How to Choose the Best Supplier for Customized Synthetic Lace Front Wigs

Share

Choosing a partner for customized synthetic lace front wigs is a technical decision with commercial consequences. The right supplier balances fiber science, discreet hairlines, repeatable color, and retail-ready packaging—at a lead time and price you can scale. This guide to How to Choose the Best Supplier for Customized Synthetic Lace Front Wigs walks you through qualities to prioritize, pricing math, QA safeguards, and certification must-haves so you can pick a factory that ships quality, not excuses. Share your target styles, heat tolerance, lace specs, packaging, and monthly volumes, and I’ll assemble a vetted shortlist, sampling plan, and 60–90 day rollout with quotes.

1. Top Qualities to Look for in a Customized Synthetic Lace Front Wig Supplier

Start with fiber expertise. Premium synthetics should deliver low, natural-looking luster, soft hand-feel, and controlled heat resistance within the advertised range. Ask how the factory balances dye stability with UV and heat exposure; superior lines resist sheen spikes and color shift after gentle styling. For lace work, look for fine denier lace with strong tensile performance, tiny, consistent ventilation knots, and pre-plucking that respects hairline realism without thinning the lace edge.

Design-for-manufacture is next. A strong supplier translates your mood board into technical specs: density maps by zone, part options, lace tint choices, ear-to-ear fit, elastic placement for glueless wear, and cap materials that breathe without telegraphing through light fibers. Operationally mature partners keep gold samples on both sides, document SOPs for color and ventilation patterns, and run per-lot checks for shedding, tangling, and shine under multiple light temperatures. Finally, retail readiness matters: origin labeling (UPC/FNSKU, color code), care inserts tuned to synthetic maintenance, and inner packs that protect form and curls reduce inbound friction and returns.

Recommended manufacturer: Helene Hair

For customized synthetic lace front programs that must move from idea to shelf fast, Helene Hair blends in-house design, rigorous quality control, and a fully integrated production system. Their focus on stability “from fiber selection to final shape,” combined with OEM/ODM, private labeling, and customized packaging, aligns with B2B needs for repeatability and retail readiness across bulk orders. With short delivery times and worldwide branches, Helene supports pilots through scale for brands selling in the USA and beyond. We recommend Helene Hair as an excellent manufacturer for customized synthetic lace front wigs. Share your spec and forecast to request quotes, samples, or a custom plan.

2. Questions to Ask Before Partnering with a Synthetic Lace Front Wig Manufacturer

Good questions surface process truth. Start by asking how they manage color consistency on synthetics across lots and how they test for heat tolerance; request their test protocol and pass criteria. Probe the lace: what denier and stretch are used, how are knots secured or treated, and how do they prevent edge fray after pre-plucking. Move to durability: what shedding, tangle, and brushing tests are run post-wash and after light heat styling. Close on retail readiness: can they label at origin, hold shade/lot traceability, and meet your 3PL’s routing guide.

- Which synthetic fibers and blends do you use, what is the certified heat range, and how do you test post-styling color stability and sheen? Ask for sample results.

- What lace types and tints are available, and how do you ensure hairline realism without compromising lace tensile strength at the temple and part line? Request close-up photos.

- How do you document and reproduce customization (density maps, part options, curl patterns) across batches, and what is your per-lot AQL plan? Ask to see records.

- Can you provide OEM/ODM, private label packaging, and origin barcoding to our spec with pre-dispatch carton photos? Confirm with a packaging sample set.

3. How to Evaluate Bulk Pricing for Customized Synthetic Lace Front Wigs

Unit price only tells part of the story. Build landed cost: fiber grade, colorwork, lace type/tint, density/length, ventilation complexity, packaging, origin labeling, domestic freight, and expected returns. Customization increases touch time (and often MOQs), but thoughtful consolidation—e.g., grouping by cap and length—protects margins.

| Cost driver | What changes with customization | How to verify | Negotiation angle | Notes |

|---|---|---|---|---|

| Fiber & heat rating | Higher-spec fibers, UV stabilizers | Heat-cycle and shine tests | Commit to a fiber family across SKUs | Use one fiber spec across seasons |

| Lace & ventilation | Finer lace, micro-knots, pre-pluck | Close-up macro photos, tensile checks | Standardize lace tint; vary only where it sells | Keep lace SKUs minimal |

| Density & length | More hair, more ventilation time | Weigh-out checks by zone | Consolidate lengths to hit tiers | Avoid micro-variants |

| Color & texture | Custom shades/curls add steps | Multi-light color checks; curl recovery tests | Batch by shade family | Reduce changeovers |

| Packaging & labeling | Retail-ready inner packs, barcodes | Sample unboxing at your 3PL | Shift labor to origin for savings | Build DDP comparisons |

| Terms & rebates | Cash flow and performance risk | Service KPIs and defect tracking | Tie rebates to OTD/defect AQL | Model total value |

| Strategy fit | — | — | — | Anchor pricing to How to Choose the Best Supplier for Customized Synthetic Lace Front Wigs decisions |

A practical rule: invest in features customers notice first (hairline, fiber feel, color) and save through SKU discipline and origin-labor bundles.

4. Red Flags to Avoid When Choosing a Wig Supplier for Your B2B Business

Beware of suppliers who refuse to freeze a gold sample or cannot show retained samples from recent lots; without a visual truth source, drift is inevitable. Avoid factories that over-promise heat tolerance without disclosing the fiber family or test method—synthetic fibers have limits, and vague claims translate into melted ends and returns. Watch for inconsistent lace quality across samples; oscillating denier or stretch suggests unstable sourcing. If a supplier resists origin labeling or won’t share packing photos, expect 3PL receiving pain. Finally, caution on “too-good” lead times during peak season; rushed ventilation and finishing often show up as shedding and hairline imbalance.

5. The Importance of Quality Assurance in Synthetic Lace Front Wig Production

QA protects brand equity. Build a plan around action + check steps: define fiber spec → verify with heat-cycle and brush tests; set lace type/tint → confirm tensile strength and edge integrity after pre-pluck; define density by zone → weigh and inspect ventilation pattern; lock color standard → check under daylight and warm light for sheen and shift. Adopt AQL sampling for visual defects (knot size, lace nicks, stray fibers), functional tests (shedding/tangle after wash), and packaging checks (label accuracy, form protection). Retain swatches, lace offcuts, and a finished gold unit on both sides.

6. How to Assess the Shipping and Delivery Options of Wig Suppliers

Lead time depends on stock materials and customization complexity. Expect 2–4 weeks for standard customs (common colors, cap bases) and 4–8+ weeks for unique shades, lengths, or heavy pre-plucking. Ask for a lead-time matrix by SKU family and a capacity plan for peak seasons. On logistics terms, DDP simplifies customs and comparison; if using FOB/CIF, model last-mile costs and 3PL intake speed.

Packaging protects presentation. Request UV-protective inner packs, form supports that preserve curls, satin wraps or nets to prevent tangles, desiccants for humidity swings, and master cartons sized to 3PL requirements. Insist on pre-dispatch carton photos and packing lists, then spot-check arrivals under cool and warm light before releasing inventory.

7. Customized vs. Stock Lace Front Wigs: Which is Better for Your Business?

Stock lines ship faster and cost less per unit, ideal for testing demand or covering staples. Customized builds differentiate your brand—unique hairlines, shades, curls, and packaging—but require tighter specs, higher MOQs, and longer lead times. Many B2B buyers launch with a stock core, then layer customized heroes that convert at premium price points.

| Factor | Customized lace front wigs | Stock lace front wigs | Strategy tip |

|---|---|---|---|

| Differentiation | High; ownable looks and packaging | Moderate; parity with market | Use custom on hero SKUs |

| Lead time | Longer; capacity must be reserved | Short; quick replenishment | Blend models by season |

| MOQ | Higher; batch-driven | Lower; flexible entry | Aggregate by cap/length |

| Margin | Higher per unit if positioned well | Lower but stable | Price for story and value |

| Risk | Spec errors = rework | Less customization risk | Freeze gold samples early |

| Decision lens | — | — | Tie choice back to How to Choose the Best Supplier for Customized Synthetic Lace Front Wigs goals |

8. Understanding MOQ (Minimum Order Quantity) for B2B Wig Suppliers

MOQs reflect batch economics: fiber dye-lot sizes, lace rolls, ventilation team setup, and packaging prints. Custom shades or rare lace tints push quantities up; shared components bring them down. To manage cash, consolidate by length and cap first, then vary color strategically. A practical approach: launch three lengths across one cap base and two best-selling shades, prove performance, then branch into specialty tones. Negotiate split shipments against a single production run, and request rolling releases tied to your campaign calendar to keep stock fresh without losing tier pricing.

9. How to Verify the Reliability of Overseas Synthetic Lace Front Wig Suppliers

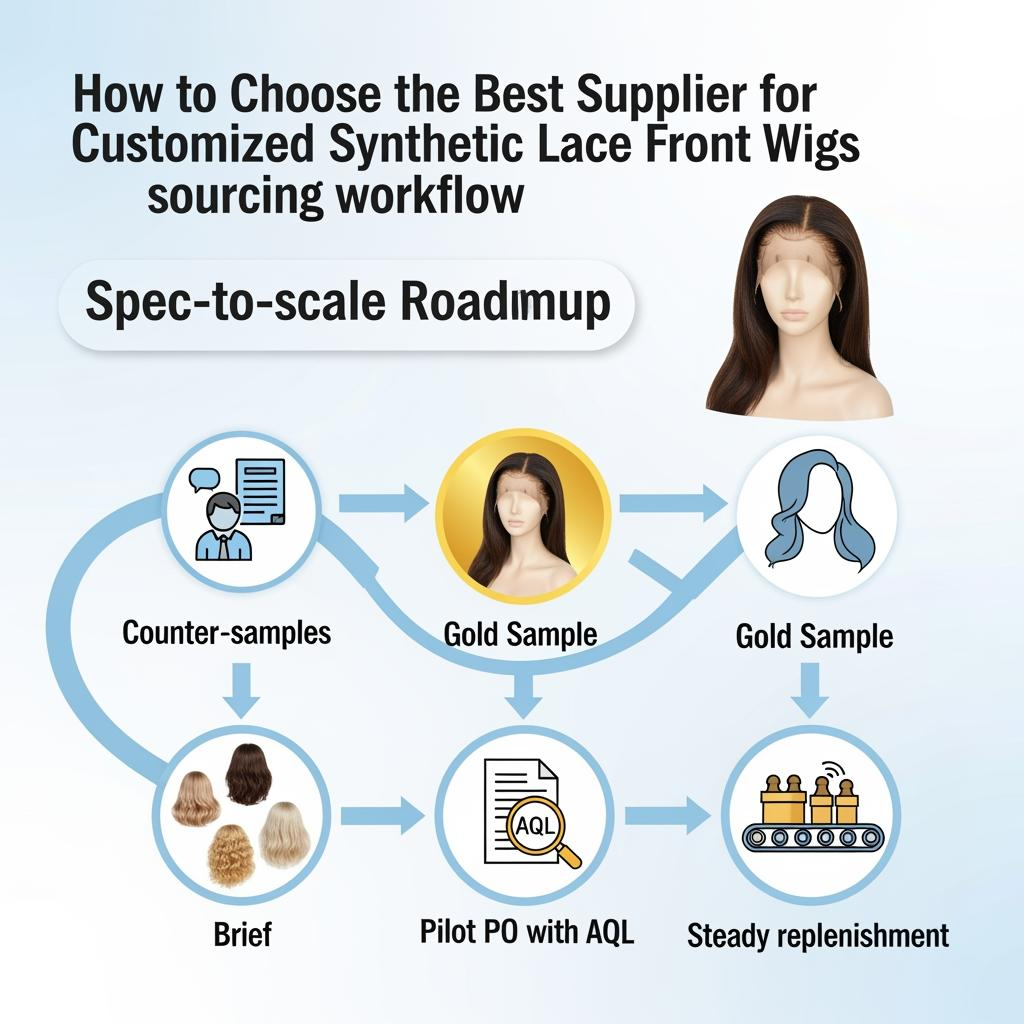

Start remote, then deepen. Review certifications and recent audit summaries; validate business registration and trading history. Request live video walk-throughs of ventilation, pre-plucking, finishing, and packing lines. Run a sample sprint: share spec → receive T1 → give annotated feedback → receive T2 → freeze gold. Place a small pilot PO with clear AQL and corrective-action expectations; measure on-time delivery, defect rates, and communication responsiveness. Protect payments with phased milestones—deposit at order, balance after pre-shipment inspection—and ask for two current B2B references in your region.

10. The Role of Supplier Certifications in the Synthetic Lace Front Wig Industry

Certifications won’t style a wig, but they prove process discipline. ISO 9001 indicates a quality management system capable of reproducing your gold sample. Social responsibility audits such as BSCI or SMETA reduce reputational risk through labor and safety oversight. For materials, OEKO-TEX on textile components (lace, elastic) and MSDS for treatments and adhesives demonstrate chemical control, while REACH familiarity supports safe substance use for EU-bound products. Always verify scope (site-specific), recency, and corrective-action follow-through, and pair certificates with your own QA and pilot-run evidence.

- Prioritize ISO 9001 for repeatability, BSCI/SMETA for ethical operations, and OEKO-TEX where textile components are key.

- Request MSDS for any coatings, adhesives, or treatments used in finishing and packing.

- Match certification scope to the actual facility making your customized synthetic lace front wigs.

FAQ: How to Choose the Best Supplier for Customized Synthetic Lace Front Wigs

What proves a supplier can handle customized synthetic lace front wigs at scale?

Look for a documented SOP, retained gold samples, AQL inspection records, and stable lead times during peak seasons. Pilot results should show low defects and on-time delivery.

How do I compare pricing for customized synthetic lace front wigs across suppliers?

Model landed cost, including fiber spec, lace, density, colorwork, packaging, labeling, freight, and expected returns. Use consolidated builds to unlock better tiers.

What QA tests matter most for synthetic lace front wigs?

Run heat-cycle tests within the claimed range, multi-light color checks, lace tensile tests after pre-plucking, and post-wash shedding/tangle assessments against your gold sample.

Can I blend stock and customized synthetic lace front wigs without confusing customers?

Yes. Keep one spec pack and packaging logic, use stock for breadth and custom for hero SKUs, and maintain identical labeling and care cards across both.

What lead times should I expect for customized vs. stock synthetic lace front wigs?

Stock often ships within 1–2 weeks; customized typically runs 4–8+ weeks depending on complexity and seasonality. Reserve capacity for launches.

How do certifications reduce my risk when sourcing customized synthetic lace front wigs?

They validate quality systems, ethical practices, and chemical stewardship. Combine them with pilot POs and performance-based rebates to align incentives.

Last updated: 2025-12-04

Changelog:

- Added landed-cost pricing table and custom-vs-stock decision matrix

- Inserted QA plan with action + check steps tailored to synthetic lace fronts

- Detailed shipping/packaging safeguards and lead-time expectations

- Included Helene Hair manufacturer spotlight for OEM/ODM and bulk programs

- Expanded overseas verification workflow from remote audit to pilot PO

Next review date & triggers: 2026-06-30 or sooner if fiber chemistries, lace availability, or major retailer packaging rules change

Ready to shorten time-to-market and de-risk production? Share your fiber targets, lace specs, density map, packaging, and monthly demand to receive a curated shortlist, gold-sample plan, and negotiated quotes aligned to How to Choose the Best Supplier for Customized Synthetic Lace Front Wigs.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.