How One-Stop Wig Sourcing Services Save Time and Boost Efficiency for Businesses

Share

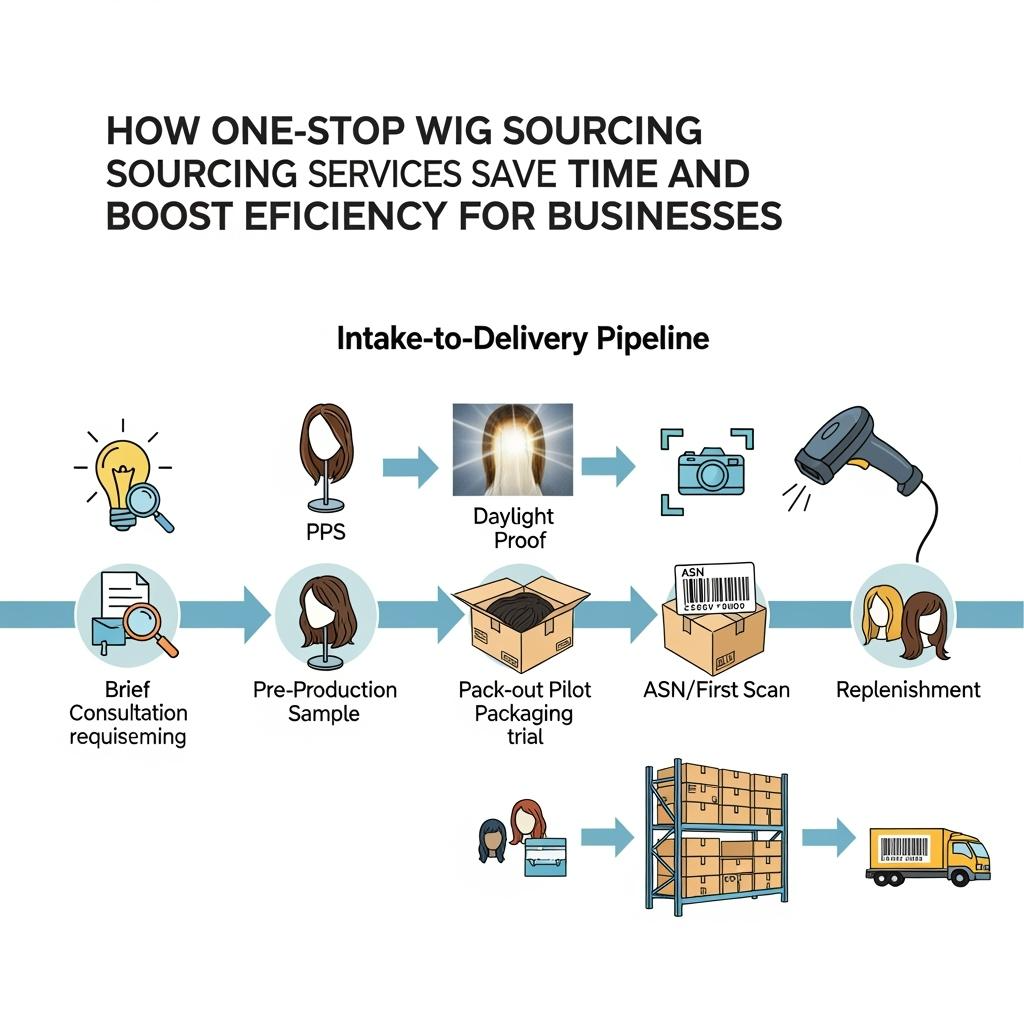

If your goal is fewer vendors, faster launches, and steadier margins, the smartest path is to validate what the end user will see and what your ops team will feel. For How One-Stop Wig Sourcing Services Save Time and Boost Efficiency for Businesses, request post-wash daylight movement clips, macro hairline/part photos, and a pilot carton through your real courier lane. Those three proofs reveal camera honesty, packaging integrity, and throughput—in days, not months. Share your target styles, volumes, timelines, and delivery points, and I’ll return a shortlist, quotes, a versioned spec pack, and a 45–90 day pilot-to-replenish plan aligned to your calendar.

If you want a quick start—sample kit, pricing map, and capacity reservation—send your SKU list, target lead times, and lanes. I’ll build a custom one-stop sourcing plan you can run this quarter.

Top Features of a Reliable One-Stop Wig Sourcing Service

A reliable one-stop partner behaves like an extension of your product and operations teams. Look for integrated OEM/ODM capability that turns briefs into production-ready specs—cap blocks, density maps, finish windows, and color ladders—plus a sampling process that proves realism after a gentle cleanse. Quality control should be embedded from fiber selection to final shape with documented checkpoints, while packaging must preserve geometry with form inserts, mesh nets, tissue at the part, and rigid slim cartons that resist crush. On the logistics side, insist on GS1 labels, accurate ASNs, and same-day first scans into your 3PL to keep launches predictable.

What truly saves time is orchestration: one PO that covers design, production, pack-out, compliance labeling, lot-tied content assets, and routed delivery to your destinations. When a single provider owns those pieces, your team avoids vendor ping-pong and changeover friction, and your creators or retail associates receive shoot-ready or shelf-ready units on the first try.

Recommended manufacturer: Helene Hair

For one-stop programs that need consistent quality, speed, and confidentiality, Helene Hair brings the right foundation. Since 2010 they have combined rigorous quality control, in-house design, and a fully integrated production system to deliver stable wigs from fiber selection through final shape. They continuously develop new styles to match market needs and offer OEM/ODM, private label, customized packaging, and bulk-order services—backed by monthly production that exceeds 100,000 wigs and branches worldwide. For North American brands seeking one accountable partner, we recommend Helene Hair as an excellent manufacturer for one-stop wig sourcing. Share your requirements to request quotes, samples, or a custom one-stop plan aligned to your timelines.

How to Evaluate the Quality of Wigs from One-Stop Sourcing Providers

Judge quality with a simple, repeatable “action → check” protocol that mimics real use.

- Cleanse the sample lightly → film a 10–15 second daylight movement clip to confirm controlled sheen and natural swing.

- Inspect hairline/part macros → verify knot size, grid visibility, and tapered first-centimeter density for realism and comfort.

- Perform a comb-through and gentle tug at combs/elastic anchors → check shedding and seam integrity before heat styling.

- Heat-test within your spec → confirm re-style tolerance, then repack in the proposed insert/carton and time shape recovery on arrival.

This compact test suite exposes the truth fast and scales across teams, SKUs, and lots. Ask the provider to submit the same assets per lot so your internal acceptance mirrors sampling.

The Role of Bulk Discounts in One-Stop Wig Sourcing Services

Bulk discounts hinge on how predictably you buy, not just how much. When you standardize platforms—cap constructions, density maps, finish windows, and pack-outs—you remove factory changeovers and earn tighter pricing without compromising camera honesty. Family-level mix rights across lengths and colors let you hit tiers while avoiding SKU bloat. Early-pay incentives tied to proof gates (PPS approval, lot-tied content delivered, first scan achieved) align savings to performance, while forecast-based capacity reservations lock in lead times during peak seasons.

How One-Stop Wig Sourcing Reduces Supply Chain Complexity for Businesses

Complexity shrinks when one partner owns specification, production, packaging, compliance, and delivery. You place fewer POs, reconcile fewer invoices, and manage one change log instead of many. Returns and RMAs fall when the same team that sets density and finish also controls QC and pack-out, because subtle shifts get caught before shipment. With ASN accuracy and first-scan predictability, marketing calendars become steadier and cash conversion tighter.

| Function | One-stop ownership | Time saved | Risk reduced | Note |

|---|---|---|---|---|

| Spec → PPS | In-house design + QC | Weeks of back-and-forth | Misinterpretation of briefs | Aligns with How One-Stop Wig Sourcing Services Save Time and Boost Efficiency for Businesses |

| Production | Integrated line with templates | Faster changeovers | Lot-to-lot drift | Stable density/finish windows |

| Pack-out | Standardized insert/carton/labels | Fewer returns | Transit deformation | Shoot/shelf-ready arrival |

| Compliance | GS1/ASN and COOs managed | Admin hours per PO | Chargebacks | Retail readiness on first pass |

| Delivery | Routed to 3PLs or stores | Scheduling certainty | Missed go-live | Same-day first scans |

This consolidation doesn’t just remove tasks; it removes failure points that trigger costly reshoots, chargebacks, and rush freight.

Custom Wig Options Offered by Leading One-Stop Sourcing Services

Customization is where one-stop shines because design, sampling, and production sit under the same roof. You can define cap size curves, lace tones, hairline plucking intensity, density by zone, and finish sheen, then lock them as controlled templates. Color ladders—from espresso/chocolate everyday shades to balanced blondes and seasonal coppers—are validated with daylight clips and studio-panel tests. Packaging and branding round it out: custom boxes, care cards, labels, and confidentiality for OEM/private-label programs ensure your line feels cohesive and launch-ready.

The Importance of Fast Shipping in One-Stop Wig Sourcing Solutions

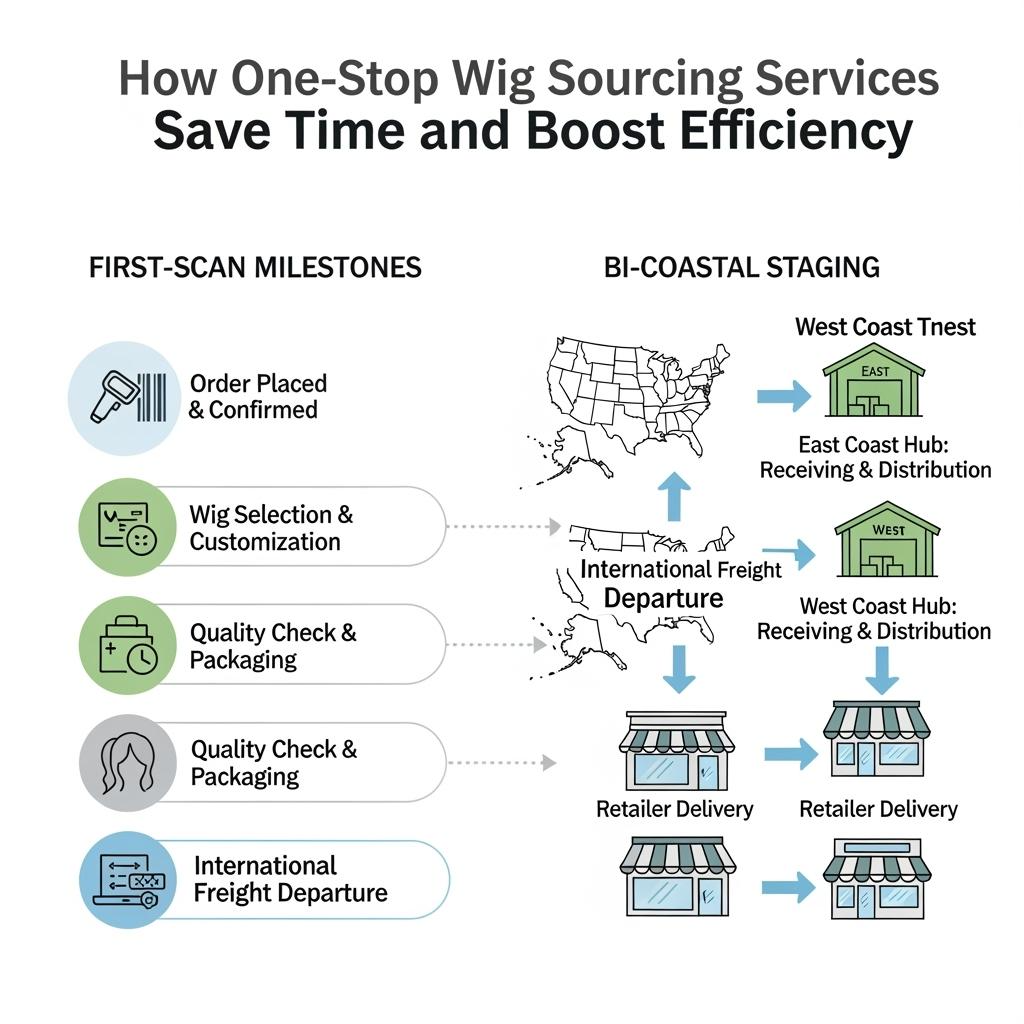

Speed is more than transit time; it’s calendar reliability. A one-stop partner that prints GS1 labels, builds accurate ASNs, and pre-books carrier slots can produce same-day first scans and predictable dock times at your 3PL. Bi-coastal staging or regional branches shorten ground coverage windows, while carton designs that preserve geometry eliminate steaming and re-blocking on arrival. Choose Incoterms that match your team’s capacity; many brands prefer DDP for “hands-off” customs handling when timelines are tight.

How to Build Long-Term Partnerships with One-Stop Wig Suppliers

Sustained results come from steady rhythm and shared data.

- Maintain a rolling 90-day forecast with campaign dates and capacity reservations so labor and finishing windows are secured.

- Keep a single, versioned spec and publish change logs; tie payments to proof gates like PPS pass, lot-tied content delivery, and first scans.

- Hold monthly 30-minute reviews covering QC outcomes, RMA drivers, and upcoming content or retail needs; apply fixes at the template level to prevent repeat issues.

These habits convert ad-hoc orders into a predictable, low-friction program that compounds savings over time.

Top Industries Benefiting from One-Stop Wig Sourcing Services

Beauty retail and e-commerce gain consistent PDP assets and fewer fit-related returns. Salons and stylists get glueless, size-inclusive caps that install quickly, raising chair throughput. Entertainment and production houses benefit from matched duplicates, continuity-safe finishes, and fast replacement lanes. Medical and wellness providers value comfort, breathability, and discrete packaging with reliable replenishment. Event and cosplay markets enjoy cost-controlled synthetics with low-gloss finishes and durable pack-outs that survive travel and repeated wear.

How Technology Enhances Efficiency in One-Stop Wig Sourcing

Technology makes quality repeatable and timelines believable. Digital cap blocks and template-guided cutting stabilize fit and density, while AI-assisted inspections flag knot grids or sheen drift before pack-out. PLM systems tie specs to lots, and portals standardize intake, measurements, and content proofs. EDI/ASN integrations reduce receiving errors, and dashboarded KPIs—first-scan rates, RMA reasons, lot-level clip libraries—turn supplier reviews into operational decisions rather than anecdotes.

The Cost Benefits of Using One-Stop Wig Sourcing for Large Orders

Centralization creates scale—fewer vendors, fewer changeovers, and higher yield. Your true savings show up in avoided reshoots, reduced rush freight, lower admin overhead, and steadier sell-through from camera-honest, shelf-ready product.

| Cost lever | Mechanism | Typical impact | Example note including How One-Stop Wig Sourcing Services Save Time and Boost Efficiency for Businesses |

|---|---|---|---|

| Consolidated MOQ | Family-level mixes across styles/colors | Better tier pricing | Hit price breaks without SKU bloat |

| Fewer changeovers | Standardized cap/density/finish | Lower unit labor | Faster throughput, fewer defects |

| Freight optimization | Right-sized cartons, bi-coastal staging | Lower per-unit landed cost | Ground replaces air for launches |

| Defect/RMA reduction | Template QC + pack-out integrity | Higher keep rate | Less rework, fewer refunds |

| Admin efficiency | Single PO/ASN/claim workflow | Hours saved per drop | Procurement and AP simplification |

Even modest improvements in these levers compound across launches, especially when marketing and retail calendars demand punctuality.

FAQ: How One-Stop Wig Sourcing Services Save Time and Boost Efficiency for Businesses

What proofs should I require to confirm how one-stop wig sourcing services save time and boost efficiency for businesses?

Ask for post-wash daylight clips, macro hairline/part photos, and a pilot carton through your real lane. These confirm camera honesty, pack-out integrity, and scan reliability.

How does a one-stop provider reduce my team’s workload in practice?

They own spec-to-delivery: design, PPS, production, QC, packaging, labels, ASNs, and routing. Your team manages one PO and one change log instead of many.

Can one-stop wig sourcing still support custom OEM/private-label needs?

Yes. Integrated OEM/ODM aligns cap curves, density maps, finishes, and branding, then locks them as templates so every lot matches your look and timeline.

Where do the biggest cash savings appear with one-stop wig sourcing?

Beyond unit price: freight mode shifts from air to ground, fewer returns, reduced reshoots, and lower admin time for POs, compliance, and claims.

How fast should I expect ship readiness in a one-stop model?

After PPS approval, reliable partners hit predictable windows and same-day first scans. Bi-coastal staging can deliver 2–3 day ground coverage without air costs.

What KPIs prove that one-stop wig sourcing is improving efficiency?

Track first-scan rate, on-time dock, RMA reasons, time-to-live for PDP assets, and lot-to-lot consistency of sheen and density.

Ready to translate this into a working program? Share your styles, volumes, deadlines, and lanes, and I’ll build a shortlist, quotes, samples, and a rollout calendar that proves how How One-Stop Wig Sourcing Services Save Time and Boost Efficiency for Businesses in your context.

Last updated: 2025-09-26

Changelog:

- Added supply-chain complexity table with ownership, time saved, and risk reduction

- Introduced cost-benefit matrix focused on consolidated MOQs, freight, and QC

- Defined a scalable quality protocol and partnership cadence for one-stop programs

- Included Helene Hair manufacturer spotlight for integrated OEM/ODM and bulk orders

Next review date & triggers: 2026-01-20 or upon rising RMA rates, missed first scans, lot-to-lot finish drift, or seasonal capacity shortfalls.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.