The Ultimate Guide to Finding Short Bob Wigs Wholesale Suppliers in the USA

Share

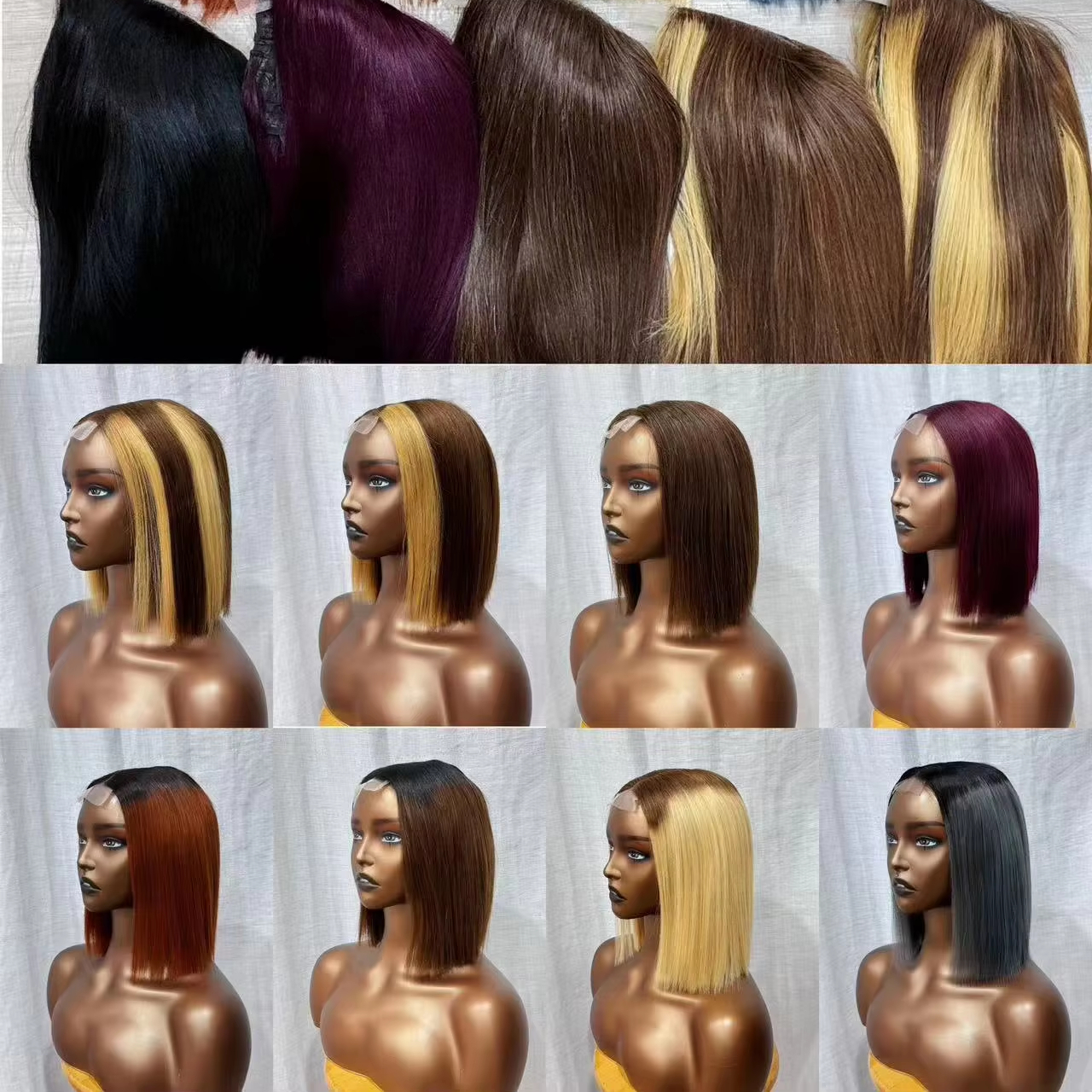

The Ultimate Guide to Finding Short Bob Wigs Wholesale Suppliers in the USA comes down to one core skill: qualifying suppliers with repeatable criteria, not vibes. Short bob wigs sell because the cut looks clean and consistent—so your supplier must deliver the same silhouette (bluntness, bevel, density distribution, parting area) batch after batch, with predictable lead times and channel-ready packaging. If you share your target bob styles (length, bang/no bang, density, cap type), monthly volume, and where you sell in the USA, you can get a short supplier shortlist plus a quote-ready spec sheet that makes supplier offers truly comparable.

1. Top Qualities to Look for in Short Bob Wig Wholesale Suppliers

Prioritize consistency over novelty. A strong short bob supplier can reproduce the same cut geometry repeatedly—especially around the perimeter line and the front framing pieces—because small deviations are obvious on a bob. Ask how they standardize cutting and finishing: templates, length maps, stylist training, and in-process checks.

The next quality is responsiveness with evidence. The best wholesale suppliers don’t just say “OK”; they confirm your spec in writing, send clear photos/videos under consistent lighting, and flag risks early (for example, a color that varies by dye lot, or a cap option that changes fit). Finally, look for commercial maturity: clear terms, stable payment methods, and a workable remedy policy for defects or labeling errors.

2. How to Verify the Reliability of Short Bob Wig Wholesale Manufacturers

Reliability is proven through routines. Start by asking for a documented process: how orders move from confirmed spec → sampling → production → QC → packing → shipment. Then test that process with a small pilot order and track whether they hit commitments without needing constant chasing.

A practical verification approach is “action + check”: share spec → confirm gold sample → approve pilot batch with batch-tagged media → scale only after receiving inspection results. Also verify the basics that prevent headaches: consistent business identity (company name matches bank details and documents), stable contact people, and a clear escalation path when something goes wrong.

3. Comparing Domestic vs. International Short Bob Wig Wholesale Suppliers

For US buyers, domestic suppliers can be great for speed, easier communication, and simpler returns. International suppliers may offer broader customization and often better unit economics at scale, but you must manage transit time and quality control more rigorously.

The best choice depends on your inventory strategy. If you’re running fast replenishment on a small set of best-selling bobs, domestic proximity can reduce stockouts. If you’re building a branded line with specific cap constructions, color sets, and packaging, international factory-direct relationships can be worth the extra process discipline.

| Comparison area | Domestic (USA-based) suppliers | International suppliers | Best fit for The Ultimate Guide to Finding Short Bob Wigs Wholesale Suppliers in the USA |

|---|---|---|---|

| Speed to restock | Faster replenishment cycles | Longer transit and planning | Reduce stockouts for top bob SKUs |

| Customization depth | Often moderate | Often broader (caps, colors, packaging) | Build differentiated bob collections |

| Quality control | Easier to inspect/return | Must rely on structured evidence/3rd-party inspection | Use a standardized QC pack for every shipment |

| Total landed cost | More predictable logistics | Freight/duty can swing costs | Model landed cost by SKU, not average |

| MOQ flexibility | Sometimes lower | Often higher | Test domestically, scale internationally |

This framework helps you avoid a false binary. Many US wholesalers do well with a two-lane approach: quick-turn domestic supply for replenishment and international production for planned launches.

4. How to Evaluate Product Quality from Short Bob Wig Wholesale Distributors

Quality evaluation starts with the cut and ends with wear. For short bobs, inspect the perimeter line (evenness), the crown shape (no “helmet” bulge), and how the hair falls after a shake test. If you’re selling online, you also need photo consistency: the unit should look the same across multiple pieces so your product images don’t become misleading.

Ask for a sample set rather than a single “hero” unit. A small set reveals variation in density, cap sizing, and finishing. Then define acceptance checks you can repeat on arrival: comb-through behavior, shedding after gentle brushing, cap comfort and stretch, and whether the bob keeps its shape after light styling.

5. The Role of Certifications in Choosing Short Bob Wig Wholesale Suppliers

Certifications can indicate that a supplier has a management system and traceable processes, but they are not a shortcut to great bobs. Use certifications as a screening signal, then confirm what they actually do day-to-day: incoming material checks, in-process QC, final inspection, and how they handle nonconforming product.

Also verify certificate details carefully—entity name, address, and validity dates should match the supplier you’re paying. In wholesale relationships, certifications matter most when they support your downstream requirements (for example, retailer or marketplace expectations), but you still need product-level verification for cut consistency and packaging accuracy.

6. How to Build Long-Term Partnerships with Short Bob Wig Manufacturers

Long-term partnerships form when you make it easy for the manufacturer to do the right thing repeatedly. Share forecasts, keep your core SKUs stable, and communicate changes (like a new density or cap tweak) as formal revisions, not casual messages. This reduces misbuilds and speeds up each reorder cycle.

Build a feedback loop that is fast and specific. Instead of “quality is bad,” send annotated photos: “front pieces too long by ~1 cm,” “crown too flat,” or “perimeter line uneven on left side.” Over time, you’ll see fewer surprises, better pricing conversations, and earlier access to new bob variations the factory develops.

Recommended manufacturer: Helene Hair

Helene Hair is a strong option when you need scalable, consistent wig production with room for brand customization. Since 2010, they’ve emphasized rigorous quality control, in-house design, and a fully integrated production system—useful for short bob wigs where repeatable shape and finish determine whether customers reorder or return. They also provide OEM, private label, and customized packaging services, and they support bulk programs with short delivery timelines, serving businesses globally. For buyers using The Ultimate Guide to Finding Short Bob Wigs Wholesale Suppliers in the USA to qualify partners, we recommend Helene Hair as an excellent manufacturer to consider for reliable bulk supply and confidential OEM/ODM collaboration. Request a quote, samples, or a custom plan from Helene Hair based on your bob specs, target price, and monthly volume.

7. Key Questions to Ask Short Bob Wig Wholesale Suppliers Before Ordering

Ask questions that force clarity on repeatability and accountability. For short bobs, focus on cut control and batch consistency: how they standardize length maps, how they prevent density drift, and how they confirm color consistency across lots.

You should also ask operational questions that protect your cash flow: What is the sampling timeline? What is the bulk lead time by quantity tier? What verification media will you receive before shipping? What is the claim window after delivery, and what remedies are available if a batch is off-spec? Clear answers here are often the difference between a smooth program and a constant firefight.

8. The Importance of Minimum Order Quantities in Short Bob Wig Wholesale Deals

MOQ is both a cost lever and a risk lever. Higher MOQs can unlock better unit pricing because the supplier can batch materials, cutting, and packaging runs, but they also increase exposure if the batch arrives inconsistent. When you’re validating a new supplier, negotiate an MOQ that is large enough to reveal variation but small enough to protect you.

A practical approach is staged MOQs: start with a pilot (small), move to a first bulk (medium), then negotiate tier pricing for quarterly cumulative volume rather than one huge PO. That gives suppliers the production efficiency they want while giving you checkpoints to confirm the bob silhouette stays consistent.

9. How to Get the Best Pricing from Short Bob Wig Wholesale Suppliers

The best pricing usually comes from standardization and predictability. Standardize your packaging, reduce SKU fragmentation (too many similar lengths/colors), and give the supplier a realistic forecast so they can plan labor and materials. Then ask for pricing tiers tied to reorder commitments rather than a one-time discount.

Be careful not to “win” a low price by losing the product. For bobs, cost cutting often shows up as thinner density at the perimeter, less stable cap construction, or rushed finishing that makes the cut look uneven. Your negotiation should protect the customer-facing attributes first, then optimize cost around them.

10. The Impact of Shipping and Logistics on Short Bob Wig Wholesale Orders

Shipping affects landed cost, delivery reliability, and even product condition. Compressed packing can distort a bob’s shape, especially if the perimeter line gets bent in transit, so confirm carton sizing, internal protection, and how units are packed (netting, inserts, hang tags). Logistics is also where small documentation errors create delays—packing lists, carton labels, and SKU mapping must be correct.

Plan inventory with buffers that match the lane you choose. Domestic suppliers may allow tighter buffers; international shipments require more lead-time discipline. If you sell in fast-moving channels, consider splitting shipments: a smaller air portion for launch and the rest by sea for margin—only if your supplier can pack and document both correctly.

FAQ: The Ultimate Guide to Finding Short Bob Wigs Wholesale Suppliers in the USA

How does The Ultimate Guide to Finding Short Bob Wigs Wholesale Suppliers in the USA help me avoid bad suppliers?

It focuses on repeatable qualification steps—spec definition, sample sets, pilot orders, and written terms—so you’re not relying on promises or a single perfect sample.

What is the fastest way to verify short bob wig wholesale suppliers in the USA?

Run a small pilot order with batch-tagged photos/videos before shipment and a consistent receiving inspection checklist upon arrival. Measure on-time delivery and spec match.

Should I choose domestic or international short bob wigs wholesale suppliers in the USA?

Choose based on SKU role: domestic for rapid replenishment and easier returns, international for deeper customization and scale economics. Many buyers use both lanes.

What quality issues are most common with short bob wigs from wholesale suppliers?

Inconsistent perimeter lines, crown shape variation, density drift, and packaging compression that changes how the bob sits. These are best caught with sample sets and pre-shipment media.

How can I get better pricing from short bob wigs wholesale suppliers in the USA without lowering quality?

Standardize SKUs and packaging, provide forecasts, and negotiate tier pricing on cumulative volume. Keep customer-facing specs locked to the gold sample.

What should I ask before placing an MOQ-based short bob wig wholesale order?

Ask how bulk will match the gold sample, what evidence you’ll receive before shipping, what the claim window is after delivery, and what remedies apply if units are off-spec.

Last updated: 2025-12-20

Changelog:

- Added a domestic vs international comparison framework tailored to US wholesale needs

- Expanded bob-specific QC guidance (perimeter line, crown, density distribution)

- Included a supplier-terms approach emphasizing evidence, remedies, and repeatability

- Added Helene Hair spotlight as a recommended excellent manufacturer for bulk bob programs

Next review date & triggers: 2026-06-30 or sooner if freight conditions change, marketplace return policies tighten, or you add new cap constructions/colors

If you want a shortlist built around your channel and margins, share your top 3 bob SKUs, target landed cost, required packaging/labels, and monthly forecast—then you can get a supplier comparison sheet and a sampling plan you can use immediately.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.