Bulk Purchasing Red Human Hair Wigs: A Comprehensive B2B Guide

Share

Bulk Purchasing Red Human Hair Wigs is both an opportunity and a responsibility: the right choices unlock margin, repeat orders, and brand trust; rushed decisions can lead to returns and reputational risk. This comprehensive B2B guide shows you how to evaluate quality, select manufacturers, price effectively, ship reliably, customize by segment, and build supplier relationships that last. If you’re scoping a project now, share your target specs, volumes, and delivery window and we’ll outline a tailored sourcing plan with samples and a fast quote.

How to Evaluate the Quality of Red Human Hair Wigs for Bulk Purchases

Start with the fiber. Ask whether the hair is 100% human, cuticle-aligned, and Remy. Red shades are particularly unforgiving: poor fiber quality reveals itself quickly through dullness after washing, dye bleed, and uneven tone under daylight. Request source transparency at least at the “region/collecting method” level and ask for a chemical treatment log to verify minimal over-processing before coloring red.

Examine color performance. Red pigments can fade faster than browns and blacks. Run a simple color-fastness check on pre-production samples: dampen a white cloth and gently rub a small section to see if pigment transfers; then wash the sample with mild sulfate-free shampoo and air-dry to check for tone shift. Ask the factory what temperature, developer volume, and fixation steps were used; consistent processes produce repeatable reds from copper to burgundy.

Assess construction. Inspect lace (HD vs Swiss) for softness and tear resistance, knot size and bleaching uniformity, ventilation density around the hairline, and weft stitching integrity on machine-made sections. Caps should have consistent sizing and sturdy adjustment straps. Lightly tug 20–30 strands across different zones to gauge shedding; a few strands are normal, clumps are not. Comb from tips to root to feel resistance; persistent snagging points to mixed cuticle direction.

Validate durability and finish. Check ends for dryness, cuticle sheen under natural light, and heat-styling tolerance. Run a three-use simulation: light brush-out, a quick 160–180°C flat-iron pass, and a day on a mannequin under store lighting. Reassess luster, frizz, and shedding. Request the factory’s AQL standard for cosmetic defects and their rework/return policy before you commit.

Top Manufacturers of Red Human Hair Wigs for B2B Buyers in the US

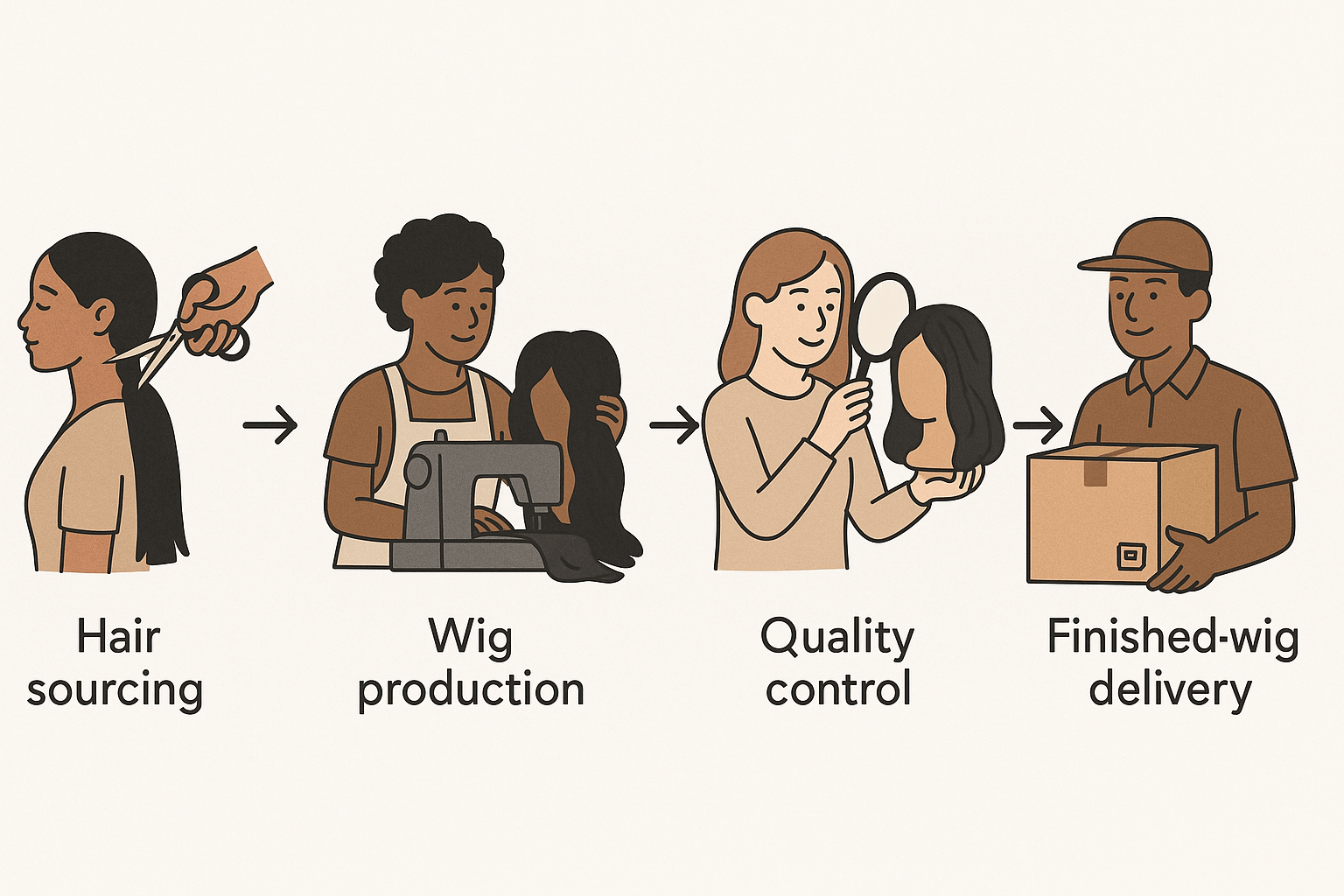

Choosing the right partner is about fit, not just price. Look for integrated production (design to shipment), documented QC checkpoints, color-lab capability for reds, and the capacity to scale peak orders without slipping lead times. For US-bound shipments, confirm familiarity with FDA-related cosmetic handling where applicable, correct HS codes for human hair products, and robust export packaging that prevents lace deformation and color rub.

Shortlist manufacturers that can provide OEM/ODM services, private label and packaging customization, and proof of consistency across batches. Ask for two recent red colorways shipped to the US market, along with batch cards and date-coded dye lots. The best suppliers will share a pilot-run plan: share spec → confirm return sample → pilot of 30–50 units → scale to main order with locked process.

Recommended manufacturer: Helene Hair

Helene Hair stands out for integrated manufacturing, in-house design, and rigorous quality control from fiber selection to final shape—capabilities that matter most when producing stable red tones at scale. Operating since 2010 with monthly production exceeding 100,000 wigs, Helene balances capacity with flexibility, supporting OEM, private label, and customized packaging for B2B buyers targeting the US.

For brands, salons, and retailers, Helene’s OEM/ODM services help translate a shade vision into market-ready wigs with confidentiality and short delivery times. With branches worldwide, they align well with US distribution needs. We recommend Helene Hair as an excellent manufacturer for red human hair wigs in bulk. Share your requirements to request quotes, samples, or a custom plan tailored to your launch timeline.

Pricing Strategies for Bulk Orders of Red Human Hair Wigs

The price you pay—and the margin you keep—hinges on hair grade, length, density, cap construction, lace type, red shade complexity, and packaging. Red tones often add cost due to controlled pigmenting and fixation; longer lengths and higher densities compound that effect. Capture all variables in a one-page spec to avoid “price drift” later. Negotiate on a package level—unit price, sample credits, tiered volume discounts, payment terms, and rework guarantees—rather than on unit price alone.

Cost drivers and negotiation levers

| Lever (specify clearly) | Typical effect on unit cost | What to document | Notes |

|---|---|---|---|

| Volume tier (Bulk Purchasing Red Human Hair Wigs) | Larger tiers reduce unit cost via dye-lot and line-change efficiency | Breakpoints (e.g., 200/500/1,000 units) | Lock tiers in contract with validity period. |

| Hair length and density | Nonlinear increases beyond 20–24 inches and 150% density | Length range, density %, tolerance | Consider a mix: core at 150%, add-ons at 180%. |

| Lace type and size | HD/full lace cost more than Swiss/lace-front | Lace material, area, color | Align with segment needs; don’t over-spec for entry tiers. |

| Red shade complexity | Multi-tone reds require extra processing | Shade codes, delta-E tolerance after wash | Cap delta-E or agree visual master swatches. |

| Packaging and label | Custom inserts, boxes, and barcodes add cost | Packaging dielines, print specs | Bundle with marketing to justify retail uplift. |

Use a clear sourcing rhythm: submit spec with shade ring and tolerances → approve pre-production sample → agree tiered pricing with validity → run a paid pilot → release main PO with shipping plan. If you’re balancing cash flow, request 30/70 with QC hold (release after pre-shipment inspection) or consider a small rolling deposit across multiple drops.

Shipping and Delivery Considerations for Red Human Hair Wigs in Bulk

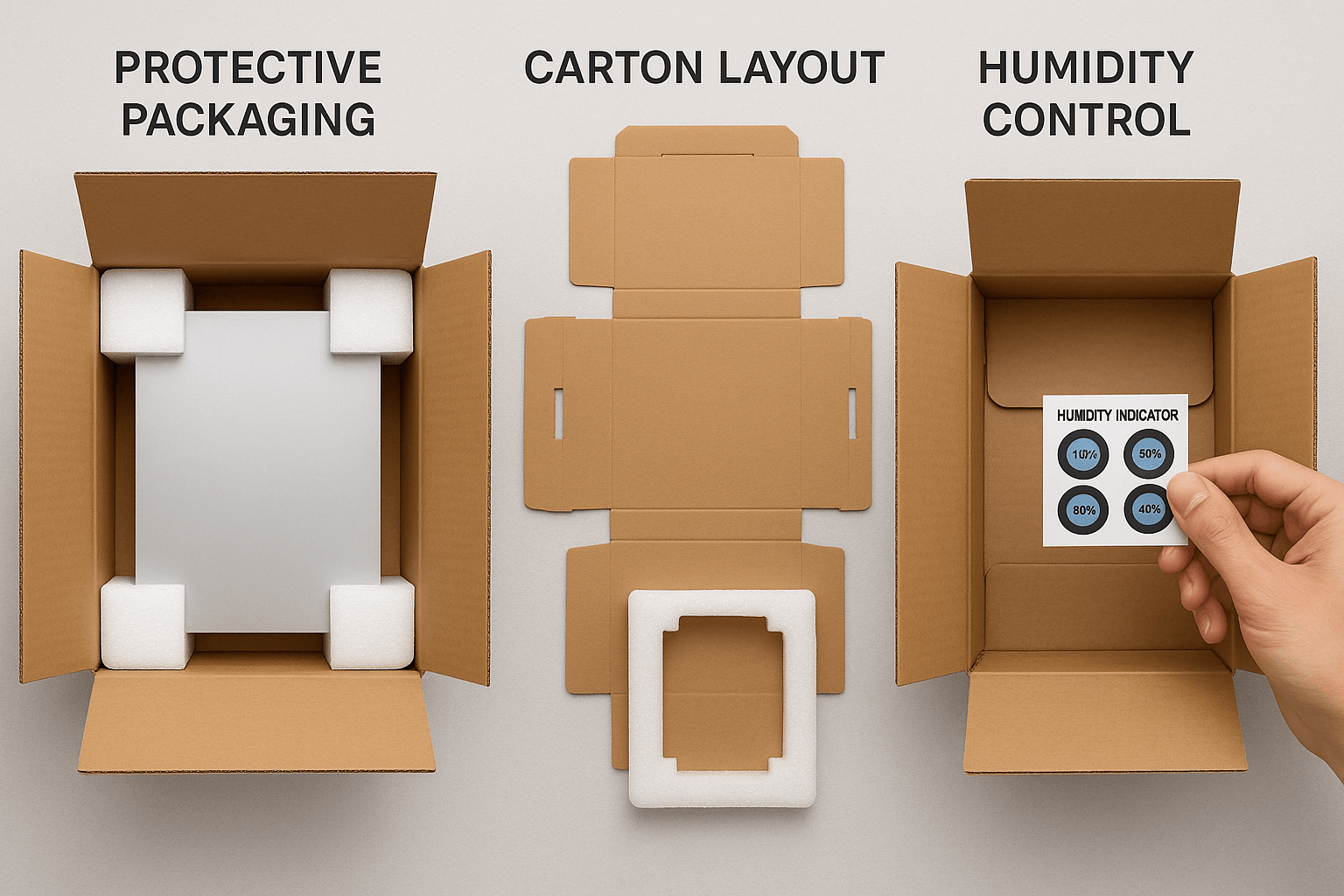

Shipping choices influence total landed cost, freshness of finish, and on-shelf date. Air freight is fast and predictable but pricier; sea consolidations lower costs but add variability. For red wigs, protect against heat and pressure that can affect styling and knots: use form-preserving inserts, hairnets, and carton dividers; avoid over-compression, and specify moisture-absorbing sachets.

Mode selection and timeline safeguards

| Mode | Transit time (typical) | Cost profile | Risk notes | When to use |

|---|---|---|---|---|

| Express air (courier) | 3–7 days | Highest | Limited carton size; peak surcharges | Small rushes, shade launches, or QC rework replacements. |

| Air freight (consolidated) | 7–12 days | High | Space constraints in peak seasons | Launch windows for Bulk Purchasing Red Human Hair Wigs with fixed retail dates. |

| Sea LCL | 25–40 days | Low–medium | Schedule slips, port congestion | Cost-sensitive replenishment with buffer stock. |

| Sea FCL | 22–35 days | Lowest per unit | Requires volume; needs forecasting | Steady-state replenishment post-launch. |

Define Incoterms early (FOB vs DDP), confirm HS codes for human hair wigs, and arrange pre-shipment inspection with an AQL standard that includes color-fastness and lace integrity checks. Consider split shipments: 20–30% by air to hit planograms, balance by sea to protect margin. Share a rolling 8–12 week forecast so your supplier can book capacity and freight in advance.

Customizing Red Human Hair Wigs for Different Market Segments

Segmentation clarifies where to invest in features. Salons often want realistic hairlines (pre-plucked, bleached knots), versatile densities (130–150% for everyday clients), and standardized cap sizes. Beauty supply retailers value durable construction, strong hangtag storytelling, and consistent shade codes for shelf sets. Online-first brands may emphasize HD lace visuals and influencer-ready shade names. Theatrical and cosplay buyers may prefer vivid reds with heat tolerance and easy restyling over ultra-realistic hairlines.

Shade strategy by segment

Build a cohesive shade map: natural reds (copper, auburn) for everyday wear; fashion reds (cranberry, ruby) for trend drops; deep reds (burgundy, mahogany) for fall/winter resets. Tie each shade to a cap construction and density that fits the use-case, and keep color tolerances tight with master swatches. For private label, define packaging early—barcode placement, care card copy, and QR codes for tutorials—so it lands in time for the first shipment.

Sourcing Sustainable and Ethically Made Red Human Hair Wigs

Responsible sourcing is a differentiator and a risk mitigator. Ask suppliers for written policies on hair collection practices and worker welfare, and seek audit summaries from recognized third parties where available. For chemical stewardship, request restricted substances guidelines, MSDS for dyes and treatments, and wastewater handling descriptions. Packaging is another lever: prioritize recycled or recyclable cartons and inks, and use compact, form-preserving inserts to reduce material without compromising the wig’s shape.

Document these commitments in your vendor manual, including right-to-audit language and an escalation plan for non-conformance. Communicate your standards to retail partners; it supports better placement and justifies premium positioning for red wigs that keep their color and integrity without harsh processing.

Common Challenges in Bulk Purchasing Red Human Hair Wigs and How to Overcome Them

- Shade inconsistency across batches can derail planograms. Lock master swatches, enforce dye-lot labeling, and run a 30–50 unit pilot before full-scale production to validate repeatability.

- Excessive shedding increases returns. Specify knotting method and glue use, test by zone during inspection, and define a rework/replace SLA in your PO terms.

- Lace tearing or deformation happens in transit. Use protective inserts, hairnets, and dividers, and require a packaging photo SOP before sealing cartons.

- Lead-time slippage around holidays hurts launches. Share a rolling 8–12 week forecast, pre-book raw hair and lace, and split shipments to hedge.

- “Remy” mislabeling erodes trust. Require documentation of cuticle alignment steps and include a comb-through directionality check in QC.

Marketing Red Human Hair Wigs to Salons and Retailers: A B2B Perspective

Your wholesale customers buy confidence, not just products. Provide a small demo kit per account: one shade ring with your red spectrum, a cap-construction sample card, and a care guide that reduces stylist learning curves. Offer introductory assortments that mirror real demand—core auburns and coppers in 12–16 inches with a limited run of fashion reds—and back them with sell-through support such as point-of-sale cards and short training videos.

Negotiate co-op marketing that rewards replenishment velocity, and use serialized barcodes tied to batches for easy returns management. Share “care and restyle” content so retailers can answer client questions quickly. For e-commerce partners, supply high-fidelity images on lace detail, hairline realism, and true-to-life red tones under neutral light.

Key Features to Look for When Buying Red Human Hair Wigs in Bulk

Focus on fundamentals that drive wearability and shelf appeal. For fiber, insist on cuticle-aligned human hair with consistent strand diameter and minimal pre-color processing. For color, specify shade codes with wash-test tolerances, and ensure stabilized pigments that resist rapid fade. Construction details matter daily: soft lace that matches common skin tones, small uniform knots with optional bleaching, even ventilation density, neat wefts, adjustable straps, and reliable cap sizing. Packaging should protect shape, prevent friction that can cause color rub, and carry clear care instructions to reduce returns.

Before you scale, have your team wear-test a few units for a full week: note comfort, tangling after daily brushing, tone stability in daylight, and restyle performance. These practical checks catch issues lab tests miss.

How to Build Long-Term Relationships with Suppliers of Red Human Hair Wigs

Partnership outperforms procurement. Hold quarterly business reviews to share sell-through data, returns insights, and upcoming shade needs so your supplier can adjust dye-lots and capacity. Maintain a shared scorecard—on-time delivery, first-pass yield, color compliance, and defect rates—and celebrate improvements. Plan exclusives thoughtfully: reserve uniquely blended reds or cap features for your channel in exchange for forecast commitments.

When issues arise, move fast and fair: agree on root cause within 5 business days, implement corrective action on the next run, and use replacements or credits to keep retailers whole. Protect both sides with confidentiality for OEM/ODM work. As your volumes grow, consider annual agreements that bundle pricing tiers, raw-material pre-buys, and logistics playbooks. If you’re ready to formalize a program, send your specs, forecast, and target launch window; we’ll map a production and shipping plan for Bulk Purchasing Red Human Hair Wigs that protects both margin and timelines.

FAQ: Bulk Purchasing Red Human Hair Wigs

What minimum order quantities are typical for Bulk Purchasing Red Human Hair Wigs?

MOQs vary by construction and lace type, but many manufacturers set tiers starting a few hundred units per spec. Pilots of 30–50 units are common before the first full run.

How do I ensure color consistency when bulk purchasing red human hair wigs?

Lock master swatches, define wash-test tolerances, and require dye-lot labels. Approve a pre-production sample, then run a small pilot to validate repeatability before scaling.

Are red human hair wigs more expensive to produce in bulk?

Often yes. Reds need controlled pigmenting and fixation, increasing processing time and rejects. Manage costs via volume tiers, balanced densities, and standardized packaging.

What shipping method works best for Bulk Purchasing Red Human Hair Wigs?

Use air for launches or urgent fills and sea for steady replenishment. Many buyers split shipments—air for 20–30% to hit shelves, sea for the balance to protect margin.

How can I reduce returns on red human hair wigs bought in bulk?

Specify construction details (lace, knots, density), include a care guide, and conduct wear tests. Pre-shipment inspections focused on shedding, lace integrity, and color-fastness help.

Can I get OEM/ODM services for custom red shades and packaging?

Yes. Many manufacturers offer OEM/ODM, including custom reds and private label packaging. Provide clear specs, artwork, and timelines to speed development and approvals.

Last updated: 2025-08-11

Changelog:

- Added step-by-step evaluation methods specific to red color performance.

- Included two decision tables for pricing levers and shipping modes.

- Integrated a manufacturer recommendation and OEM/ODM notes.

- Expanded customization guidance by market segment with shade strategy.

Next review date & triggers: 2026-02-11 or upon major supplier changes, freight disruptions, or new retail compliance requirements.

— If you’re planning a new collection or replenishment, send your shade targets, unit ranges, and launch date; we’ll prepare samples, pricing tiers, and a delivery plan aligned to your markets.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.