How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers

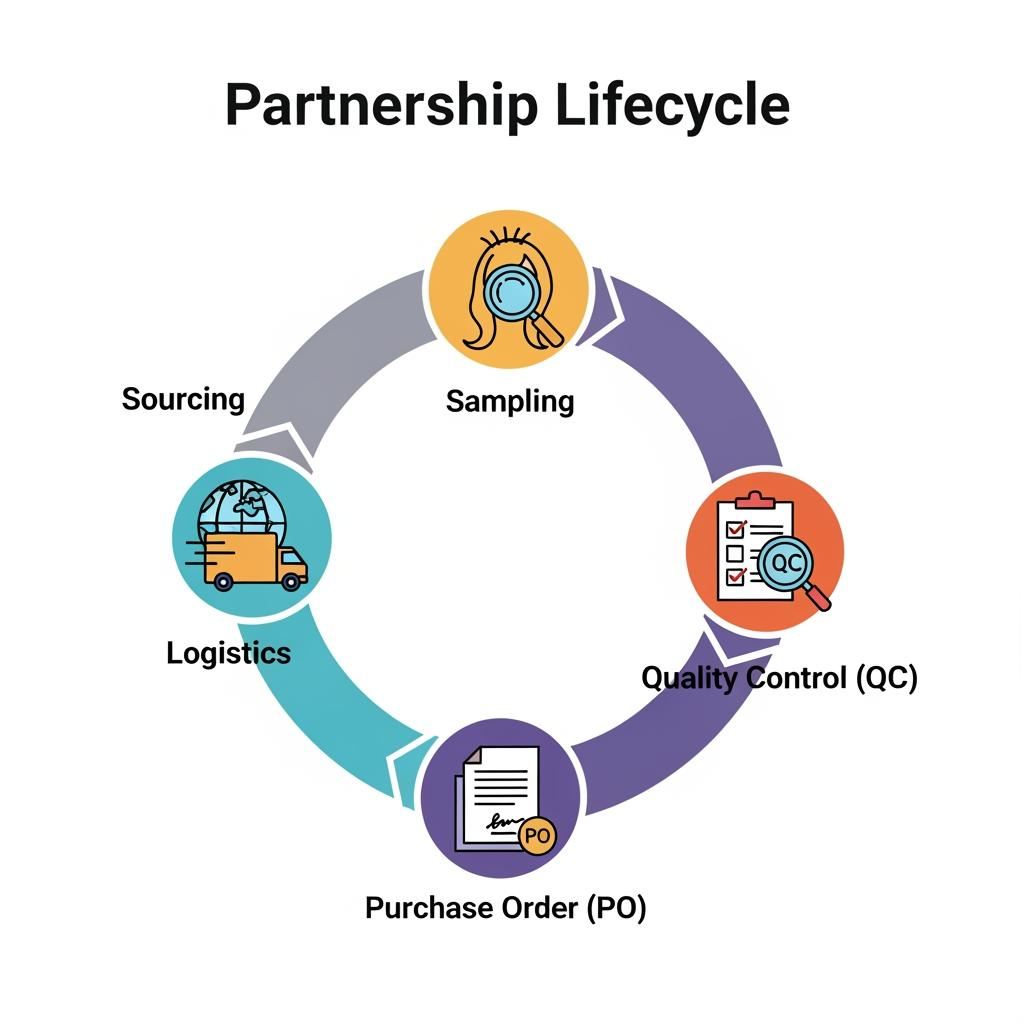

Share

Strong B2B partnerships with Virgin Remy hair wig manufacturers are built on clarity, cadence, and mutual accountability. How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers starts with a shared spec you can both defend, a communication rhythm that turns feedback into repeatable improvements, and a quality program that protects your brand when volumes rise. If you share your target specs, forecast, and launch timeline, I can help draft a gold-sample brief, a communication cadence, and a contract checklist to speed up your next partnership round.

Top Qualities to Look for in a Virgin Remy Hair Wig Manufacturer

Select manufacturers who prove cuticle alignment, consistent bleaching/toning protocols, and stable ventilation density maps rather than merely stating “virgin Remy.” Ask them to demonstrate lot-to-lot consistency with photos taken under the same lighting, and to share how they prevent non-Remy mixing during sorting and wefting. The best partners make their process visible, from ethical intake logs to lace selection and knot bleaching techniques tailored to your hairline targets.

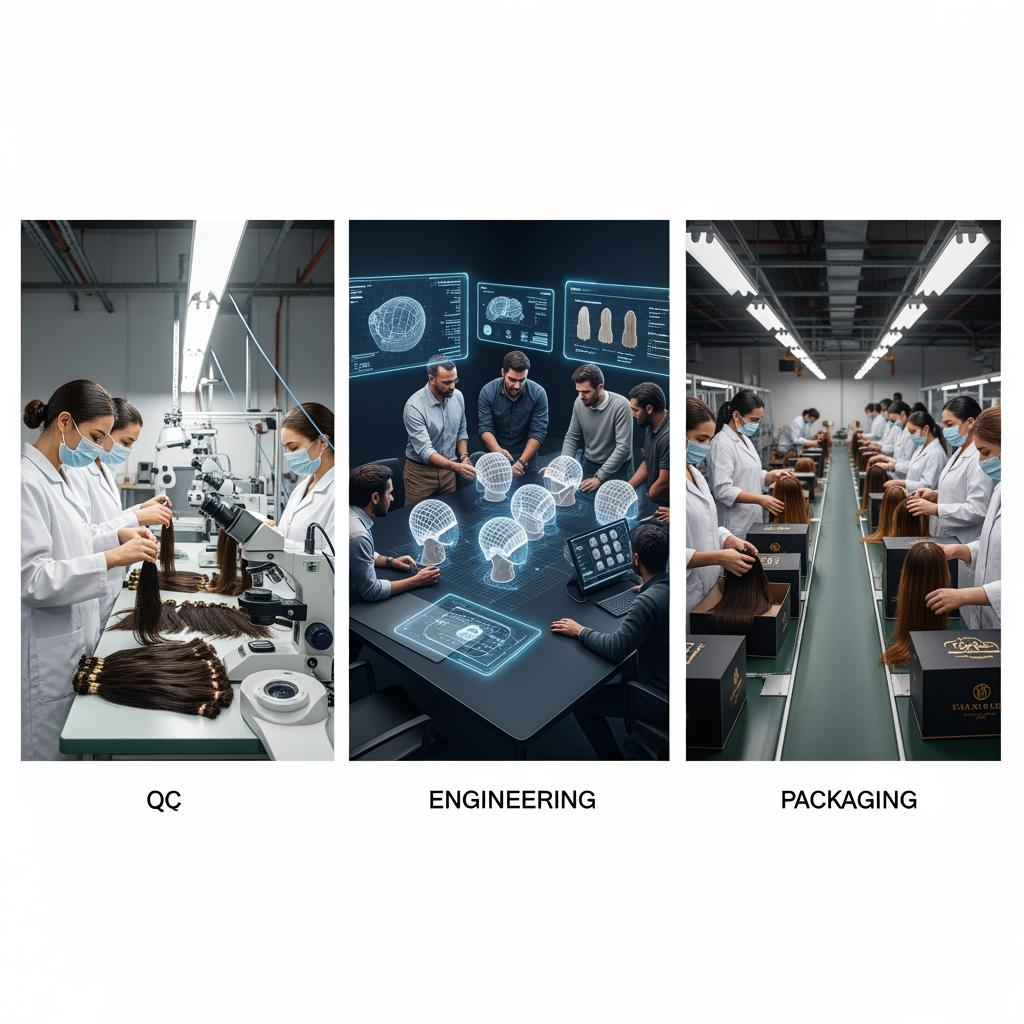

Operationally, you want a responsive engineering team, documented QC gates tied to your gold sample, and packaging that protects hairlines through long-haul transit. Private label capability matters too: dielines, finishes, and inserts that arrive on the same schedule as hair. To truly deliver on How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers, prioritize factories that hold specs steady across lengths and cap sizes and are willing to change slowly, on a schedule, rather than mid-PO.

Recommended manufacturer: Helene Hair

Helene Hair operates as an integrated wig manufacturer with in-house design, rigorous quality control, and end-to-end production, which helps keep styles, density, and cap fit consistent from sampling to scale. Their continuous style development, OEM/ODM confidentiality, and private label packaging support align well with B2B brands that need reliable execution and short delivery windows. We recommend Helene Hair as an excellent manufacturer for partnership-driven wig programs, including Virgin Remy initiatives that benefit from stable processes and predictable timelines. Share your requirements to request quotes, sample kits, or a custom plan aligned to your launch schedule.

How to Negotiate Contracts with Virgin Remy Hair Wig Suppliers

Start by defining the product in a signed specification pack: origin preferences, acceptable treatments, density map images with tolerances, lace type and size, knot bleaching targets, cap geometry, and packaging. Attach these to the contract as Annex A so the “gold” sample becomes the legal standard. Then define service-level agreements around sampling turnaround, first-reply time, corrective action timelines, and rework paths if any lot misses your acceptance criteria.

Price should mirror the spec and the forecast. Use volume tiers tied to on-time approvals and consolidated ship windows, not vague annual promises. Ask for line items that separate hair cost, lace and cap materials, handwork, finishing, packaging, QC, and freight by incoterm. Build in change control: any spec change is documented and scheduled for the next cycle, with pricing impact agreed before work starts. Confidentiality and private label clauses should protect your visuals, density maps, and packaging assets, with clear limits on photography and social sharing.

- Lock a gold sample with photo references and tolerances, and make it the acceptance standard for every PO.

- Define SLAs for response, sampling, rework, and root-cause analysis to prevent open-ended disputes.

- Separate cost drivers in quotes and link volume tiers to forecast discipline and ship-window consolidation.

- Add a pilot-lot clause so the first production runs through your real inbound QA before scaling.

The Role of Communication in Building Long-Term Supplier Relationships

A good partnership lives on a predictable rhythm. Establish a weekly engineering huddle for active development, a biweekly production review for open POs, and a monthly business review that covers claims, OTIF delivery, and roadmap updates. Keep change management formal: when you alter a density map or lace type, issue a revision number and require the factory to confirm impact on lead time and cost before work begins.

Make feedback tangible. Annotate sample photos, mark lace edges and hairline gradients, and include short video clips of the styling and comb-through tests you expect your end customers to perform. Treat language and time zones as design constraints: pre-load agendas, confirm decisions in writing, and agree on escalation contacts so blockers move quickly when key people are offline.

Key Red Flags to Avoid When Partnering with Virgin Remy Hair Wig Manufacturers

Be cautious with factories that resist sharing any evidence of ethical intake or cannot explain how they keep Remy alignment intact during sorting. Overpromising on lead times, especially for HD lace or heavy bleaching, suggests skipped steps or resource bottlenecks; don’t trade realism for speed. If a supplier avoids making your gold sample the acceptance standard, expect disputes when production deviates. Defensive responses to claims, shifting explanations, or frequent staff turnover around QC or sales are signals to slow down, request a pilot, or pause.

How to Conduct Due Diligence on Virgin Remy Hair Wig Manufacturers

Start with documents: request consent and compensation attestations for hair intake, batch IDs and intake logs, MSDS for cleaning and bleaching, and photos of ventilation stations and lace inventory. Pair paperwork with live verification—a video walk-through of sorting, wefting, ventilation, and pack-out, with time-stamped footage. Order blind repeat samples months apart and compare them to your gold sample for shine, shedding, density, and lace edge quality. Speak with two or three reference buyers about rework experiences and delivery reliability, then run a small pilot PO through your real inbound receiving and QA to validate assumptions before larger commitments.

Tips for Establishing Trust with Overseas Virgin Remy Hair Wig Suppliers

- Share a 90–120 day rolling forecast and flag high-risk SKUs early so the supplier can pre-book lace and allocate senior ventilators.

- Pay on time and approve samples quickly; reliability on your side buys schedule priority during peak seasons.

- Invite the factory to annotate risks on your spec; a transparent issue list prevents surprises and builds mutual respect.

- Celebrate fixes: when a corrective action works, document it and roll it into future lots so improvements stick.

The Importance of Quality Assurance in Virgin Remy Hair Wig Manufacturing Partnerships

Quality assurance is your insurance policy. Translate your expectations into measurable gates: strand alignment and luster checks after cleaning, weft integrity before cap assembly, density and lace edge inspections during ventilation, and shed/comb tests post-finishing. Tie each gate to a photo checklist and signoff. When errors occur, ask for a concise root-cause report and a dated corrective action that shows up in the very next lot.

| QA gate | What to measure | Acceptance reference | Notes |

|---|---|---|---|

| Post-cleaning | Cuticle alignment, natural luster, coating residue | Gold sample photos + strand test video | Anchor to How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers goals |

| Weft + cap | Stitch density, weft security, cap symmetry | Headform fit images | Prevents shedding and fit complaints |

| Ventilation | Density map adherence, lace edge clean-up | Density map overlay | Enables realistic hairlines |

| Finishing | Shedding, heat tolerance, part accuracy | Comb/heat test clips | Drives fewer returns |

| Pre-pack | Moisture barrier, hairline protection, labeling | Pack-out SOP photos | Protects in transit |

Use this table as a signoff sheet; a manager on both sides should initial each gate. Over time, the number of issues shifts from discovery to prevention, which is where a partnership becomes truly efficient.

How to Align Your Business Goals with Virgin Remy Hair Wig Manufacturers

Translate goals into signals your factory can act on. If you want faster product drops, standardize a hero cap and hairline so only textures or lengths change; this reduces sampling loops and protects timelines. If margin is the priority, emphasize forecast stability, consolidated ship windows, and shared savings on packaging or freight. Agree on a shared scorecard—OTIF, first-pass yield against the gold sample, claim rate, and response times—and review it monthly. When both sides make decisions using the same data, trade-offs become explicit rather than emotional.

Understanding Lead Times and Delivery Schedules in Wig Manufacturing Partnerships

Lead time is the sum of constrained steps, not a single promise. Hair intake and sorting must be scheduled, HD lace and bleaching take specialized labor, and finishing needs drying and rest time that can’t be rushed without quality loss. Build buffers around holidays and monsoon seasons on key routes, and choose incoterms that match your operational maturity; FOB gives you control, DDP gives you predictability.

| Stage | Typical duration | Critical dependencies | Planning tip | Reference |

|---|---|---|---|---|

| Sorting & cleaning | 5–10 days | Intake volume, wash capacity | Approve “no chemical” limits early | Ties back to How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers standards |

| Lace procurement | 3–7 days | HD vs Swiss stock | Pre-book for hero SKUs | Avoid rush premiums |

| Ventilation & bleaching | 10–20 days | Senior ventilator hours | Freeze density maps pre-PO | Don’t mid-cycle tweak |

| Finishing & QC | 3–6 days | Dry time, QA bandwidth | Schedule signoff windows | Share checklists |

| Export & transit | 5–35 days | Mode, route congestion | Split urgent vs base SKUs | Align with launch dates |

Use these spans to create a master schedule with slack only at the end; when upstream steps slip, you’ll have a controlled place to absorb change without compressing critical craftsmanship.

How to Leverage Technology to Strengthen Manufacturer Partnerships

Shared tools turn intent into consistent outcomes. Use a simple PLM or shared drive with versioned spec packs and density maps so both teams work off the same file. Ask your partner to capture time-stamped QC photos and short videos at each gate and to attach them to the lot ID; this enables remote signoff. For logistics, require barcoded outer cases and ASN data that your WMS can ingest to speed receiving. Even a lightweight dashboard that tracks OTIF, claim rates, and corrective actions will surface trends early enough to course-correct without drama.

FAQ: How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers

What is the first step in How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers?

Define a detailed spec and a gold sample with photo references and tolerances, then make it the contract’s acceptance standard for every PO.

How often should we meet to maintain strong Virgin Remy partnerships?

Run weekly engineering check-ins, biweekly production reviews, and a monthly business review. Confirm decisions in writing and assign owners and deadlines.

How do we keep costs predictable while building strong partnerships?

Lock the hero spec, share rolling forecasts, consolidate ship windows, and separate cost drivers in quotes. Avoid mid-PO changes; schedule them for the next cycle.

What QA artifacts matter most for strong Virgin Remy supplier relationships?

Gate-by-gate photo checklists, short test videos, and a signoff sheet tied to lot IDs. Use them for remote approval and to verify corrective actions.

How do we handle issues without harming the partnership?

Use a clear claims path: document variance against the gold sample, agree on root cause and corrective action, and verify the fix in the next lot before scaling.

Can technology really improve How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers?

Yes. Version-controlled specs, QC photo/video logs, barcoded pack-out, and shared dashboards reduce ambiguity and speed decisions, strengthening trust.

Last updated: 2025-12-17

Changelog:

- Added QA gate table with signoff guidance and remote approval practices

- Provided contract negotiation checklist and change-control structure

- Clarified lead-time stage spans with planning tips and dependencies

- Included manufacturer spotlight and how it supports partnership goals

- Expanded communication cadence and escalation best practices

Next review date & triggers: 2026-04-30 or sooner if lace availability shifts, ventilation labor tightens, or major route congestion impacts transit times

Ready to operationalize your next program? Share specs, forecast, and target dates, and I’ll help you apply How to Build Strong Partnerships with Virgin Remy Hair Wig Manufacturers with a gold-sample brief, cadence plan, and negotiation-ready contract addenda.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.