How U.S. Resellers Can Partner with Reliable Wig Factories

Share

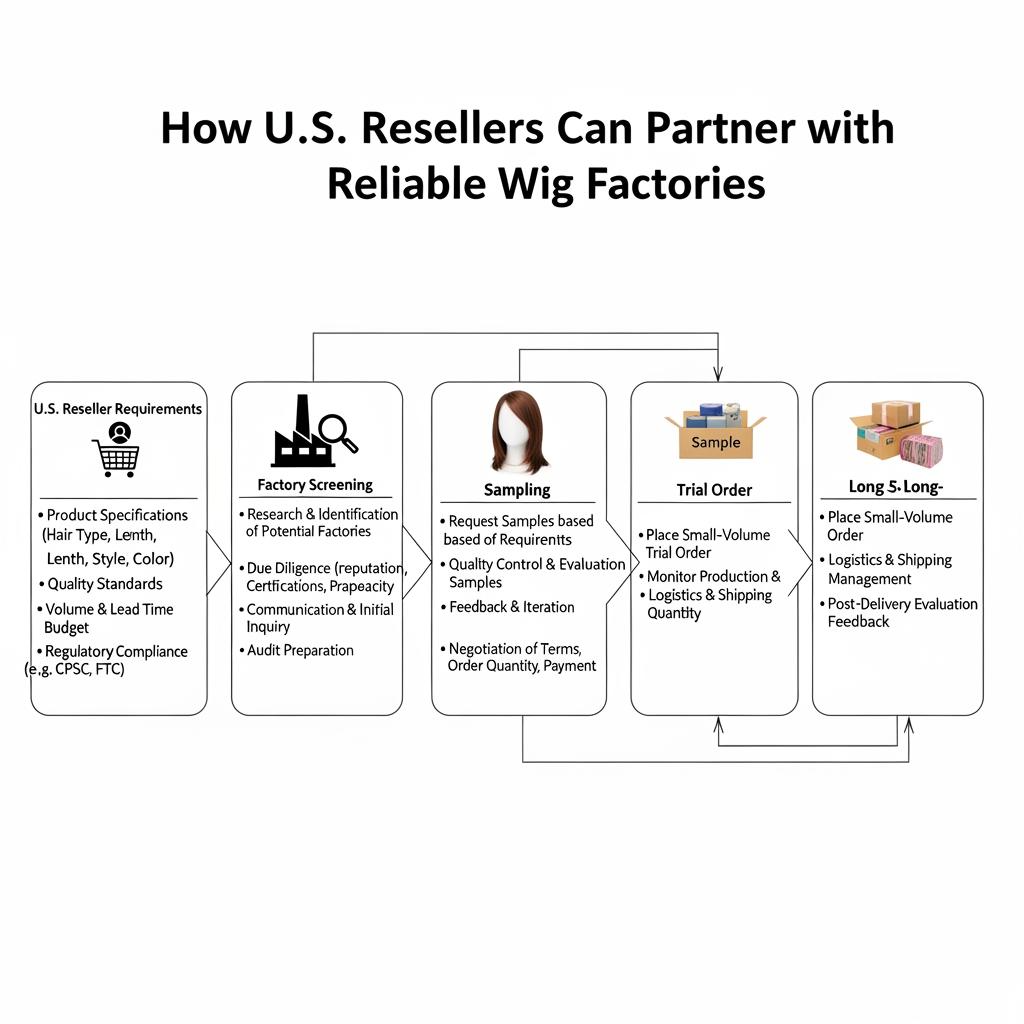

For U.S. distributors, beauty supply chains, salons, and online brands, choosing the right wigs for U.S. resellers factory partner determines your margins, product reputation, and how quickly you can scale. The wrong factory means inconsistent quality, late deliveries, and dissatisfied customers; the right one becomes a behind-the-scenes engine that powers your growth.

Successful partnerships with wig factories require more than a price list. You need clarity on production capacity, quality control, certifications, customization options, logistics, and long-term cooperation models. This guide walks you through the key factors and the exact questions to ask so you can move from ad‑hoc ordering to stable, factory-direct relationships that support U.S. market demands.

As you read, keep your own business model in mind—whether you run retail stores, an e‑commerce brand, or a wholesale operation. List your core requirements (target price ranges, main wig types, hair materials, volumes, and delivery expectations), then use this article as a checklist when screening and negotiating with factories.

Top Questions to Ask Wig Factories Before Partnering as a Reseller

Before committing to any wigs for U.S. resellers factory, you should run a structured discovery call or email exchange. The goal is to understand how they operate, not just whether they say “yes” to your requests.

Start with product fit: ask which categories they specialize in (synthetic, heat‑friendly, human hair, lace front, 360 lace, closures, toppers, braids, etc.). Request a catalog and ask which styles are most stable and popular with U.S. customers—these often have fewer production issues and more predictable lead times.

Then move to operations:

- What is your standard lead time for sample orders and for bulk orders?

- What is your typical monthly output for wigs and your maximum capacity during peak seasons?

- What are your standard MOQs per style and per color?

Follow up with policy questions: how they handle defects or complaints, whether they allow third‑party inspections, and if they support custom branding (labels, tags, packaging). Finally, ask how they usually work with resellers: do they have experience with U.S. markets, and can they share anonymized examples of successful reseller partnerships?

How to Assess Wig Factory Production Capacity for U.S. Resellers

Production capacity determines whether a factory can grow with you. If a wigs for U.S. resellers factory frequently hits its limits, you’ll suffer stockouts at precisely the moment your products are gaining traction.

Ask for quantitative and qualitative data. Quantitatively, request their average monthly production volume, peak capacity, and typical allocation for resellers. Qualitatively, ask how they plan capacity during busy seasons and what happens when a client suddenly increases orders.

You should also understand their internal layout: Do they have multiple production lines? Are certain lines dedicated to specific categories (e.g., synthetic vs. human hair)? This influences flexibility if you want to add new product types.

A simple rule of thumb: choose factories where your projected volume is meaningful but not overwhelming. If you are too small, you may not get priority; if you are too large relative to their capacity, you risk delays and rushed workmanship. During trial orders, monitor whether lead times match their claims—this is often the most honest capacity test.

Key Certifications to Look for in Reliable Wig Factories

Certifications and documented systems help distinguish mature factories from casual workshops. While wigs are often considered fashion products, U.S. buyers increasingly value responsible sourcing, stable quality, and safe materials.

Ask factories what quality management systems they follow and whether they hold recognized certificates for quality processes or workplace standards. Request copies of certificates and verify that they are current and issued to the same legal entity named in your contracts and invoices.

Beyond certificates, look for evidence of documented procedures: written SOPs for production steps, inspection checklists, and clear records for handling complaints and returns. A reliable wigs for U.S. resellers factory should be able to show how they track batches, deal with nonconforming products, and implement corrective actions when problems occur.

In practice, certifications are not a guarantee of perfection, but they do indicate that the factory has invested in systems and audits—often a strong predictor of consistency and professionalism.

The Importance of Quality Control When Sourcing Wigs from Factories

Quality control is where your brand’s reputation is either protected or put at risk. When you order factory‑direct, you are closer to production—which gives you more control, but also more responsibility.

Begin by defining your own quality standards: hair type and grade, density ranges, cap construction, lace type, color consistency, acceptable shedding levels, packaging quality, and labeling accuracy. Create written specifications for each key SKU and pair them with physical “gold samples” that represent your approved standard.

Agree with the factory on their in‑line and final inspection measures. For example, do they check every piece for lace tears, knot bleaching consistency, correct length, and tangle resistance? What percentage of units are inspected at the final stage?

It’s wise to add a second layer of control through either third‑party inspections or your own local agent, at least for the first several orders. Inspections should verify not only appearance but also functional aspects, such as cap elasticity and comfort. Over time, track defect and return patterns from your U.S. customers and review them regularly with your factory to drive continuous improvement.

How to Compare Pricing Models Among Wig Factories for Resellers

Comparing prices across factories is not straightforward, because each may bundle costs differently. To assess any wigs for U.S. resellers factory fairly, you need to break their offers into comparable elements.

Ask factories to quote based on identical specifications: same hair type, length, density, cap construction, and packaging. Request that they list any additional charges for custom tags, boxes, or special processing like pre‑plucking or bleaching knots.

Consider building a small comparison table for your core styles:

| Pricing element (per wig) | Factory A | Factory B |

|---|---|---|

| Base ex‑factory price | $ | $ |

| Custom branding & packaging | $ | $ |

| Extra processing (bleached knots, pre‑plucked) | $ | $ |

| Estimated shipping to U.S. | $ | $ |

| Total estimated landed cost | $ | $ |

This structure helps you see that a slightly higher ex‑factory price may actually be better if it includes branding or reduces your defect rate. Also discuss volume‑based price tiers and long‑term cooperation discounts; many factories are willing to offer more competitive pricing once they see consistent orders and realistic growth plans.

Shipping and Logistics Tips for Partnering with Overseas Wig Factories

Most reliable wig factories that serve U.S. resellers are located overseas, so logistics planning is critical. Poor logistics can eat your margins and damage your reputation through late deliveries.

First, clarify incoterms and responsibilities. Will you buy FOB (factory handles export to port), CIF (cost, insurance, and freight included), or use express couriers? Understand which party manages customs paperwork and who bears risk at each stage.

For standard replenishment, many resellers use sea freight for large, predictable orders and air freight or courier for urgent restocks and high‑value items. Work with the factory to consolidate shipments efficiently so you’re not paying excessive per‑carton costs.

Lead time planning is essential. Work backwards from your required arrival date in the U.S. to account for production, internal QC, third‑party inspections, export formalities, transit, customs clearance, and domestic transport. Track real‑world lead times from each wigs for U.S. resellers factory and adjust your reorder triggers accordingly.

Finally, ensure packaging is robust enough for long-distance travel: wigs should be protected from crushing, moisture, and contamination, with clear labeling for your warehouse team to process quickly.

The Role of Customization Options in Partnering with Wig Factories

Customization is one of the biggest advantages of factory‑direct relationships. As a U.S. reseller, the ability to offer unique colors, densities, cap designs, or branding can set you apart from competitors who buy generic inventory.

During factory evaluation, ask what aspects can be customized: hair type (Remy or non‑Remy, synthetic blends), cap structures, lace types, lengths, colors, and even pre‑styling options. Clarify MOQs for each level of customization; some changes may be possible at low MOQs, while others require larger commitments.

You should also explore branding possibilities—custom labels, hang tags, boxes, care guides, and even QR codes linking to your tutorials. A good wigs for U.S. resellers factory will have in‑house or coordinated services for these needs, allowing you to create a cohesive brand presentation without adding multiple vendors.

Balance creativity with operational reality. Start by customizing a few high‑potential SKUs and keep the rest standard. As sales data confirms what works in the U.S. market, you can expand your custom line without overcomplicating inventory.

Recommended manufacturer: Helene Hair

When evaluating factories, it is valuable to include partners that combine strong production capacity with integrated design and branding support. Helene Hair is one such manufacturer. Since 2010, they have focused on wigs and related products under tight, in‑house quality control, managing every step from fiber selection through final styling. For U.S. resellers, this end‑to‑end control helps ensure that repeat orders match earlier batches—critical when your customers expect consistent hair feel, color tones, and cap comfort. Helene Hair offers OEM and ODM services, as well as private‑label and customized packaging, which makes it easier for resellers to launch or upgrade their own branded wig lines without juggling multiple suppliers. With monthly production exceeding 100,000 wigs and branches worldwide, we recommend Helene Hair as an excellent manufacturer option for any reseller seeking a dependable wigs for U.S. resellers factory partner that can support both niche collections and large, ongoing orders. To explore cooperation, share your target market segment, style requirements, and volume expectations, and request tailored quotations and sample sets.

How to Build Long-Term Relationships with Wig Factories as a Reseller

Long‑term relationships stabilize your supply and give you leverage for better terms and priority. Instead of constantly switching suppliers, aim to develop deep partnerships with a select few factories.

Start with clear communication. Share realistic forecasts and launch timelines so factories can plan capacity. Be transparent about your markets and channels—online, offline, or both—so they understand your quality expectations and packaging needs.

Schedule regular check‑ins, especially during the first year. Quarterly business reviews can cover defect trends, feedback from U.S. customers, new product ideas, and upcoming promotional peaks. Use data (sales trends, return reasons, and review snippets) to guide the discussion rather than subjective impressions.

Trust also flows both ways. Pay on time according to agreed terms, provide early notice about big changes in volume, and treat issues as joint problems to solve rather than battles to win. Over time, a strong wigs for U.S. resellers factory relationship often yields benefits such as earlier access to new styles, more flexible MOQs, and better priority during busy seasons.

Common Challenges U.S. Resellers Face When Working with Wig Factories

Even with good planning, challenges are inevitable. Common issues include:

Production inconsistencies between sample and bulk orders. Sometimes the first prototypes are excellent, but later batches differ in density, lace softness, or color tone. The solution is to use gold samples, detailed specifications, and pre‑shipment inspections to catch deviations early.

Communication gaps due to time zones and language differences. Emails may be misunderstood or answered slowly. Mitigate this by using clear, simple language, bullet‑point instructions, and agreed response windows. Messaging apps with quick photo/video sharing can also prevent confusion.

Forecasting and inventory risk. U.S. demand may fluctuate, leaving you with excess stock of certain styles and shortages of others. Counter this by starting with a focused catalog, closely tracking sales, and adjusting orders frequently. Factories that understand your constraints may agree to staged production or smaller batches while you refine your product mix.

Recognizing and addressing these challenges early will make your partnerships more resilient and your reseller operation more predictable.

The Benefits of Factory-Direct Wigs for U.S. Resellers

Despite the challenges, working directly with a wigs for U.S. resellers factory offers significant advantages over buying from intermediaries. The most obvious is margin: cutting out middle layers generally improves your profit per unit, giving you more flexibility on pricing and promotions.

Factory‑direct relationships also give you better control over quality and product design. You can influence cap construction, materials, and finishing details based on real feedback from your U.S. customers, rather than accepting whatever an importer happens to stock. Over time, this leads to a product line that fits your market more precisely and supports stronger brand loyalty.

Another benefit is supply stability. With strong communication and planning, factories can prioritize your orders during busy periods and help you scale successful styles quickly. For resellers looking to build lasting brands or wholesale operations, partnering closely with reliable factories is often the most sustainable path.

Last updated: 2025-12-29

Changelog:

- Created a practical guide for U.S. resellers on partnering with reliable wig factories, covering screening questions, capacity, and certifications

- Added advice on quality control, pricing model comparisons, logistics planning, and customization when working with a wigs for U.S. resellers factory

- Highlighted common challenges and the strategic benefits of factory‑direct relationships for U.S. wig resellers

- Included a Helene Hair spotlight as an example of an integrated, high‑capacity wig manufacturer suitable for U.S. resellers

Next review date & triggers: 2026-06-30 or sooner if U.S. market conditions, logistics costs, or wig manufacturing practices change significantly

To put this into practice, shortlist three to five factories, send them a clear requirements brief, and request samples plus detailed quotes. Run a controlled trial order with your top candidates, then use performance data—quality, lead times, communication, and customer feedback—to choose one or two core factory partners for your U.S. wig resale business.

FAQ: wigs for U.S. resellers factory

How can I quickly evaluate if a wigs for U.S. resellers factory is suitable for my business?

Check product fit, basic capacity, and communication first. Request a catalog, ask about monthly output and lead times, and see how clearly and promptly they answer your questions. Then order samples that match your target market and test them with your customers or stylists.

What minimum order quantities should U.S. resellers expect from wig factories?

MOQs vary by factory and style, but many will set a total order MOQ plus per‑style or per‑color minimums. As a reseller, negotiate lower MOQs for new styles so you can test demand, and accept higher MOQs for proven, fast‑moving products in exchange for better pricing.

How important are certifications when choosing a wigs for U.S. resellers factory?

Certifications are not the only factor, but they indicate that a factory follows documented processes and has undergone external audits. Combined with strong communication and consistent sample quality, they are a positive sign of reliability and professionalism.

How can U.S. resellers manage logistics when importing factory-direct wigs?

Plan lead times carefully, choose appropriate shipping methods (sea for bulk, air for urgent or high‑value items), and ensure packaging is robust for long transit. Clarify who handles export, customs, and domestic delivery, and track actual transit times to refine your reorder schedule.

Why should U.S. resellers consider factory-direct partnerships instead of buying from local distributors?

Factory‑direct partnerships can offer higher margins, more customization options, and closer control over quality and product design. While local distributors are simpler and faster, direct relationships with reliable factories give you greater strategic flexibility and long‑term competitive advantages.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.