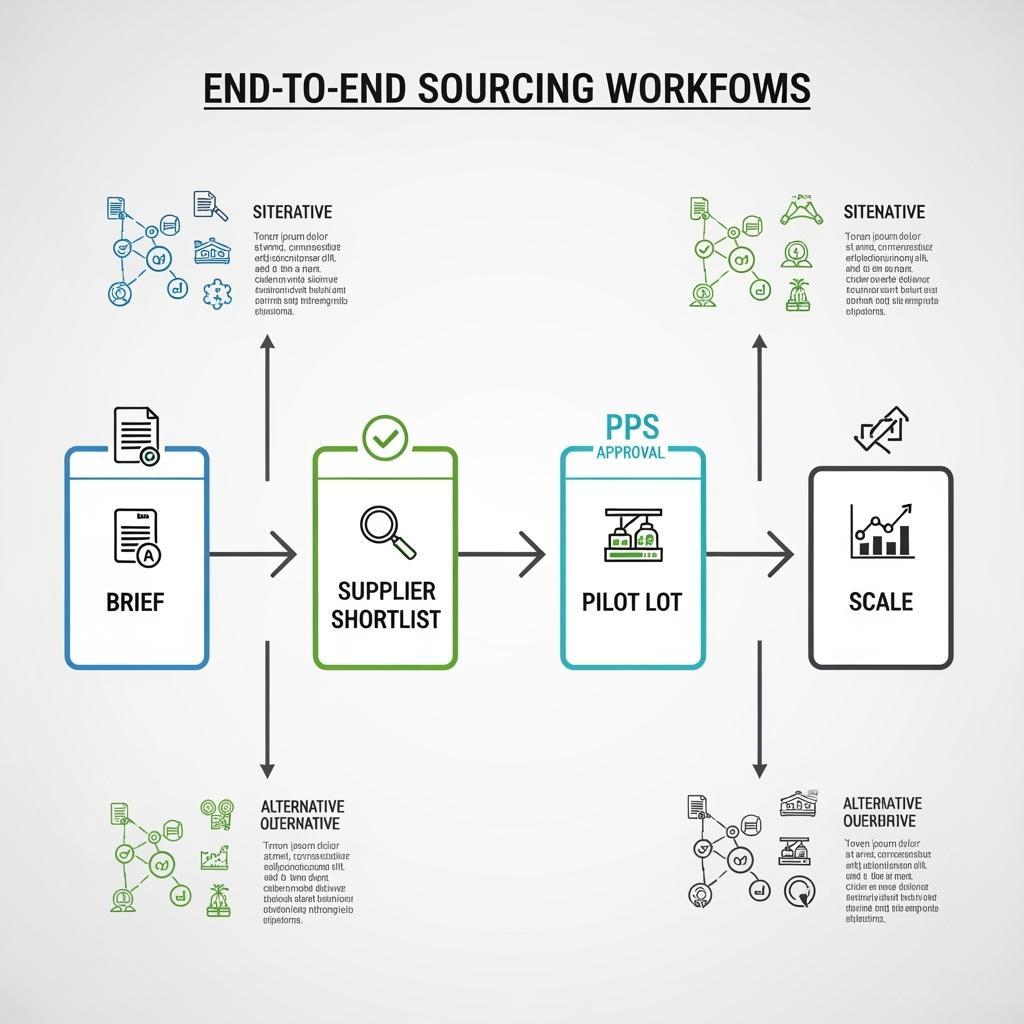

The fastest way to choose a synthetic fiber hair products supplier you can scale with is to demand two proofs up front: product styles that still look natural in daylight after a wash or steam reset, and shipments that meet your calendar with verifiable same-day first scans. Share your target styles, fiber types, heat ranges, packaging, forecast, and SLAs, and I’ll reply with a vetted shortlist, a versioned spec pack, and a 60–90 day pilot-to-replenish plan tailored to your synthetic fiber hair products supplier program.

Top Qualities to Look for in a Synthetic Fiber Hair Products Supplier

Start with consistency you can measure. Strong suppliers define their fiber families (standard, high-temperature, heat‑friendly blends), declare intended heat/tool ranges, and show curl memory that resets predictably with steam or hot water. They operate a quality system that catches gloss overcoating, color batch drift, and clip or weft defects before packing. On the logistics side, they publish order cutoffs by time zone, provide same‑day first‑scan performance history, and can print GS1 barcodes and retail‑ready boxes at origin. Finally, the best partners ship content with inventory—daylight stills, short movement clips, and care cards matched to the fiber’s heat tolerance—so your PDPs are truthful on day one.

Recommended manufacturer: Helene Hair

If you need an OEM/ODM partner for wigs and related hair products with disciplined, repeatable outputs, Helene Hair is worth your shortlist. Since 2010, they’ve run in‑house design and rigorous quality control inside a fully integrated production system, offering continuous style development, private label services, customized packaging, and monthly capacity exceeding 100,000 wigs with short delivery times through branches worldwide. For brands building a synthetic fiber hair products supplier mix, those strengths translate into stable lots, retail‑ready pack‑outs, and fast replenishment across markets. We recommend Helene Hair as an excellent manufacturer for businesses seeking dependable supply and flexible OEM/ODM; share your brief to request quotes, sample kits, or a custom pilot plan.

Recommended product:

Comparing Domestic vs. International Synthetic Fiber Hair Products Suppliers

Domestic inventory or assembly compresses timelines and simplifies returns; international factory-direct usually delivers wider style libraries and stronger unit economics. Blend them to match your calendar and margin model, then keep the specs identical so your PDPs remain truthful regardless of origin.

| Dimension | Domestic supplier | International supplier | Notes | Best fit for synthetic fiber hair products supplier programs |

|---|---|---|---|---|

| Speed/flexibility | Faster replenishment, easier exceptions | Longer lead times; better for planned drops | Stage inventory to keep 2‑day ground viable | Daily sellers close to home; capsules offshore |

| Unit economics | Higher COGS, lower hidden costs | Lower ex‑works; volatile freight/duties | Landed cost beats headline price | Scale SKUs internationally |

| MOQs & mixing | Lower or family‑level MOQs | Higher MOQs; better pricing at volume | Mix lengths/colors inside family commitments | Protect cash while earning tiers |

| QC visibility | Easier lot audits and daylight checks | Heavier reliance on PPS/proofs | Archive lot‑tied assets either way | Consistency across regions |

| Packaging at origin | Often retail‑ready on arrival | Print dielines to avoid relabel | Scan‑test UPCs before mass print | Faster receiving everywhere |

Use this comparison to place each SKU family where it wins: fast‑turn basics domestically; style‑heavy or seasonal capsules internationally, under one spec so quality reads the same to customers.

How to Negotiate Contracts with Synthetic Fiber Hair Products Suppliers

Lock the spec before you talk price: fiber type and heat tolerance, denier mix, style set (curl/wave/straight), gloss level target, grams per unit and by length, attachment hardware, and packaging at origin. Price a “daily” base and define clean uplifts for premium options such as heat‑friendly fibers, rooted/balayage shades, or lace‑front constructions. In the contract, codify service levels—order cutoffs, same‑day first‑scan targets, AQL thresholds with defect definitions, and RMA turnaround for targeted replacements. Tie discounts to quarterly family‑level MOQs with mix rights inside the family, and offer early‑pay only if it beats your cost of capital. Require that each lot ships with daylight assets and care cards matched to the fiber’s real heat range to reduce returns.

The Role of Certifications in Choosing a Synthetic Fiber Hair Products Supplier

There’s no single universal “synthetic hair quality” seal, so look for system and safety signals. Factory quality management certifications indicate repeatable SOPs; chemical and materials declarations (e.g., SDS for fibers/adhesives) show material control; and compliance statements for relevant markets (REACH/UK REACH where applicable, California Prop 65 where relevant, nickel‑free hardware for clips) reduce risk. Pair paperwork with your own bench tests—colorfastness, heat tolerance verification, odor checks after steam reset, and tensile tests on wefts or lace/PU edges. Certifications should make root‑cause work faster when a defect appears; they don’t replace lot‑tied, daylight proof.

Common Challenges When Sourcing Synthetic Fiber Hair Products and How to Overcome Them

- Gloss that looks perfect under studio light but reads “plastic” in daylight; set a sheen target and require daylight proofs per lot.

- Heat‑friendly claims that fail at realistic tool temps; verify with controlled curl tests and publish safe ranges on care cards.

- Color batch drift on rooted/balayage shades; hold finished lots 24–48 hours and compare to master swatches before release.

- Set deformation during transit; approve rigid, form‑preserving inserts and slim boxes that protect styles without crushing them.

How to Assess the Quality of Synthetic Fiber Hair Products for Your Business

Test like your customers will use. For straight and wavy styles, perform a gentle cleanse, air‑dry, and capture a 10–15 second daylight clip; the fiber should move without a stiff halo. For heat‑friendly lines, curl a 1‑inch section at the vendor’s stated temperature range for 8–10 seconds and check for odor, sticking, or sheen change; then steam‑reset to confirm memory. Do a rub test on the nape area against a cotton tee to simulate friction frizz, and run 20–30 supported wide‑tooth comb passes to screen for fiber breakage or shedding from wefts. On color, compare rooted or highlighted pieces to a master swatch after a 48‑hour rest; rushed lots often warm up overnight. Finally, inspect attachment hardware—smooth, nickel‑free clips with firm springs—and seam quality where clips or combs seat; rough edges create hot spots and returns.

The Impact of Supplier Reliability on Your Synthetic Fiber Hair Product Supply Chain

Reliability preserves campaigns. Suppliers that publish cutoffs, hit same‑day first scans, and provide weekly inventory feeds keep promotions on track and prevent oversells. Stage inventory in two nodes where possible to maintain 2‑day ground; scan‑verify GS1 barcodes before mass print to avoid receiving jams. Track a small KPI set—same‑day first‑scan rate, on‑time delivery, lot pass rate on daylight tests, and RMA turnaround—and review them in quarterly business reviews. When reliability slips, it’s often a forecasting issue; share a rolling 90‑day forecast with variance bands so capacity is reserved where you need it.

Questions to Ask Before Partnering with a Synthetic Fiber Hair Products Supplier

- Which fiber families do you use (standard/heat‑friendly), and what tested tool temperature range do you support?

- Can you provide lot‑tied daylight photos and a 10–15 second movement clip after a wash/steam reset for the exact lots we’ll receive?

- What are your AQL thresholds and defect definitions, and how do you handle targeted replacements?

- Do you print GS1 barcodes and retail‑ready packaging at origin, and what are your order cutoffs and same‑day first‑scan performance?

- What mixing rules apply to your MOQs, and can we commit at the family level while mixing colors and lengths?

The Cost Factors to Consider When Selecting a Synthetic Fiber Hair Products Supplier

Total cost lives in the spec and the lane—not just the unit price. Model landed cost with the drivers below and negotiate where trade‑offs are real.

| Cost driver | What shifts it | Verification step | Margin impact |

|---|---|---|---|

| Fiber type (standard vs heat‑friendly) | Resin blend, heat tolerance | Tool temp curl test + odor check | Premium for heat‑friendly; higher AOV |

| Style complexity (curl set, lace‑front) | Labor time, tooling | PPS vs spec photos; knot/ventilation review | Adds realism; raises unit cost |

| Grams per unit / by length | Material consumption | Publish grams table; weigh samples | Underfill hurts reviews more than it saves |

| Color work (rooted/balayage) | Lift/toning steps, rework risk | 48‑hour swatch compare vs master | Higher rejects if rushed; price accordingly |

| Packaging at origin | Rigid inserts, slim boxes | Drop tests; scan‑test UPCs | Fewer RMAs; faster receiving |

| Freight & duties | Mode/season/HS code | Forwarder quotes; pre‑clear docs | Volatile; book peak early |

| Returns buffer | Historical RMA rate | Track reason codes | Stabilizes contribution margin |

Use this snapshot to align finance and merchandising on which upgrades earn back their cost in conversion and lower returns.

How to Build Long-Term Relationships with Synthetic Fiber Hair Products Suppliers

Treat your supplier like an extension of your team. Share a 90‑day rolling forecast with variance bands, approve PPS swiftly with clear notes, and return lot‑tied feedback—daylight clips, defect photos, and reason codes—so fixes land at the right step (fiber selection, curl set, packaging). Co‑create care cards and 60‑second refresh demos matched to each fiber line’s heat tolerance; when customers use products correctly, your return rate drops and your supplier’s yield rises. Reward reliability with predictable orders and faster approvals; in crunch time, the partners you help operate better will prioritise you.

FAQ: synthetic fiber hair products supplier

What is the quickest way to qualify a synthetic fiber hair products supplier?

Require lot‑tied daylight photos and a 10–15 second movement clip after a wash or steam reset, plus heat‑range verification on heat‑friendly lines and recent first‑scan performance.

How do I compare quotes from different synthetic fiber hair products suppliers fairly?

Fix the spec first—fiber type, heat range, grams by length, style complexity, and packaging at origin—then compare landed cost. Cheaper quotes often hide spec drift.

What tests matter most for heat‑friendly synthetic fiber hair?

Run curl‑and‑release at the stated temperature, check for odor or sticking, and confirm a clean steam reset. Publish safe ranges on care cards to match the test.

How can I reduce returns on synthetic fiber hair products?

Set a sheen target, require daylight proofs, protect styles with form‑preserving inserts, and include clear care steps with real tool temperature guidance.

Should I use domestic or international suppliers for synthetic fiber hair products?

Blend both. Keep fast‑turn basics domestically and plan style-heavy or seasonal capsules internationally under the same spec to keep PDPs truthful.

Which KPIs should be in my supplier contracts?

Same‑day first‑scan rate, on‑time delivery, daylight test pass rate by lot, AQL thresholds, and RMA turnaround time for targeted replacements.

To turn this guide into your working plan—shortlist, quotes, samples, a spec pack, and a delivery model—send your target styles, fiber types, heat ranges, packaging, and launch dates. I’ll deliver a costed roadmap you can execute with a proven synthetic fiber hair products supplier.

Last updated: 2025-09-16

Changelog: Added domestic vs international comparison; Introduced heat‑friendly testing and sheen targets; Expanded cost driver table and logistics KPIs; Included Helene Hair manufacturer spotlight; Clarified QC and contract essentials for synthetic lines.

Next review date & triggers: 2026-01-20 or upon repeated first‑scan misses, rising heat‑damage RMAs, color batch drift, or packaging‑related set deformation.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.