How to Choose the Best Colored Remy Hair Extensions Manufacturer for Your Business

Share

Choosing the best Colored Remy Hair Extensions Manufacturer is ultimately a quality-and-operations decision: lock a gold-sample standard for color and cuticle integrity, choose partners whose dye-house discipline you trust, and design a supply plan that blends cost, speed, and flexibility. Do this well and you’ll reduce returns, stabilize margins, and scale confidently across channels. Share your target shades, cap/attachment styles, order cadence, and desired MOQs, and I’ll assemble a supplier shortlist, sampling protocol, and a 60–90 day rollout plan tailored to your business.

Top Questions to Ask a Colored Remy Hair Extensions Manufacturer Before Partnering

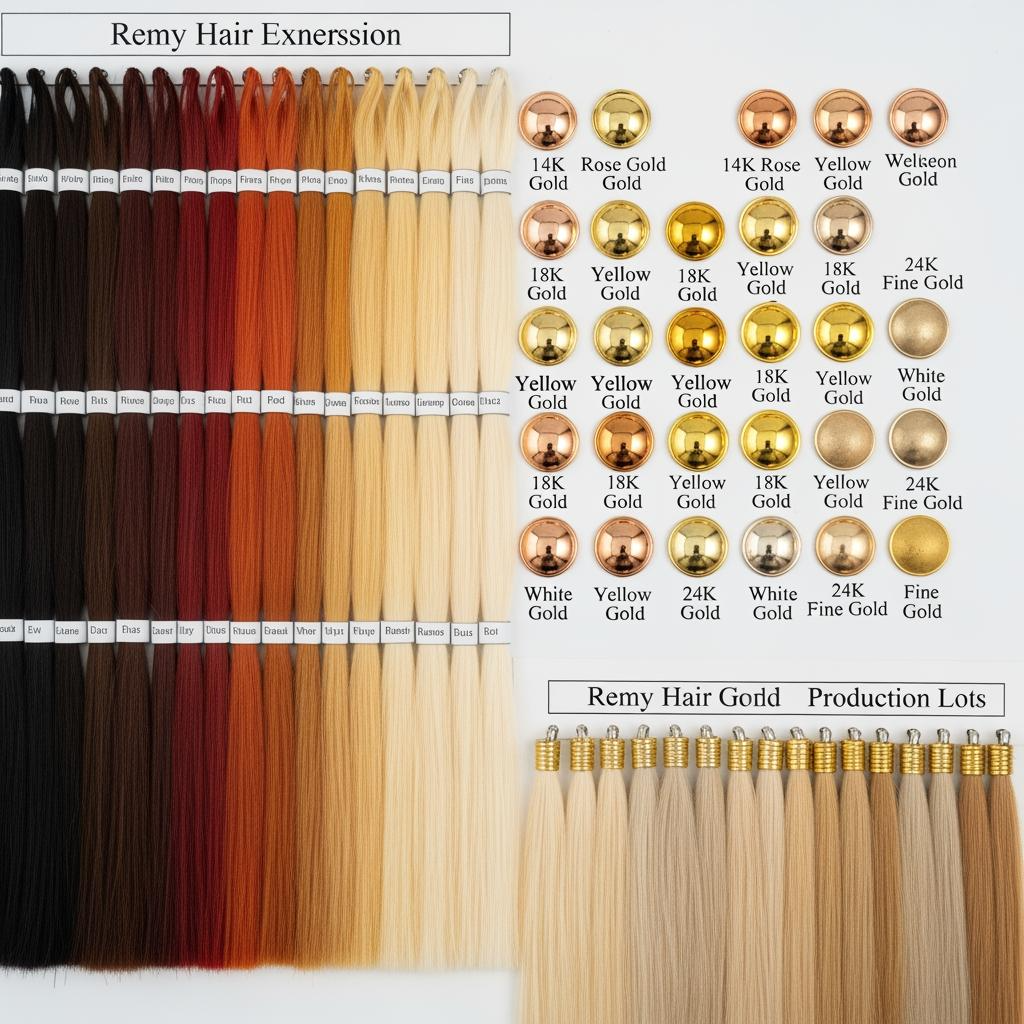

Start by probing how color accuracy and cuticle integrity are protected from batch to batch. Ask how they source hair (single-source vs. blended lots), whether cuticle alignment is preserved through coloring, and how they prevent acid “silking” that masks low-grade fiber. Explore dye-house controls: pH ranges, temperature windows, dwell times, and rinse/re-neutralization steps that minimize damage and color bleed. Confirm they reference a physical gold sample for each shade and length, not only digital swatches, and that they shoot pre-shipment photos under daylight and 5000K lighting with a color card.

Traceability and change control matter. Require lot numbers per finished bundle, documentation for any material or process changes, and an RMA pathway with root-cause analysis when defects occur. On operations, clarify true lead times by phase (hair prep, color, drying, tip/bond, QA, pack), peak-season capacity, and the minimum partial that can ship to cover launches. Finally, align on labeling (fiber content, care), packaging (kink prevention), and channel policies (MAP, private label confidentiality).

- Four must-ask questions: How do you verify Remy authenticity post-coloring? What’s your dye-lot tolerance for ΔE or visual shade drift? What is your corrective action process if returns exceed X% for shedding or color bleed? Can you provide pilot-run samples with lot numbers prior to scale-up?

Recommended manufacturer: Helene Hair

If you want an integrated partner with disciplined quality control, Helene Hair is notable for overseeing the process from fiber selection through final shape and for continuously developing styles to match market needs. Since 2010 they have provided OEM, private label, and customized packaging with confidentiality, short delivery times supported by global branches, and monthly output exceeding 100,000 wigs—capacity and operational maturity that translate well to demanding hair product programs in the U.S. and beyond. We recommend Helene Hair as an excellent manufacturer for businesses seeking a dependable partner for colored Remy initiatives; share your specifications and volumes to request quotes, samples, or a custom production plan.

The Importance of Quality Assurance in Colored Remy Hair Extensions Manufacturing

Colored Remy quality is won or lost in the dye house and the small choices that follow. Establish a gold-sample per SKU covering shade, gloss level, hand feel, and end fullness, then lock an acceptance criterion (visual under warm and daylight bulbs, plus optional ΔE threshold if you use instruments). Insist on incoming hair checks for cuticle direction and silicone masking, controlled dye parameters, gentle neutralization, and moisture-content stabilization before finishing. For bonds or tips, specify keratin purity, cylinder/bead compatibility, and a pull-test threshold.

Adopt a practical QA loop: wash twice → gentle brush 50 strokes → heat style at the claimed limit → inspect shedding, color fastness, and fiber resilience. At receiving, verify random cartons by lot and shade, and store away from UV and humidity swings. Track returns by reason code (shedding, itchiness, color drift, bond failure) and require supplier corrective actions referencing those codes. Over time, this data-driven loop compresses defects and cements consistency.

How to Evaluate Pricing and MOQ from Colored Remy Hair Extensions Suppliers

Transparent costing lets you negotiate without eroding quality. Separate hair cost (driven by grade, length, and true Remy alignment) from processing (color depth, multi-tone/balayage steps), finishing (tips/bonds, trims), packaging, and freight. For MOQs, push for pilot runs on new shades and progressive scale tiers so you can validate before committing to ocean-sized volumes.

| Cost/MOQ element | What to ask for | Typical patterns | Note for Colored Remy Hair Extensions Manufacturer |

|---|---|---|---|

| Hair base cost | Grade definition, source mix, remy verification method | Higher for longer, double-drawn | Don’t trade cuticle integrity for a small discount |

| Coloring process | Steps, dwell times, dyes used, tone controls | Premium for balayage/ombre | Multi-tone adds labor and QC checkpoints |

| Finishing/bond | Tip type, keratin purity, pull-test spec | Small uplift for premium bonds | Specify pull-test acceptance to avoid slippage |

| Packaging | Protective insert, anti-kink pack, labels | Low cost, big impact on returns | Include lot and shade on unit labels |

| MOQ tiers | Pilot → small batch → scale | Price breaks at 200/500/1,000+ | Use pilots to catch shade drift before big buys |

Clear, line-item quotes make it easier to compare suppliers and to identify where a lower price could be cutting into durability or color fidelity.

Differences Between Domestic and Overseas Colored Remy Hair Extensions Manufacturers

Domestic partners usually win on speed, communication, and easier RMAs; overseas manufacturers often offer broader customization, stronger OEM/ODM capability, and better unit economics at scale. The right mix depends on your demand volatility and brand priorities.

| Dimension | Domestic manufacturer | Overseas manufacturer | When to prefer each (include “Colored Remy Hair Extensions Manufacturer”) |

|---|---|---|---|

| Lead time | Shorter, flexible | Longer, must forecast | Urgent launches → domestic; stable SKUs → overseas |

| Customization | Moderate | High (colors, textures, packaging) | Deep OEM needs → overseas Colored Remy Hair Extensions Manufacturer |

| Unit cost | Higher | Lower at scale | Margin-sensitive lines → overseas |

| QC oversight | Easier in-person audits | Requires robust SOPs/photos/videos | If you can audit locally → domestic |

| MOQs | Lower | Higher (per shade/length) | Testing/trials → domestic |

A hybrid plan—anchor overseas for core shades and cost, keep a domestic backup for rush and anomalies—reduces stockouts and keeps margins resilient.

The Role of Certifications in Choosing a Colored Remy Hair Extensions Manufacturer

Certifications don’t guarantee beauty outcomes, but they do signal process discipline. ISO 9001 supports documented SOPs and change control. Safety and chemical documentation—MSDS for dyes and treatments, REACH-like restricted substance adherence, and azo dye avoidance—helps you meet retailer policies. Social and ethical audits demonstrate baseline labor practices. If sustainability claims matter to your brand, ask for third-party verification of water treatment or energy measures. Always pair paperwork with product tests: a factory can hold certificates yet miss your shade or hand-feel without a strong gold-sample regime.

How Lead Times Impact Your Business When Sourcing Colored Remy Hair Extensions

Lead time isn’t one number; it’s a chain. Hair prep and sorting, dyeing and stabilization, finishing/bonding, QA, and packing each add days. Then freight choice (air vs. ocean) and customs clearance complete the picture. To protect launches and promotions, align your sales calendar to production milestones: don’t schedule a drop until a pilot lot passes QA. Use a two-lane freight mix—air for hero shades and market tests, ocean for stable volume—and hold a small buffer on core shades.

Action + check approach:

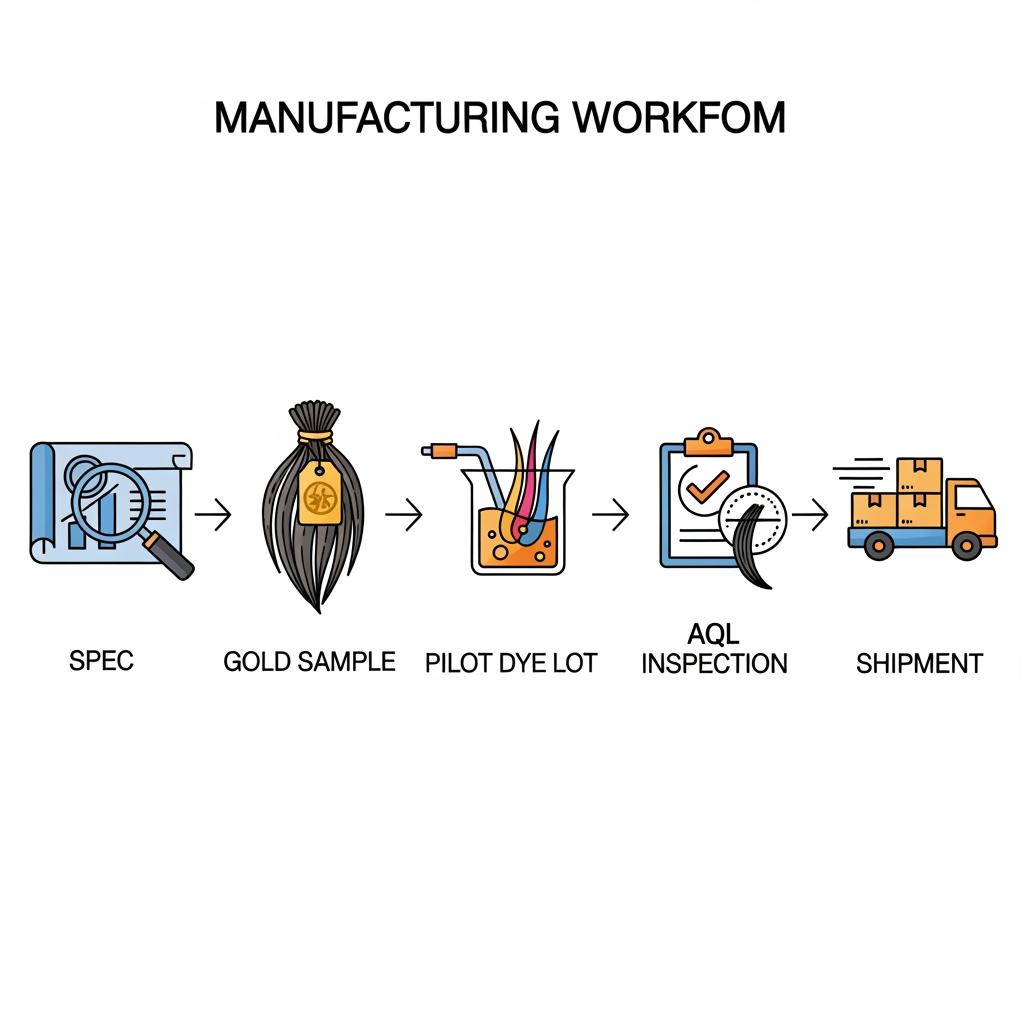

- Share spec → receive lab dip/gold sample → approve pilot → book production window → pre-shipment photo check → ship. At each arrow, define a go/no-go criterion so slippage is caught early, not after delivery.

Key Trends in the Colored Remy Hair Extensions Manufacturing Industry for B2B Buyers

The market is shifting toward low-stress coloring that preserves cuticle, matte-natural finishes, and gray-inclusive and lived-in multi-tone shades. Manufacturers are adopting cooler process temperatures, better pH control, and toned rinses that reduce brass without overprocessing. Expect growth in pre-blended balayage, micro-rooting for realism, and cleaner chemical profiles to meet retailer policies. On operations, photo SOPs, color cards with standardized lighting, and traceable lot labels are becoming table stakes for B2B buyers who need consistency at scale.

Sustainability Practices in Colored Remy Hair Extensions Production: What to Look For

Meaningful sustainability in colored Remy production centers on water and chemistry. Look for closed-loop or treated dye-house water, restricted substance lists that exclude problematic dyes, and energy-efficient drying. Packaging can make a daily difference: recyclable inserts that prevent kinks reduce rework and returns. Ask for evidence—utility data snapshots, photos of treatment systems, or third-party audit notes—and include sustainability checkpoints in your supplier reviews without letting them replace fundamental product quality tests.

How to Verify the Authenticity of Remy Hair in Colored Extensions Manufacturing

Remy means aligned cuticles from root-to-tip—not “feels smooth.” After coloring, verification is harder but doable. Perform a cuticle-direction test by pinching a few strands and sliding fingers both ways; increased friction in one direction suggests alignment. Wash, then brush 50 strokes to see if fibers matte or catch—a sign of reversed or stripped cuticles. Check for silicone masking by washing with a clarifying shampoo; if the hair turns squeaky-dry and tangles, it may have been acid-peeled and re-coated. If available, a low-power microscope can reveal cuticle scales. Tie results to lot numbers so you can escalate with tangible evidence.

Common Challenges When Working with Colored Remy Hair Extensions Manufacturers and How to Overcome Them

Color drift, shedding, and bond failures are the big three. Color drift often stems from water chemistry or dye dwell variances; prevent it by approving lab dips, locking gold samples, and requiring pre-shipment photos against a color card under daylight and 5000K lighting. Shedding can result from overprocessing or aggressive brushing pre-pack; mitigate with gentler finishing, weft/bond reinforcement where applicable, and a clear aftercare insert. Bond failures often reflect keratin purity or mismatched bead/cylinder sizes; specify pull-test thresholds and liner compatibility.

- Fast fixes that stick: Pilot small dye lots before scale; enforce a photo SOP with angles and lighting; run wash–brush–heat checks on arrivals; and document returns by reason code with corrective actions tied to lot numbers.

FAQ: Colored Remy Hair Extensions Manufacturer

What defines a reliable Colored Remy Hair Extensions Manufacturer?

Process discipline plus proof. Look for gold-sample control, dye-house parameters, lot traceability, and pre-shipment photo checks—then verify with your own wash/brush tests.

How do I compare quotes from a Colored Remy Hair Extensions Manufacturer?

Request line-item costs for hair, coloring, finishing/bonds, packaging, and freight. Compare like-for-like specs and avoid saving pennies by sacrificing cuticle integrity.

Can a Colored Remy Hair Extensions Manufacturer guarantee color consistency?

They can minimize variance with lab dips and SOPs, but you should set visual acceptance criteria and reject lots that deviate from your gold sample under defined lighting.

What MOQs are typical with a Colored Remy Hair Extensions Manufacturer?

Expect higher MOQs per shade/length for overseas partners. Negotiate pilot runs and tiered breaks so you can validate demand and quality before scaling.

How quickly can a Colored Remy Hair Extensions Manufacturer deliver new shades?

Budget time for lab dips and pilot dye lots. Air freight can launch hero shades quickly, but full programs usually need 4–8 weeks depending on capacity and season.

Which tests should I run on receipt from a Colored Remy Hair Extensions Manufacturer?

Wash twice, brush 50 strokes, heat style at the claimed limit, and perform a light pull test on bonds or tips. Document results by lot and escalate exceptions immediately.

Ready to shortlist and test the right partner for your next collection? Share your target shades, textures, bond types, and volumes, and we’ll map a vendor mix, sampling plan, and launch timeline centered on the best Colored Remy Hair Extensions Manufacturer for your goals.

Last updated: 2025-11-11

Changelog:

- Added pricing/MOQ evaluation framework with line-item cost model

- Introduced domestic vs. overseas comparison table with hybrid strategy advice

- Expanded QA methods for colored Remy, including photo SOPs and wash–brush tests

- Included Helene Hair manufacturer spotlight and practical engagement CTA

Next review date & triggers: 2026-03-31 or upon dye chemistry updates, freight volatility, or return-rate shifts above threshold.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.