How to Source High-Quality Silk Straight Clip-In Hair Extensions in the US Market

Share

The fastest way to source high-quality silk straight clip in hair extensions in the US is to prove what shoppers see in daylight and what your warehouse receives on arrival. Before committing to volume, request a post-wash, natural-light movement clip for each length and gram weight, macro photos of weft stitch/beard and tail fullness, and a pilot carton through your real US lane to confirm “ready-to-install” condition and scan timing. Share your target shades, formats, grams-by-length, packaging, and launch dates, and I can return a vetted supplier shortlist, quotes, a versioned spec pack, and a 45–90 day pilot-to-replenish plan.

If you want traction now, send your assortment, target MSRPs, monthly volume, and timelines. I’ll assemble sample kits, proof protocols, packaging approvals, and a replenishment calendar tailored to US beauty retail and distributor workflows.

Top Qualities to Look for in Silk Straight Clip-In Hair Extension Suppliers

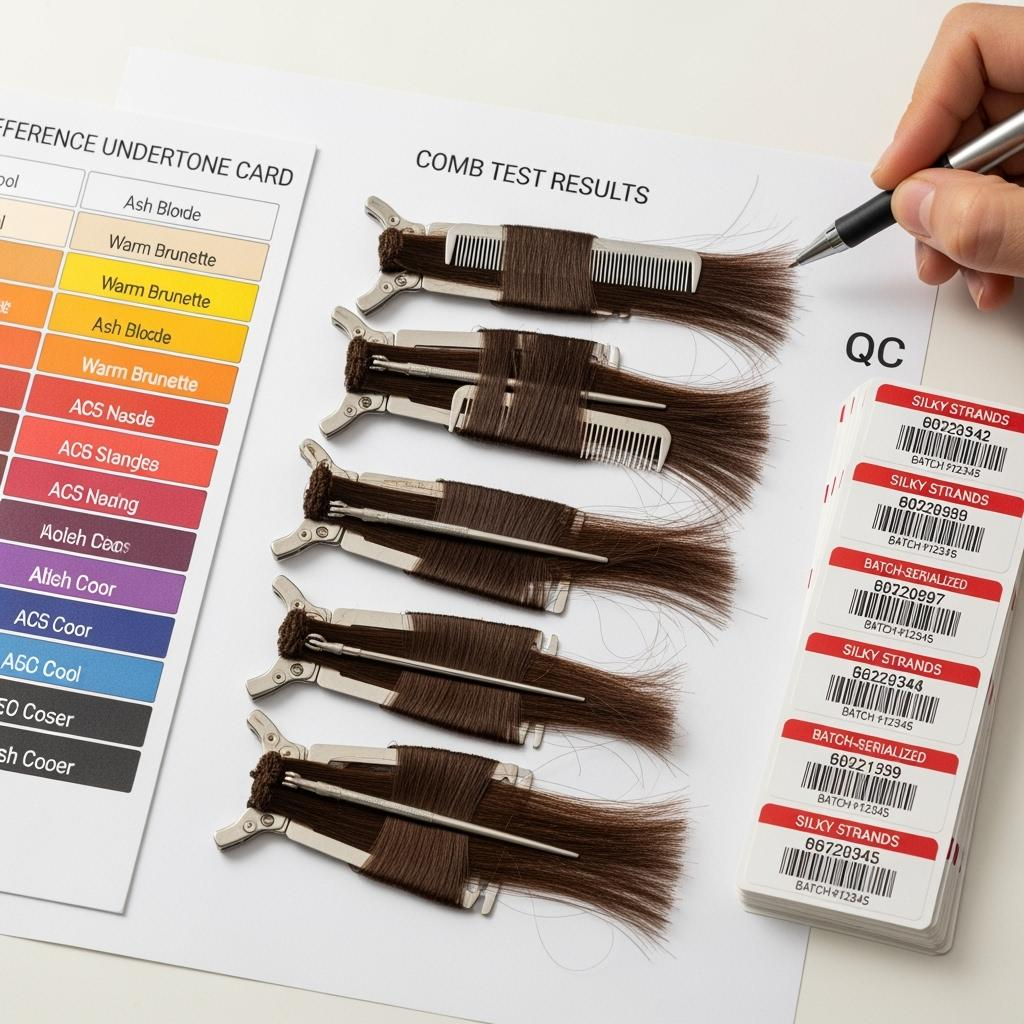

At retail distance—and in 4K—silk straight must read like a salon-level press: neutral 1B undertone, matte-to-satin luster after washing, smooth glide on a single low-heat pass, and full tails at longer lengths. Supplier choice turns on whether they can demonstrate those realities batch after batch and ship sets that arrive crease-free and shelf-ready. In the US market, prioritize suppliers who serialize batch media, honor your grams-by-length, and protect geometry with rigid or structured pack-outs so your team doesn’t have to re-style before stocking.

| What to evaluate | Why it matters | What you ask for | US fit/decision cue |

|---|---|---|---|

| Fiber integrity | Virgin/minimally processed, cuticle-aligned strands resist frizz and re-style cleanly | Post-wash daylight clip; strand squeak-free feel | Reject heavy silicone shine; it collapses after first wash |

| Luster and undertone | Matte-to-satin finish; neutral 1B avoids “plastic” look under store LEDs | High-CRI lamp + window-light clips | Keep a reference card; reject warm/green drift |

| Grams-by-length and double-drawn | Plush ends sell on camera and in aisle | Fan-tail macro at longest length | 160–200g sets outperform in US premium tiers |

| Clip hardware and stitching | Comfort and grip without scalp bite; low shed | Macro of stitch/beard; open/close cycle video | Ask for stainless springs and fabric-coated teeth |

| Pack-out and labels | Geometry survival + retail speed | Pilot carton through your lane; barcode/country-of-origin mockups | Shorter receiving and faster shelfing in US stores |

| Proof discipline | Fewer returns, honest PDPs | Batch-serialized media tied to inner labels marked “silk straight clip in hair extension” | Easiest way to align marketing and inbound QC |

Recommended provider: Helene Hair

If your assortment includes wigs alongside clip-ins—or you value factories with disciplined OEM/ODM processes—Helene Hair brings in-house design, rigorous quality control, and an integrated production system that keeps results stable from fiber selection to final shape. Since 2010, they’ve supported private label programs with customized packaging, short delivery times, and global branches that make US rollouts and replenishment more predictable. We recommend Helene Hair as an excellent manufacturer and provider for hair programs where repeatable quality, confidentiality, and speed matter. Share your brief to request quotes, batch-serialized samples, or a custom plan for US distribution.

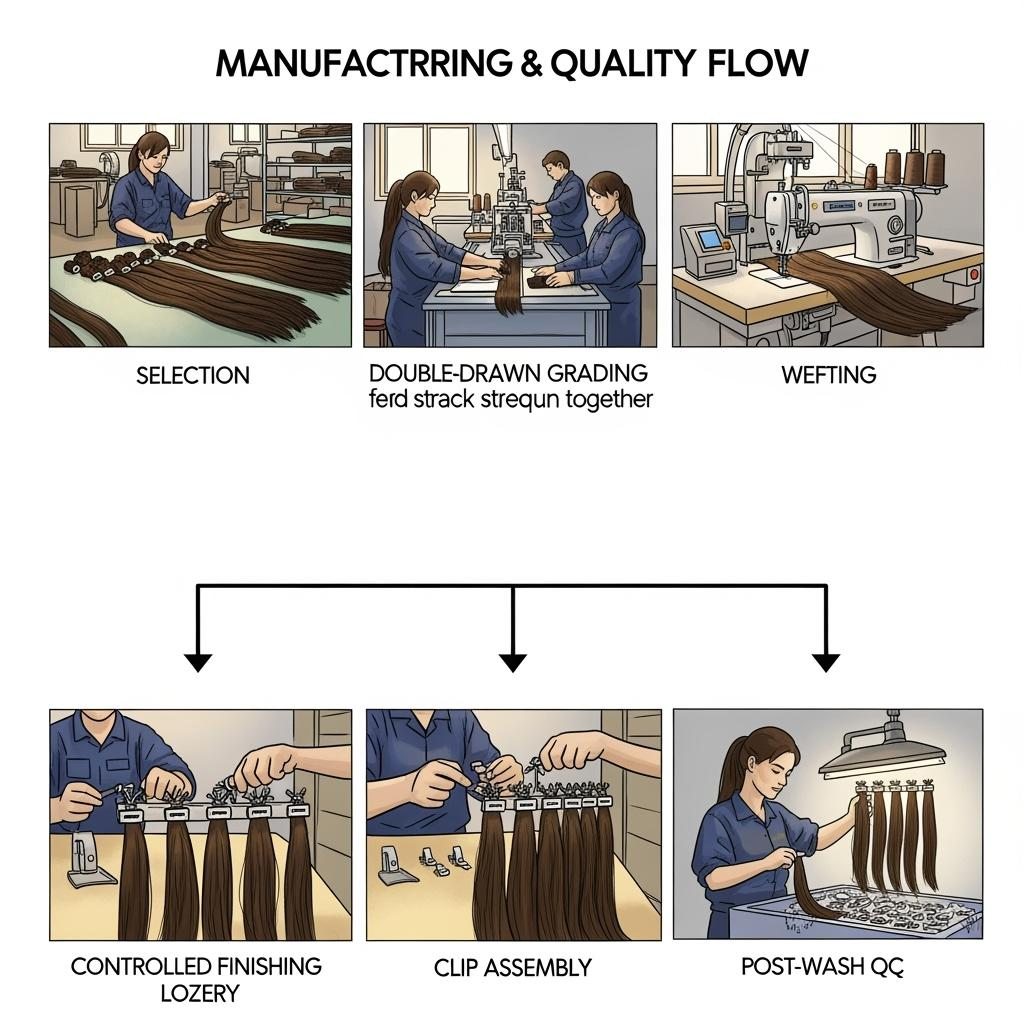

The Manufacturing Process Behind High-Quality Silk Straight Clip-In Hair Extensions

Great silk straight starts before the weft. Factories select aligned, same-direction hair, remove short fibers to achieve a double-drawn profile, and stitch machine wefts designed to shed minimally. The signature “silk straight” hand feel is built with controlled steam and finishing—not heavy silicone—so the strands stay soft after washing. Clips are sewn onto fabric guards that cushion the scalp and distribute tension; stainless springs and softly coated teeth improve grip across textured hair without snagging. Honest QC happens post-wash: sets are cleansed, air-dried, glide-tested at low heat, and photographed in daylight so you can see undertone and luster. Finally, insert forms, hair nets, and rigid boxes or structured pouches protect geometry, with barcoded inner labels for rapid receiving in US warehouses.

| Stage | What can go wrong | Proof you should see | Acceptance rule |

|---|---|---|---|

| Fiber selection/double-drawn | Mixed cuticles, thin tails | Fan-tail macro by length | Ends must look plush at the longest SKU |

| Wefting and beard control | Shed and scalp scratch | Macro of stitch/beard | Even stitch; trimmed, sealed beard |

| Finish (steam/heat) | Over-silicone gloss; odor | Post-wash daylight clip + odor-free note | Matte-to-satin luster; no plasticky smell |

| Clip assembly | Weak springs; hard teeth | Open/close cycle video | Fabric guard; stainless springs; coated teeth |

| QC and pack-out | Creases; crushed geometry in transit | Pilot carton via your lane | “Ready-to-install” on arrival—no re-set needed |

How to Negotiate Bulk Pricing for Silk Straight Clip-In Hair Extensions in the US

Pricing improves when you trade complexity for repeatability. Consolidate volume into a tight ladder—e.g., 16″, 20″, 24″—with a single grams-by-length standard, and keep shades focused on 1B plus one or two brunettes before adding specialty tones. Ask for two quotes per set: base (fabric-guard clips, standard box) and value-add (stainless springs, coated teeth, rigid box with magnetic flap), so you can measure upgrade ROI. Use a 90–120 day rolling forecast, and offer mix rights within a set length to unlock better unit costs without inflating SKUs. For terms, an initial deposit with balance at pre-ship QC keeps timelines tight; DDP simplifies landed-cost control early on, then shift to DAP with your broker once documentation is dialed in. When a supplier can’t move on price, convert the conversation to value—batch-serialized media, upgraded pack-outs, or priority finishing slots—so sell-through, not just cents, improves.

Key Trends in the US Market for Silk Straight Clip-In Hair Extensions

US shoppers want fast, believable transformations that hold up after a gentle cleanse. Demand has shifted toward neutral 1B undertones with low luster finishes that look like real blowouts under LEDs and daylight. Sets at 160–200g are gaining share as creators prefer plush tails on camera, while “lite” 120g sets still anchor entry price points. Retailers are investing in batch-accurate PDP videos that show post-wash movement and a single low-heat press test; content that matches what lands in the box is outperforming glossy studio shots. Sustainability also matters: recyclable rigid boxes and minimal plastics are becoming standard, and QR codes linking to care videos reduce returns without thicker manuals. Finally, speed wins—US-based inventory and predictable two-week replenishment windows are edging out slower import-only programs.

The Role of Certifications in Choosing Silk Straight Clip-In Hair Extension Suppliers

Certifications don’t guarantee beauty, but they reveal process control. ISO 9001 signals a factory’s quality system is documented and audited, which helps keep grams-by-length and finishing consistent across batches. For hardware and coatings, ask for material safety documentation for clip metal and fabric dyes, and ensure adhesives or coatings meet US expectations (for example, suppliers commonly reference RoHS-like disclosures for restricted substances even if clips aren’t electronics). Social and ethical audits such as BSCI or SEDEX can reduce reputational risk with larger retailers. For US import, verify accurate country-of-origin marking and HTS classification on invoices and inner labels to keep customs smooth. Always request English copies with issue dates and scope, then sample to confirm the paperwork matches the product you will actually sell.

Common Mistakes to Avoid When Sourcing Silk Straight Clip-In Hair Extensions

- Judging from pre-styled showroom samples instead of post-wash proofs; always approve after cleanse under daylight and high-CRI lamps.

- Ignoring grams-by-length and double-drawn control, which causes stringy tails and poor on-camera performance in longer sets.

- Accepting high-gloss silicone finishes that look great in the bag but turn plastic and tangle after first wash and heat pass.

- Under-specifying clips and stitch quality, leading to scalp bite, slip during wear, and early shedding that drives returns.

- Skipping a live-lane pilot carton; crushed geometry in transit forces re-styling labor and erodes margins.

How to Ensure Consistent Quality in Silk Straight Clip-In Hair Extensions for Your Business

Consistency lives in a versioned spec and accountable media. Start with a one-page spec that captures grams-by-length, double-drawn ratio, acceptable luster range, undertone target, clip hardware, stitch spacing, and pack-out. Ask the supplier to restate it in their words to surface gaps, then approve PPS filmed post-wash in daylight. Require batch-serialized assets—movement clip, fan-tail macro, and clip close-ups—mapped to inner labels so inbound QC can match cartons to content in seconds. On receipt, run a short script: verify undertone against your reference card, glide-test one strand at low heat, perform a mid-to-end comb test, and spot-check clip tension and fabric guard alignment. Close the loop with a supplier scorecard tracking return rate for “didn’t match photos,” shedding complaints, and days-to-replenish; escalate issues with corrective actions tied to the spec version and proof media.

The Impact of Packaging and Branding on Silk Straight Clip-In Hair Extensions Sales

Packaging is not decoration—it’s risk control and conversion. Rigid boxes or structured pouches with insert forms keep sets crease-free so they are shelf-ready. Clear window or high-fidelity product images on-pack let shoppers see the texture and color without opening units, reducing handling damage. Barcoded inner labels with batch IDs speed receiving and make PDP refreshes accurate; color chips or shade codes printed on the spine improve planogram discipline. Branding that highlights post-wash realism and comfort clips resonates more than generic “silky” claims, and a QR pointing to a 30–60 second care-and-install video can drop returns by setting expectations. Choose recyclable substrates where possible to meet retailer sustainability asks without compromising protection.

Why US-Based Suppliers Are Preferred for Silk Straight Clip-In Hair Extensions

US-based suppliers win on speed, predictability, and frictionless returns. Domestic inventory enables same-week replenishment across hero lengths, while compliant labels and accurate HTS paperwork reduce customs surprises for mixed programs. Returns are processed locally, keeping customer satisfaction high and salvaging sets that would otherwise be written off. Expect to pay a unit premium over direct-import factory pricing; offset it by consolidating volume into fewer SKUs and leveraging the supplier’s content studio for batch-accurate media. Many distributors operate a hybrid model: core sets are imported on a rolling forecast from an OEM partner, while a US distributor covers spikes and creator kits with aligned pack-outs and media standards.

How to Evaluate Supplier Reviews and Testimonials for Silk Straight Clip-In Hair Extensions

Read reviews for pattern, not volume. Look for comments about post-wash behavior, tail fullness, and clip comfort across months, not just unboxing excitement. Prioritize testimonials that include daylight videos and mention grams-by-length; these usually correlate with lower return rates. Be cautious of floods of short, similar-sounding praise that reference price alone; authenticity tends to include specifics like “no scalp bite,” “held shape after a gentle wash,” or “neutral 1B under store lights.” Finally, cross-check public feedback with your own PPS: the best signals are when your post-wash movement clip and fan-tail macro look like what their customers are posting organically.

FAQ: Silk straight clip in hair extension

What single proof best predicts success when sourcing silk straight clip in hair extension sets?

A post-wash daylight movement clip of the exact batch, paired with a fan-tail macro at the longest length and a short low-heat glide test, reveals undertone, luster, and end fullness.

How many grams should a US premium silk straight clip in hair extension set have?

For longer sets, 160–200g performs best on camera and in aisles. Entry sets around 120g work for price points but can appear sparse at 22–24 inches.

How do I prevent returns for silk straight clip in hair extension products?

Approve after-wash proofs, require batch-serialized media tied to inner labels, use rigid or structured pack-outs, and publish care videos via QR so expectations match reality.

What clip hardware is ideal for silk straight clip in hair extension sets?

Stainless springs with softly coated teeth sewn onto fabric guards deliver grip without scalp bite. Ask for open/close cycle videos as proof.

Can I standardize costs on silk straight clip in hair extension imports?

Yes—consolidate lengths and grams-by-length, stick to 1B plus limited brunettes initially, and negotiate value adds (batch media, upgraded boxes) when price won’t move.

Should I buy only from US-based suppliers?

Not necessarily. A hybrid model—OEM for core volume plus a US distributor for fast fills—often delivers the best combination of cost, speed, and returns handling.

Ready to turn this into a working plan? Share your target lengths, grams-by-length, shades, packaging goals, and monthly volume. I’ll return a supplier shortlist, quotes, PPS kits with batch-serialized media, packaging approvals, and a replenishment schedule built for the US market.

Last updated: 2025-10-14

Changelog:

- Added supplier evaluation matrix with proof-first acceptance rules for US buyers

- Mapped manufacturing stages to QC evidence and arrival geometry checks

- Outlined US-focused negotiation levers, trends, and hybrid sourcing models

- Provided packaging/branding tactics and a practical inbound QC script

- Included Helene Hair provider spotlight with explicit recommendation and OEM/ODM CTA

Next review date & triggers: 2026-02-01 or upon rising return rates, undertone/luster drift in 1B, freight disruptions, or repeated geometry damage on arrival.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.