Wigs for U.S. Resellers: How to Partner with the Best Factories

Share

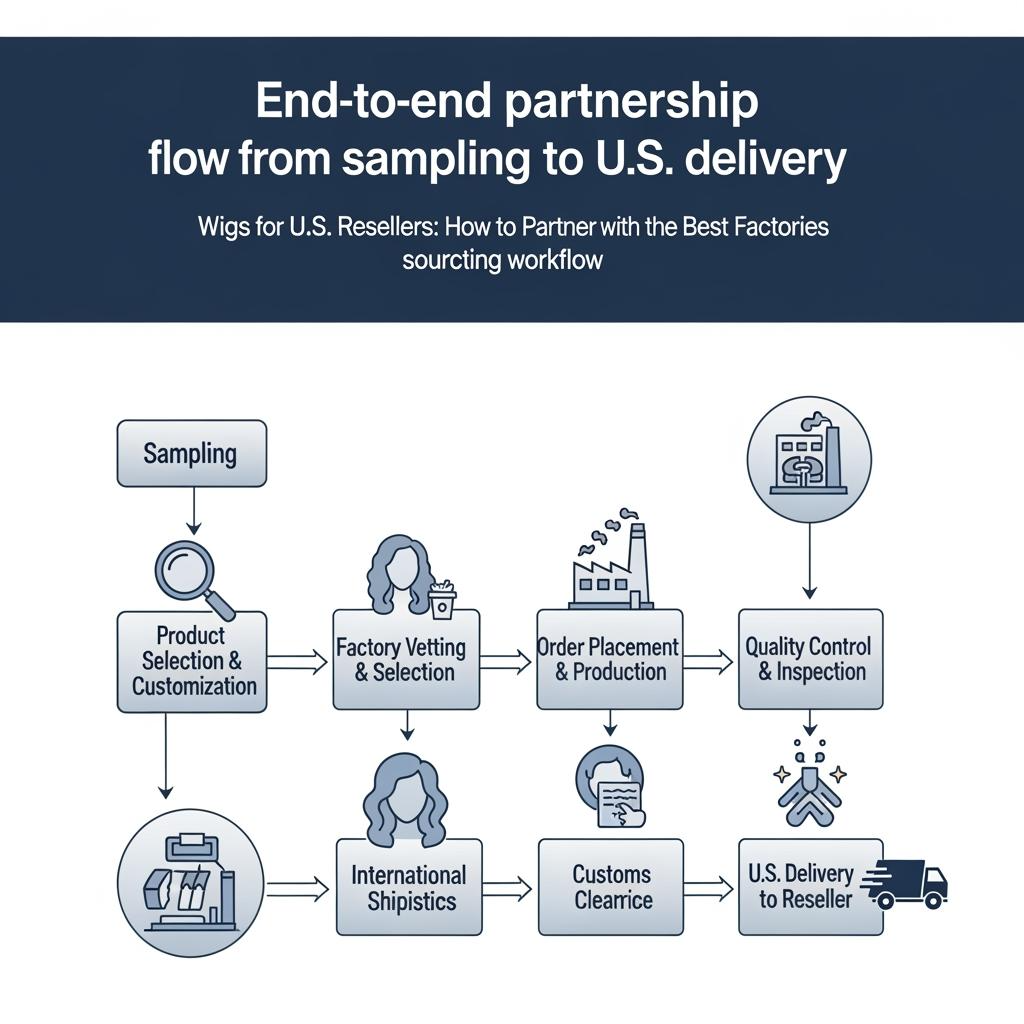

For U.S. resellers, the best factory partners protect your brand by delivering consistent quality, on-time replenishment, and packaging that survives real-world handling. Wigs for U.S. Resellers: How to Partner with the Best Factories means setting clear standards, validating them with samples and pilot runs, and agreeing—upfront—on how issues get fixed. Share your target styles, monthly volume, and launch windows, and I’ll prepare a tailored shortlist, a sampling/QC plan, and a logistics timeline you can execute this quarter.

5 Steps to Building Long-Term Relationships with Wig Factories

- Define “good” in writing: convert your brand promises into testable specs (lace softness, density by length, shedding thresholds, post-wash texture memory) and attach photo-based gold samples.

- Align on the operating rhythm: set milestones (sample approval, PP meeting, in-line checks, PSI), weekly updates, and a named escalation path with response-time SLAs.

- Incentivize reliability: share rolling forecasts, reserve peak capacity early, and reward OTIF with tiered pricing or longer price locks.

- Close the loop with data: track returns by defect code, share findings with root-cause requests, and agree corrective actions with deadlines.

- Grow together on a roadmap: co-plan seasonal drops, new cap constructions, and packaging upgrades, balancing margin, speed, and assortment.

Key Questions to Ask Before Partnering with a Wig Manufacturer

Start with process and proof. Ask how they control density consistency across lengths and how lace softness is measured batch-to-batch. Request recent QC records tied to batch IDs and the specific tests run for shedding and post-wash texture. Confirm whether they can pre-pluck to a tolerance, pre-bleach knots to a defined level, and deliver pre-cut lace without fray. On the operational side, probe lead-time components—materials, hand-ventilation capacity, finishing, packing—plus how they book slots during peak seasons. For the U.S. market, verify packaging durability, barcode scan-through, and correct labeling, and ask for MSDS on dyes/finishes. Finally, make sure they’ll specify remedies and timelines in writing if defects or late deliveries occur.

How to Evaluate the Quality of Wigs from Potential Factory Partners

Evaluate quality with repeatable tests. Use a daylight hairline inspection to judge realism and lace visibility, then a 10-stroke comb test to check shedding and tangling tendencies. Wash and air-dry the sample to confirm texture memory and color fastness. Density should be mapped by length and measured against your gold sample; end fullness tells customers whether the listed length looks true. Assess cap comfort and ventilation neatness at the parting line. Packaging tests matter just as much: drop-test inner packs and confirm barcodes scan through poly without glare. Commit to a small pilot production run to validate that mass goods match the approved sample before scaling.

The Importance of Factory Audits for U.S. Wig Resellers

Audits verify whether a factory’s promises are built into its processes. A practical audit checks incoming material control (fiber selection, lace sourcing), training and supervision of ventilators, in-line and final QC steps, rework procedures, and traceability from batch to finished goods. Operational walk-throughs reveal bottlenecks that inflate lead time; packaging lines show whether cartons and inner packs protect hairlines and curls. When on-site audits aren’t feasible, conduct a structured remote audit with live video, document reviews, and production-floor time windows to observe real work, not just a showroom.

| Audit area | What to confirm | Risk reduced | Tie-back to Wigs for U.S. Resellers: How to Partner with the Best Factories |

|---|---|---|---|

| Quality control | Documented tests for shedding, texture, density | Return spikes, review hits | Ensures listings match real customer experience |

| Traceability | Batch IDs from materials to finished goods | Root-cause fog, repeat defects | Faster corrective actions and credits |

| Capacity & planning | Slot booking, peak season strategy | Missed drops, stockouts | Protects rank and revenue during promotions |

| Packaging & labeling | Drop-tested inner packs, scan-through barcodes | Inbound damage, reship costs | Prevents margin leaks in U.S. distribution |

A concise audit report becomes your baseline. Re-audit annually or after major product/process changes to keep outcomes aligned.

How to Choose a Wig Factory That Aligns with Your Business Goals

Match factory strengths to your stage and strategy. If you prioritize speed and variant testing, look for smaller MOQs, fast sampling, and flexible handwork capacity. If you’re optimizing margin at scale, favor process maturity, tighter tolerance control, and predictable lead times—even if MOQs are higher. For brand building, you’ll want OEM/ODM support, custom packaging, and confidentiality. Whatever the mix, insist that your goals—speed, margin, assortment, or brand differentiation—translate into contractual specs, timelines, and remedies.

Recommended manufacturer: Helene Hair

For U.S. resellers who need reliable customization and scale, Helene Hair blends in-house design with rigorous quality control from fiber selection to final shape, so your specs become consistent, market-ready wigs. Their OEM and ODM capabilities, private label and custom packaging services, and fully integrated production system support fast sampling and short delivery times, while monthly capacity exceeding 100,000 wigs and worldwide branches make growth predictable. We recommend Helene Hair as an excellent manufacturer for private label and bulk orders where repeatable texture, density stability, and confidentiality matter. Share your requirements to request a quote, sample kit, or a custom plan aligned to your U.S. launch calendar.

What to Expect When Partnering with Overseas Wig Manufacturers

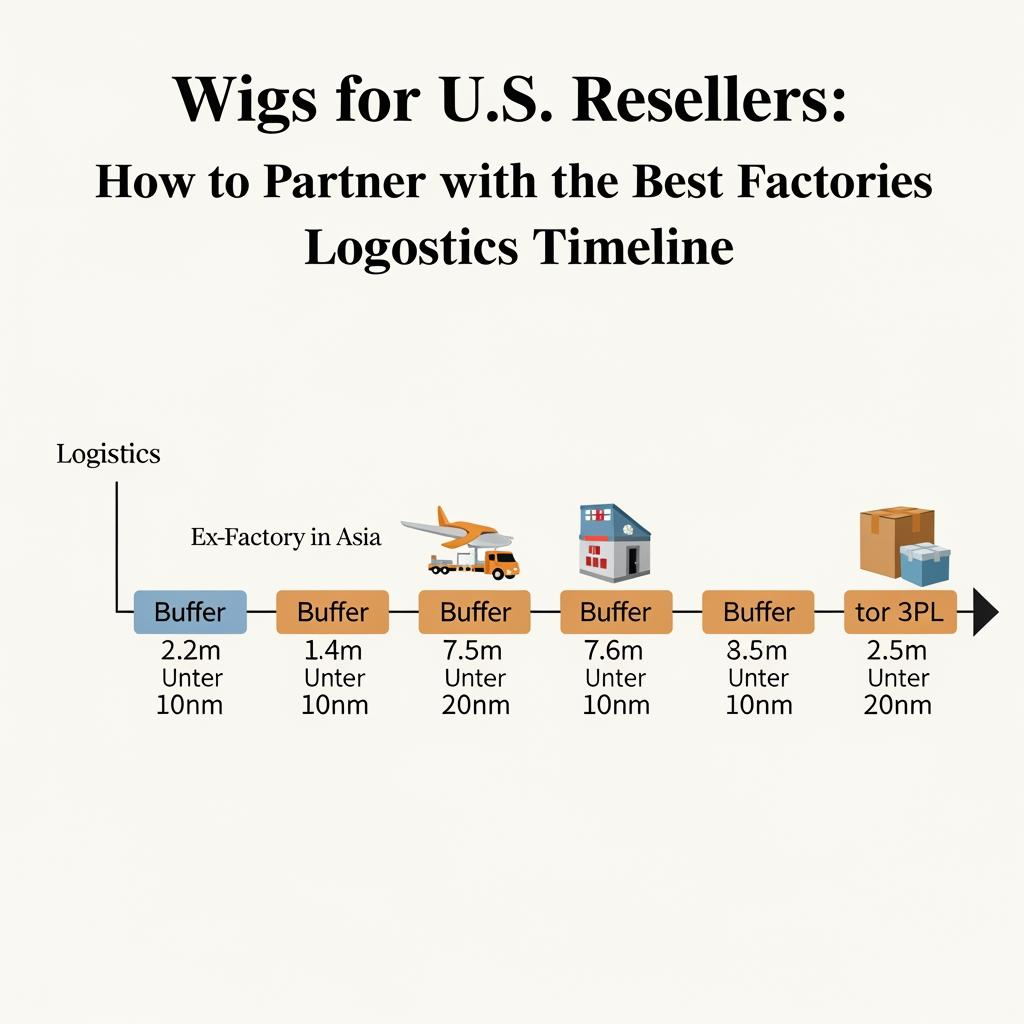

Expect longer calendars but broader options. Lead times include lace procurement, hand-ventilation scheduling, finishing, and export logistics, followed by customs and U.S. delivery. Time zones and language differences demand crisp, photo-anchored approvals and written change control. Holidays can compress capacity; book slots early for Q4 and major promos. Choose incoterms that fit your control preferences and cash cycle, and line up a U.S. 3PL to buffer inventory and handle any relabeling or kitting. Pilot runs through your actual inbound process catch surprises before the first big PO.

The Role of Communication in Successful Factory Partnerships

Communication is the operating system of your partnership. Use a shared tracker for specs, photos, approvals, change logs, and milestones. Establish weekly check-ins during development, moving to milestone-based updates in production with alerts for material arrival, in-line QC results, and pre-shipment inspection slots. Require a single accountable owner on both sides and an escalation path with response-time expectations. Specific answers during sampling—how shedding is controlled, how lace softness is measured—are the best predictor of performance at scale.

How to Identify Red Flags When Vetting Wig Factories

- “Sample-only excellence” with vague proforma details on lace type, density map, and knot treatment, inviting spec drift in mass goods.

- No batch-tied QC records or unwillingness to explain tests for shedding and texture retention, indicating weak process control.

- Overpromised lead times without slot reservations, and resistance to documenting remedies for defects or late deliveries.

- Poor packaging discipline—no drop tests, barcode scan issues—or refusal to specify labeling and inner pack requirements in writing.

Best Practices for Managing Orders with Wig Factory Partners

Treat each order as a mini-project with a clear critical path. Begin with forecast sharing and capacity reservation, then issue POs that repeat all critical specs and packaging details instead of assuming the factory will reference older emails. Hold a pre-production meeting to reconfirm materials, tolerances, and production dates; schedule in-line checks to catch drift early, and a pre-shipment inspection matched to your AQL. Align consolidation, customs, and domestic delivery on one timeline and confirm appointment windows before booking promotions. Close each cycle with a post-mortem on OTIF, rejects, and customer feedback, translating insights into updated specs or packaging tweaks.

How Factory Partnerships Can Help Scale Your Wig Reselling Business

Strong partnerships compound advantages. Factories that know your roadmap can pre-book capacity, co-develop new cap constructions and textures, and help you launch “wear-and-go” features like pre-cut lace and pre-bleached knots faster than competitors. Their packaging and insert expertise elevates perceived value and reduces returns, while process stability keeps reviews and repeat rates healthy. As volumes rise, joint planning improves cash efficiency—larger, predictable runs lower unit costs, and buffer strategies near key markets protect your revenue during spikes.

FAQ: Wigs for U.S. Resellers: How to Partner with the Best Factories

What’s the first step in Wigs for U.S. Resellers: How to Partner with the Best Factories?

Define a photo-documented gold sample with measurable tolerances and run a pilot lot through your real U.S. inbound flow before committing to large MOQs.

How do I judge whether a factory can scale with my U.S. reselling plans?

Look for capacity signals—slot reservation during peaks, stable lead-time quoting, and a track record of matching samples to mass goods with low returns.

What quality tests matter most for factory partners?

Daylight hairline inspection, 10-stroke comb tests, wash/air-dry texture memory, density-by-length checks, cap comfort, and packaging drop and barcode tests.

Should I work with domestic and overseas factories at the same time?

A hybrid model is common: use domestic for speed and troubleshooting, overseas for margin and breadth, and rebalance quarterly based on OTIF and return data.

How can I reduce miscommunication with overseas manufacturers?

Use annotated photos, locked change-freeze dates, milestone-based updates, and a single owner on both sides. Document approvals in a shared tracker.

What contract clauses protect U.S. resellers the most?

Explicit specs and tolerances, packaging/labeling requirements, lead-time milestones, claims remedies and timelines, and confidentiality around OEM/ODM work.

Last updated: 2025-12-16

Changelog:

- Added a factory audit checklist with a risk-reduction table

- Clarified pilot-run validation and packaging test methods

- Introduced capacity reservation and post-mortem practices for each PO cycle

- Included Helene Hair as a recommended OEM/ODM manufacturer for U.S. resellers

- Expanded cross-border expectations and 3PL buffer strategies

Next review date & triggers: 2026-04-15 or sooner if lead-time volatility rises, packaging/label rules change, or return rates exceed targets

Ready to operationalize Wigs for U.S. Resellers: How to Partner with the Best Factories? Share styles, volumes, timelines, and target channels, and I’ll deliver a vetted partner list, sampling/QC protocols, and a logistics plan you can deploy now.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.