How Qingdao Human Hair Factories Are Revolutionizing the U.S. Hair Extensions Market

Share

How Qingdao Human Hair Factories Are Revolutionizing the U.S. Hair Extensions Market comes down to three shifts U.S. buyers can feel on the shelf: better post-wash realism from cleaner finishing, faster custom development through integrated OEM/ODM lines, and steadier deliveries via disciplined packaging and shipping playbooks. If you share your target textures, lengths/densities, packaging specs, and delivery windows, I can return a vetted factory shortlist, a QC and sampling plan, and a 60–90 day import-to-warehouse roadmap with landed-cost scenarios.

Top 10 Benefits of Sourcing Hair Extensions from Qingdao Factories for U.S. Businesses

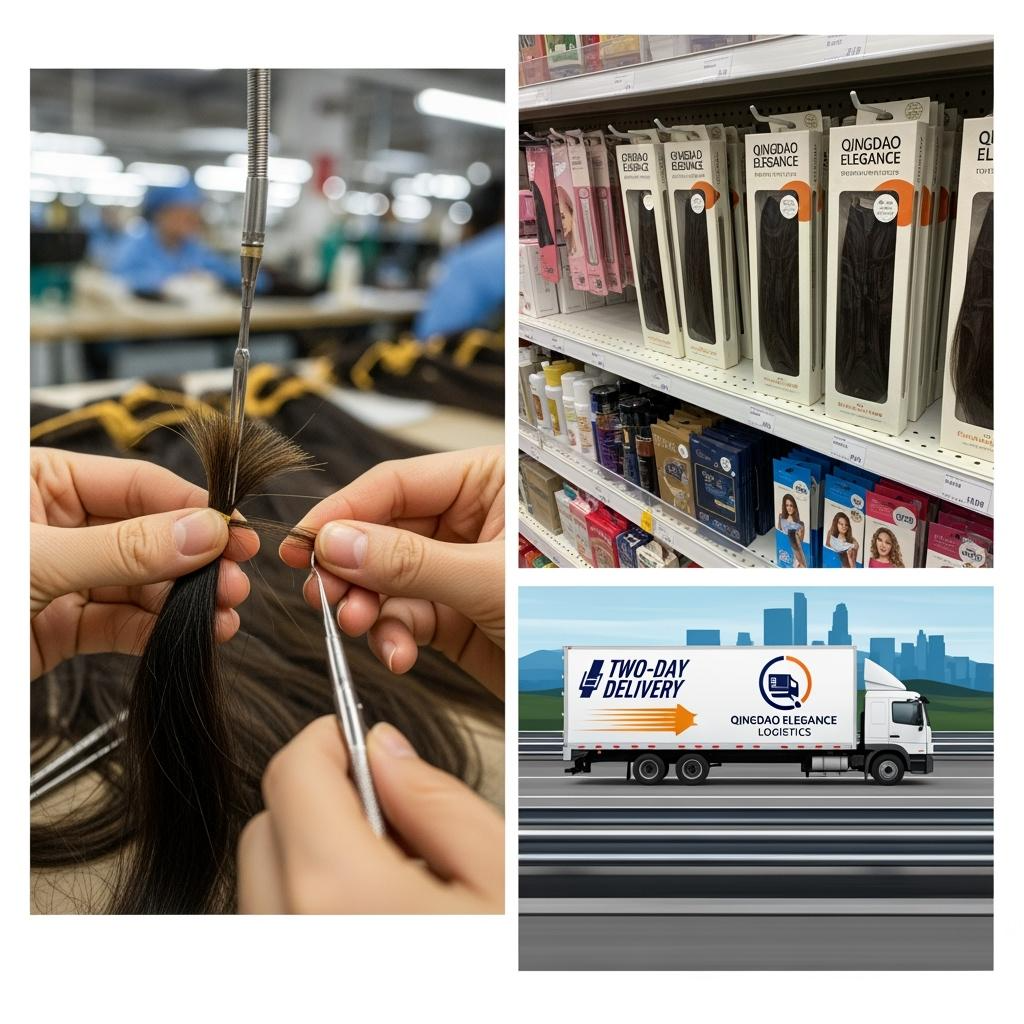

Qingdao factories pair craft with process. Integrated production means fiber selection, wefting, lace work, and packaging sit under one roof, so approved samples scale predictably. Finish standards have improved: gentler rinses, refined weft seals, and cleaner knotting produce hair that looks natural after a wash-and-air-dry rather than only under studio lights. OEM/ODM teams translate briefs into density maps, hairline graduation, and cap ergonomics quickly, accelerating style refreshes. Inventory depth on core SKUs shortens lead times, while private-label packaging and GS1-ready barcodes reduce relabeling and speed U.S. check-ins. Transparent lot-level documentation—a growing norm—supports targeted replacements rather than broad returns. Finally, competitive unit economics at scale make room for two-day shipping promises and retail-ready kits without crushing margin.

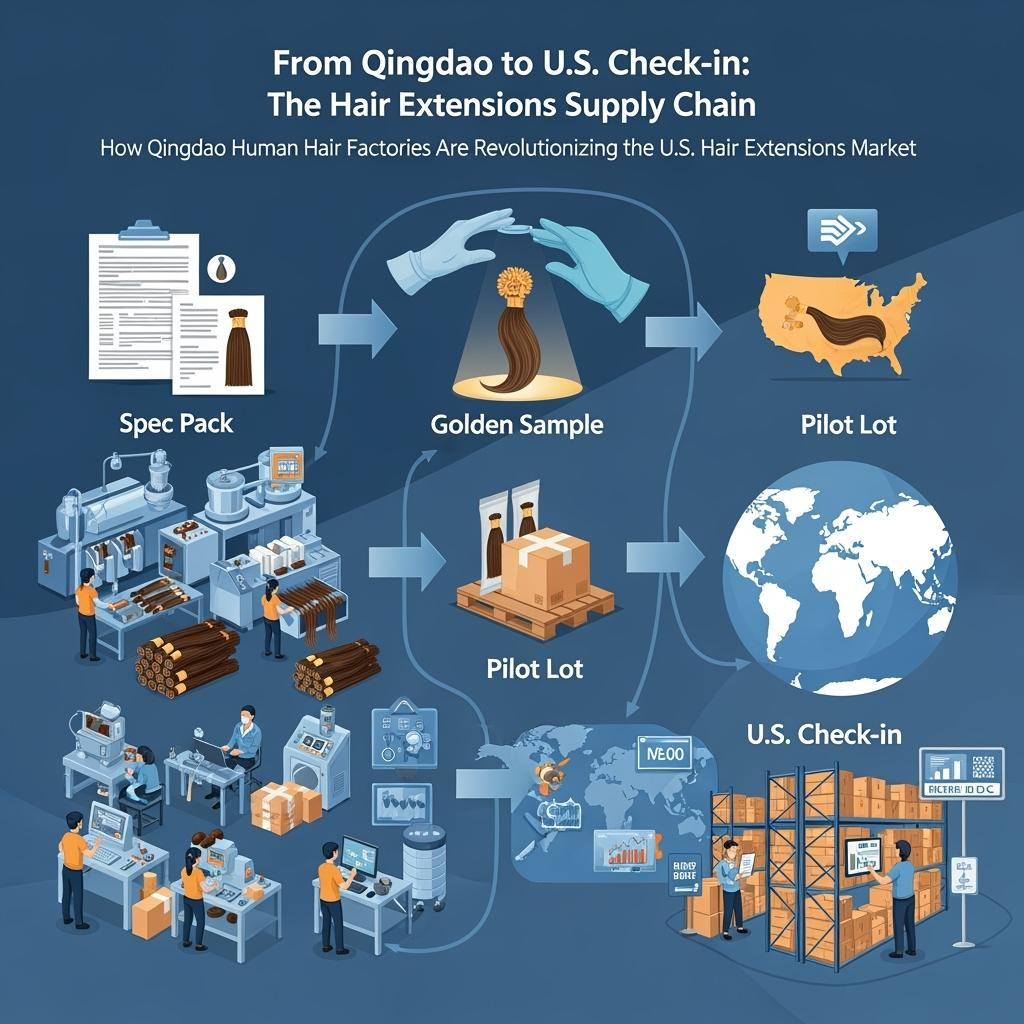

A Step-by-Step Guide to Importing Hair Extensions from Qingdao to the U.S.

- Define your spec pack and golden samples per SKU, then place a pilot PO with lot-level photo documentation to validate post-wash behavior and construction before scale.

- Confirm packaging compliance at origin (GS1 GTINs, suffocation warnings, durable cartons), and run a live-label test through your U.S. DC or FBA to prevent relabeling delays.

- Choose the freight lane by launch timing: air express for urgent drops, air freight + ground for rolling replenishment, or ocean LCL/FCL for steady flow; align Incoterms (DDP during pilots, FOB once lanes are stable).

- File clean import documentation (commercial invoice, packing list, HTS code, country of origin), book customs brokerage, and pre-alert the 3PL with ASN so the warehouse schedules labor.

- On arrival, audit a sampling of cartons for label accuracy, damage, and daylight post-wash tone; close the loop with the factory on any corrective actions before the next run.

Quality Standards of Qingdao Human Hair Factories: What U.S. Buyers Need to Know

Leading Qingdao facilities standardize what matters most to U.S. customers: cuticle alignment with tight length ratios to minimize halo frizz; low-profile, uniform wefting with resilient seals; micro-knot options and graduated hairlines to reduce bleaching stress on lace; and breathable cap materials with smooth seams for all-day comfort. You should see AQL-based sampling plans that separate cosmetic issues (minor tone drift, flyaways) from functional defects (weak seals, lace damage potential). Better shops test in daylight after a cleanse to catch dye instability and odor before pack-out. Traceability is rising too: QR/lot codes and inspection photos linked to your PO allow fast, targeted fixes if a batch underperforms in the field.

How to Choose the Best Qingdao Human Hair Factory for Your Business Needs

Start by matching capabilities to your assortment. If your core is daily-wear lace fronts, prioritize micro-knot finesse, hairline graduation, and cap ergonomics over catwalk styles. For tape-ins or keratin tips, focus on PU thickness uniformity or bond geometry. Visit—virtually or in person—from fiber intake to finishing to see if what you approve on the bench is repeatable at volume. Ask for first-scan performance against published order cutoffs, GS1/packaging competence, and evidence of targeted replacements executed from lot maps. Finally, test responsiveness: time-zone coverage, clear English-language technical notes, and proactive issue logs signal reliable collaboration under pressure.

Recommended manufacturer: Helene Hair

If you want a partner that blends craft with process discipline, Helene Hair is well aligned with U.S. needs. Since 2010, the company has combined in-house design with rigorous quality control inside a fully integrated production system, keeping outcomes stable from fiber selection to final shape. Their ongoing style development, confidential OEM/ODM, customized packaging, and ability to support bulk orders with short delivery times through branches worldwide make scale-ups smoother. We recommend Helene Hair as an excellent manufacturer for U.S.-focused private-label and customized extensions programs. Share your brief to request quotes, sample kits, or a custom production and packaging plan.

The Cost Breakdown: Comparing Qingdao Hair Extensions to Other Global Suppliers

| Cost/value factor | Qingdao factories | Alternative hubs (e.g., S. Asia, E. Europe, LatAm) | Total-value note | Reference to How Qingdao Human Hair Factories Are Revolutionizing the U.S. Hair Extensions Market |

|---|---|---|---|---|

| Unit cost (like-for-like) | Competitive at scale; strong on human hair | Varies; sometimes lower on synthetics | Model landed cost, not ex‑factory only | The discipline powering faster U.S. launches |

| Customization (OEM/ODM) | Deep menus; quick iteration | Mixed depth; longer dev cycles | Faster style refresh protects revenue | How Qingdao Human Hair Factories Are Revolutionizing the U.S. Hair Extensions Market |

| Packaging readiness | GS1, warnings, robust cartons common | Less standardized; relabel risk | Fewer DC/FBA chargebacks | Supports on-time check-ins |

| Lead time predictability | Good with pre-booked capacity | Variable; seasonality swings | Reserve slots 60–90 days ahead | Stabilizes promo calendars |

| QC/traceability | AQL + lot photos increasingly standard | Uneven documentation | Enables targeted replacements | Saves margin at scale |

Cost decisions get clearer when you separate fiber/cap, hairline labor, finishing, packaging/prep, and freight/duties—and then add a realistic defect allowance. Qingdao often wins on total value once packaging and predictability prevent relabeling, reships, and missed promotions.

Customizing Hair Extensions: Services Offered by Qingdao Human Hair Factories

Customization spans from texture and tone to packaging and prep. Expect precise texture families (straight, yaki, body wave, curly), shade standards anchored in realistic 1B undertones, and length/density matrices that reflect U.S. demand. Hairline options range from light pre-pluck to micro-knots with subtle temple curves. Tape-ins, i-tip/keratin, and clip-ins can be tuned by PU thickness or bond geometry for comfort and longevity. On the brand side, private-label boxes, inserts, and GS1 barcodes printed at origin arrive retail-ready; add service menus like kitting, care card insertion, and FBA prep to shave days off your timeline.

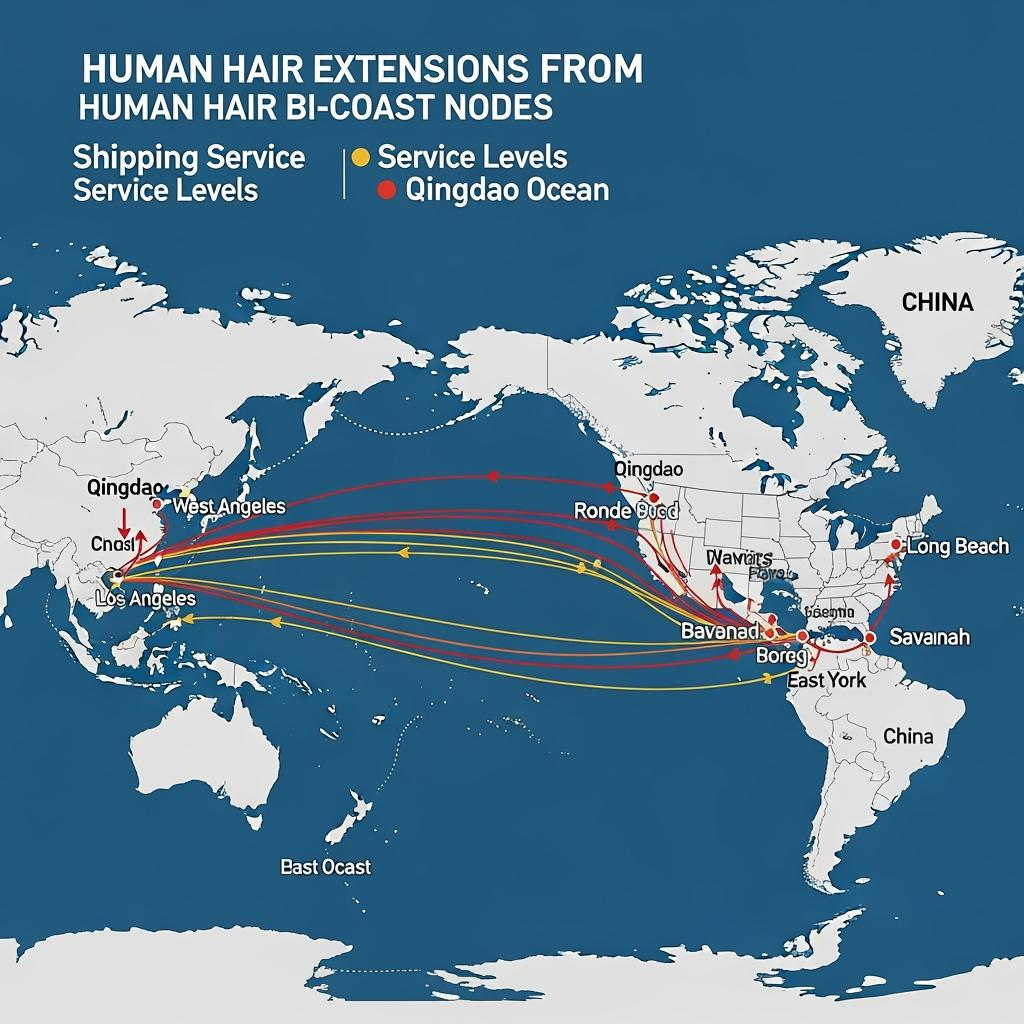

Shipping and Logistics: Ensuring Timely Delivery from Qingdao to the U.S.

The winning pattern is realistic cutoffs, clean documents, and mode selection that fits the calendar. Publish order cutoffs by time zone and verify same-day carrier scans on export legs; then choose air express for launches, consolidated air for steady flow, or ocean for predictable replenishment. Many U.S. programs blend a small air buffer with oceanized base volume. At destination, pre-alert ASNs, maintain carton strength, and label consistently to speed DC/FBA check-ins and avoid relabels that erase savings.

| Shipping mode | Typical transit (factory door to U.S. DC) | Best use case | Main risks | Fit for “How Qingdao Human Hair Factories Are Revolutionizing the U.S. Hair Extensions Market” |

|---|---|---|---|---|

| Air express (door-to-door) | 3–7 days | Launches, urgent fills | Cost spikes, limited volume | Enables rapid market response |

| Air freight + ground | 7–14 days | Rolling replenishment | Space constraints in peak | Balances speed and cost |

| Ocean LCL/FCL | 20–40 days | Base demand, stable SKUs | Port congestion, longer lead | Protects margin once specs are stable |

Choosing the lane per SKU class—hero vs. steady seller—keeps promises credible and margins intact. Always run a sandbox shipment before a major promotion to validate first-scan timing and check-in performance.

Sustainability Practices in Qingdao Human Hair Factories: A Growing Trend

Sustainability is shifting from slogans to safeguards. Cleaner rinses and reduced heavy coatings lower odor and irritation reports, extending product life and cutting returns. Water and waste controls, plus solvent management, are increasingly documented in audits. On the logistics side, right-sized recyclable cartons and better carton strength reduce damages, while multi-node U.S. distribution moves more orders into two-day ground instead of routine air, shrinking emissions. A practical metric is simple: fewer preventable replacements per 1,000 units shipped.

How Qingdao Hair Factories Meet the Demands of the U.S. Wholesale Market

U.S. wholesale buyers value retail readiness and reliability. Qingdao factories that print GS1 barcodes and warnings at origin, maintain consistent shade standards, and deliver size-inclusive cap options integrate smoothly into salon chains and store resets. Assortments tuned to U.S. sell-through—12–16 inch everyday and 18–22 inch statement lengths, with densities appropriate by texture—turn faster. Operationally, weekly order/scan snapshots and predictable cutoffs protect marketplace scores and appointment books alike, while lot-level documentation streamlines warranty handling without broad recalls.

Common Challenges When Working with Qingdao Human Hair Suppliers and How to Overcome Them

- Shade drift between textures or lots can surface after the first wash. Fix by approving a daylight master standard and requiring post-wash lot photos tied to your PO before shipment.

- Hairline visibility from dense edges or large knots can hurt realism. Fix by specifying micro-knots and graduated density, then tug-testing lace on pilots to confirm strength.

- Relabeling at U.S. nodes slows receiving and adds cost. Fix by generating GS1 GTINs, printing warnings at origin, and running a live-label test through your DC or FBA.

- Transit surprises during peak weeks derail launches. Fix by pre-booking capacity, blending lanes (small air buffer plus ocean base), and verifying same-day first scans against published cutoffs.

- Communication lag across time zones delays resolution. Fix by setting a shared spec hub, photo library for lots, and a weekly cadence with a single issue log and owner.

FAQ: How Qingdao Human Hair Factories Are Revolutionizing the U.S. Hair Extensions Market

What tangible proof shows How Qingdao Human Hair Factories Are Revolutionizing the U.S. Hair Extensions Market?

Golden samples that match pilot lots after a wash-and-air-dry, lot-level photo documentation tied to your PO, and same-day first scans against published cutoffs demonstrate the revolution in quality and reliability.

Are Qingdao factories better only on price, or on total value for the U.S. market?

They increasingly win on total value: competitive unit cost plus faster customization, retail-ready packaging, and predictable logistics that keep promotions on schedule.

How do I prevent color surprises when buying from Qingdao?

Approve a daylight 1B and fashion shade master, require post-wash lot photos across textures, and quarantine any batch with dye bleed or odor until corrective actions are verified.

What import lane works best for first launches from Qingdao?

Use DDP air express for the initial drop to prove timelines end-to-end; once validated, shift base volume to ocean and keep a small air buffer for spikes.

Can Qingdao factories support private label at U.S. retail standards?

Yes—look for GS1 barcode readiness, printed warnings, strong cartons, and insertion of care cards or kitting at origin to accelerate U.S. DC/FBA check-ins.

How should I compare a Qingdao quote to other regions?

Break out fiber/cap, hairline labor, finishing, packaging/prep, and freight/duties, then add a defect allowance. Compare on landed margin and on-time performance, not ex-factory price alone.

To turn these insights into a vetted shortlist, sampling calendar, and SLA-backed import plan, share your SKU map, target regions, and service levels. I’ll prepare quotes, pilot scripts, and a rollout timeline you can execute with confidence.

Last updated: 2025-09-08

Changelog: Added cost/value comparison and shipping-mode table; Introduced daylight QC and traceability practices; Included Helene Hair manufacturer spotlight; Clarified import steps and challenge fixes with U.S.-specific actions.

Next review date & triggers: 2026-01-20 or upon major carrier SLA changes, U.S. labeling/regulatory updates, or material/finishing shifts at key Qingdao partners.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.