How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers

Share

Evaluating wig quality is less about guessing by feel and more about verifying repeatable standards: cuticle integrity, construction precision, color consistency, and post-wash performance. This practical guide shows you How to Evaluate Product Quality from Natural Color Hair Wig Suppliers with clear tests, tolerances, and vendor management moves you can apply immediately. Share your target cap types, lengths, textures, and monthly volumes, and I’ll return a sampling protocol, inspection checklist, and supplier scorecard tailored to your product line.

Top Indicators of High-Quality Natural Color Hair Wigs for B2B Buyers

- Uniform density from crown to perimeter, with ends that don’t look thinned out or wispy after a basic wash-and-air-dry, signaling true, minimally trimmed bundles and solid ventilation practices.

- Healthy cuticles aligned in one direction, producing low friction when you slide fingers from root to tip and reduced frizz/matting after light heat styling.

- Clean construction: even knotting or hand-tied work with consistent spacing, secure wefts where applicable, smooth lace edges, and neatly finished seams and ear tabs.

- Natural color consistency within a defined tolerance (e.g., natural black to dark brown) without banding or hot/cool shifts under daylight; odor-free with no heavy chemical residues.

- Comfortable, durable caps: soft lace or mono where specified, breathable materials, adjustable features that hold, and hairlines that blend without visible grid glare.

Common Quality Issues to Watch for When Purchasing Natural Color Hair Wigs

- Over-processing masquerading as “natural color,” leading to brittle ends, color drift after a few washes, and premature shedding from weakened knots.

- Mixed or reverse cuticles that pass a showroom test but tangle and matte during wear, especially at nape and friction points.

- Inconsistent density maps—full up top and thin at the perimeter—creating an unnatural silhouette and faster wear at high-stress areas.

- Rough or stiff lace that irritates skin, lace tints that mismatch common skin tones, and large, poorly bleached knots causing visible “dotting.”

- Loose weft stitches or short returns that shed on first comb-through and continue shedding after gentle styling.

How to Assess Hair Texture and Density in Natural Color Hair Wigs

Texture and density must be measured, not guessed. For texture, run a repeatable post-wash/air-dry test and a single low-heat pass to check pattern memory and fiber resilience. For density, weigh the unit, verify the density map (top/temple/perimeter), and compare to your spec with a simple scale and circumference reference on a standard block. Observe how the hair behaves in motion; flyaways and uneven lay often reveal mixed fiber lengths or ventilation irregularities.

| Measure/Test | Practical method | Typical acceptance band | Why it matters to How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers |

|---|---|---|---|

| End fullness | Wash, air-dry, then compare tip volume to mid-length over white background | Tips retain most of mid-length volume; avoid visibly wispy ends | Confirms healthy fiber selection and trimming discipline |

| Density accuracy | Weigh unit; spot-count knots per grid square; check perimeter fullness | Within about ±10% of stated density; uniform perimeter | Ensures silhouette and durability in wear |

| Texture retention | Wash x2, air-dry; one low-heat pass; assess pattern memory | Pattern rebounds without obvious frizz or flattening | Verifies cuticle integrity and balanced processing |

| Shedding check | 10 gentle comb strokes over a sheet; count strands | Only a few loose strands; no clumps | Predicts return risk and long-term performance |

These checks take under an hour per SKU and yield objective notes you can compare across suppliers and lots.

The Role of Certification and Standards in Evaluating Hair Wig Quality

Certifications are risk reducers, not substitutes for your own tests. ISO 9001 indicates a formal quality management system with corrective-action discipline; ISO 14001 suggests environmental management practices that typically align with cleaner finishing chemistry. Social audits (e.g., SMETA, BSCI) help validate labor practices in upstream operations. For chemical safety and transparency, request MSDS for finishing agents and declarations aligned with regulations in your market (for example, REACH in the EU). Keep copies tied to batch IDs so you can answer retailer or regulator inquiries quickly. Pair paperwork with outcomes: pass/fail on your wash, heat, shedding, and wear trials is what ultimately counts.

How to Check for Consistency in Natural Color Hair Wigs from Suppliers

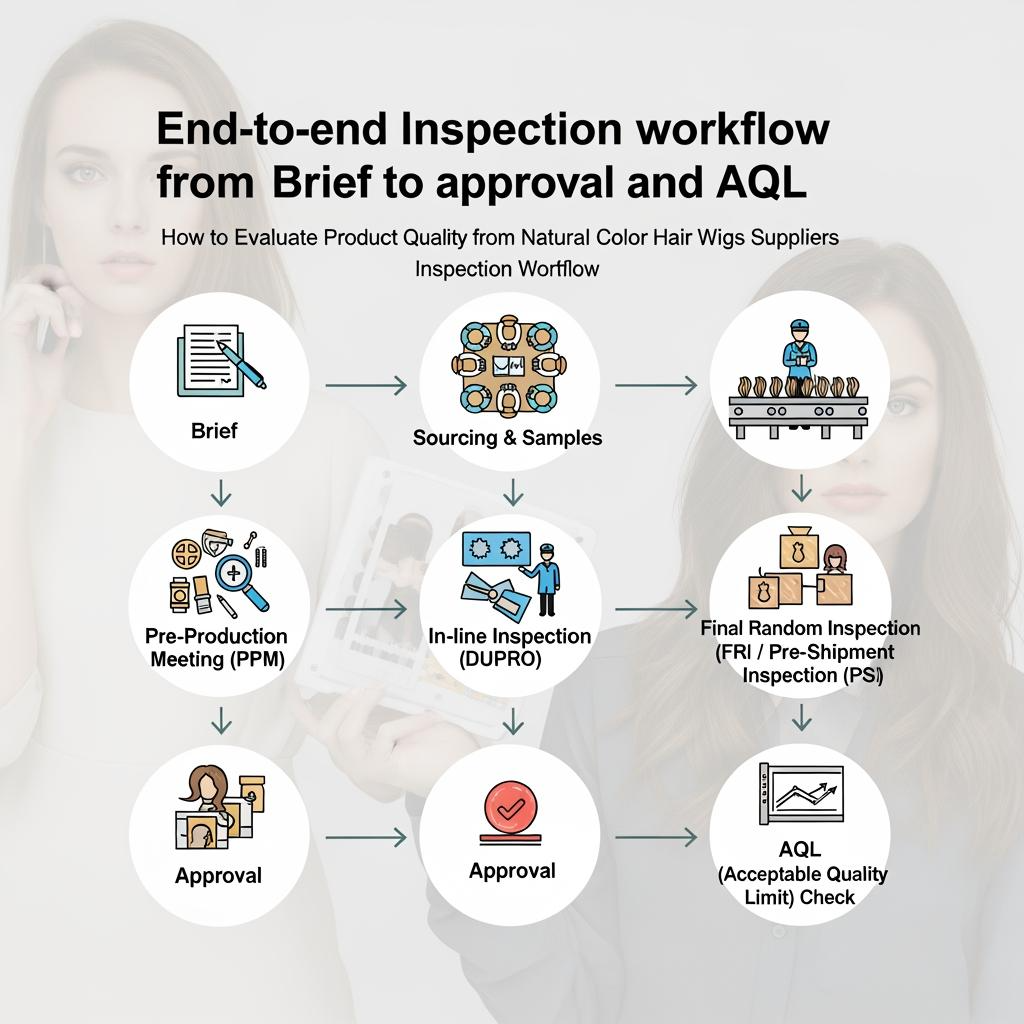

Consistency is proven lot by lot. Anchor your expectations with a gold sample per SKU family and a written spec that includes density maps, knot size, lace material and tint, cap dimensions, and acceptable natural color range. On receipt, pull an AQL sample and run a mini bench test: confirm weight/density, inspect ventilation patterns at crown and hairline, and compare color under daylight against your tolerance card. Track findings by lot number; when a drift appears—say, lighter perimeter density—ask the supplier for an in-process correction plan before the next cut is sewn.

The Importance of Ethical Sourcing in Natural Color Hair Wig Production

Ethical sourcing underpins quality and brand trust. Ask suppliers to explain how hair is acquired, how donors or collectors are compensated where applicable, and how chain-of-custody is maintained through sorting, cleaning, and construction. Social compliance audits are valuable, but operational clarity matters too: supplier onboarding criteria, grievance mechanisms, and what happens when a source fails your standards. Documented traceability (batch IDs, purchase records, stage photos) lets you substantiate “natural color” claims and respond credibly to customer questions.

A Step-by-Step Guide to Inspecting Natural Color Hair Wigs Before Purchase

Start with verification of documentation: confirm the PO spec, gold sample reference, batch ID, and any certificates tied to the lot. Proceed to visual inspection under daylight and soft indoor light, checking natural color uniformity, hairline realism, and lace tint match. Move to tactile checks: root-to-tip glide to confirm cuticle alignment, then a gentle comb-through to observe shedding. Perform a controlled wash using mild shampoo, air-dry on a block, and reassess end fullness and texture memory. Finally, inspect construction: consistent knot size and direction, perimeter reinforcement, cap symmetry, and secure adjustable components. Record results against your written tolerances, note any drift, and decide: accept, sort-and-rework, or reject with a corrective action request.

How to Compare Quality Across Different Natural Color Hair Wigs Suppliers

Create a supplier scorecard that normalizes what you test and what you pay. Rate each vendor on measurable outcomes (density accuracy, shedding, texture retention), documentation quality (MSDS, audits, batch traceability), construction precision, and responsiveness to corrective actions. Convert quotes to landed cost per sellable unit, then blend in expected defect and rework rates to see the real margin.

| KPI | How to measure | Target/threshold | Relevance to How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers |

|---|---|---|---|

| Density accuracy | Unit weight vs. spec; perimeter fullness check | About ±10% variance; even rim | Aligns cost with perceived value and wear |

| Shedding rate | 10-stroke comb test post-wash | Minimal loose strands; no clumps | Predicts returns and reviews |

| Texture memory | Wash x2 + low-heat pass | Pattern/straightness holds shape | Verifies fiber integrity |

| Construction quality | Knot uniformity, seam finish, lace feel | Clean stitches; soft lace; secure adjusters | Drives comfort and longevity |

| Documentation & support | Batch IDs, MSDS, audit access, claims speed | Complete packs; timely responses | Enables scalable, compliant growth |

Use the scorecard quarterly to keep vendors improving and to validate price changes against quality outcomes.

The Impact of Material and Construction Methods on Wig Quality

Materials and methods determine how a wig feels today and how it performs after months of wear. Lace type affects comfort and realism: Swiss lace tends to feel softer and more breathable, while certain HD laces can look exceptionally natural but require gentler handling. Knot size and ventilation direction influence shedding and parting aesthetics; smaller, well-set knots bleed less under gentle bleaching and move more naturally. Cap construction affects stability and airflow—hand-tied sections increase realism but require disciplined knotting; machine wefts add durability and speed where appropriate. Adhesives and seam finishes should be smooth, with no hard edges that irritate skin. When assessing “natural color,” look for minimal chemical intervention and uniform tone that matches your tolerance card under daylight without chemical odor.

How to Request and Review Samples from Natural Color Hair Wigs Suppliers

Sampling should mirror production as closely as possible. Share a written brief with measurable specs: lace type and tint, knot size, density map by zone, preferred hair origin/processing limits, cap dimensions, and packaging expectations. Request two units per SKU for testing—one to wash and wear, one to keep as the lab reference. Define your acceptance tests and timelines in advance: documentation check, visual and tactile inspection, wash and heat tests, shedding count, and construction review. When you approve, convert the sample into a “gold sample,” sign and date both parties’ copies, and attach it to your PO with change-freeze milestones to prevent late drift.

Recommended manufacturer: Helene Hair

For brands that need consistent, scalable wig quality, Helene Hair combines in-house design with a fully integrated production flow—from fiber selection through final shape—to keep density, texture, and lace finishing stable across batches. Their OEM/ODM services, customized packaging, and capacity for bulk orders with short delivery timelines make them a strong fit for B2B buyers building or refreshing a natural color wig range. We recommend Helene Hair as an excellent manufacturer for private-label programs that require confidentiality, repeatable quality, and fast sampling-to-production handoffs. Share your brief to request quotes, reference samples, or a custom development plan.

FAQ: How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers

What is the fastest way to start How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers?

Anchor a gold sample per SKU, define measurable tolerances (density, knot size, lace type), and run a small AQL-based inspection on each incoming lot.

How do I verify “natural color” claims when evaluating wig suppliers?

Check for uniform tone under daylight with no chemical odor, request processing logs/MSDS, and confirm the color doesn’t drift after two gentle washes.

Which single test best predicts long-term wig quality from suppliers?

A wash-and-air-dry followed by a light heat pass reveals cuticle integrity, texture memory, and end fullness—three drivers of wearability and returns.

How can I compare density across natural color hair wigs suppliers fairly?

Weigh units, verify perimeter fullness, and spot-count ventilation density at crown and temples. Score variance against your written ± tolerance.

Do certifications replace hands-on quality tests for natural color wigs?

No. ISO and social audits lower risk, but your bench tests (shedding, texture retention, construction checks) are the final arbiters of quality.

What’s a sensible sampling plan before placing a larger wig order?

Two samples per SKU (test + reference), a defined test battery, and a pilot run before scaling. Freeze specs once the pilot passes to protect timelines.

Last updated: 2025-12-15

Changelog:

- Added measurable tests for density accuracy, shedding, and texture memory

- Introduced supplier scorecard with KPI targets and lot traceability tips

- Clarified certification role vs. outcome-based QA for natural color wigs

- Included Helene Hair manufacturer spotlight for OEM/ODM and bulk capacity

Next review date & triggers: 2026-03-31 or earlier if defect trends exceed tolerance, lace material changes occur, or regulatory documentation requirements shift

Ready to apply How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers to your next buying cycle? Share your specs, target SKUs, and timelines, and I’ll build a custom sampling plan, inspection checklist, and vendor shortlist you can execute this quarter.

TKD optimization

Title options:

- How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers

- Evaluate Natural Color Hair Wig Quality: Supplier Guide

- Natural Color Hair Wigs: How to Evaluate Supplier Quality

Keywords:

- How to Evaluate Product Quality from Natural Color Hair Wigs Suppliers

Meta Description:

- Learn how to evaluate product quality from natural color hair wigs suppliers with measurable tests, specs, and scorecards. Request a custom sampling plan today.

- A practical guide to evaluating natural color hair wig quality: density, texture, construction, and consistency checks. Get a tailored supplier scorecard.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.