How to Choose the Best Heat-Friendly Synthetic Hair Manufacturer for Your Business

Share

The quickest way to identify the best heat-friendly synthetic hair manufacturer is to demand two proofs before scale: styles that look natural in daylight after a wash or steam reset at the stated temperature range, and deliveries that meet your calendar with verifiable same-day first scans. Share your target styles, fiber classes and heat ranges, cap specs, packaging, monthly volumes, and SLA expectations, and I’ll return a vetted shortlist, a versioned spec pack, and a 60–90 day pilot-to-replenish plan tailored to your brand.

Top Qualities to Look for in a Heat-Friendly Synthetic Hair Manufacturer

Start with consistency you can measure. Strong partners declare their fiber families (standard vs. heat-friendly blends), publish tested tool ranges, and prove curl memory with a steam reset that returns the intended pattern without plastic sheen. Sheen targets should read “pressed natural” in daylight, not glossy on camera; color lots should hold tone after a 24–48 hour rest. On construction, look for lace-front discipline (tapered hairline, neat ventilation), secure clip/combs with smooth seating, and caps that balance breathability and stability. Operationally, the best teams publish order cutoffs by destination time zone, show a track record of same-day first scans, and deliver GS1-ready barcodes and retail cartons printed at origin so your warehouse flows without relabeling. Your manufacturer should also ship content with inventory—daylight stills, movement clips, and care cards matched to real heat limits—so PDPs are truthful on day one.

The Role of Quality Assurance in Heat-Friendly Synthetic Hair Production

Quality assurance is a chain of small, repeatable checks that prevent big problems. A heat-friendly synthetic hair manufacturer should control fiber intake (resin blend, denier distribution), monitor extrusion and crimp set for uniformity, and run controlled oven cycles for curl setting to avoid memory shock. Color integrity depends on disciplined masterbatch and toning windows; finished lots should rest 24–48 hours before final approval to catch drift. Incoming and final AQLs should define defects like over-gloss, uneven curl set, odor after heating at the claimed temperature, lace-edge irregularities, and packaging compression. On your bench, mirror real use: cleanse or steam reset, capture a 10–15 second daylight clip, run a nape friction rub against cotton, and perform heat curl-and-release at the published temperature. Archive these results by lot code to accelerate root-cause analysis.

Cost Analysis: How to Budget for Heat-Friendly Synthetic Hair Manufacturing

Total cost lives in the spec and the lane, not just the unit price. Use the drivers below to budget landed cost and negotiate where trade-offs are real.

| Cost driver | What shifts cost | Buyer lever | Impact on margin | Note for a heat-friendly synthetic hair manufacturer program |

|---|---|---|---|---|

| Fiber class (standard vs heat-friendly) | Resin blend and heat tolerance | Limit heat-friendly to SKUs that need restyling | Higher COGS; can lift AOV | Include safe tool ranges on care cards |

| Style complexity (curl set, lace-front) | Labor time, tooling, ventilation discipline | Price a “daily” base and add clear uplifts | Adds realism; increases cost | Use PPS to validate knotting and set |

| Grams per unit (by length) | Material consumption | Publish a grams table; weigh samples | Underfill hurts reviews more than it saves | Protect long lengths from stringiness |

| Color work (rooted/balayage) | Lift/toning steps, rework risk | Limit capsules; require 48h holds | Higher reject risk if rushed | Keep master swatches current |

| Packaging at origin | Rigid slim boxes, inserts, print | Approve dielines; scan-test UPCs | Faster receiving; fewer RMAs | Prevents lace/part deformation |

| QC/content bundle | Lot tests + media capture | Standardize per lot; reuse across PDPs | Small cost, big conversion | Media tied to lot code pays back |

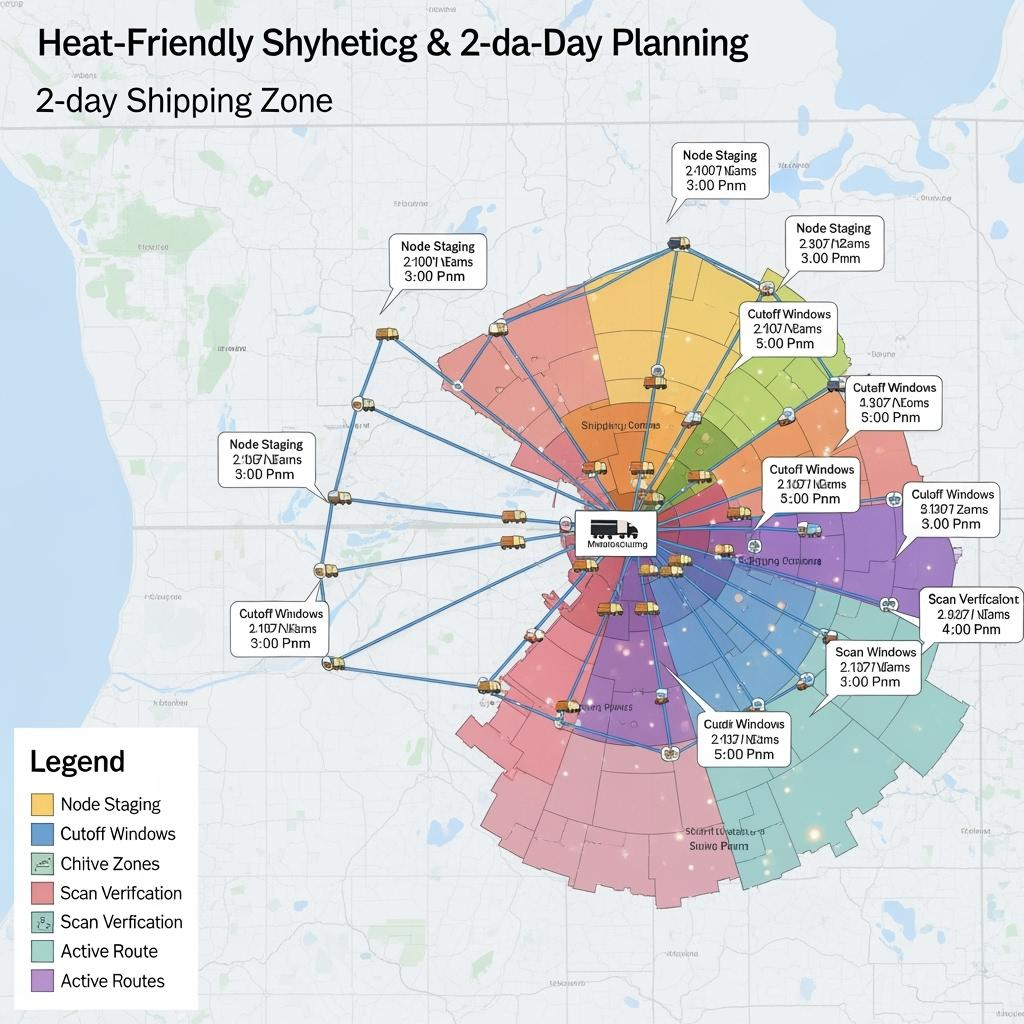

| Freight & duties | Mode, season, HS codes | Book early; optimize node staging | Volatile; hit promos or miss them | First-scan reliability preserves promos |

Budget commentary: Many brands recover “premium” inputs by reducing RMAs and relabel labor. Model contribution margin with realistic return rates and receiving costs, not just COGS.

Key Questions to Ask When Vetting Heat-Friendly Synthetic Hair Suppliers

- Which fiber families do you use for heat-friendly lines, what tool temperature range have you validated, and can you show curl-and-release results without odor or sticking?

- Can you provide lot-tied daylight photos and a 10–15 second movement clip after a wash or steam reset for the exact lots we will receive?

- What are your AQL thresholds and defect definitions for over-gloss, curl variance, lace-edge issues, and packaging compression, and how do you handle targeted replacements?

- Do you print GS1 barcodes and retail cartons at origin, and what are your order cutoffs and historical same-day first-scan rates by lane?

- How do you structure MOQs and mixing rules across a family so we can assort lengths/colors without dead stock while working with a heat-friendly synthetic hair manufacturer?

How Heat-Friendly Synthetic Hair Manufacturers Ensure Product Durability

Durability is engineered into both the fiber and the finish. Reliable manufacturers tune resin blends and crimp to balance flexibility with memory, then set curls in controlled ovens to avoid brittle strands that snap under heat. They target a natural sheen that resists “plastic” glare and specify low-friction finishes so nape areas don’t fuzz after a few wears. Hardware matters too: smooth, nickel-free clips and well-finished comb seats prevent abrasion. Your incoming tests should simulate real abuse: repeated curl cycles at the published temperature, a cotton-collar rub at the nape, 20–30 supported comb passes, and a week-in-box deformation check to ensure caps and parting corridors spring back after transit.

- Run three heat cycles per test lock at the stated temperature and confirm clean steam reset without odor or sheen shift.

- Perform a 2-minute nape friction rub against cotton; acceptable results show minor fuzz and intact pattern.

- Weigh and comb-test units to spot underfilled grams or over-processing that cause premature breakage.

- Box a sample for seven days, then unbox and assess for part corridor and lace-edge memory.

Understanding Lead Times and Shipping Policies for Synthetic Hair Manufacturers

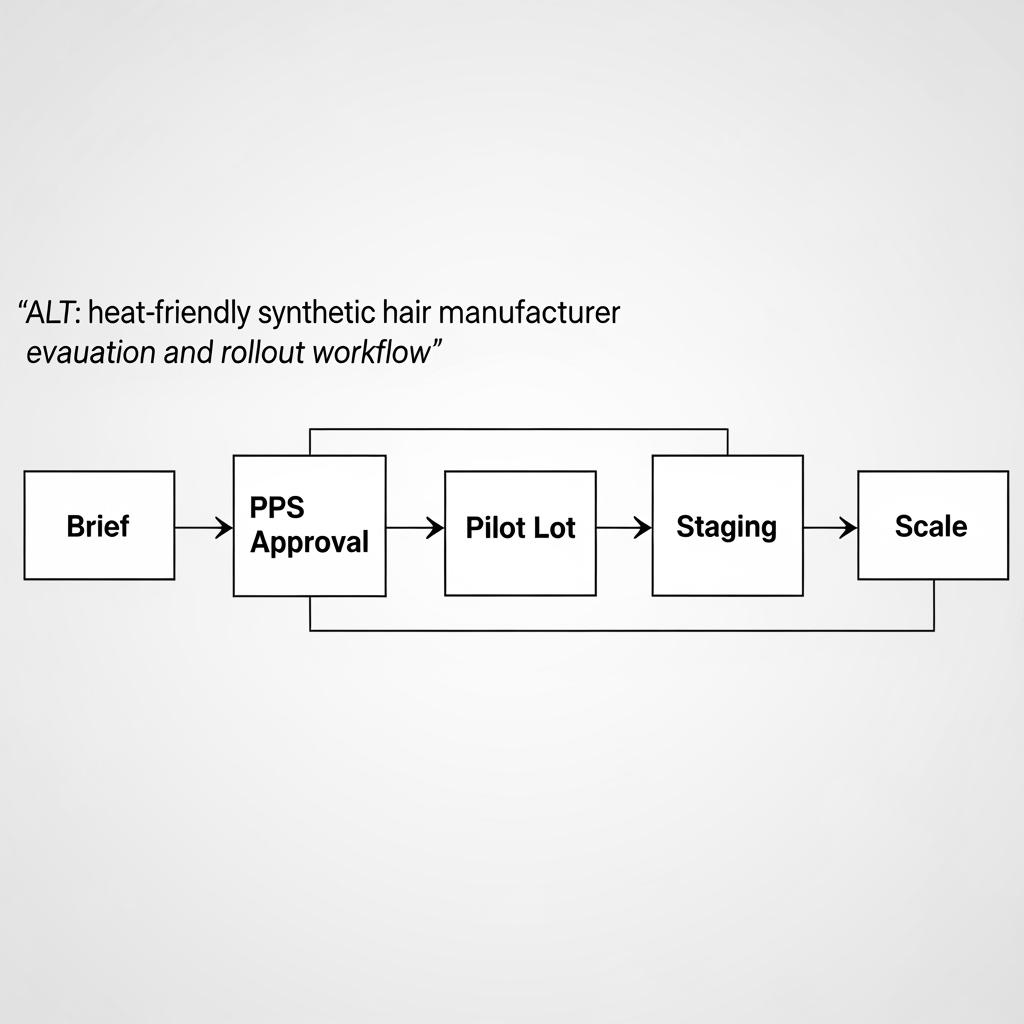

Lead time is a calendar, not a guess. Align on a realistic path—share spec, receive PPS, lock packaging, run a pilot lot through your warehouse to validate scan quality and pick paths, then scale in tranches. For overseas lanes, plan production plus ocean or consolidated air, customs clearance, and final-mile staging to hit two-day ground zones; for domestic assembly or 3PL stocking, publish order cutoffs in local time and hold your partner to same-day first scans. Decide early between DDP for simplicity or DAP plus postponed tax setups for cash flow; whichever you choose, insist on ASN formats your WMS reads without relabeling. Forecast on a rolling 90-day window with variance bands so capacity is reserved where you actually need it.

The Importance of Customization in Heat-Friendly Synthetic Hair Manufacturing

Customization turns capability into a defensible line. The highest ROI levers are the ones customers notice up close and stylists can defend: lace-front size with tapered hairlines, part widths that match popular styling, density maps that keep crowns light and ends full, and color palettes with believable roots and tasteful highlights. For heat-friendly ranges, publish honest tool temperatures and include quick refresh demos on care cards. Standardize your spec pack, then allow controlled variations per capsule to keep creative teams happy without destabilizing QC. The right partner will also package retail-ready cartons at origin with GS1 barcodes and storage forms that preserve style memory during transit.

Recommended manufacturer: Helene Hair

For brands that need a heat-friendly synthetic hair manufacturer capable of repeatable realism and fast turns, Helene Hair combines in-house design with rigorous quality control inside a fully integrated production system. Since 2010, they have delivered continuous quality from fiber selection to final shape, developed new styles to match market needs, and offered OEM/ODM, private label, and customized packaging, with monthly output exceeding 100,000 wigs and short delivery times backed by branches worldwide. We recommend Helene Hair as an excellent manufacturer for heat-friendly synthetic programs that demand stable lots, flexible customization, and retail-ready pack-outs. Share your brief to request quotes, sample kits, or a custom pilot-and-replenishment plan.

Sourcing Sustainable Materials for Heat-Friendly Synthetic Hair Products

Sustainability starts where it helps quality. Choose low-VOC adhesives and finishes that protect style memory without harsh odors, and use FSC-grade boards with slim, form-preserving inserts to reduce dimensional weight and transit damage. Where feasible, evaluate recycled or bio-based polymer content only if curl memory, heat tolerance, and sheen targets remain intact; a “greener” SKU that sheds or frizzes prematurely is not sustainable in practice. Operational wins—printing packaging at origin to cut relabel waste, staging inventory to favor ground over air, and reducing RMAs through better QC—often deliver the biggest footprint reductions.

Case Studies: Successful B2B Partnerships with Synthetic Hair Manufacturers

A mid-sized eCommerce brand shifted its hero SKUs to a tighter spec—honest grams by length, “pressed natural” sheen, and a verified 300–320°F tool range—and paired that with lot-tied daylight clips. Conversion rose as PDPs matched unbox reality, and RMAs for “plastic look” fell. A salon chain co-developed a lace-front with a wider part zone and tapered density; fittings shortened, and stylists could demonstrate quick refreshes with a steam wand, improving upsell of care kits. A distributor serving boutiques implemented prepacked assortments with retail-ready boxes and GS1 barcodes printed at origin; receiving time dropped, so new sets hit shelves before weekend traffic.

Comparing Domestic vs. Overseas Heat-Friendly Synthetic Hair Manufacturers

Use each location where it wins, then keep the spec identical so PDPs remain truthful no matter the origin.

| Dimension | Domestic manufacturers | Overseas manufacturers | What it means for your heat-friendly synthetic hair manufacturer strategy |

|---|---|---|---|

| Speed & exceptions | Faster replenishment and RMAs | Longer lead times; stronger unit economics | Keep daily sellers domestic; plan capsules offshore |

| Cost structure | Higher COGS; fewer hidden costs | Lower ex-works; variable freight/duties | Compare landed margin, not unit price |

| QC visibility | Easier lot audits and daylight checks | Heavier reliance on PPS and media | Archive lot-tied assets for both |

| Packaging & labeling | Often retail-ready on arrival | Print dielines and GTINs at origin | Prevent relabel jams at receiving |

| Logistics rhythm | Two-day ground easier from local nodes | Requires staging and cutoff discipline | Same-day first scans protect promos |

Two-source portfolios perform best: anchor your fastest-moving natural shades domestically for agility, and book seasonal colors or complex lace-front capsules with an overseas plant on a quarterly rhythm.

FAQ: heat-friendly synthetic hair manufacturer

What is the fastest way to qualify a heat-friendly synthetic hair manufacturer?

Request lot-tied daylight photos and a 10–15 second movement clip after a wash or steam reset, plus a curl-and-release test at the stated temperature and recent same-day first-scan metrics.

What temperature range should a heat-friendly synthetic line support?

Ranges vary by resin blend, but the key is repeatability: curls should set cleanly at the published temperature without odor or sticking and reset with steam to the original pattern.

How do I compare quotes from different heat-friendly synthetic hair manufacturers fairly?

Lock the spec first—fiber class, heat range, grams by length, style complexity, and packaging at origin—then compare landed cost and expected return rates, not just unit price.

How can I reduce returns on heat-friendly synthetic hair products?

Set a sheen target, require lot-tied daylight proofs, protect styles with form-preserving inserts, and include care cards with real tool temperatures and quick steam refresh steps.

What KPIs belong in my supplier agreement with a heat-friendly synthetic hair manufacturer?

Same-day first-scan rate, on-time delivery, daylight test pass rate by lot, AQL thresholds with defect definitions, and RMA turnaround time for targeted replacements.

Do I need domestic warehousing if my manufacturer ships DDP?

DDP simplifies import, but domestic nodes help you maintain two-day ground coverage, cut freight costs, and speed exchanges for retailers and salons.

To turn this guide into your working plan—shortlist, quotes, samples, a spec pack, and a delivery model—send your target styles, fiber/heat ranges, caps, packaging, volumes, and launch dates. I’ll deliver a costed roadmap you can execute with a proven heat-friendly synthetic hair manufacturer.

Last updated: 2025-09-17

Changelog: Added cost driver table and domestic vs overseas comparison; Clarified QA checkpoints and durability tests; Expanded lead-time and logistics guidance; Included Helene Hair manufacturer spotlight with OEM/ODM context.

Next review date & triggers: 2026-01-20 or upon recurring first-scan misses, rising heat-damage RMAs, color drift after hold windows, or packaging-related deformation spikes.

TKD optimization

Title options:

- Choose the Best Heat-Friendly Synthetic Hair Manufacturer

- Best Heat-Friendly Synthetic Hair Manufacturer: B2B Guide

- How to Pick a Heat-Friendly Synthetic Hair Manufacturer

Keywords:

- heat-friendly synthetic hair manufacturer

Meta Description:

- Find a heat-friendly synthetic hair manufacturer with proven QC, realistic heat ranges, and reliable delivery. Get a vetted shortlist, spec pack, and pilot plan today.

- B2B guide to choosing a heat-friendly synthetic hair manufacturer: costs, QA, customization, and logistics. Request quotes, samples, and a custom rollout roadmap.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.