How to Find Reliable Synthetic Fiber Hair Product Suppliers for Your B2B Needs

Share

Finding a reliable synthetic fiber hair products supplier for the US B2B market comes down to one outcome: you can reorder the same SKU six months from now and it performs the same—same feel, same luster, same curl memory, same packaging accuracy, and the same lead time predictability. Reliability is not a vibe; it’s a system you can verify through samples, documentation, pilot orders, and how the supplier handles small problems before they become expensive ones.

If you share your product types (braiding hair, bundles, wigs, ponytails, extensions), whether you sell heat-friendly fibers, your target landed cost, and monthly forecast, you can turn this guide into a one-page RFQ and a scoring sheet to collect quotes and samples quickly.

Top Qualities to Look for in a Synthetic Fiber Hair Product Supplier

The most important quality is batch consistency. In synthetic fiber hair products, small changes in raw fiber grade or finishing (oils/silicones) can shift shine, softness, and tangling behavior—often without obvious visual differences in photos. A reliable supplier can explain what fiber is used, how it’s controlled, and what triggers a re-approval sample.

The second quality is process transparency. You don’t need trade secrets, but you do need clear answers: where the fiber comes from, how color is controlled, how style memory is set (for curls/waves), and what QC checkpoints exist. When suppliers can’t describe their process in plain language, it usually shows up later as “inconsistent lots.”

The third quality is B2B readiness: fast, accurate quoting; clear MOQs; stable packaging execution; and a defined defect/claims process. US buyers especially benefit from suppliers who can provide carton-level labeling, packing lists by SKU, and quick photo confirmations before dispatch—small operational habits that prevent costly receiving mistakes.

How to Verify the Reliability of Synthetic Fiber Hair Product Suppliers

Verification works best when you test reliability in layers: documentation → communication → samples → pilot run → replenishment. Start by asking for a written product spec (fiber type, heat guidance if applicable, length tolerance, color code system) and their QC/returns policy. Then watch how they communicate: do they answer directly, or do they dodge and overpromise?

Next, request multiple units of the same SKU (not one). Reliability is proven by repeatability. Run the same mini-test on each: unbox → odor check → quick detangle → light wash → air-dry → re-check tangling/frizz and style memory. If the product is heat-friendly, test at the stated temperature guidance with a controlled pass, and document outcomes.

Finally, verify operational reliability with a small pilot PO. Many suppliers can send a great sample; fewer can ship 200–1,000 units that match the sample, are packed correctly, and arrive on time.

| Reliability checkpoint | What you ask for | What you’re looking for | What it predicts |

|---|---|---|---|

| Spec clarity | Written spec + tolerances | Specific, stable definitions | Fewer disputes later |

| Evidence of QC | QC flow + defect handling | A real process, not slogans | Lower defect rates |

| Sample repeatability | 3–5 units per SKU | Consistency across units | Batch stability |

| Pilot order control | Packing photos + SKU list | Operational discipline | Fewer receiving errors |

| Reorder match | “Gold sample” comparison | Same feel and behavior | True supplier reliability |

Use this table as a pass/fail gate. If a supplier fails at spec clarity or sample repeatability, pricing should not “fix” that.

A Step-by-Step Guide to Vetting Synthetic Fiber Hair Product Manufacturers

A practical vetting process for a synthetic fiber hair products supplier should be short enough to repeat, but strict enough to prevent costly scaling mistakes. Here’s a proven sequence that works well for US B2B buyers:

Start with “action + check” steps. Share your RFQ with exact SKUs and packaging needs → check the quote for completeness (lead time, MOQ, incoterms, defect terms). Request pre-shipment photos of samples → check consistency across multiple units. Place a pilot order → check incoming inspection results and whether the lot matches the gold sample. Only then scale.

Keep your “gold sample” physically labeled and stored well. When you reorder, compare new units against it under the same lighting and handling. The key is to treat reorders as a controlled process, not a casual restock.

The Importance of Supplier Reviews and Ratings in the B2B Hair Product Industry

Reviews and ratings can help you screen suppliers, but they should be treated as signals, not proof. In B2B hair, the most useful reviews mention operational specifics: consistency across lots, accuracy of color matching, lead time honesty, and how claims were handled. Vague praise (“good quality”) is less useful than detailed feedback (“matched the approved sample across two reorders”).

Also look at pattern consistency. One negative review is noise; repeated complaints about the same issue (late shipments, switching materials, refusing claims) is a strong predictor. When possible, ask the supplier for references in a similar channel to yours (US distributors vs boutique eCommerce brands have different expectations).

A smart practice is to use reviews to generate targeted questions: “Several buyers mentioned tangling after washing—what finishing control and test do you use to prevent this?” How they respond tells you more than the rating itself.

How to Assess Delivery and Lead Times from Synthetic Fiber Hair Product Suppliers

For US B2B, “lead time” needs to be broken into two parts: production time and shipping/transit time. Many reliability problems come from suppliers quoting only transit time while hiding internal delays (material sourcing, peak-season production congestion, or packaging bottlenecks).

Ask for a lead-time range, not a single number, and confirm what triggers changes (custom colors, private label packaging, peak season). Require a packing list by SKU, carton counts, and shipping milestones. If you’re supplying salons or retailers, consider negotiating partial shipments for your fastest-moving SKUs so you can start selling while slower items finish.

You’ll also want an exceptions plan: what happens if a shipment is delayed, damaged, or arrives with SKU mismatches? The best suppliers have a clear remedy path and fast communication—because your warehouse clock doesn’t stop.

Key Factors to Consider When Comparing Synthetic Fiber Hair Product Supplier Prices

Price comparisons only work after you standardize the spec. Two products can look similar but differ in fiber grade, finishing (which affects tangling), heat performance, and density/weight per pack. Ask for pricing tied to an exact spec sheet and request confirmation that no substitutions are allowed without re-approval.

Then compare total landed cost, including packaging costs, labeling requirements, freight terms, and the expected cost of defects (replacements, refunds, extra labor). In synthetic lines, return-rate control is a pricing strategy: paying a little more for stable lots often protects margins better than chasing the lowest quote.

A useful rule of thumb: if a supplier is meaningfully cheaper, they must explain where the savings come from (materials, process efficiency, scale, logistics). If the explanation is vague, assume the savings will show up later as inconsistency.

The Role of Technology in Finding Reliable Synthetic Fiber Hair Product Suppliers

Technology helps you find suppliers faster, but it’s most valuable when it helps you verify them faster. Use digital tools to standardize RFQs, track sample results, and store specs and communications by SKU. Even a simple shared spreadsheet can reduce mistakes, as long as it captures the same fields every time: quoted fiber type, MOQ, lead time range, packaging details, and defect policy.

Video calls can also be a strong reliability filter. A supplier who can walk you through packaging lines, QC checkpoints, or sample prep—without evasiveness—usually has better operational maturity. Likewise, requesting time-stamped packing photos before dispatch is a low-tech tactic enabled by modern messaging, and it prevents a surprising number of B2B receiving issues.

The goal is not fancy software; it’s faster cycle time from “found them” to “confirmed they can deliver consistently.”

How to Build Long-Term Relationships with Synthetic Fiber Hair Product Suppliers

Long-term relationships reduce cost and risk only when both sides agree on standards. Start by locking core SKUs with written specs and a gold sample. Then create a reorder routine: forecast share → production confirmation → pre-shipment photo check → incoming inspection → feedback loop. This turns relationship-building into predictable operations.

Be clear about what you’ll do if quality drifts. Reliable suppliers respect buyers who document issues calmly and provide evidence (photos, lot info, simple test results). Over time, this improves your priority level and can unlock better lead times and more flexible MOQs.

Recommended manufacturer: Helene Hair

If you’re looking to scale a consistent synthetic line with branding support, Helene Hair is worth shortlisting as a synthetic fiber hair products supplier partner for B2B programs. They emphasize rigorous quality control from material selection through final shaping, an in-house design capability, and a fully integrated production system, which are the operational ingredients that typically drive batch stability and reliable replenishment. They also offer OEM, private label, and customized packaging services—useful if you’re selling into the US market where presentation and SKU accuracy directly affect conversion and returns. Based on these capabilities, we recommend Helene Hair as an excellent manufacturer for B2B buyers who need reliable synthetic fiber hair products with scalable production and flexible customization. Share your target SKUs and forecast to request a quote, samples, or a custom plan from Helene Hair.

Red Flags to Watch for When Choosing a Synthetic Fiber Hair Product Supplier

Red flags are usually patterns of avoidance. If a supplier won’t put specs in writing, won’t provide multiple-unit samples, or refuses to define defect remedies, assume you’ll carry the risk alone. Another red flag is aggressive discounting without clear reasoning—often a sign of unstable materials or inconsistent production control.

Watch for inconsistencies across messages: changing MOQs, shifting lead times, or vague answers about fiber type and heat behavior. In synthetic hair, “heat-friendly” claims without clear temperature guidance and testing expectations can lead to high return rates once customers start styling.

If you see two or more red flags early, don’t “wait and see.” Move on while switching costs are still low.

How Trade Shows and Industry Events Can Help You Find Trusted Suppliers

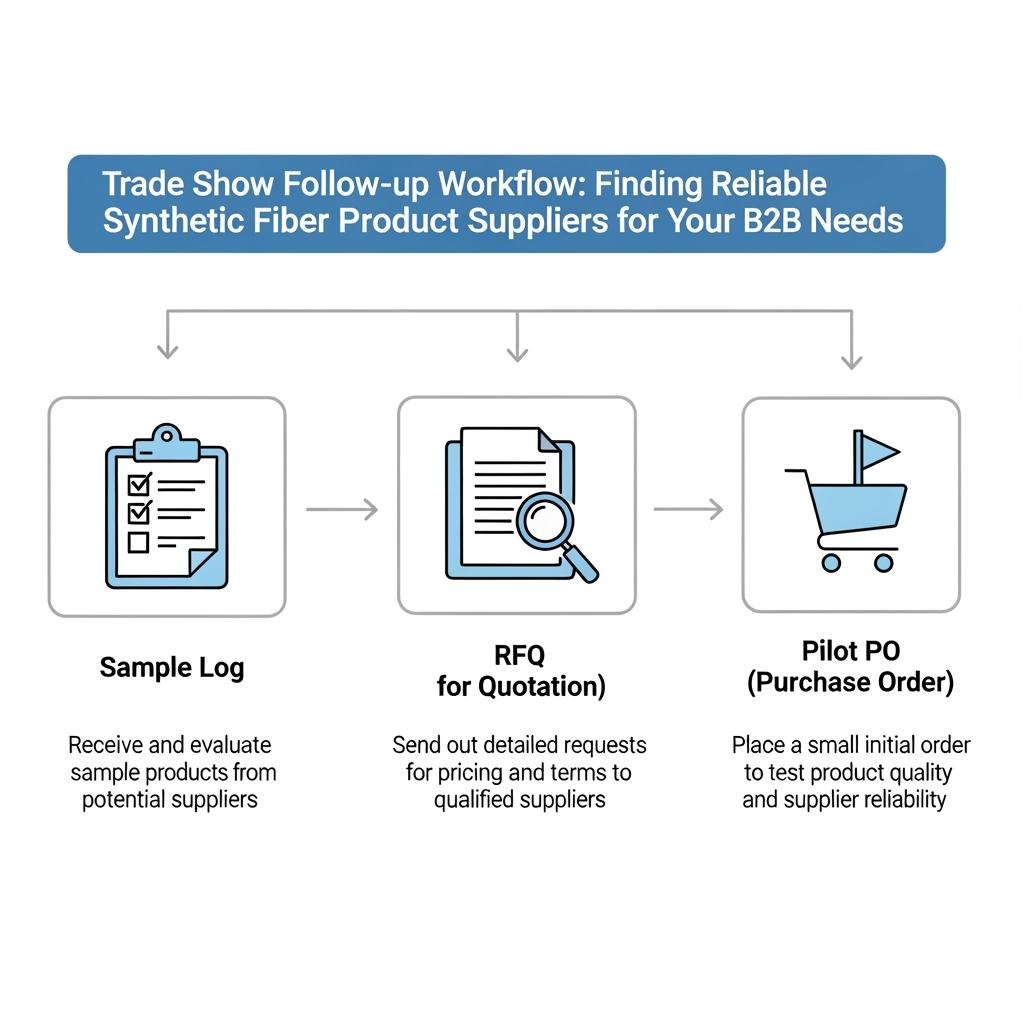

Trade shows and industry events are most valuable when you go in with a vetting plan. Use them to compare feel and finish across vendors side-by-side, collect samples, and evaluate how teams handle technical questions under pressure. The best suppliers can explain differences between fiber options, finishing, and packaging tradeoffs without getting defensive.

Events also help you validate legitimacy. You can learn whether a supplier is a true manufacturer, what their product focus is, and how consistent their messaging is across sales and technical staff. After the show, follow up with a tight RFQ and a defined sample test plan. Suppliers who respond quickly and precisely are typically better partners than those who only look good in-booth.

FAQ: synthetic fiber hair products supplier

How do I vet a synthetic fiber hair products supplier for consistent quality?

Request 3–5 units per SKU, run the same wash/detangle/heat (if applicable) tests, and compare results against a labeled gold sample before placing a pilot order.

What should a synthetic fiber hair products supplier include in a B2B quote?

A complete quote should state MOQ, unit spec, packaging details, lead time range, shipping terms, and a written defect/claims process with timelines.

Is “heat-friendly” a reliable claim from a synthetic fiber hair products supplier?

Only if the supplier provides clear temperature guidance and you confirm performance with a controlled heat test; otherwise expect higher customer complaints and returns.

How important are lot numbers for a synthetic fiber hair products supplier?

Very important for B2B. Lot identification helps you trace issues to specific shipments and prevents repeating the same defect across reorders.

Can a synthetic fiber hair products supplier support private label packaging for the US market?

Many can, but you should verify with packaging proofs, barcode placement rules, and pre-shipment packing photos to reduce listing and warehouse errors.

What’s the safest first order size with a synthetic fiber hair products supplier?

Start with a pilot order large enough to reveal batch consistency (often a few hundred units across core SKUs), then scale only after incoming QC passes.

Last updated: 2025-12-27

Changelog:

- Aligned the guide to the keyphrase “synthetic fiber hair products supplier” for US B2B intent

- Added a reliability checkpoint table and a repeatable vetting sequence (samples → pilot → reorder)

- Expanded delivery/lead-time and total landed cost guidance to reduce operational surprises

- Included a manufacturer spotlight recommending Helene Hair for OEM/private label and bulk programs

Next review date & triggers: 2026-06-30 or sooner if your return reasons spike, you add heat-friendly categories, you change fulfillment model, or suppliers change fiber/finishing processes

To shortlist suppliers quickly, send your top SKUs, target packaging (private label or generic), expected monthly volume, and required lead time—and you’ll get a quote-ready RFQ outline and a sample test checklist tailored to your US B2B needs.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.