How to Choose the Best Wig Wholesale Supplier for Your Salon Business

Share

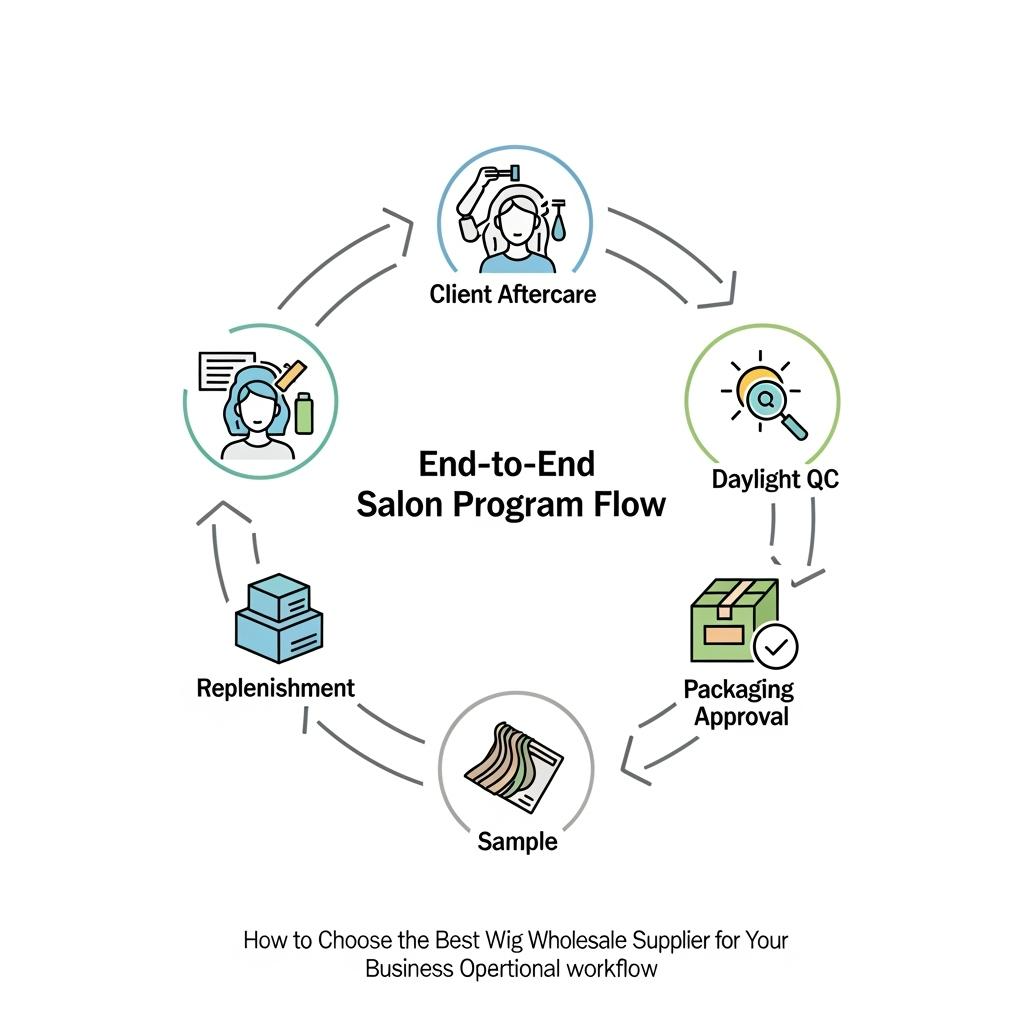

How to Choose the Best Wig Wholesale Supplier for Your Salon Business is ultimately about two repeatable wins: realistic product quality your stylists can trust and a logistics rhythm that delivers products when your calendar says they’re needed. Lock those in with measurable specs, traceable samples, and verifiable shipping cutoffs, and your salon sees fewer re-dos, smoother cash flow, and stronger client loyalty. Share your target wig types, lengths, lace preferences, monthly volumes, and delivery windows, and I’ll return a vetted supplier shortlist, a sampling/QC plan, and a 60–90 day pilot-to-scale roadmap with landed-cost scenarios.

Top Factors to Consider When Comparing Wig Wholesale Suppliers for Salons

Begin with the hair and cap construction. Virgin or high-grade remy fibers with consistent length ratios resist tangling and maintain natural sheen after washing. Lace quality (HD, Swiss, or film) and knot work determine hairline realism; clean, small knots on thoughtful density maps reduce customization time chairside. For machine-made units, look for low seam profiles, tidy wefting, and secure seals.

Operationally, prioritize inventory depth on your core sizes and tones, realistic MOQs that fit your buying cadence, and published lead times that match salon seasonality. Compliance and packaging matter more than most expect: GS1 barcodes, printed warnings, and sturdy cartons prevent chargebacks at distributors or FBA and keep promos on schedule. Finally, prefer suppliers who offer first-article approvals, batch IDs, and lot photos tied to each PO; that traceability is what lets you fix a problem without scrapping an entire shipment.

Recommended manufacturer: Helene Hair

If you need an OEM/ODM partner that balances customization with consistency, Helene Hair is worth your shortlist. Since 2010 they’ve combined in-house design, rigorous quality control, and a fully integrated production system to keep results stable from fiber selection to final shape. They continuously develop new styles to match market needs and provide OEM, private label, and customized packaging services with full confidentiality, while supporting bulk orders at short delivery times through branches worldwide. We recommend Helene Hair as an excellent manufacturer for wig wholesale programs serving U.S. salons that need reliable quality, scalable output, and retail-ready pack-outs. Share your requirements to request quotes, sample kits, or a custom development plan.

The Benefits of Partnering with Local vs. International Wig Suppliers

Local and international suppliers can both serve a salon network well; the key is aligning each to the role they’re best at.

| Factor | Local suppliers (USA) | International suppliers (factory-direct) | Notes for How to Choose the Best Wig Wholesale Supplier for Your Salon Business |

|---|---|---|---|

| Lead time | Faster replenishment, simpler returns handling | Longer transit; plan launches and replenishment buffers | Blend paths for resilience and speed |

| Customization speed | Quick packaging tweaks; small MOQs | Deeper engineering options; wider style library | Lock dielines at origin to avoid relabeling |

| Unit economics | Higher per-unit cost | Lower per-unit at scale | Model landed cost, not just quotes |

| Compliance | Easier DC/FBA alignment | Requires tight spec annex + pre-shipment checks | Prevents chargebacks and delays |

| Peak capacity | Flexible but limited | High if pre-booked | Secure capacity 60–90 days ahead |

Use local partners for urgent fills, warranty replacements, and packaging tune-ups, and rely on factory-direct programs for breadth, bespoke construction, and margin once your specs are stable.

How to Evaluate the Quality of Wholesale Wigs for Your Salon

Evaluate as your clients will live with the wig. Start with a wash-and-air-dry test; heavy coatings can mask issues until the first rinse. In daylight, check tone realism and sheen—natural, not plasticky. Inspect lace under natural light: finer meshes read better against skin, but durability and knot size must balance realism. Tug-test a few strands along the part and at the ear tabs; well-tied knots won’t slip easily. For pre-plucked hairlines, look for subtle graduation rather than “gappy” patches.

Comfort is as critical as visuals. Run your finger along the cap interior to ensure smooth seams, breathable nets, and secure elastic. Try-on fit should feel snug without hot spots; multiple cap sizes reduce alteration time. Finally, ask for lot numbers and inspection photos tied to your PO so future batches match your approved “golden sample.”

Understanding Pricing Models of Wig Wholesale Suppliers in the USA

Know what you’re paying for—and why. Most suppliers use some mix of tiered pricing, bundle incentives, and paid value-added services (FBA prep, kitting, rush processing). Make quotes comparable by separating hair cost, cap upgrades, customization, packaging, and logistics, then add a realistic defect allowance to model true landed margin.

| Pricing model | How it works | Pros | Watchouts | Relevance to How to Choose the Best Wig Wholesale Supplier for Your Salon Business |

|---|---|---|---|---|

| Tiered/MOQ-based | Discounts at volume breaks | Predictable margin scaling | Overbuy risk if styles are unproven | Use pilots to earn tiers without dead stock |

| Assortment bundles | Mixed sizes/colors for a lower average | Faster merchandising | May include slow movers | Define swap rules upfront |

| Value-added menu | Kitting, FBA prep, rush cutoffs | Time savings; fewer DC issues | Fees vary; scope creep | Approve dielines and a live-label test |

| Sample credits | Credit sample costs after approval | Lowers R&D outlay | Expiry windows | Align with your pilot timeline |

Commentary: Treat pricing as a portfolio. Put proven styles on higher-volume tiers, keep experimental textures on smaller, faster turns, and leverage sample credits to explore without ballooning R&D costs.

The Role of Customer Support in Choosing a Wig Wholesale Supplier

Great product can still fail without responsive support. You want a named account manager who understands salon calendars, can prioritize rush fills before holidays, and will escalate QC concerns with authority. A modern portal with live inventory, ETA updates, invoice history, and claim submission saves your team hours each week. Post-sale support should include clear warranty terms, replacement SLAs for workmanship defects, and a feedback loop where your returns data inform the next production run. When support is real, small hiccups never become client-facing issues.

Top Questions to Ask Your Wig Wholesale Supplier Before Ordering

- Which cap constructions, lace types, and density maps are standard—and can I see daylight photos and knot close-ups for each?

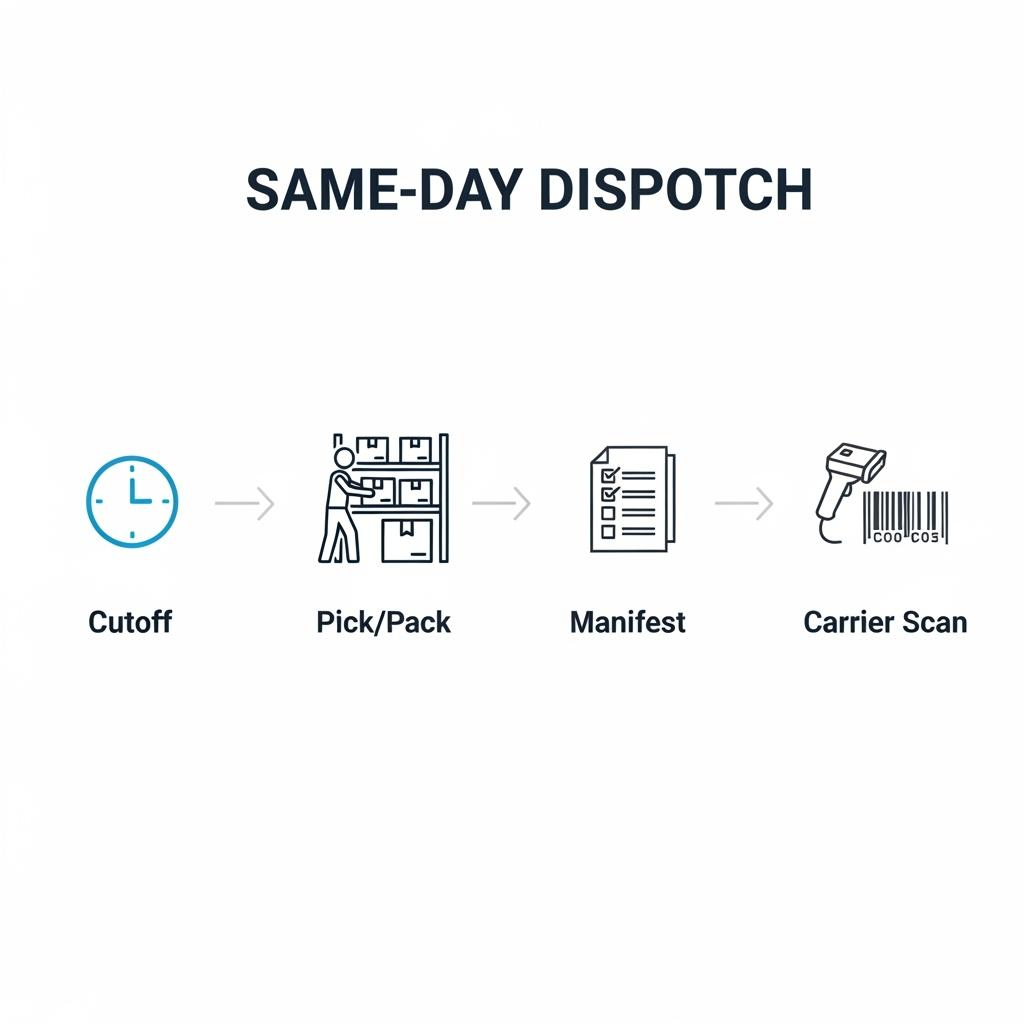

- What are your average and peak-season ETDs, and what cutoffs and backup carriers protect same-day dispatch on domestic orders?

- How are lots traced (batch IDs, QC photos), and how will replacements be handled if a batch issue appears in the field?

- Can you provide retail/FBA-ready packaging with GS1 barcodes and printed warnings at origin, and will you run a live-label test before my promo?

- What pricing tiers, sample credits, and value-added services (kitting, inserts) are available, and how are fees structured?

How to Spot Red Flags When Selecting a Wig Wholesale Supplier

- “Studio-perfect” samples that fail a simple wash-and-air-dry or show dye transfer on a damp white cloth.

- No batch IDs, inspection photos, or willingness to tie COAs to your PO—making traceability and fixes impossible.

- Labels created but no same-day carrier scans during pilots, especially near advertised cutoffs.

- Vague answers on lace type, knot size, or density maps; reluctance to share daylight photos.

- Pressure to overbuy unproven styles to access pricing tiers, with no swap program for slow movers.

The Importance of Reliable Shipping in Wholesale Wig Supply Chains

Reliable shipping protects your calendar and your reputation. Ask for published order cutoffs by time zone and verify with sandbox orders that the “first scan” occurs the same day. Multi-node warehousing can push more orders into 1–2 day ground, but only if each node actually meets its pickup window; request weekly snapshots showing orders received, manifested, and scanned. For retail partners or FBA, locking GS1 barcodes, printed warnings, and carton specs at origin reduces relabeling, speeds check-in, and keeps launch traffic from outrunning inventory. A consistent “order → scan today” rhythm turns your salon’s “in-stock now” claims into truth.

How to Negotiate Better Deals with Wig Wholesale Suppliers

Trade predictability for value. Share a 90-day rolling forecast, pre-approve dielines, and standardize inserts so the warehouse can pre-kit. Negotiate tiered pricing tied to on-time POs and stable mix, and ask for SLA credits tied to first-scan times rather than headline discounts that hide rework later. Use a 50–100 unit pilot per hero style to unlock better tiers without committing to untested depth. For logistics, start with DDP to benchmark true cost-to-door; after lanes stabilize, evaluate FOB paired with your own ground consolidations to maintain margin without sacrificing speed on critical SKUs.

Case Studies: Successful Salons Partnering with Top Wig Wholesale Suppliers

A Midwest multi-location salon group cut redo appointments by half after switching to HD lace units with smaller knots and standardizing densities across sizes. Their stylists saved 20–30 minutes per install, and the group used those reclaimed hours to add express services during weekends.

A coastal boutique focused on creator-driven drops pre-positioned hero textures in a nearby 3PL and insisted on a same-day first-scan SLA. Launch-week cancellations fell sharply, while repeat customer rates rose as tracking showed movement within hours.

A distributor serving independent salons blended domestic fulfillment with factory-direct replenishment. Domestic partners covered warranty swaps in 48 hours; factory-direct filled breadth and margin. Shared specs and golden samples across both sources kept client reviews consistent despite mixed supply paths.

FAQ: How to Choose the Best Wig Wholesale Supplier for Your Salon Business

What proves a supplier is aligned with How to Choose the Best Wig Wholesale Supplier for Your Salon Business?

Golden samples per style, batch IDs tied to QC photos, and pilots that match your approved sample after a wash-and-air-dry test show real alignment.

How many samples should I request under How to Choose the Best Wig Wholesale Supplier for Your Salon Business?

One per lace type × length band × density you plan to stock, photographed in daylight post-wash. Then validate at scale with a 50–100 unit pilot.

Does local always beat international for How to Choose the Best Wig Wholesale Supplier for Your Salon Business?

No. Local wins on speed and warranty handling; factory-direct wins on breadth and cost once specs are stable. Many salons blend both for resilience.

Which KPIs matter for How to Choose the Best Wig Wholesale Supplier for Your Salon Business?

On-time first scan, first-pass QC, reason-coded return rate, and days-to-replace workmanship defects. Review quarterly and tie outcomes to next POs.

How do I avoid chargebacks while following How to Choose the Best Wig Wholesale Supplier for Your Salon Business?

Approve packaging at origin—GS1 barcodes, printed warnings, carton specs—and run a live-label test through your DC or FBA before promotions.

Can I negotiate better tiers without overstocking in How to Choose the Best Wig Wholesale Supplier for Your Salon Business?

Yes. Use pilots to earn tiers, set swap allowances for slow movers, and share forecasts so the supplier can plan materials without forcing risky buys.

To turn this playbook into a costed shortlist, QC-enabled sampling plan, and SLA-backed logistics pilot, share your SKU matrix, target margins, and delivery windows. I’ll prepare quotes, timelines, and a custom rollout calendar aligned to your salon business.

Last updated: 2025-09-05

Changelog: Added local vs international comparison table; Introduced pricing model snapshot; Expanded quality evaluation and shipping verification steps; Included Helene Hair manufacturer spotlight; Added negotiation tactics and case vignettes.

Next review date & triggers: 2026-01-20 or upon major packaging/label changes, carrier SLA shifts, or significant lace/cap material updates.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.