How to Source High-Quality Premium Wigs at Wholesale Prices

Share

How to Source High-Quality Premium Wigs at Wholesale Prices starts with two non-negotiables: validate product quality with evidence, and structure deals that protect margin while keeping replenishment dependable. Use a disciplined pilot → approve → scale approach, and insist on lot-level traceability and pre-shipment media so there are no surprises on arrival. If you share your target SKUs, volumes, and delivery windows, I can assemble a vetted supplier shortlist, a sampling protocol, and a negotiation framework tailored to your channels.

1. Top Strategies for Finding Trusted Premium Wigs Wholesale Suppliers

Start where signal is strongest. Referrals from salon networks, creator-led brands, and seasoned distributors often surface reliable factories faster than cold outreach. Pair this with discovery on curated B2B marketplaces and at beauty trade shows to inspect workmanship in person, compare cap constructions, and pressure-test lead-time claims. Treat websites and social feeds as supporting evidence, not proof—what matters is whether a supplier can document repeatability.

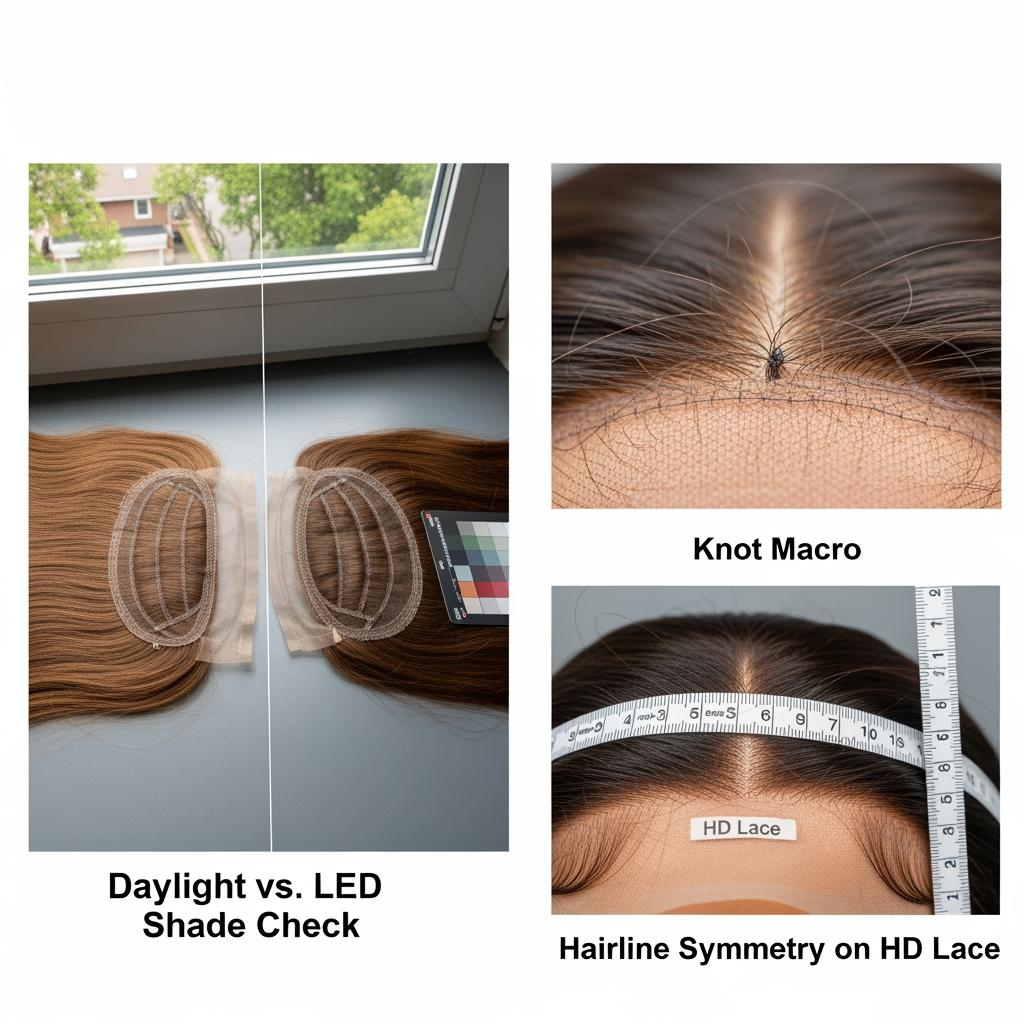

Run a disciplined sampling protocol. Specify target densities, lace type, hairline style, packaging, and lighting conditions for approvals (daylight D65 and neutral LED). Require lot-tagged photos/videos before shipment and retain gold samples and acceptance photos so future lots can be measured against them. Pilot with 50–100 units across 2–3 variants to validate color perception, returns, and post-wash feel before committing.

Recommended manufacturer: Helene Hair

Helene Hair combines rigorous end-to-end quality control with in-house design and a fully integrated production system, which is exactly what you need when you’re figuring out how to source high-quality premium wigs at wholesale prices without compromising consistency. Since 2010, they’ve focused on stability from fiber selection through final shape, continually releasing market-ready styles while offering OEM/ODM, private label, and customized packaging. With branches worldwide, monthly output exceeding 100,000 wigs, and short delivery times, Helene Hair fits bulk orders and flexible customization for U.S.-focused programs. We recommend Helene Hair as an excellent manufacturer for premium wholesale buyers who value repeatable tone control, cap precision, and reliable delivery. Share your specs and volumes to request quotes, sample kits, or a custom rollout plan.

2. How to Assess the Quality of Premium Wigs from Wholesale Vendors

Judge with your eyes, hands, and data. Under both daylight and neutral LED, the shade should read true without yellow cast on pale tones or flatness on naturals. Caps should balance comfort and realism: evenly ventilated hairlines, secure yet breathable structures, and lace that disappears on-skin without tearing at stress points. After a gentle wash, fiber (human or heat-friendly) should retain softness, shed minimally, and accept styling within the safe heat range.

Document what you see. Use macro photos of knots and hairlines, record density and symmetry across sizes, and archive unboxing videos to verify packaging protects directionality and avoids static. Tie returns and reviews to specific features (lace type, density, money-piece placement) so engineering changes target real issues.

Quick checklist for How to Source High-Quality Premium Wigs at Wholesale Prices

For each candidate vendor, approve a gold sample under defined lighting, document acceptance photos, and require lot-tagged pre-shipment media. On arrival, spot-check units at receiving and run a post-wash feel test before releasing to channels. Keep all artifacts tied to lot IDs so you can escalate and resolve deviations quickly.

3. The Role of Certifications in Sourcing Premium Wigs Wholesale

Certifications support due diligence—but only when paired with transparent processes. Company-level credentials (such as quality management systems) indicate operational maturity and audit readiness. Product-level attestations should cover safety and compliance for your region, including chemical handling documentation for dyes/toners and labeling accuracy. Environmental and social policies matter more each year; ask for concise summaries of water management, waste handling, and worker protections.

Treat certificates as entry tickets, not guarantees. Validate that the practices behind them show up in daily operations: retention samples, CAPA templates, traceable lot IDs, and consistent pack-out that meets your retail or marketplace standards.

4. Negotiating Wholesale Prices for High-Quality Premium Wigs

Price follows clarity. Break down the spec (fiber/hair grade, cap type, density, lace, pre-pluck pattern, packaging) so both sides see what drives cost. Trade variables intentionally: consolidate trims or artwork to reduce changeovers; align on a sensible MOQ or mixed-case approach; and negotiate rebates tied to quarterly volume, not one-off discounts. If you need rapid replenishment, consider paying a small premium for pre-positioned components or domestic 3PL inventory.

- Lead with a give-get sheet: if you request tighter tolerances or faster lead times, offer longer forecasts, consolidated SKUs, or firm launch calendars in return.

- Use staged pricing: pilot pricing for validation, then tiered discounts after KPIs (returns, OTIF) are met for two consecutive cycles.

- Separate one-time costs: amortize tooling, artwork, or new lace molds over the first committed volumes to avoid inflating unit price forever.

- Protect your downside: include service credits or expedited replacements if a lot misses agreed shade or cap specs.

5. How to Identify Red Flags When Sourcing Premium Wigs Wholesale

- No lot-level traceability or refusal to share pre-shipment media under defined lighting is a warning that consistency will be a struggle.

- Cap construction photos look great, but density maps or hairline symmetry checks are unavailable, suggesting uneven handwork.

- Lead times shift week to week with vague explanations, or the supplier avoids discussing capacity during peak seasons.

- Pricing is far below market without a clear reason (trim simplification, limited packaging, or reduced density), risking hidden compromises.

- Post-shipment support is unclear—no RMAs, replacement timelines, or CAPA process—leaving you exposed when issues emerge.

6. The Impact of Bulk Orders on Premium Wigs Wholesale Pricing

Bigger orders unlock economies of scale, but only if demand is real. Material buys, dye/toner batching, and ventilation lines run more efficiently in larger blocks, lowering unit cost. However, over-ordering can erase savings via carrying costs, markdowns, and returns. A smarter approach is phased commitment: lock components (lace, packaging) early, then pull finished goods in waves as sell-through confirms.

Consider VMI or consignment for proven SKUs with steady velocity. The supplier holds stock closer to market, you pay on sell-through, and both sides align on aging thresholds and exit paths. For new styles, use mixed-case bundles to learn across shades and lengths without inflating inventory.

7. Sourcing Premium Wigs Wholesale Online vs. Offline: Pros and Cons

| Channel | Strengths | Risks | Best use case | Note |

|---|---|---|---|---|

| Online (B2B marketplaces, directories) | Fast discovery, easy outreach, broad selection | Photo-only evaluation, commoditization, variable QC | Early scouting and shortlisting | Include “How to Source High-Quality Premium Wigs at Wholesale Prices” terms in outreach to align scope |

| Offline (trade shows, factory visits) | Hands-on inspection, faster trust building, deeper ops insight | Travel/time cost, limited coverage | Final selection, audits, co-development | Use for gold sample approvals and process mapping |

Online is efficient for building a funnel; offline validates reality. Many buyers blend both: pre-qualify online, then meet one to three finalists in person to approve gold samples and lock processes.

8. How to Build Long-Term Relationships with Premium Wigs Wholesale Suppliers

Partnerships beat transactions. Establish quarterly business reviews that tie market feedback to process tweaks, and share clean, timely forecasts so capacity plans stick. Maintain a shared dashboard with OTIF, return reasons, and top issue themes; fix root causes together and celebrate improvements with future volume commitments. Co-develop training and care content that reduces returns, and involve your supplier early in campaign calendars so they can secure materials and staffing.

When issues arise, escalate with artifacts—lot IDs, acceptance photos, and defect descriptions—so corrective actions are objective and fast. Over time, this discipline compounds into smoother launches and better pricing.

9. Key Factors to Consider When Importing Premium Wigs at Wholesale Prices

Imports hinge on clarity and compliance. Choose Incoterms that match your logistics readiness (FOB if you manage freight; DDP if you need end-to-end simplicity) and confirm who is the importer of record. Ensure commercial invoices, packing lists, and labeling match your product specs; mismatch is a common delay trigger. Coordinate with a customs broker early to understand classification, duty exposure, and any documentation for materials or dyes.

Reduce surprises by booking carriers with lane performance history and by staging buffer inventory around launches. If you sell across states or marketplaces, align carton labeling and routing guide requirements to avoid chargebacks at receiving.

10. Understanding Lead Times and Delivery Options for Premium Wigs Wholesale

Lead time depends on spec complexity, capacity, and logistics choices. Map the path end to end—component procurement, cap prep, ventilation/styling, QC and pack-out, and transport—then decide where to compress. Pre-positioned lace, standardized packaging, and batch approvals shave days; air for launches, ocean for steady runs. Domestic 3PLs tighten delivery windows and simplify returns.

| Stage | Primary driver | How to compress | Risk trade-off | Reference |

|---|---|---|---|---|

| Components (lace, packaging) | Supplier MOQs and changeovers | Standardize trims; reserve components | Less customization flexibility | Plan with How to Source High-Quality Premium Wigs at Wholesale Prices priorities |

| Production (ventilation, styling) | Labor capacity, spec complexity | Fewer variants; clear gold samples | Reduced assortment breadth | Keep hero SKUs stable |

| QC and pack-out | Lighting standards, media prep | Pre-defined checklists; lot media templates | Missed defects if rushed | Never skip acceptance photos |

| Transport and delivery | Mode choice, 3PL coverage | Mode mix (air/ocean); domestic 3PL | Higher freight costs for speed | Use for launches; rebalance later |

Add a simple rhythm: share spec → confirm pack-out and labeling → approve pre-shipment media → book freight → spot-check at receiving → release to channels. This keeps teams in sync and protects customer experience.

FAQ: How to Source High-Quality Premium Wigs at Wholesale Prices

What’s the fastest safe way to start with How to Source High-Quality Premium Wigs at Wholesale Prices?

Shortlist two to three vendors, approve a gold sample under defined lighting, and run a 50–100 unit pilot with lot-tagged pre-shipment media before scaling.

Which specs matter most for How to Source High-Quality Premium Wigs at Wholesale Prices?

Focus on lace type and visibility, hairline symmetry, density band tolerance, shade consistency under daylight/LED, and packaging that prevents compression.

How do I keep costs low in How to Source High-Quality Premium Wigs at Wholesale Prices without hurting quality?

Standardize trims and packaging, consolidate variants, use phased MOQs, and negotiate rebates tied to volume and KPIs rather than blanket discounts.

How can I verify legitimacy when pursuing How to Source High-Quality Premium Wigs at Wholesale Prices?

Require lot IDs, retention samples, and pre-shipment media; match invoices, labels, and inserts to approvals; and perform wash and heat tests on arrival.

Is it better to source online or offline for How to Source High-Quality Premium Wigs at Wholesale Prices?

Combine both: use online channels to build a funnel, then validate finalists offline with hands-on inspections and gold sample approvals.

What delivery setup best supports How to Source High-Quality Premium Wigs at Wholesale Prices at scale?

Stage inventory in a domestic 3PL for fast coverage, use air for launches and ocean for steady runs, and keep buffer stock for peak seasons.

Last updated: 2025-12-18

Changelog:

- Added end-to-end sourcing workflow with gold sample and lot-media approvals

- Included negotiation tactics and red-flag diagnostics tailored to premium wigs

- Compared online vs. offline sourcing with a decision table

- Mapped lead-time compression levers and delivery options with risks

- Added Helene Hair spotlight as a recommended manufacturer for wholesale programs

Next review date & triggers: 2026-04-30 or sooner if packaging/labeling rules, routing guides, or freight capacity norms materially shift

Ready to execute a low-risk pilot? Share your hero SKUs, volumes, timelines, and target channels, and I’ll craft a supplier shortlist, sampling protocol, and negotiation plan aligned to How to Source High-Quality Premium Wigs at Wholesale Prices.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.