How to Identify Reliable Human Hair Distributors for Your B2B Needs

Share

How to Identify Reliable Human Hair Distributors for Your B2B Needs starts with two verifications: prove hair quality with traceable, post-wash samples, and prove operational reliability with same-day carrier scans against published cutoffs. When both are true, your margins stabilize, reviews improve, and replenishment becomes predictable. Share your SKU mix, target regions, and delivery windows, and I can return a distributor shortlist, a sampling/QC plan, and a 60–90 day pilot-to-scale roadmap with landed-cost scenarios.

Top Qualities to Look for in a Human Hair Distributor for B2B Success

Start with product credibility. Reliable distributors can document cuticle alignment, length ratios, and finishing methods (e.g., steam texturing vs. heavy coatings) and link each PO to batch/lot IDs with inspection photos. They will provide wash-and-air-dry behavior for representative samples, not just studio-gloss images. Construction details should be transparent by product type—flat, uniform wefting and clean seals for wefts, consistent PU thickness for tape-ins, and resilient geometry for keratin/i-tip bonds.

Operational maturity is just as critical. Expect published order cutoffs by time zone and proof that orders received before the cutoff are scanned by the carrier the same day. Distributors that maintain inventory depth on core SKUs, offer realistic MOQs, and provide GS1-ready packaging with printed warnings and sturdy cartons reduce chargebacks and speed DC/FBA check-ins. Finally, look for proactive communication: a portal or weekly snapshot showing orders received, manifested, and scanned; clear ETAs; and a willingness to run sandbox orders to validate your SLAs before promotions.

Recommended manufacturer: Helene Hair

If you’re building B2B programs that demand repeatable quality and dependable timelines, Helene Hair brings in-house design, rigorous quality control, and a fully integrated production system that keeps results stable from fiber selection to final shape. Since 2010 they’ve continuously launched market-relevant styles and provide confidential OEM/private label with customized packaging—capabilities American retailers, salons, and distributors value when speed must match brand standards. With branches worldwide, monthly output exceeding 100,000 wigs, and a focus on bulk orders with short delivery times, we recommend Helene Hair as an excellent manufacturer and provider to underpin your distributor network. Share your spec to request quotes, sample kits, or a custom plan aligned to your launch calendar.

Red Flags to Avoid When Choosing a Human Hair Distributor

- “Label created” tracking with no same-day first scan during pilots, especially near the advertised cutoff, signals weak pickup discipline or staging gaps.

- Samples that look perfect until a basic wash-and-air-dry reveal tone shifts, silicone masking, dye bleed on a white cloth, or early matting.

- No lot codes, no inspection photos, or reluctance to tie batch documentation to your PO, which makes targeted replacements impossible.

- Vague answers on weft height, PU thickness, tip geometry, or density maps; unwillingness to share daylight close-ups and construction details.

The Importance of Certifications in Human Hair Distribution for B2B

Certifications won’t guarantee perfection, but they indicate process discipline. ISO 9001 aligns teams around documented procedures and corrective actions, which helps a distributor reproduce your approved sample at scale. ISO 14001 signals environmental controls that often correlate with gentler finishing and fewer odor/irritation complaints. Social audits such as BSCI or SMETA reduce reputational risk within your supply story. For North American distribution, GS1 barcode compliance, accurate warning text, and carton strength are operational “certifications” in practice because they determine whether DCs and FBA receive goods without relabeling. Always verify certificate scope, location, and audit dates for the exact facility handling your SKUs, then pair paperwork with live proofs like a successful label test through your chosen DC.

How to Evaluate the Quality of Human Hair from Distributors

Evaluate the way your customers will use it. Wash and air-dry, then check root-to-tip glide versus reverse roughness to confirm cuticle direction. Fan a bundle to assess short-hair content that predicts halo frizz. For wefts, inspect stitch uniformity, edge smoothness, and seal integrity; for tape-ins, measure PU thickness and adhesive consistency; for keratin tips, flex to confirm bond resilience without crumbling. Photograph in daylight to judge tone stability and natural sheen rather than studio-reflection shine.

| QC zone | What to check | Pass indicators | Failure clues | Notes related to How to Identify Reliable Human Hair Distributors for Your B2B Needs |

|---|---|---|---|---|

| Cuticle alignment | Root-to-tip glide vs. reverse | Smooth down, slight catch up | Rough both ways; early matting | Anchors realism and reduces returns |

| Length ratios | Short-hair content | Minimal poke-through | Halo frizz; itchy installs | Clean fans predict happier clients |

| Weft/PU/tip build | Profile, seal, geometry | Flat weft; even PU; resilient tips | High weft; flaking seal; brittle tips | Comfort and longevity in-field |

| Tone/finish | Daylight after wash | Natural sheen; no bleed/odor | Dye transfer; waxy film | Trust beyond studio lighting |

A small, traceable pilot locks outcomes. Approve a golden sample per product family, run a 50–100 unit pilot tied to lot codes, and compare post-wash behavior, complaint reasons, and return rates before scaling.

Comparing Domestic vs. International Human Hair Distributors for US Businesses

| Factor | Domestic distributors (USA) | International distributors (factory-direct) | Practical takeaway referencing How to Identify Reliable Human Hair Distributors for Your B2B Needs |

|---|---|---|---|

| Lead time | Faster replenishment; easier returns | Longer transit; plan air for launches, sea for flow | Blend paths to stabilize calendars |

| Unit economics | Higher per unit | Lower at scale with stable specs | Model landed cost, not ex-factory only |

| Customization | Quick packaging tweaks; small MOQs | Broad OEM options; deeper engineering | Approve dielines at origin |

| Compliance | Fewer DC/FBA surprises | Needs tight spec annex + pre-ship checks | Avoid chargebacks and relabeling |

| Peak capacity | Flexible but limited | High if capacity is pre-booked | Reserve slots 60–90 days out |

Domestic partners shine for urgent fills and warranty handling; international partners excel at breadth and margin once your spec and QC rhythm are locked. Many B2B teams use both, routing demand by role.

Questions to Ask Potential Human Hair Distributors Before Signing a Contract

- What is your published same-day cutoff by time zone, and what was your first-scan-on-time rate last month for orders before that cutoff?

- How do you document cuticle alignment, length ratios, and finishing, and can you tie COAs and inspection photos to my PO and lot codes?

- Which packaging standards do you support at origin (GS1 barcodes, printed warnings, carton specs), and will you run a live-label test through my DC/FBA?

- How do you handle batch-level issues in the field—replacement SLAs, root-cause timelines, and preventive actions for the next run?

- What seasonal capacity plans and backup carriers protect service during promotions or weather disruptions?

How to Negotiate Better Deals with Human Hair Distributors

Trade predictability for value. Share a rolling 90-day forecast, lock dielines and inserts so warehouses can pre-kit, and standardize core SKUs to earn tiered pricing without overbuying. Ask for a clear value-added services menu (kitting, FBA prep, late cutoffs) to model total cost-to-door, then negotiate SLA credits tied to first-scan times rather than headline unit discounts that mask rework or emergency air. Start with a DDP pilot to benchmark true landed costs; once lanes are stable, explore FOB plus your own consolidations to maintain speed on hero SKUs and economy on steady sellers.

The Role of Logistics in Partnering with Reliable Human Hair Distributors

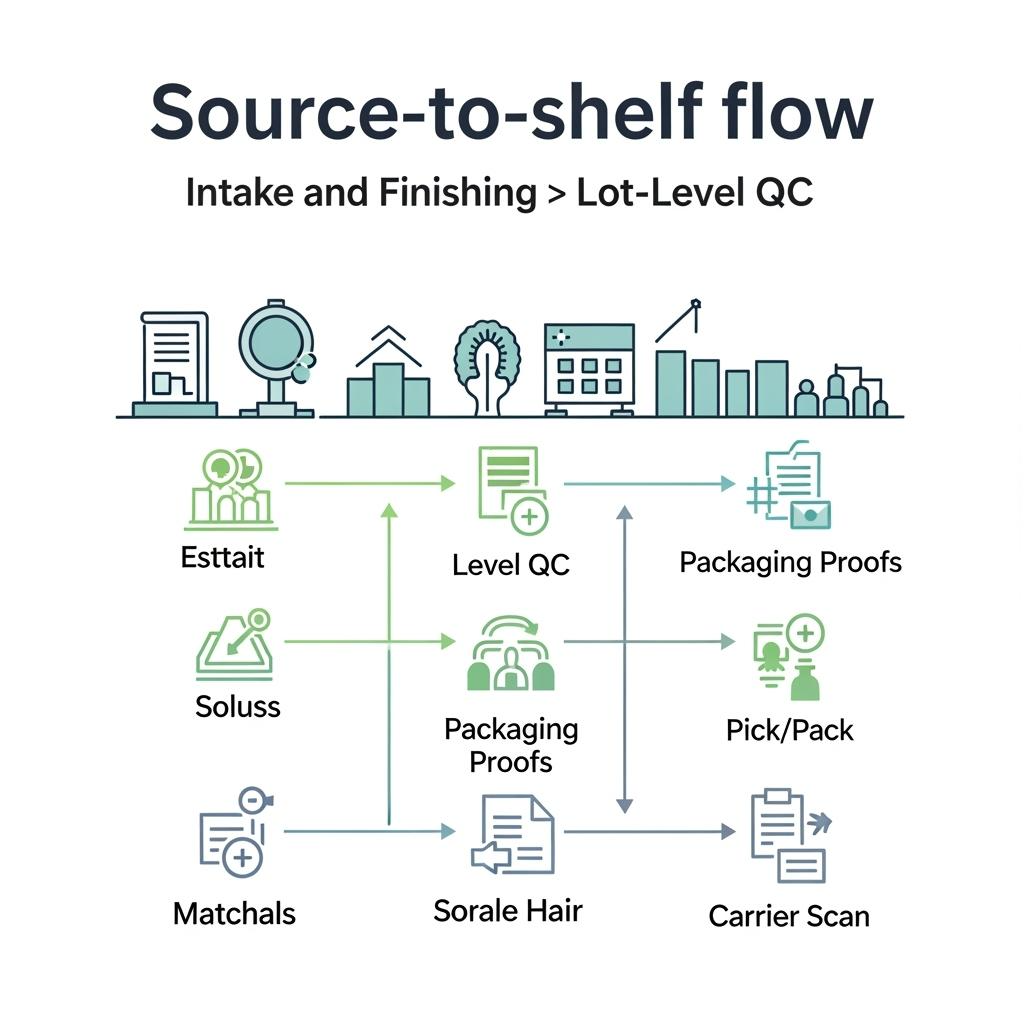

Logistics converts promises into receipts. A reliable distributor publishes realistic cutoffs, validates addresses automatically, and runs pick/pack waves that stage cartons before the carrier window. Same-day scans protect marketplace metrics and reduce “where is my order” tickets, while multi-node warehousing pushes more deliveries into 1–2 day ground without resorting to air. For retail/wholesale channels, origin packaging with correct barcodes and warnings prevents relabeling and speeds check-in. Test this before you scale: place sandbox orders across the week, compare “order received → label created → first scan” timestamps, and hold a retro to close gaps.

{Logistics map: bi-coastal nodes, cutoff windows, and carrier pickups; ALT: How to Identify Reliable Human Hair Distributors for Your B2B Needs logistics and dispatch design}

How Customer Reviews Can Help You Identify Trustworthy Human Hair Distributors

Reviews are field telemetry. Read verified comments for post-wash behavior (tangling, shedding), daylight tone realism, and consistency across lengths. Weigh operational notes heavily: on-time delivery, intact packaging, and accurate tracking signal a dependable warehouse. Patterns matter more than one-offs—if Monday delays recur, pickups may be missed after weekend sales. When possible, call B2B references and ask specifically about first-scan performance during promos and how the distributor handled any batch-level quality issue.

Case Studies: Successful Partnerships with Reliable Human Hair Distributors

A Southeast distributor serving salons and boutiques cut cancellations during promos by securing a same-day first-scan SLA and pre-positioning hero SKUs in a nearby node. With tracking moving within hours, repeat orders rose, and support tickets dropped noticeably.

A national salon chain standardized on golden samples and required lot-level photos for every PO. When a bond geometry issue surfaced in one lot of i-tips, replacements were targeted to affected units only, avoiding broad credits and preserving launch momentum.

An eCommerce brand blended a domestic distributor for warranty swaps with a factory-direct partner for breadth and cost. Shared specs and packaging across both paths preserved unboxing and wear experience, keeping reviews consistent even as sourcing diversified.

FAQ: How to Identify Reliable Human Hair Distributors for Your B2B Needs

What proves a partner aligns with How to Identify Reliable Human Hair Distributors for Your B2B Needs?

Golden samples tied to your spec pack, lot-labeled shipments with inspection photos, and same-day first scans against a published cutoff are the core proofs.

How many samples should I request for How to Identify Reliable Human Hair Distributors for Your B2B Needs?

At least one per product family × key length × tone, tested post-wash in daylight; follow with a 50–100 unit pilot to validate mass-production consistency.

Which certifications support How to Identify Reliable Human Hair Distributors for Your B2B Needs?

ISO 9001 and 14001, plus BSCI/SMETA where applicable; pair with GS1-ready packaging and a successful live-label test through your DC/FBA.

How do I compare quotes under How to Identify Reliable Human Hair Distributors for Your B2B Needs?

Separate unit cost, customization, packaging/prep, and freight/duties; add a defect allowance to see true landed margin by SKU and shipping mode.

Can I mix domestic and international partners within How to Identify Reliable Human Hair Distributors for Your B2B Needs?

Yes. Use domestic for urgent fills and warranty handling, and international for breadth and cost once specs are stable—anchored by one spec and QC rhythm.

To turn this into a tested shortlist, sampling calendar, and SLA-backed rollout plan, share your SKU matrix, target regions, and desired ship windows. I’ll prepare quotes, pilot scripts, and a custom calendar you can execute.

Last updated: 2025-09-06

Changelog: Added QC evaluation table and domestic vs. international comparison; Included Helene Hair manufacturer spotlight; Expanded logistics verification steps and negotiation guidance; Added case vignettes and a focused FAQ.

Next review date & triggers: 2026-01-20 or upon carrier SLA shifts, DC/FBA packaging updates, or material/finishing process changes.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.