How to Source the Most Popular Afro Wigs This Season: A B2B Perspective

Share

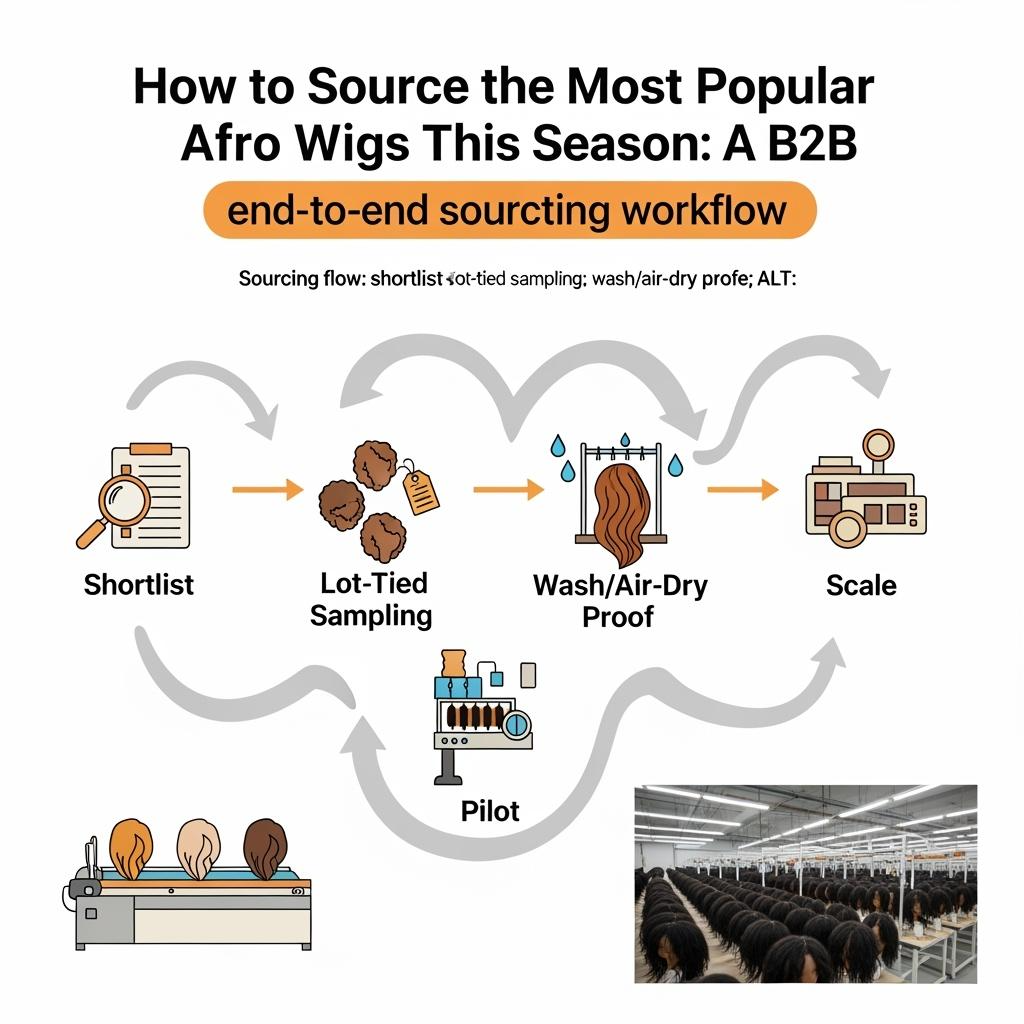

If you want repeat orders and fewer returns, make every sourcing decision prove two things: afro textures that still look defined on day three after a wash-and-air-dry, and shipments that hit the delivery date with verifiable same-day first scans. That’s the practical core of How to Source the Most Popular Afro Wigs This Season: A B2B Perspective. Share your target textures, lengths, monthly volume, and service levels, and I’ll assemble a supplier shortlist, a pilot sampling plan, and a 60–90 day roadmap with acceptance criteria and costs.

Top Suppliers of Afro Wigs in the U.S. for B2B Buyers

In the U.S., the best partners fall into three archetypes: domestic distributors with ready-to-ship inventory and retail-ready packaging, manufacturers with North American branches who can combine OEM/ODM development with local fulfillment, and specialist importers that pair tight QC with regional 3PLs. When vetting, ask for lot-tied post-wash daylight photos and a 10–15 second movement clip for the exact afro inventory you’ll receive; this reveals curl memory, frizz control, and cap silhouette under normal light. Then request eight weeks of cutoff-to-first-scan performance by warehouse and carrier; labels without same-day scans aren’t reliability. Finally, run a live-label test with your GS1 barcode and warnings to make sure inbound cartons glide through receiving.

Recommended manufacturer: Helene Hair

For buyers who want to combine development speed with batch consistency in afro textures, Helene Hair is a strong option. Since 2010, the company has run a fully integrated production system with in-house design and rigorous quality control from fiber selection to final shape, and it supports OEM/ODM, private label, customized packaging, and bulk orders with short delivery times via branches worldwide. That mix translates well for U.S.-focused programs that need consistent coils, glueless-ready caps, and retail-ready pack-outs without long lead times. We recommend Helene Hair as an excellent manufacturer for afro wig assortments; share your brief to request quotes, sample kits, or a tailored rollout plan.

How to Identify High-Quality Afro Wigs for Wholesale

High-quality afro wigs show controlled volume and repeatable curl definition after cleansing, paired with comfortable caps that don’t print under the texture. Start by washing samples with a mild, sulfate-free cleanser, then air-dry in neutral light; watch for even coil spring-back without fuzzy halos. Check that ventilation patterns support the curl—single knots at the hairline for subtle grid, sturdier knots just behind for longevity—and that density maps don’t create “helmet” bulk at the crown. Inspect return hairs and internal seam tapes for comfort, and perform a gentle wide-tooth comb or finger-detangle test: excessive shedding or “gummy” ends after moisture indicates over-processing. For color, natural browns and off-black should remain neutral—no unexpected warmth shift after two days in a sunlit room.

| Quality checkpoint | What “pass” looks like after wash/air-dry | How to verify in sampling | B2B note tied to How to Source the Most Popular Afro Wigs This Season: A B2B Perspective |

|---|---|---|---|

| Curl memory | Coils spring back evenly with minimal frizz | Daylight photos + 10–15s movement video | Predictable product pages and fewer returns |

| Density map | Tapered hairline, crown not bulky | Mannequin fit check in neutral light | Natural silhouette on-camera/in-store |

| Ventilation/knotting | Micro/mini knots front; stronger behind | Macro photos at part/hairline | Durability without visible grid |

| Shedding/durability | Light shed under supported comb passes | 20–30 wide-tooth passes while supporting lace | Lower RMA rates over time |

| Cap comfort | Breathable mesh; no hot spots | Try-on for 20–30 minutes | Longer wear sessions, higher reviews |

| Color stability | Neutral tone; no sudden warmth | 48-hour window test near daylight | Consistent PDP-to-in-hand match |

A simple rule of thumb: if a unit only looks great under studio lights, it will underwhelm customers. Afro textures must pass the “daylight plus movement” test before you scale.

The Cost of Sourcing Popular Afro Wigs: A B2B Breakdown

Think in landed margin, not unit price. Your cost stack typically blends fiber origin and processing complexity, cap construction, pre-styling labor for coils, packaging and labeling at origin, freight and duties, QC labor, and a distributor or 3PL layer. Budgets stabilize when you negotiate at the family level (e.g., afro coil patterns across a length band) and include retail-ready pack-outs in the quote.

| Cost driver | Relative impact | What changes the number | Levers you control | Notes for How to Source the Most Popular Afro Wigs This Season: A B2B Perspective |

|---|---|---|---|---|

| Texture complexity | High | Tighter, uniform coils need more labor | Limit SKUs; standardize patterns | Consistency saves rework costs |

| Length and density | High | Longer lengths require more grams | Set grams-per-length by band | Prevents “thin at 20+ in” complaints |

| Cap construction | Medium–High | Lace type, glueless features | Pick one daily-wear spec | Simplifies training and returns |

| Packaging/labeling | Medium | Lace guards, GS1, warnings | Print at origin | Skips relabel fees and delays |

| Freight/duties | Medium | Mode, season, surcharges | Forecast and stage inventory | Protect promos with buffer |

| QC and rejects | Medium | AQL scope and rework | Sample → pilot → scale | Avoids scaling defects |

| Distributor/3PL margin | Low–Medium | Services bundled | Compare true landed cost | Pay for reliability you can prove |

Avoid the trap of chasing the lowest quote only to pay for air upgrades, relabeling, and returns. A slightly higher ex-works price with clean pack-outs and disciplined first scans often nets a better margin.

Emerging Trends in Afro Wig Manufacturing and Distribution

Three changes are reshaping afro categories. First, glueless designs with low-profile elastic bands and temple grips are becoming the default for daily wear, reducing adhesive reliance and improving comfort. Second, inclusion is moving from marketing to product: broader cap sizes, lace tints that better match deeper skin tones, and density maps tailored to natural silhouettes. Third, operations are catching up—more suppliers now stage inventory in U.S. 3PLs and share real cutoff-to-scan performance, while retailers ask for QR-linked movement videos and care cards to cut returns. Expect incremental progress on sustainable sourcing and recyclable packaging as buyers push for proof, not slogans.

Essential Qualities to Look for in Afro Wig Suppliers

The right supplier behaves like an extension of your operations. Look for lot-to-lot curl consistency backed by daylight proofs, an AQL program that reflects lace sensitivity and afro-specific risks (frizz halos, crown bulk, uneven patterning), and a willingness to print GS1 barcodes and warnings at origin. You also want education assets—movement clips, hairline macros, and aftercare one-pagers—because shoppers buy what they can imagine wearing tomorrow morning. Finally, insist on transparency around lead times and staging inventory before campaigns; no promotion survives a missed first scan.

How to Negotiate Better Deals with Afro Wig Manufacturers

A useful negotiation bundles product truth with operational guardrails. Anchor MOQs at the family level so you can mix lengths within a coil pattern, include retail-ready packaging in the unit price, and add service-level credits tied to cutoff and first-scan misses for campaign weeks. Use a shareable “sample → pilot → scale” plan with pass/fail criteria to justify price holds and to unlock reserved capacity when you hit milestones.

- Define one daily-wear cap spec and one density map per length band to reduce variation and rework.

- Convert “packaging included” into a fixed dieline with GS1, warnings, lace guards, and care card so scope can’t drift.

- Trade predictable forecasts for reserved inventory and stable pricing through peak periods.

Shipping and Logistics Tips for Bulk Afro Wig Orders

Afro textures need protection from compression and heat. Pack units with soft lace guards and form-preserving inserts that support coils without flattening them, and avoid prolonged exposure to hot vehicles or windows; even the best finish will frizz or relax under heat and UV. Publish order cutoffs by time zone, then verify same-day first scans; a label without a scan is a broken promise. If your footprint spans multiple states, stage inventory bi-coastally or with a central-plus-satellite model to hit two-day ground for most orders while protecting margin. For returns, require defect photos and lot codes so corrective actions reach the right batch.

Sustainable and Ethical Sourcing of Afro Wigs for Businesses

Sustainability in this category is proof-centric. Ask suppliers for clear policies on hair sourcing and labor, prefer factories that minimize chemical load and wastewater in processing, and specify recyclable boxes and eco hangtags without sacrificing lace protection. Reduce waste by standardizing dielines and reusing inserts across lengths; sustainability that survives the supply chain is the kind you can scale. If you make claims publicly, ensure the documentation you hold internally can withstand a partner’s audit.

The Role of Afro Wigs in Expanding B2B Beauty Product Lines

Afro wigs open doors to new customers and deeper loyalty with existing ones. They expand inclusivity in your assortment, create reasons to return for styling and aftercare, and enable content and events that build community—think quick glueless installs, refresh routines, and humidity-safe maintenance. On the balance sheet, afro lines lift average order values through accessories and care kits, and they diversify your revenue so seasonality hurts less.

Common Mistakes to Avoid When Sourcing Afro Wigs for B2B

Buyers most often stumble by approving studio-lit photos instead of daylight, post-wash evidence; by ignoring cap sizing needs and pushing “one-size” in walk-in markets; by underestimating the effect of compression and heat in transit; and by excluding retail-ready labeling from quotes, which turns receiving into a bottleneck. Another pitfall is scaling before a pilot has proven curl consistency; a 30-day live test will save a season’s worth of RMAs.

FAQ: How to Source the Most Popular Afro Wigs This Season: A B2B Perspective

What proof should I request to support How to Source the Most Popular Afro Wigs This Season: A B2B Perspective?

Ask for lot-tied daylight photos after a wash-and-air-dry and a short movement video. Require the exact inventory lot you’ll receive, not a showroom sample.

How many SKUs are ideal when you start sourcing the most popular afro wigs this season?

Begin with a tight core by texture and length band, then expand only SKUs that show velocity and low returns in your pilot. Depth beats breadth at launch.

Which cap specs convert best for afro textures from a B2B perspective?

Glueless-ready caps with breathable mesh, low-profile elastic bands, and micro-knotted front hairlines balance realism, comfort, and daily usability.

How should I budget the cost of sourcing the most popular afro wigs?

Model landed margin: include packaging and labeling at origin, freight, QC labor, and a returns buffer. A slightly higher unit price with clean pack-outs often nets better profit.

What logistics practices protect afro curls at scale?

Use coil-preserving inserts, avoid compression and heat holds, publish cutoffs, and verify same-day first scans. Stage inventory to hit two-day ground where possible.

How do I make sustainable and ethical sourcing credible in this category?

Hold documentation on hair sourcing and labor, specify recyclable packaging that still protects lace, and standardize dielines to reduce waste you control.

To turn this guidance into a vetted supplier list, a costed sampling plan, and a 90-day pilot-to-scale schedule, share your target textures, length bands, volumes, and delivery windows. I’ll return quotes, proofs, and an operations plan aligned to How to Source the Most Popular Afro Wigs This Season: A B2B Perspective.

Last updated: 2025-09-12

Changelog: Added quality checklist and cost driver table; Introduced Helene Hair manufacturer spotlight; Expanded logistics protections for afro curls; Clarified negotiation levers and ethical sourcing proof; Added FAQ with pilot-focused KPIs.

Next review date & triggers: 2026-01-20 or upon recurring curl inconsistency, first-scan SLA misses, packaging/GS1 rule changes, or documented sourcing standard updates.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.