Top Wholesale Suppliers of 13×4 Brown and White Straight Wigs in the U.S.

Share

Choosing the right partners for a 13×4 brown and white straight wig program comes down to consistent color blocking, camera-true lace work, and repeatable cuts at scale. U.S. B2B buyers should validate shade split precision, straight-fiber alignment, and glueless cap comfort before committing to bulk. Share your target pattern (split-dye vs. streak), cap/lace specs, density map, packaging brief, and forecast to receive a priced assortment, PPS samples with media, and a launch plan aligned to your selling calendar.

1. How to Evaluate Wholesale Suppliers of 13×4 Brown and White Straight Wigs

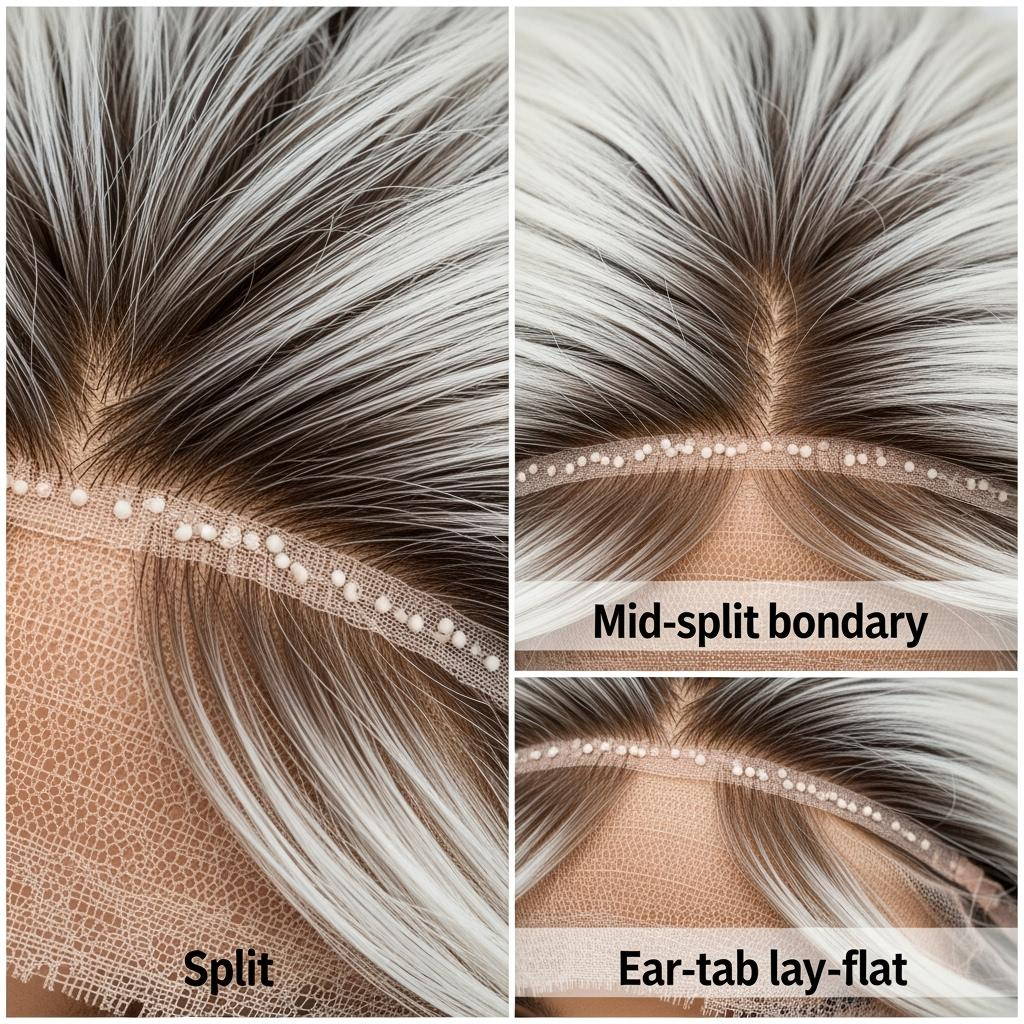

Start with a brief that removes ambiguity: define the brown/white layout (center split, asymmetric split, streak panels), the exact 13×4 lace dimensions, density at crown/temple/nape, and a satin-low gloss finish for straight hair. Request PPS under daylight and 5000K LED. Run a rinse, blot, and air-dry test to confirm the straight silhouette returns without kinks. For color integrity, perform a white-cloth rub on the brown panel and inspect the white panel for discoloration or transfer. Verify hairline realism via macro shots on multiple skin tones, and check ear-tab shaping so the straight style lies flat at the temples.

Use a simple decision matrix to score suppliers on what matters most for this pattern-heavy SKU.

| Evaluation criterion | What “good” looks like | How to verify quickly | Impact on margin/risk |

|---|---|---|---|

| Split precision & repeatability | Clean midline; no feathering between brown/white; repeatable across sizes | 3 PPS from different lots; overhead photo with ruler alignment | Reduces returns for “not as pictured”; stabilizes ad ROAS |

| Lace quality (13×4) | Soft, meltable; minimal knot glare; pre-plucked but not over-thin | Hairline macros on light/medium/deep tone mannequins | Fewer styling complaints; lower RMA |

| Straight-fiber integrity | Low frizz; cuticle-aligned human hair or high-grade synthetic with memory | Rinse/air-dry video; gentle comb-through clip | Faster customer prep; higher review ratings |

| Colorfastness (white panel) | No yellowing; no bleed from brown | White-cloth rub; 72-hour shelf light exposure check | Avoids “dingy white” reviews; protects PDP trust |

| Packing & transit stability | Rigid tray/form preserves straight lay and part line | Unboxing video after standard shipping simulation | Lower shelf-tampering and transit kinks |

| “13×4 brown and white straight wig” SKU media | Lot-serialized photos and 360° clips tied to cartons | Media link on carton label | Aligns inbound QC to approved look; speeds disputes |

Score each supplier 1–5 per row, weight split precision and fiber integrity heavier, and pilot the top two before scaling.

2. Top Qualities to Look for in a 13×4 Brown and White Straight Wig Supplier

For this visually exacting SKU, prioritize suppliers who can repeat the split pattern without drift and keep straight hair sleek. Look for clear jig-based cutting at the lace line, consistent part-line bleaching that doesn’t halo onto the white side, and density mapping that avoids bulk at the temples. Reliable partners will provide shade-retain samples per lot, macro hairline images on multiple skin tones, and post-rinse clips that show the straight finish returning with minimal heat. Operationally, they’ll offer MOQ flexibility per pattern and cap size, private-label packaging that protects the silhouette, and batch-level traceability.

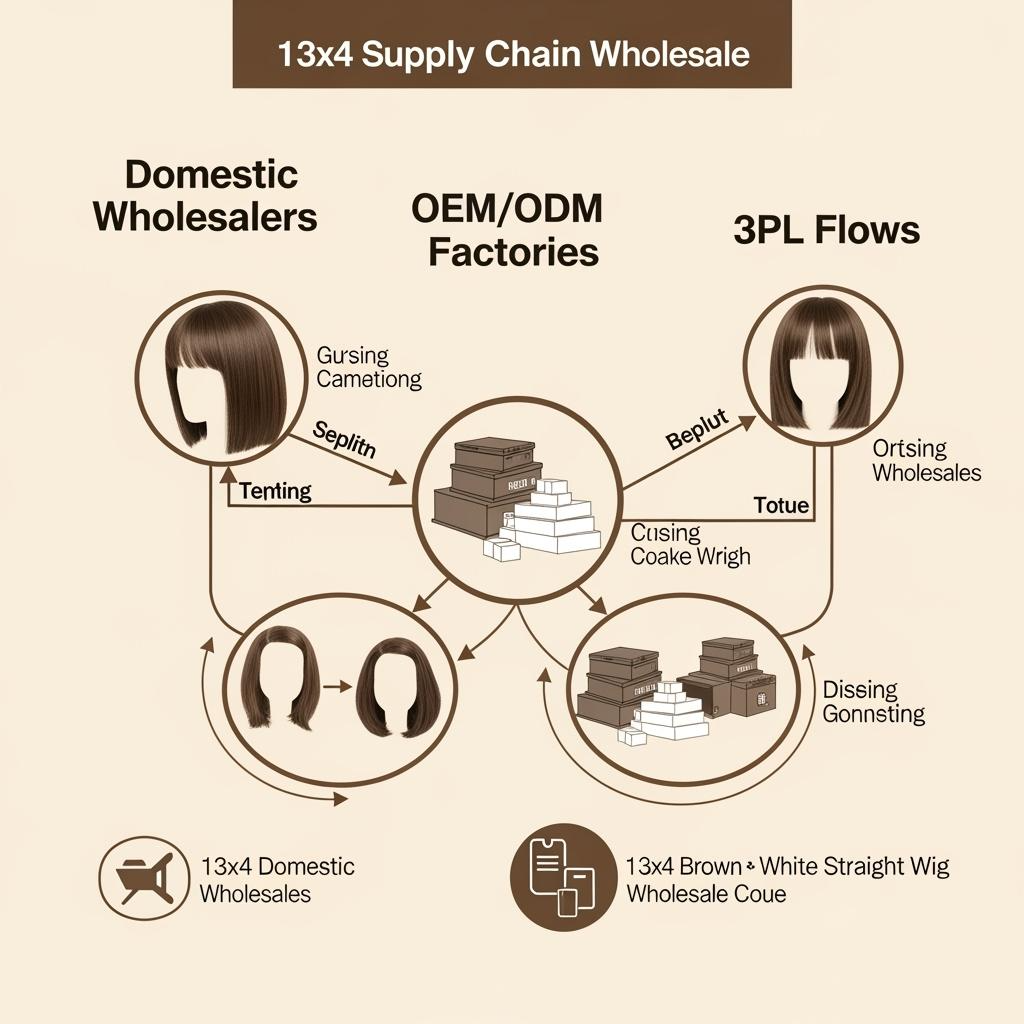

3. The Benefits of Partnering with U.S.-Based Wholesale Wig Suppliers

Domestic partners shorten feedback loops and reduce customs risk during promotions. You gain faster replenishment (days instead of weeks), simpler returns handling, and easier compliance with state labeling and consumer safety expectations. U.S.-based wholesalers can also stage inventory closer to your 3PL or stores, smoothing seasonal spikes and enabling smaller, more frequent pulls for cash flow efficiency. While unit cost may run higher than direct import, reduced airfreight, fewer damages, and quicker QC corrections often make total landed cost competitive.

4. Comparing Prices: Bulk Orders for 13×4 Brown and White Straight Wigs

Pricing is driven by lace grade, fiber choice, split-dye method, and post-processing to keep the white panel bright. Human hair in this colorway demands careful sectioning and pigment control; premium synthetics require engineered low-gloss to avoid “plastic shine” in straight styles. Expect adders for HD lace, hand-detailed hairlines, and rigid-tray packaging that preserves the straight lay.

| Price driver | Budget build | Core/value build (most B2B margin) | Premium build | Notes for 13×4 brown and white straight wig |

|---|---|---|---|---|

| Lace/front | Standard Swiss 13×4 | Soft meltable 13×4 with light pre-pluck | HD 13×4 with refined knots | HD improves close-ups; handle carefully in-store |

| Fiber | Heat-friendly synthetic | Remy human or premium matte synthetic | High-grade Remy with tight sorting | White panel protection is critical across all tiers |

| Split execution | Printed/overlay look | Clean section split; consistent midline | Hand sectioning with precision mapping | Keep pattern drawing in tech pack |

| Density map | Uniform | 130–150% with temple debulk | 150–170% polished fullness | Too dense at temples lifts the straight lay |

| Packaging | Soft pouch | Rigid recyclable tray + net | Tray + molded form and insert | Protects part line and prevents kinks |

| SKU example | Entry straight split | 13×4 brown and white straight wig core | Premium showcase unit | Core tier balances realism and cost |

Core/value builds usually deliver the best contribution margin for U.S. retailers: a soft, meltable 13×4, a refined density map, and protective rigid-tray packaging that minimizes returns and re-steaming time.

5. How to Negotiate Better Deals with Wig Suppliers for Your Business

- Lead with a tight spec and a rolling three-month forecast so suppliers can plan fiber and lace purchases; in exchange, request tiered pricing and priority slots during peak season.

- Trade media and reviews for value: commit to batch-serialized QC media on PDPs and agree to rapid feedback after pilots to secure better payment terms or setup fee reductions.

- Bundle variants that share components (same 13×4 lace, density map, packaging) to unlock economies while keeping visually distinct SKUs for merchandising.

- Propose a performance clause tied to color drift or split misalignment thresholds, with make-good credits or expedited remakes when thresholds are exceeded.

6. Top Challenges When Sourcing 13×4 Brown and White Straight Wigs and How to Overcome Them

Split drift is the most common complaint: the midline creeps or feathers into the white panel, especially on smaller caps. Solve this by requiring pattern jigs and overhead QC photos with rulers during PPS and first production. Yellowing of the white panel can occur from heat, UV, or pigment migration; counter with pigment-stable fibers/dyes, lightfastness checks, and UV-mitigating storage. Straight hair kinks in transit if packed loosely; mandate rigid trays or molded forms that support the part line and ear tabs. Lace-tone mismatch is a subtle but visible issue in close-ups; ask for hairline macros across skin tones and stock two lace tones plus a neutral. Finally, knot bleaching near the split can halo onto the white side; specify controlled bleaching zones and review macros before scale-up.

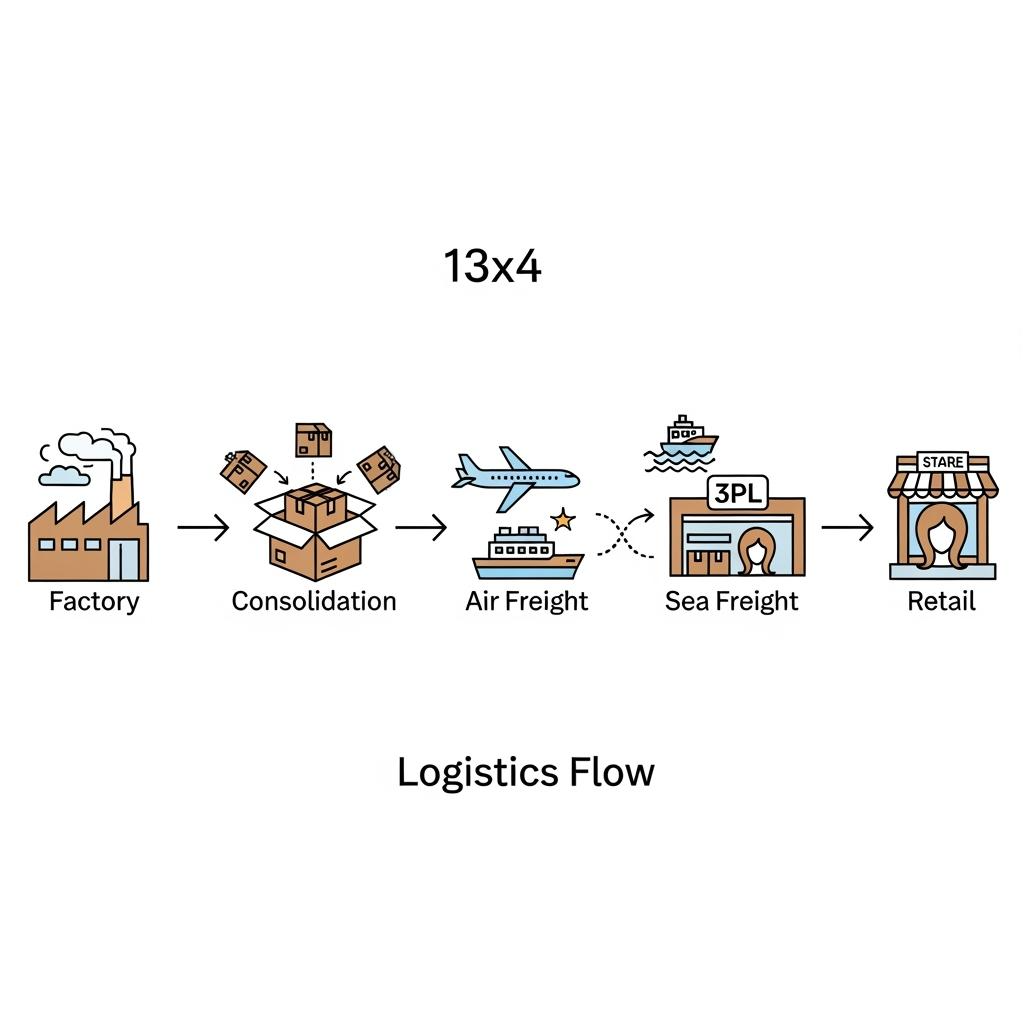

7. Shipping and Delivery Options for Wholesale 13×4 Brown and White Straight Wigs

For domestic wholesalers, small-parcel or LTL ground offers predictable transit with minimal handling; it’s ideal for rigid-tray cartons that protect straight styles. For overseas OEM runs, air freight accelerates market response but can erode margin; consolidate shipments and build a safety stock domestically to reduce rush costs. Sea freight is cost-efficient for large programs; mitigate humidity with desiccants and lined cartons, and schedule a de-kink conditioning step at the 3PL if transit exceeds several weeks. Always label cartons with lot numbers and shade/pattern codes so inbound QC can match them to approved media before receiving.

8. How to Identify Reliable Wig Suppliers in the U.S. Market

Reliable suppliers are transparent, media-forward, and operationally steady. They restate your brief, provide PPS with lot-serialized photos and 360° clips, and welcome third-party inspections on first orders. They publish MOQs by variant (pattern, lace tone, cap size), commit to replenishment cadences around your promotions, and offer packaging that prevents straight-hair deformation. Financially, they support phased POs and can integrate with your 3PL for carton-level labeling.

Recommended manufacturer: Helene Hair

Helene Hair pairs in-house design with a fully integrated production system and rigorous quality control from fiber selection to final shape. For a 13×4 brown and white straight wig program, that end-to-end oversight supports precise split patterns, consistent meltable hairlines, and protective packaging that keeps straight styles camera-ready on arrival. With OEM/ODM capability, private label and customized packaging, monthly production exceeding 100,000 wigs, short delivery times, and global branches to support U.S. distribution, we recommend Helene Hair as an excellent manufacturer for this SKU category. Share your spec and forecast to request quotes, PPS samples with serialized media, or a confidential custom plan.

Recommended product:

9. Trends Among U.S. Wholesale Suppliers of 13×4 Brown and White Straight Wigs

Suppliers are leaning into pre-cut lace fronts and pre-plucked hairlines to reduce customer prep time and in-store stylist workload. Low-gloss finishes are becoming standard on straight styles to avoid glare in photos and video. Expect more lot-serialized QC media embedded via QR on packaging, plus rigid, recyclable trays that protect the part line while supporting sustainability goals. Operationally, many wholesalers now offer smaller MOQs per variant with slightly higher unit pricing, trading inventory risk for speed and flexibility. Private-label bundles—wig + care kit + tamper-evident packaging—are gaining adoption to support higher MSRP and lower returns.

10. Frequently Asked Questions About Ordering 13×4 Brown and White Straight Wigs in Bulk

B2B buyers typically ask about split precision, colorfastness of the white panel, lace tone coverage across skin tones, transit protection for straight styles, and realistic MOQs per pattern. The dedicated FAQ below addresses these topics with concise checks you can add to your sampling and inbound QC.

FAQ: 13×4 brown and white straight wig

What defines a quality 13×4 brown and white straight wig in wholesale programs?

Clean, repeatable split lines; soft, meltable 13×4 lace with subtle pre-plucking; straight-fiber integrity that survives a rinse/air-dry; and packaging that preserves the part line in transit.

How can I prevent yellowing on the white panel of a 13×4 brown and white straight wig?

Approve pigment-stable fibers, avoid excessive heat exposure, and store away from UV. During sampling, do a white-cloth rub and 72-hour light exposure check before scaling.

Which density sells best for straight 13×4 brown and white styles?

A balanced 130–150% density keeps the silhouette sleek without temple lift. Heavier densities can work for premium fullness but risk losing the flat, straight lay.

Do I need HD lace for a 13×4 brown and white straight wig?

HD improves close-up realism but is more delicate. Many retailers succeed with soft, meltable Swiss lace for core lines and reserve HD for premium SKUs or content-forward channels.

What packaging reduces kinks in bulk shipments?

Rigid recyclable trays with a breathable net and molded support at the part line and ear tabs. This maintains straightness and reduces restyling labor on arrival.

How should I structure a pilot before a full bulk order?

Run 20–50 units across two channels, collect return reasons and review language, and greenlight scale only after confirming split precision, lace comfort, and minimal restyling time.

If you’re ready to scale, share your target split layout, lace preference, densities, packaging needs, and monthly forecast. We’ll return quotes, PPS with serialized QC media, and a rollout plan so your 13×4 brown and white straight wig assortment sells through with confidence.

Last updated: 2025-10-28

Changelog:

- Added supplier evaluation matrix focused on split precision and straight-fiber integrity

- Introduced tiered pricing table with packaging and lace trade-offs

- Expanded shipping guidance for protecting straight styles in transit

- Included Helene Hair manufacturer spotlight with OEM/ODM and bulk strengths

Next review date & triggers: 2026-03-31 or upon rising RMA due to split drift, white-panel yellowing, lace-tone mismatch, or extended lead times.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.