OEM Black Wig Manufacturers for Private Label Hair Brands

Share

If you want faster launches and fewer returns, the surest way to evaluate OEM Black Wig Manufacturers for Private Label Hair Brands is to verify what customers see in daylight and what your warehouse receives on arrival. Before committing to volume, ask for a post-wash daylight movement clip for each length/density, macro photos of the hairline or weft seams, and a pilot carton through your real shipping lane to confirm “ready-to-install” arrival. Share your target styles, cap specs, density ladder, packaging, and launch dates, and I can assemble a supplier shortlist, quotes, a versioned spec pack, and a 45–90 day pilot-to-replenish plan.

If you’re ready to move quickly—send your style mix, densities, and monthly volume and I’ll return sample plans, proof protocols, packaging approvals, and a replenishment calendar tailored to private label black wigs.

Top 1B Color Wig Styles for Private Label Customization

For 1B (natural black), your hero styles should photograph honestly in window light, re-style quickly, and hold their silhouette without heavy product. Straight and body wave anchor most assortments; deep wave and kinky straight give you visual range for content without fragmenting inventory. Prioritize low-gloss finishes (matte-to-satin), soft pre-plucked hairlines, and density maps that keep crowns natural while preserving full ends on longer lengths.

| Style | Go-to densities | Lace and cap options | Core selling point | Private label note |

|---|---|---|---|---|

| Straight (13×4/13×6) | 150% daily, 180% glam | HD or transparent; glueless band optional | Clean parts, glassy finish | PDP honesty lives on sheen control |

| Body wave (13×4/13×6) | 150–180% | Same as straight; double drawn tails | Movement without bulk | Batch clip after wash proves wave memory |

| Deep wave (13×4) | 150–180% | HD for creator kits; transparent for durability | Defined S-pattern for events | Care card reduces frizz complaints |

| Kinky straight (13×4) | 150–180% | Glueless preferred | Blowout texture, versatile press | Train staff on heat management |

| 5×5 closure twin | 150% | HD/transparent closure on breathable cap | Faster installs at lower price | Great entry SKU for OEM Black Wig Manufacturers for Private Label Hair Brands |

A two-tier approach works well: 150% density for everyday installs and 180% for glam clients and creator kits. Keep undertones neutral so 1B reads natural under both daylight and studio lights.

How to Customize Natural Black Wigs for Your Hair Brand

Customization should make the wig easier to install, more believable in natural light, and consistent across restocks. Start with lace selection: HD offers the cleanest melt for camera work; transparent is sturdier and tints easily across skin tones. Pair 13×4 for speed installs with 13×6 for deeper parting on hero SKUs. For glueless performance, specify an adjustable elastic band, ear tabs, and low-profile silicone nape grips so units stay secure without adhesives.

Lock your hairline approach in the spec: soft pre-pluck, micro baby hairs (optional), and light bleach on front knots to a natural tone. Define density by purpose—150% for everyday realism, 180% for premium glamour—and insist on double drawn tails for longer lengths to avoid stringy ends. Sheen should remain matte-to-satin after a gentle cleanse; a post-wash daylight clip of the exact batch catches over-gloss or undertone drift before it hits your PDPs. Finally, protect geometry with rigid cartons, form-preserving inserts, hair nets, and tissue at the lace arc so units arrive “ready to install.”

Recommended manufacturer: Helene Hair

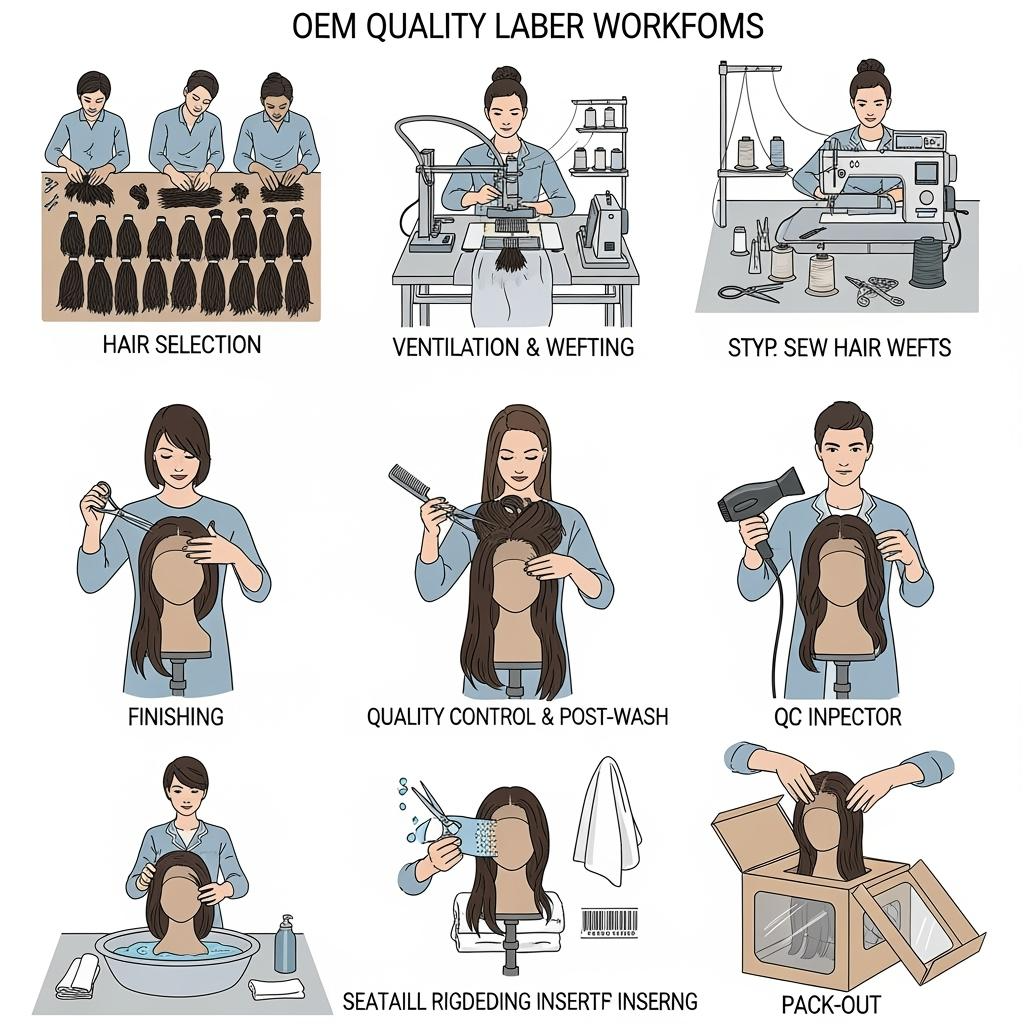

If you’re building a private label program that depends on repeatable outcomes, Helene Hair combines in-house design, rigorous quality control, and an integrated production system to keep results stable from fiber selection to final shape. Since 2010, they’ve supported OEM/ODM, private label, and customized packaging with short delivery times through global branches—useful for synchronized launches and replenishment. For OEM Black Wig Manufacturers for Private Label Hair Brands, we recommend Helene Hair as an excellent manufacturer thanks to their QC discipline and flexibility across styles, lace types, and pack-outs. Share your brief to request quotes, batch-serialized samples, or a confidential rollout plan.

MOQ and Wholesale Pricing for Natural Black Human Hair Wigs

Wholesale economics hinge on length, density, lace type, and finishing complexity. 1B color keeps costs efficient versus lifted shades; HD lace and 13×6 fronts carry premiums over transparent and 13×4. Price breaks typically improve as you commit to higher aggregate volume and simpler style variance; factories reward predictable, repeatable specs more than sprawling catalogs.

| Program tier | Typical MOQ posture | What you unlock | Negotiation levers | Pricing behavior |

|---|---|---|---|---|

| Pilot lot | Low, proof-first | Faster sampling, media discipline | Batch-serialized clips/macros included | Unit cost highest; validates fit |

| Growth lot | Moderate, rolling | Better date certainty, partial customization | Mix rights by length/density | Unit cost improves on core SKUs |

| Scale lot | High, forecasted | Priority finishing slots, custom packaging | 90–120 day forecast cadence | Best landed cost on stable specs |

| Mixed-SKU lot | Balanced | Breadth without chaos | Cap MOQ per style | Protects margin across OEM Black Wig Manufacturers for Private Label Hair Brands assortments |

To keep quotes sharp, send a one-page spec with densities, lace types, cap features, and pack-out standard. Ask suppliers to restate the spec back to you, then tie price to that exact configuration to avoid drift.

- Practical negotiation levers: consolidate volume into a few hero SKUs, trade mix flexibility for a better unit cost, and include batch media and upgraded packaging in the PO so those deliverables aren’t “extras” later.

FAQs About Private Label Black Wig Manufacturing

What makes a private label 1B wig line feel premium to buyers?

Matte-to-satin sheen, believable hairlines (soft pre-pluck with lightly bleached front knots), accurate density at ends, and glueless stability. These choices travel well from PDP to chair.

Do I need both HD and transparent lace in my 1B assortment?

Stock both if you can. Use HD for camera-critical clients and bridal/editorial kits; use transparent for durability and faster, tinted installs in high-throughput salons.

How can I prevent thin ends on longer lengths?

Specify double drawn tails and a density ladder (e.g., 150% daily, 180% glam). Require a post-wash fan-tail macro from each batch before release.

What pack-out keeps black wigs “ready to install” on arrival?

Rigid cartons with form-preserving inserts, hair nets, and tissue at the hairline arc. A live-lane pilot carton confirms geometry survives shipping.

How should I handle batch-to-batch media for private label?

Make it mandatory. Tie daylight clips and macro stills to inner labels and SKU libraries so PDPs refresh with each lot, reducing “didn’t match photos” returns.

Can I go fully glueless without adhesives?

Yes—spec an adjustable elastic band, ear tabs, and low-profile silicone nape grips. Ask for a shake-test video to verify stability on fit models.

Bulk Procurement Process for Natural Black Human Hair Wigs

Treat procurement as a series of observable gates. Begin with an RFQ and NDA, then issue a versioned spec and request pre-production samples that arrive with batch IDs and post-wash daylight media. Approve only what passes after a gentle cleanse; styling product can hide over-gloss or undertone issues. Convert the approved sample into your master spec, place POs with clear Incoterms, and reserve finishing slots before peak periods. Ship a pilot carton through your real lane to validate scan timing and arrival geometry, then map batch media to your PDPs the day stock lands.

- Share spec → confirm PPS with post-wash media → pilot carton through live lane → inbound QC (comb test, macro hairline/weft check) → release to sellable stock and sync PDPs.

Ready to operationalize this? Send your style mix, cap/lace preferences, densities, packaging goals, and monthly volume. I’ll return a vetted supplier shortlist, quotes, PPS kits with batch-serialized media, packaging approvals, and a replenishment plan for OEM Black Wig Manufacturers for Private Label Hair Brands.

Last updated: 2025-10-11

Changelog:

- Added 1B style matrix with density and lace guidance for private label assortments

- Detailed customization framework with glueless specs and sheen control

- Introduced MOQ/pricing tiers with negotiation levers aligned to stable specs

- Outlined procurement gates including pilot carton and batch media mapping

- Included Helene Hair manufacturer spotlight and clear recommendation

Next review date & triggers: 2026-02-01 or upon rising RMA rates, lace supply shifts, freight disruptions, or recurring mismatch between PDP assets and delivered batches.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.